Overview of armored transporters and infantry fighting vehicles (Part of 1)

The new floating VBA car (Veicolo Blindato Anfibio) is currently undergoing qualification tests in Italy

The mission in Afghanistan is coming to an end and therefore the demand for Mrap class cars is steadily declining. One can only guess where the western troops will be called next time, but no doubt the next scenario will again be asymmetrical in nature. In this case, a certain part of the experience gained in Afghanistan might well be useful, although the terrain, often defining tactics and means of warfare, may turn out to be completely different.

The first Gulf War opened its eyes to the requirements for the deployment of military contingent, so air transport, apparently, remains the main criterion in the design of combat vehicles (with a few exceptions). At the same time, defense will definitely remain among the top priorities, since Western public opinion is not ready to accept its soldiers returning home in their coffins. Apparently, without major breakthroughs in technology that would allow for any significant change in the mass-protection paradigm (although active protection systems could ultimately come to the rescue), there are not that many revolutionary ones machines will be able to reach mass production.

However, some lessons have been learned. This is especially true for general situational awareness and driver review, because only this can change the appearance of future cars. But even in this case, approaches to the design of promising machines are very different in different countries. For example, Israel with its Rakiya is trying to reduce weight compared to the current family of cars based on tank Merkava, while future combat vehicles of the American army are likely to weigh more than the current M1A2 Abrams tank.

Compared with several years earlier, when the wheels were very popular, 2013 year passes under the sign of returning to the tracks, despite the higher cost of their operation. Undoubtedly, one program can change the future of tracked infantry fighting vehicles: after the program closes, the Combat Systems of the Future, the American army still has no substitute for the Bradley family, the birth of which dates from the 70 years of the last century. Therefore, after forty years, given the urgent need for such a replacement, the project on ground combat vehicle Ground Combat Vehicle (GCV) must be expected to survive the current sequestering. Another significant American program is the Armored Multi-Purpose Vehicle (AMPV) multi-purpose armored vehicle program, which should replace all support vehicles based on the M113 chassis. However, in this case, the dramatic choice between tracks and wheels is still ahead.

Turkey is undoubtedly the most active country in the development of new machines. On the eve of new applications that may be filed shortly by the Turkish Defense Industry Secretariat (SSM), at least IDT 2013 presented at least one new product from each of the main players in this country. On the other hand, some new cars appear on the European scene, where the industry is still waiting for the post-crisis steps to change the market. Although it must be said that the number of companies capable of producing armored vehicles, especially wheel types, is still growing, especially in the Middle and Far East.

The new “Next Generation Armored Wheel Machine” from Patria was shown at DSEI 2013 (below). It weighs 30 tons, of which 13 tons is the net payload. A prototype of the Saab Trackfire combat module with an 25-mm gun was installed.

Based on the tank chassis, Uralvagonzavod developed Terminator, a tank support vehicle with impressive firepower.

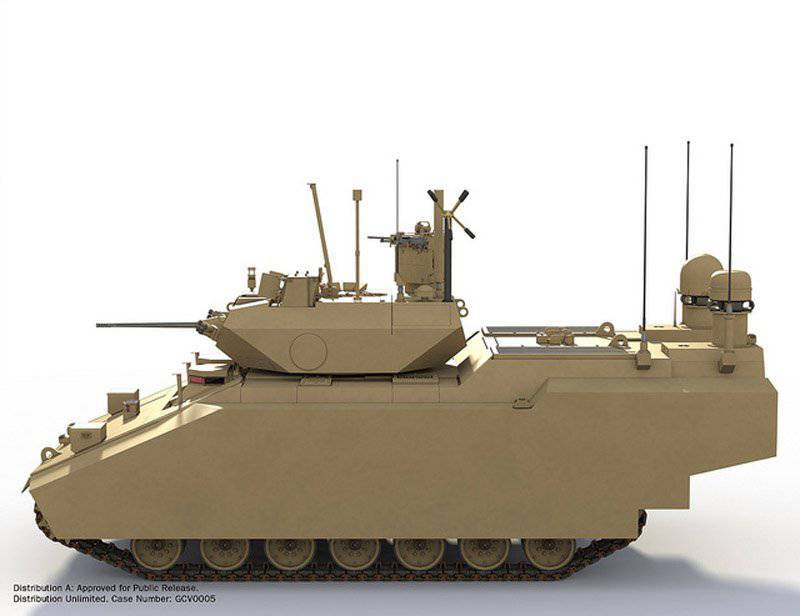

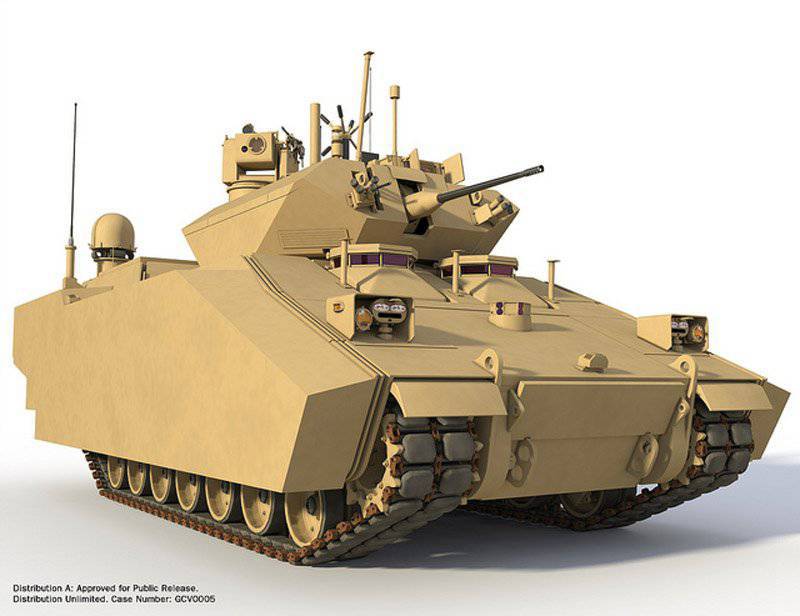

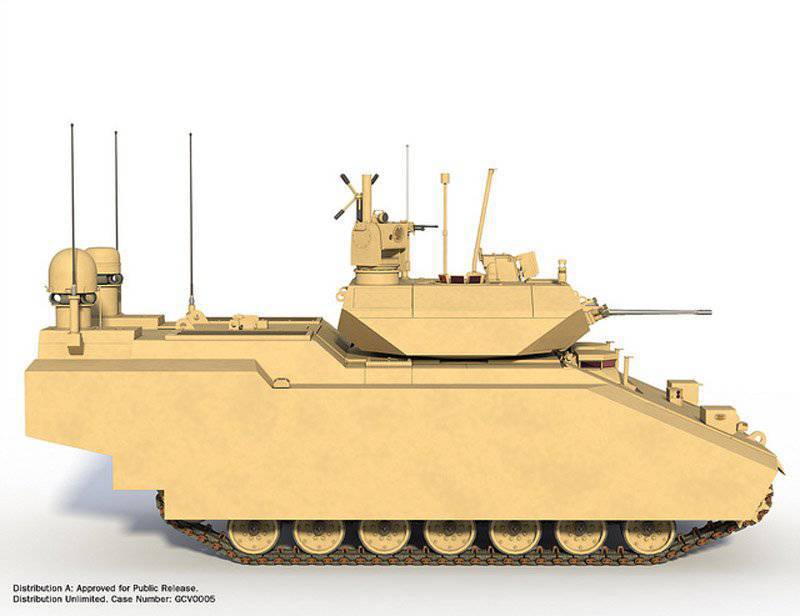

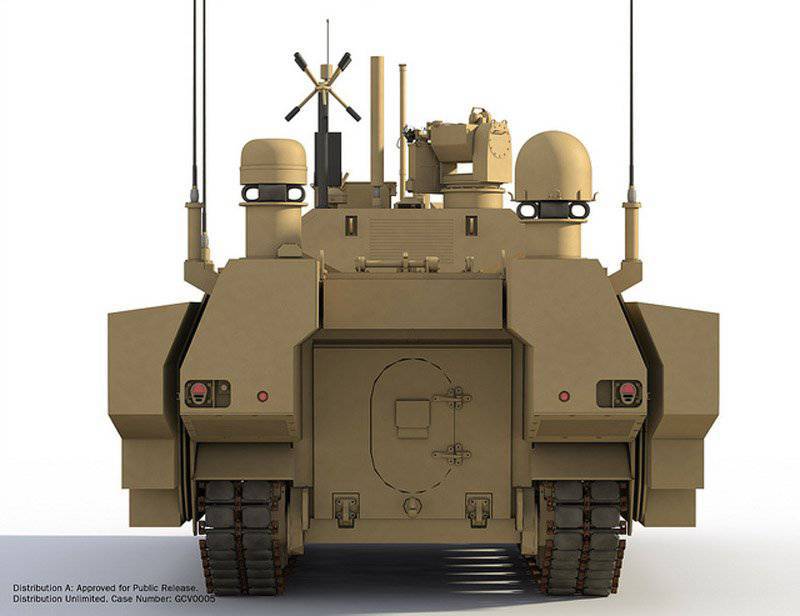

Artistic representation of the machine, presented by the company BAE Systems on the program GCV. It is possible that, despite its similarity with the Bradley BMP, the new machine will have a mass over 60 tons!

Back to the tracks

As mentioned above, the caterpillar appears to be returning. But it will attract to itself the attention that has attracted in the recent past, we can only guess, because you can not discount the constant progress in the technology of the suspension and wheels. On the basis of a purely subjective impression, the caterpillar always seems more aggressive, which contradicts the concept of peacekeeping.

Several types of BAE Systems GCV project: the company decided to adopt a hybrid electrical circuit based on its Traction Drive System powertrain and QinetiQ EX-Drive transmission

Ground combat vehicles on steroids?

If this article should start with heavier and more complex tracked vehicles, then it must inevitably start with the GCV project.

The decision to issue a contract for the development of a technology sample of approximately 450 million to BAE Systems and General Dynamics Land Systems (GDLS) companies dates back to August 2011. “Faster, lighter, more economical alternatives” Bradley is what Army Chief of Staff General Eric Shinseki announced in 1999 as requirements for new machines. After almost 15 years, his wishes for a light BMP did not become a reality, the current predicted weight of the Ground Combat Vehicle is more than twice the mass of the Bradley BMP in its original version. In addition, due to recent cuts in the defense budget, a decision on the production of GCV may not be made through 20 years after General Shinseki’s speech. By that time, the first Bradley machines will be in operation for over 35 years, but if everything goes well, the army hopes to get its first GCV production cars in 2017. The decision to delay (at least six months) the development stage of the technological sample due to budgetary pressure was announced at the end of January 2013. As a result, the request for proposals on the stage of final development and introduction into production, originally planned for the autumn of 2013, was postponed to the spring of the year, 2014. Another solution, which runs counter to the army’s desire on a competitive bid, concerns a reduction in the number of contractors at this stage to one. However, according to some estimates, this decision will help save approximately 4 billion dollars in the next five years. What remains unchanged today is the requirements for the car, which must accommodate three crew members plus a squad of nine soldiers, be well protected and fully networked, and also have a power plant with significantly lower fuel consumption.

Under this GCV program, BAE Systems has teamed up with Northrop Grumman and this team is in fact the only applicant to reveal some details of their proposal. Probably starting with the problem of mass, the first M2 Bradley had a combat mass of 22,6 tons and accommodated three crew members and seven paratroopers, and its proposed successor (according to the company's prospectus) will have a lot of 63,5 tons and more.

Admittedly, the Bradley BMP was criticized for its relatively weak defense, which led to several upgrades, as a result of which the combat mass of the latest Bradley A3 variant was 34,3 tons. The new power plant should provide good mobility and a small increase in the maximum speed of 70 km / h (the M2A3 variant develops the 61 km / h). The company BAE Systems decided for the GCV project to adopt its new hybrid electric propulsion system. It received the designation Traction Drive System (TDS) and was developed jointly with the firm QinetiQ, which provided a key component for TDS - the EX-Drive transmission. TDS can be installed on 20 - 40 tons of vehicles and is based on two symmetrical power units, which increases reliability and provides limited functionality that is not available in single engine configurations.

TDS is considered to be at the level of technological readiness of 6-7 (prototype refinement), and BAE Systems has published presentation materials with some characteristics of the new installation. Its power 1500 hp corresponds to the parameters of modern battle tanks (but the mass of the new machine will correspond to the mass of the tank). However, the hybrid drive, in which the final stage is performed by electric motors, offers a number of advantages. In addition to less penetration into the architecture of the car, fuel economy from 10% to 20% is claimed, which means a power reserve of 300 km with a full fuel tank of 965 liters (compare with M2A3, which drives more than 402 km on 662 liters, but weighs two times less ). Take the modern 70-ton tank for the criterion, it will burn about 55600 liters of fuel per 180-day campaign. A new type of machine with the same mass, but working on a mechanical power transmission, can consume 39700 liters, but the same machine with a BAE Systems TDS power unit will consume 33235 liters, in other words, almost 6500 liters less. This means that three cars will save the equivalent of two M948 HEMTT fuel tanks. The large torque of the electric motors increases maneuverability at low speeds, and during dismounted operations, the hybrid configuration allows the machine to move silently. As noted above, the increase in maximum speed with a new hybrid installation is not very large (not the main issue from an operational point of view), but the acceleration increases by 25% due again to the large electric motor moment; the car accelerates from 0 to 32 km / h in 7,8 seconds versus 10,5 seconds for a conventional 70-ton car.

The QinetiQ EX-Drive transmission also provides seamless switching between all driving modes. In addition to silent operation, another key advantage of TDS is the presence of an electric generator with an 1100 kW power, which is sufficient to provide all future subsystems with a margin. The BAE Systems-Northrop Grumman GCV will have 7 track rollers with hydropneumatic suspension and tracks 635 mm wide.

If you look at the drawings provided by the company, then in the view from above you can clearly see two power units in the stern and a central passage that allows infantrymen to parachute through the stern ramp. In the case of armor steel in front of the left is the driver, to his right, where the power unit was usually installed, the commander is placed. Protection levels will be very high, BAE Systems states that they will exceed the protection of the RG-33 Mrap machines from mines and charges such as a shock core (not without the aid of a half-meter ground clearance). The pictures clearly show the additional armor mounted on the sides, which increases the width of the car to 5 meters. This is definitely not an advantage when driving on city streets, considering the length of this behemoth 9 meters (in Bradley M2A3, the width of the 3,2 meter and the length of 6,5 meters).

The firepower is determined by the remotely controlled TRT (Tactical Remote Turret) turret from BAE System Dynamics, which can accept a double-feed caliber gun to 30 mm. And for the American army, apparently, proposed tower TRT25. Although the TRT tower is also remotely controlled, it features a sunroof providing direct visibility to crew members. A remotely controlled combat module is installed at the top of the tower, and is controlled by the squad leader, who can not only shoot, but also conduct observation through an optical sight in order to increase situational awareness. The machine has an open-air architecture and is ready for the installation of interchangeable sensors and systems that will form its automated system of operational management, communications and intelligence.

For its part, GDLS does not provide information on its proposal in the framework of the new car program.

According to one estimate, the GCV mass can reach 84 tons, although some believe that the issue is still open and you need to wait at least until next year to have a clear idea of how the American Army 2020 BMP will look like.

For the AMPV program, BAE Systems offers a Bradley chassis-based vehicle, many of which are located in army warehouses.

General Dynamics UK's Specialist Vehicle mobile test rig was presented at DSEI 2013 in reconnaissance support configuration with an installed Kongsberg Protector combat module with an 12,7-mm machine gun

AMPV project

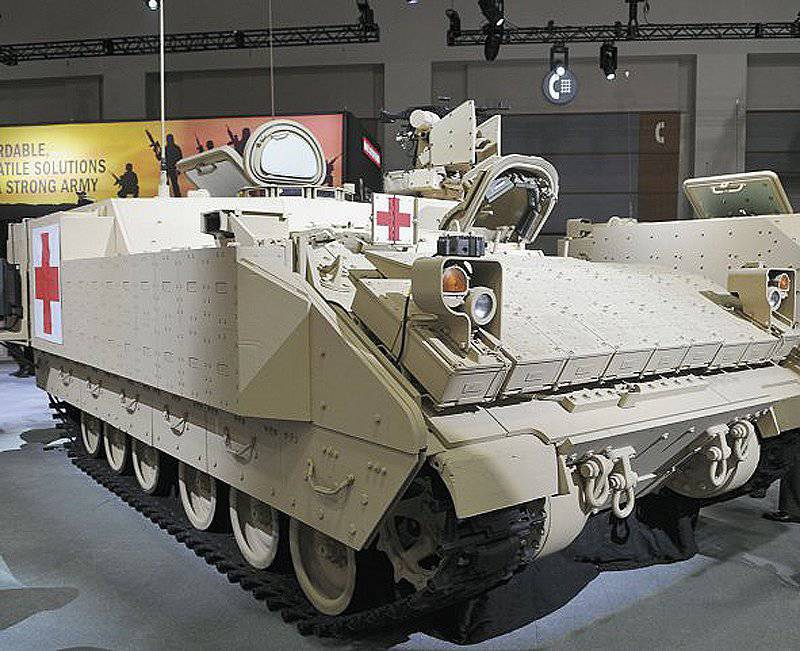

Another program that could add a new tracked vehicle to the register of the US Army is the AMPV (Armored Multi-Purpose Vehicle) armored vehicle. The goal of this program, which is based on existing and proven technologies, is to replace the M113 based support machines with the following five options: command (MCmd), sanitary (MTV), evacuation of the wounded (MEV), universal (GP) and mortar transporter (MCV). The current machines are not capable of maneuvering at the same speeds as the first-line machines like the OBT Abrams and the BMP Bradley. AMPV should be a relatively inexpensive program, the average factory cost was determined in 1,8 million dollars, which is six times less than the cost of the already mentioned GCV machine.

Priority in the new project is to protect the soldier, networking opportunities, mobility and growth potential. Requirements for the new underbody protection define mobility comparable to the mobility of Abrams and Bradley infantry fighting vehicles and protection comparable to the level of protection of combat vehicles against the most likely threats of direct and indirect fire fire and explosions under the bottom.

Today, the American Army armored brigade has 114 machines based on M113, which provide support and support functions, which is 32% of the total number of vehicles. To describe in more detail the composition, it 41 commander M1068A3 MCmd, 19 general purpose M113A3 GP, 31 health care M113A3 MEV, 8 medical evacuation M577 MTV and 15 mortar conveyors M1064 MCV. The new AMTV vehicle will be distributed in a slightly different proportion, or rather each armored brigade will receive 39 MCmd, 18 GP, 30 MEV, 8 MTV and 14 MCV, a total of 109 machines. To these must be added five reserve vehicles, that is, a total of also 114 AMPV machines per brigade.

The army wants to have at least 57% uniformity of parts and components for the entire AMPV fleet. It is planned to receive cars with brigade sets, according to 2 - 3 brigades per year during mass production. The draft request for proposals was published on 21 in March on 2013 of the year, Industry Day was organized a month later, and the request for proposals came out on June 28. A “cost plus incentive” contract for the final development and implementation phase of production must be issued to 28 on May 2014 of the year to one contractor (and not to two as announced at the beginning) for the 42 month with the following distribution by year: 65 million dollars to 2014 year, 145,5 on 2015 year, 109,9 on 2016 year and 67,4 on 2017 year. Next, a three-year contract for the initial production of three options with annual financing of approximately 350 million dollars will be issued. The distribution of machines in these three options is as follows: 1-th - 52 AMPV machines, the second - 105 and third - 130, total 287 machines, which is about 10% of the total predicted 2897 machines AMPV. For details, see the table.

The Department of Defense proposes a version of the agreement to replace existing Bradley, M113, M1064, M1068 and / or M577 machines with new AMPV systems.

The five companies that participated in Industry Day at the end of April are the most likely bidders for an AMPV bid: BAE Systems, General Dynamics Land Systems, AECOM, Lockheed Martin, and Mack Defense.

As expected, BAE Systems will leave its proposal based on the Bradley BMP. The first prototype with a raised roof behind the driver's seat, which was designated RHB (Reconfigurable Height Bradley - Bradley with a changeable height), was ready in the fall of the year 2011. The roof of this car can be removed in less than a day in order to adapt it to its functional requirements (the sanitary option, for example, requires a roof height greater than the standard).

The power unit is the same as that of the Bradley M2A3, that is, the Cummins engine with an 600 horsepower X. coupled with the L-3 CPS HMPT-500 transmission, the suspension has been upgraded. The fuel tanks are moved outside, on each side of the stern ramp, which not only increases safety, but also increases the internal space. Installed air conditioning systems and protection against weapons of mass destruction, with the exception of the mortar installation, which will have an opening roof. The latest dynamic protection units adopted for the Bradley BMP and the “floating” floor, developed by BAE Systems, will increase the survivability of the crew, especially when undermining mines and roadside bombs.

BAE Systems, which is currently upgrading Bradley’s 1500 machines to A3 standard, is fighting against the possible closure of the Bradley production line in mid-2014 and extending its operation for at least another three years. The AMPV contract may be the solution that will allow not to close it.

At AUSA 2012, General Dynamics Land Systems presented a new AMPV program based on the Stryker machine, which received the designation Stryker + Tr. This concept of a tracked vehicle is a deep modernization of the wheel-driven Stryker with a double V-shaped hull. The Stryker tracked prototype on the 203 mm is wider and weighs about 30 tons with the potential for weight gain to 38 tons. The second prototype should be ready at the beginning of the 2014 of the year, although its size and weight may increase along with the width of the tracks in order to reduce the specific pressure on the ground. GDLS offers the 625 horsepower engine. Despite the fact that in the current request for proposals, preference is given to the tracked solution, GDLS does not exclude the possibility of offering a wheel version based on its newest versions of Stryker if it is better suited to the final requirements of the request for proposals.

In addition to the two companies mentioned, others also appeared on the Industrial Day. If Lockheed Martin has confirmed that it is not going to participate in the AMPV program, then little is known about the intentions of Mack Defense and AECOM.

US Army Bradley BMP, equipped with an Urban Survivability Kit III Urban Survival Kit. The army is considering Ground Combat Vehicle as a replacement for this vehicle, which entered service in the early 80s

At the IDEF 2013, the Tulpar vehicle was shown, claiming to be the tracked BMP of the Turkish army. In the armored units, it will operate in conjunction with the tank Altay

Caterpillars from Turkey

One of the most active countries in the field of tracked vehicles is currently Turkey. At IDEF in May 2013 in Istanbul at least three tracked vehicles were shown.

The winged horse Tulpar (Pegasus) gave its name to the Otokar tracked infantry fighting vehicles. The Turkish army is the operator of the BTR M113 of various modifications, the driving performance of which, however, is worse than the mobility of the new tank. Given that the army would soon need a new car with better mobility, protection and firepower, Otokar decided to invest in this new car. Last year's prototype will be followed by an unnamed number of other experimental machines (tests of the current machine began immediately after the IDEF 2013 exhibition).

In order to reduce costs and risks and optimize logistics, some of the Tulpar subsystems are directly borrowed from the Altay tank, although they may not necessarily be identical. From the very beginning, the engine compartment of the Tulpar was designed to accept two different power plants. The current power unit is a Scania DI 16 Turbo engine with an HP 810 power. with intermediate cooling and a common fuel line connected to X-NUMX-speed automatic transmission SG-32 produced by the Spanish company SAPA Placencia. This power unit will be left in case of increasing the mass of the machine from the current 850 tons to 32 tons. For large masses or for operators operating machines in hot climates, Otokar offers a power unit with an MTU engine with an 35 hp power. and a Renk transmission that could handle the Tulpar 1100-ton.

The new BMP is equipped with a remote-controlled Mizrak-30 turret, which was shown two years ago by Otokar and is already being installed on its Arma 8 × 8 armored personnel carrier. In the turret with electric drives installed 30-mm ATK Mk44 cannon with double feed with 210 ready shots and twin 7,62-mm machine gun with 500 cartridges. Independently stabilized in two axes day / night sights of the shooter and the commander with a thermal imager and a laser range finder are also installed in the turret. The Mizrak-30 combat module does not penetrate the inside of the vehicle and allows you to increase the effective volume of the feed compartment. Access for the landing party, the commander and the arrow through the stern ramp. The need to protect the turret is reduced, which allows the machine's center of gravity to be lowered, therefore Tulpar is able to overcome 40% side slopes. Chassis protection level information was not provided. The modular booking kit, described as “a set of modern high standards,” is being developed in collaboration with the German company IBD Deisenroth, although production is planned to remain in Turkey.

As for solutions for active protection, Turkey is counting on local developments with the assistance of foreign companies. These solutions, originally developed for Altay OBT, can be configured to be installed on other machines. If the machine is supposed to work alongside Altay MBT, then the Tulpar BMP is an obvious candidate for installing active protection systems. Soon, the Turkish Defense Procurement Agency SSM should begin a tender for these systems. The company believes that Tulpar can compete with such well-known models like Ascod, CV-90 and Puma, although the Turkish car also has the potential to grow 10 tons. Mine design protection was put at the forefront, but almost nothing is known about the mine protection set, except for the 450 mm ride height and energy absorbing seats.

The machine meets the requirements of the Turkish army in terms of the internal volume of the 13 m 3, including the driver’s office, which is not separated from the general feed compartment. The overall interior of the vehicle is very “smooth” and continuous, which allows the crew and the landing party to have direct eye contact. The Tulpar BMP was specially designed to enter the Airbus Military A400M transport aircraft, which Turkey ordered 10 units. Among the options offered for Tulpar, there is an auxiliary power unit, which can become very popular for some of the many options offered by Otokar, for example, the command post and the sanitary option.

For the first time at IDEF, FNSS presented two tracked vehicles. Although the ACV30 does not fit into the BMP category, it deserves a few words here, since this new tracked support machine was designed specifically for the 35-mm self-propelled Korkut anti-aircraft complex, which is purchased by the Turkish army from Aselsan’s main contractor. FNSS used its experience in designing vehicles based on the M113 BTR to give life to this “steroid-inflated” machine — its impressive volume is a consequence of the Korkut buoyancy requirement. In the 30 vehicle weighing tons, two water cannons are installed, which allow the company to develop a maximum floating speed of 6 km / h. Since a potential order for 13 anti-aircraft batteries, each of which consists of an operational control vehicle and three anti-aircraft installations, is expected, a prototype of the operational management variant with an installed radar was also made. ACV30 should also be used as a T-Malamids medium-range anti-aircraft missile system chassis.

The second tracked vehicle, first introduced by FNSS, is more relevant to this review. At first glance, the Kaplan tracked reconnaissance vehicle (Tiger) has a well-sign appearance, since, due to its five-roll chassis, it is very similar to the M113 modification. However, the first impression is rather deceptive, since the reconnaissance version of what is known as the LAWC-T (Light Armored Weapon Carrier concept - Tracked, the concept of a light armored personnel carrier - tracked) has a completely different architecture. This is indicated by the front of the machine, which is distinguished by a periscope system for almost the entire width of the hull, which indicates that the driver and the commander are sitting next to each other. This layout is inherited from the layout of the wheeled vehicles of the FNSS Pars 6 × 6 and 8 × 8 family; it provides optimal situational awareness, allowing you to drive with the hatch closed even in situations characterized by heavy traffic of cars and people, which can be observed during operations to stabilize the political situation.

The field of view in the front cockpit exceeds 180 ° and thus is also a key factor allowing the crew to be aware of the combat situation. The transmission of the car was installed in the front of the chassis, and the engine was moved back and to the right, which made it possible to get a small passage to the stern door of the Tiger. In this small passage, folding seats for five soldiers are installed, two more are installed immediately behind the driver and commander. Weapons of various types can be installed on the machine, LAWC-T can receive manned and uninhabited towers with weapons of caliber from 25 to 40 mm, as well as towers with anti-tank missiles or towers with reconnaissance equipment weighing up to 1,8 tons. At the IDEF exhibition, the Kaplan vehicle (Tigris) was shown with a still nameless, remotely controlled turret developed in collaboration with Roketsan, armed with an 12,7-mm machine gun and four Omtas medium-range missiles (a side development of a Umtas long-range rocket with a similar infrared sensor). Inside the car are placed from 4 to 6 additional missiles. The sight includes a day camera, a thermal imager and a laser rangefinder. The Kaplan car is equipped with a Cambus-based vetronic (which is a modified version of the FNSS Pars armored personnel carrier), which allows the installation of plug & play electronic systems. The prototype shown at IDEF had front, side and rear day / night cameras; the front ones are used to help the driver, and the rest provide circular situational awareness. The crew has access to the car through two side doors. Protection against kinetic (armor piercing) threats - 4 level, that is, 14,5-mm armor-piercing bullet with 200 meters, and mine protection is equal to 3a Level, that is, 8 kg under the track. The ground clearance of the 400 - 450 mm, the bottom has a V-shaped. The current total weight of the machine is 9 tons, although the chassis can accept 14 - 15 tons; Thus, a significant mass margin allows in the long run to increase protection. There is no data on the engine, but the company FNSS states that the power density should be greater than 25 hp / t, which implies for a machine weighing ten tons an 250 hp engine. The prototype presented at the exhibition will be followed by a second prototype that will be floating - an urgent need for a reconnaissance vehicle and a twice necessary parameter given that the Turkish army requires amphibious capabilities in all its new projects. According to the FNSS designers, the location of the engine in the stern and center of gravity close to the center of buoyancy significantly improves the characteristics of the water. In addition, the low center of gravity also allows 40% side slopes to be overcome. FNSS plans to begin testing LAWC-T / Kaplan in the middle of the 2014 year. In June, the Turkish SSM agency 2013 announced a competitive bid for the 184 tracked weapons transporter - a role that is undoubtedly appropriate for Kaplan. In addition to the national market, the company is confidently looking at the markets of South-East Asia, where low ground pressure (6 tons / m2 with a mass of 10 tons) will allow Kaplan to move along soft soils, dirt and rice fields and follow the path of its predecessor, the CVR- T. It is still unclear to what extent Kawlan's LAWC-T will be used as the basis for developing a new family of machines for Indonesia under an agreement between the two countries signed on IDEF 2013 with the participation of PT Pindad and FNSS.

ACV30 was developed by FNSS in response to the demands of the Turkish army for a floating anti-aircraft complex. With a mass of 30 tons, the machine inevitably has a huge size in order to maintain the necessary buoyancy

The Kaplan light tracked reconnaissance vehicle was developed by the Turkish company FNSS with borrowing of some elements of the PARS wheel family, for example, this is a windshield with a wide view.

Materials used:

Armada Compendium to 5 / 2013

www.baesystems.com

www.generaldynamics.com

www.fnss.com.tr

Information