Power systems of domestic light machine guns: problems and prospects

Is it possible to grasp the immensity

To automatic firearms armsincluding small ones, different people make different demands: the designers defend their point of view, the generals - their own, the military officials - theirs, the production workers - theirs, and experts from the closed Central Research Institute, the Research Institute and the OKB often “bend” such that hard to imagine. Moreover, now the Ministry of Internal Affairs also has its own views on the “gun case”. Finally, the gorey-infantryman, who is carrying all this “iron” on himself, dismantling - collecting “on his knee” (in mud, without tools and instructions), and also firing, handing his life to the “soulless gland” - thinks about it . However, his opinions, as a rule, are not asked. In other words - each has its own truth.

From all this heap of completely contradictory and sometimes even quite fair demands, the following follows.

The one who directly exploits small arms and whose life directly depends on him, wants it to be smaller in size and weight, device and maintenance - simpler, the power supply capacity, rate of fire and survivability would be higher so that at high rate of fire ribbons and shops should be changed less, and equipping them with ammunition quicker and more comfortably, and, besides, wearable ammunition would be small in terms of weight, and large in terms of the number of shots.

The manufacturer of small arms is trying with all its might to make it constructively and technologically convenient to manufacture, simply dreams that it would not have scarce materials, that it would be suitable for production on existing (and, as a rule, outdated) equipment, and if possible would use the previously harvested assemblies and components from earlier samples (for example, shops, ribbons, etc.) would require minimal time and energy for production.

The main buyers of weapons (the army and other "power" structures) want it to be at high rates and cheap and maintainable as much as possible so that old ammunition, lubricants and maintenance materials, spare parts, cartridge tapes and shops from earlier models, prepared previously, items of ammunition and equipment (such as: pouches, containers, covers of various kinds, belts, etc.), as well as the appropriate devices for its storage (boxes, pyramids, etc.) would be docked with this weapon.

Here, only a part of the requirements for any sample is given, and it only marks the beginning of a long series of problems. Of course, all these variegated and variegated requirements cannot be fully combined with each other. However, there are two or three problems, the solution of which allows to satisfy at least half of the above requirements and get high rates for a new weapon.

This should take into account two very important aspects.

First, since virtually any weapon does not exist by itself, but is part of a weapon complex (OK), then small automatic weapons are also part of such a complex, consisting of three equal and interrelated components - ammunition (cartridges), systems power supply (devices for their placement / short-term storage and supply to the Launching part) and from the Launch (Armory) part, which, in fact, is considered a weapon. In addition, there are some third-party organizations - both technical and biological, formally not included in the Complex, but ensuring its efficiency. Therefore, any problem confronting OK is solved jointly in all three of its components; the slightest change in one of them must be closely linked to the functioning of the others, on which it inevitably affects. Therefore, the solution of any issues cannot be a single decision, but becomes a system of measures affecting all three components.

Secondly, there is another “trinity” - three so-called Essential features, which are also closely interconnected with each other: this is the firing rate, capacity and weight. Not only do they not exist separately, they still appear in full force with an enviable constancy in all three components of the Weapon Complex.

How to ensure high rate of fire

Since the time of the Crimean War, there has been a need for small arms, which ensure the maximum rate of fire for the longest time possible. This is true today. But the rate of fire is ensured not only by the presence of automatic (re) loading, but also by the presence of a sufficiently capacious Power System. And the more its capacity - the more (total) the weight of the array of ammunition (cartridges) put into it. This results in an increase in the weight of the mechanisms and components of both the Power System and the entire weapon (or rather, the Weapon Complex).

One of the most difficult problems for small arms - the problem of weight, or rather, the task of reducing it. Simply put, there are approximate boundaries: for such an ammunition, an automatic rifle or a light machine gun with equipped shops should have weights within strictly defined limits. The task is to increase the capacity of the power supply system (for example, a store) without leaving the weight frameworks set.

Let's see what can be done for this in each component of the OK.

Weight reduction in the “Ammunition” component is possible due to the transition to a new, reduced caliber (with a corresponding change in the geometric dimensions of the cartridge); by replacing the conventional materials and components in the ammunition with lighter and more modern ones; seriously (deeply) changing the design of the ammunition (cartridge) or by switching to a different principle of its operation.

In the case of a transition to a smaller caliber, a change in the size of the munition occurs, a transition to another cartridge. For example, in the AKM Kalashnikov assault rifles, the replacement of the cartridge 7,62x39 arr. 1943 G. on 5,45x39 arr. 1974 d. The first cartridge has a weight of 16,2 g, the second - only 10,5 g. This led to the birth of a new model - AK-74.

If we follow the path of replacing traditional materials with lighter and more modern, then the changes will first of all affect the device, which unites all elements of the ammunition (shot) into one whole, into the unitary cartridge - this is a case. For example, replacing brass or steel in it with light alloys (possibly based on aluminum) or even plastics will significantly reduce the weight of the entire ammunition.

In the case of a serious change in the design of the ammunition, it is the “device that unites the elements of the ammunition that are rigidly fixed relative to each other in the corresponding positions” in a specific sequence. The most famous and common of such devices is the cartridge case, but this is far from the only unifying or connecting structure. In addition to the liner, there are at least five such structures; no one can guarantee that they are not more.

Machine gun "Revelli-Fiat" arr. 1914

9-mm submachine gun MP-40 / I arr. 1942

A fragment of the submachine gun MP-40 / I arr. 1942 d. Movable cartridge with two windows for standard box stores is clearly visible

If we refuse the cartridge case, then we discard the cartridge case cartridge and, most likely, switch to a case without a cartridge. This is a very serious step with far-reaching and not quite predictable consequences. Firstly, it significantly changes the design of the Armory of the complex, and, secondly, the cartridgeless ammo is also different: “checkers” - similar to the 4,7-mm ammunition company “Dynamite Nobel” for the German rifle 0-11 .; “Yubochnye” - similar to the 9-mm cartridge of the Italian machine gun-gun of the Armi Benelli company М2; and other designs. Changes may be required - and required! - not only in the Armory of the complex, but also in the power system. For example, bezgilzovye cartridges "checker" type have an interesting feature - they can form the so-called "phantom" conveyors, that is, some analogues of cartridge tapes. Constructed with this feature in mind, the power supply system has a traction body in the form of a rail or tape, the weight of which is zero: there are cartridges - there is a traction body, there are no cartridges - there is no traction body. Such a vanishing tape, which “disappears” as the cartridges are used up, can significantly reduce the weight of the Power System. All this is true, but the changes that will entail a “only” transition to a cartridgeless cartridge will change the whole Weapon Complex so much that it may be a question of the technical and economic feasibility of this step: enormous problems will arise with the production of new ammunition; equipment at weapons factories will have to replace percents with 80, etc.

Well, if we talk about switching to a different principle of action of a weapon, then this means not so much a change in the principle of operation of the ammunition, as a transition to another type of destructive principle, and therefore, to completely new models, to other Weapon Complexes - perhaps even non-gunshot.

RPK and RPKS machine guns chambered for 7,62x39. These samples differed from each other by the butts - in the PKK it is inconsistent, and in the RPCS - folding

The weight reduction in the “Power System” component is solved primarily by placing the maximum amount of ammunition in the minimum space. For this you need:

- pick up as long as possible, but with a minimum number of curves of small radii, the trajectory of the supply of ammunition, "packaged" in a given space (dimensions);

- to create a mechanism for the supply of ammunition, ensuring their safe passage along the chosen path of supply;

- to ensure the lowest possible "dead" weight of the Power System - that is, to solve the problem of the ratio of the capacity of the Power System and its weight in the emptied state: to make so that the capacity unit of the Power System would have as little as possible the weight of its components and mechanisms.

The trajectory of the filing can be any, but not to each of them, you can pick up an easy and reliable mechanism for the supply of ammunition, even if you consider that you can not extend the trajectory of the filing infinitely. The simpler it is, that is, closer to the straight line, and the shorter it is, the simpler it is in design, lighter in weight, and the ammunition supply mechanism functions more reliably. Experiments with the paths of supply and the corresponding mechanisms for the supply of ammunition were conducted by gunsmiths from different countries since the 70-s. XIX century, and by the middle of the XX century there was already a solid "collection" of diverse feeders, bunkers, bands, drums and shops - tubular, box-shaped, rotor, auger, rack, multi-chamber, box, snail, saddle-shaped ... Tried It seemed that all possible types of trajectories of innings - both in “pure” form, and in various combinations. Approximately the same can be said about the mechanisms of supply of ammunition - in general, they are known; Although the original designs of such mechanisms can still be created, they are unlikely to have a “breakthrough” character.

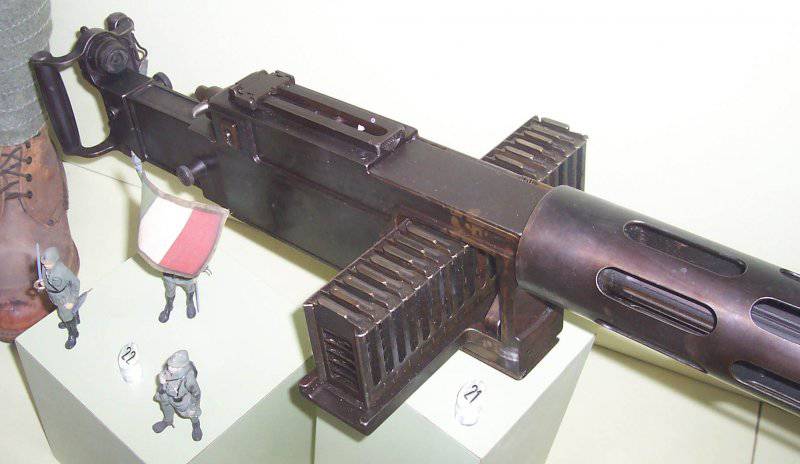

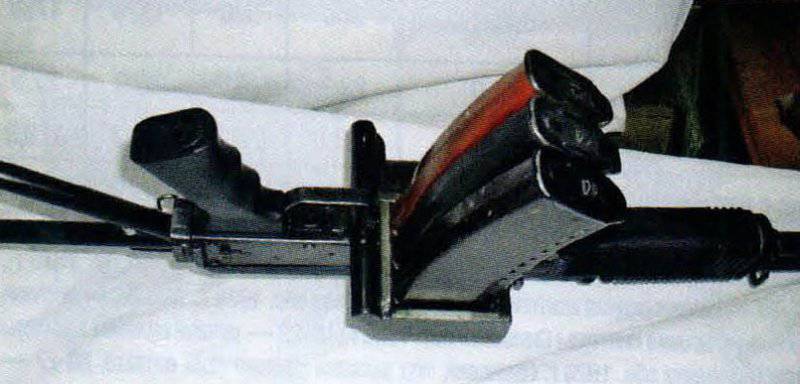

Product “RPKS-SP No. XXUMX” (below) and “RPKS-SP No. XXUMX” (above). View from above. Barrel covers, bolt closures, trigger parts, barrels and magazines are missing for clarity. The mechanism for controlling the feeding of the cassette is well visible; "Pocket" receiver under the breech

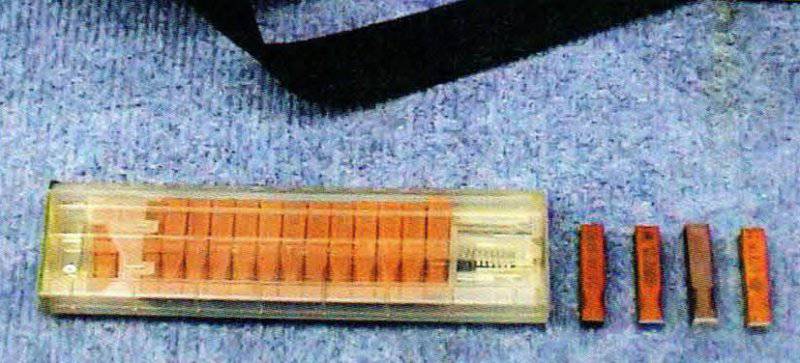

Cartridges for standard shops of products "RPKS-SP No. XXUMX" (on the left) and "RPKS-SP No. XXUMX" (on the right)

For the Power System, the “dead” weight is the ratio of the weight of the emptied food system to its maximum capacity (number of cartridges) and is expressed in grams - this is the “dead” weight “in grams”. “Dead” percentage weight is the ratio of “dead” weight “in grams” to the table weight of one ammunition (cartridge) and expressed as a percentage of the weight of ammunition, that is, multiplied by 100.

Very often, and frankly, almost always for automatic weapons with tape feed - most of the cartridge feed mechanism is fixed on the weapon itself and when reloading an empty Power system it is not separated from it (that is, it serves as a so-called non-replaceable part). In practice, this leads to the fact that it is necessary to consider the absolute and “dead” weights (simple and percentage) of two objects: the replaceable part of the Power System (magazine, tape with a box) and the “dead” weights of the emptied Power System completely (replaceable + non-replaceable parts) together with the weapon on which it is all set.

The “dead” weights of the replaceable part of the Power Supply System are defined in the same way as for store Supply Systems. The “dead” weight in grams for an emptied Power System together with a weapon is the ratio of the weight of a weapon with an empty Power System to its maximum capacity, and the percentage “dead” weight is the ratio of the “dead” weight of a weapon in grams with an emptied Power System to a table weight of one ammunition as a percentage of its weight, that is, multiplied by 100.

Weight reduction in the “Weapon” component is the main direction of weapons creation (at least abroad). It involves two ways:

- development of high-performance original weapon mechanisms, which, due to the merits of the design, are small in size and light in weight. This is a difficult, complex and multi-cost way;

- replacement of the heavy and metal-consuming parts and assemblies in the well-known and already developed weapons with parts and assemblies from light alloys (based on aluminum, titanium, etc.), composite materials, some types of metal ceramics, plastics and synthetic rubbers.

The latter path requires, in addition to the use of these materials, use and appropriate technology. Today, "casting under pressure", special types of welding, various types of stamping and drawing, "powder" metallurgy, soldering, gluing, etc. are used. General technical fasteners are also widely used - "roll-on" and tubular axes and pins, lock washers, etc. D. All this really significantly reduces not only the weight of the weapon, but also the cost of its production; however, in parallel with this, there is a decrease in its performance. Reduced resistance to heat, shock, pollution; significantly maintainability. Repair is possible only by replacing units (units) - and then only if the weapon is designed according to the so-called. modular principle. In fact, in recent years abroad they have been following the path of creating a one-time weapon that was not designed for repairs: shot out the prescribed number of shots or before the appearance of faults - and threw it away.

Power systems problems

Taking into account the military-economic situation in our country, we hardly need to copy the decisions of foreign gunsmiths. Yes, their experience must be taken into account, but it is necessary to go its own way - our developments should not stand still.

From the foregoing, it is obvious that, at the present time, when developing new and modernizing old small arms, the ammunition should remain unchanged, and to make minimal, minor changes to the weapon itself.

Thus, in the OC two components (“Ammunition” and “Weapon”) are not subject to fundamental changes; a leap in quality and, in the first place, a solution to the weight problem should be achieved practically only at the expense of the Power System. The situation is difficult, but not hopeless.

Characteristics of stores for domestic 7,62-mm rifle cartridges mod. 1891-08-30 biennium. (Aka 7,82x0411) used in automatic small arms

Devices for placing ammunition | Shops | ||||

Weapon sample | DCT-35 / SVT-38 | ABC-38 | 13-26 | DP-27 | DT-28 |

Ammo Capacity | 10 | 15 | 20 | 47 | 63 |

Store body material | Steel | Steel | Steel | Steel | Steel |

Weight of the magazine without cartridges, g | 300 | 350 | 330 | 1175 | 1730 |

"Dead" weight, g | 30,0 | 23,3 | 16,5 | 25,0 | 27,5 |

"Dead" weight,% | 137,6 | 107,0 | 75,7 | 114,7 | 126,0 |

Weight with cartridges, g | 518 | 677 | 766 | 2200 | 3104 |

Note. DKT-35 - an automatic carbine of the Tokarev system arr. 1935, S8T-38 — self-loading rifle systems ,! Tokarev arr. 1938, ABC-38 - an automatic rifle of the Simonov system arr. 193B., LS-26 - machine gun system Lahti Salorant arr. 1926 (Finnish, under the Russian military cartridge), DP-27 - machine gun of the Degtyarev system arr. 1927, DT-28 - tankHe is a manual machine gun of the Degtyarev system arr. 1928

Power systems have always been the “unloved sons” of the developers of rifle systems. There are many classifications of automatic weapons and weapons, written fundamental works on its evolution, there are very complex methods of calculations of almost everything that relates to weapons and ammunition. But there is not a single extensively developed classification of power systems, nor is there any serious work on them.

So, you need to create a power system of increased capacity, but with a minimum weight - both absolute and "dead." Where to begin? With the analysis of the situation! Table 1 shows the characteristics of the magazines under the 7,62-mm rifle cartridge 7,62x54R.

The weight to capacity ratio for them is noted in Fig. 1 as 1 curve. This curve is very close to the parabola; if it is continued, that is, to create stores with the capacity of 80-100 cartridges, then it may even go parallel to the ordinate axis. Even without this, it is clear that an increase in the capacity of shops for rifle cartridges will be paid for by an excessive, disproportionately large weight. The weight of "iron" per unit capacity will negate the feasibility of creating such a store. Despite the appearance of new materials, the question of reliable, capacious and light stores under the domestic rifle cartridge remains open, and so far cartridge cartridge reigns supreme.

Characteristics of stores and ribbons used in domestic machine guns for automatic cartridges.

Devices for placing ammunition | Shops | Tape | ||||||||||||||||||

Capacity, cartridges | 30 | 40 | 45 | 60 | 75 | 100 | ||||||||||||||

Cartridge | 7,62x3B | 5,45x39 | 7,62x39 | 5,45x39 | 7,62x39 | |||||||||||||||

Material, magazine / tape case and its box | Steel | Plastic | "Light" alloy | Plastic | Steel | Plastic | "Light" alloy | Plastic | Steel | |||||||||||

Weight unloaded, g | 330 | 245 | 190 | 200 | 410 | 375 | 200 | 280 | 320 | 935 | 800 | |||||||||

"Dead" weight, g | 11,0 | 8,16 | 6,33 | 6,66 | 10,25 | 6,37 | 5,0 | 6,22 | 5,33 | 12,46 | 8,0 | |||||||||

"Dead" weight,% | 67,90 | 50,41 | 36,06 | 63,49 | 63,27 | 57,87 | 30,86 | 59,25 | 50,79 | 76,95 | 49,40 | |||||||||

Weight with cartridges, g | 816 | 731 | 676 | 515 | 1058 | 1023 | 848 | 752,5 | 950 | 2150 | 2420 | |||||||||

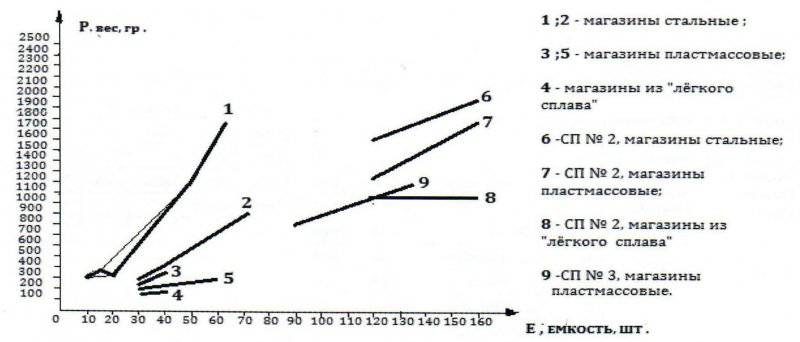

The situation is somewhat different with the power systems for domestic 7,62xXNNUMX and 39x5,45 mm automatic cartridges. Table 39 shows the characteristics of shops and ribbons of light machine guns of the RPK type (store supply) and RPD (tape feed). The weight-capacity ratios are also shown in fig. 2 curves 1, 2, 3, 4.

It should be immediately noted here that these curves are closer in appearance to straight lines. Moreover, they do not “fly up” as steeply as the 1 curve discussed above. The 2 curve, although it “risks”, with its continuation, turns into a parabola - but not so steep as 1. The curves, or rather the straight lines 4 and 5, are much closer to the x-axis than to the y-axis. But this is all in stores, the capacity of which does not exceed 75 cartridges; Attempts to create reliable stores of larger capacity will inevitably “pull” curves upward, repeating the situation with the 1 curve. The reasons? Objective! Even if you use “super-light” modern materials, it is impossible to create a reliably working, rigid and lightweight box magazine with a capacity of 100 cartridges at their staggered arrangement. Firstly, it must have a very powerful supply spring to move the entire array of cartridges placed in the mine of the shop body, but then in the fully-equipped state of the store at the bolt of the machine gun or machine gun just do not have the strength to “tear out” the cartridge from the bends of the store and send it in the barrel, and in fact it is necessary not only to close the bolt, but also to lock it. Secondly, having such a long store, it is very difficult to shoot from the “lying” position; it seems that the store will have to dig a separate trench. Thirdly, to ensure the rigidity of such a store, it is necessary to significantly increase the thickness of its walls and strengthen the neck, which will cause a disproportionate capacity increase in weight, and so on. There are examples of such kinds of “arts”, obviously, made in China - boxed monsters on 50 and 80 7,62x39 cartridges.

In order to get away from such a curve of the shaft sticking out of the receiving window of the machine gun or machine gun, it is necessary to place the trajectory of the supply of ammunition in space more compactly, i.e. bend it even more, turn it into a circle, spiral or helix, in other words, go to the drum , disk and screw shops. But these stores have more complex and material-intensive buildings, more complex and capricious mechanisms for the supply of cartridges, which means their weight increases - both absolute and “dead”. In addition, these types of stores are much more difficult to operate than the box. It remains when creating a power supply system with a capacity from 100 cartridges and higher to switch to tape feed, which, by the way, has no less disadvantages than advantages ...

All of this suggests that none of the applied paths of supply and none of the corresponding mechanisms for the supply of cartridges does not provide an increase in the capacity of the power system with acceptable weight and performance characteristics.

A graph of the weight of emptied replaceable parts (magazines and magazines with magazines) Power systems for automatic small arms using cartridges 7.62x54R (1), 7,62x39 (2, 3, 4, 6, 7, 8) and XNXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX7XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX.

Weight characteristics of replaceable parts of experienced Power systems of increased capacity to domestic light machine guns of type РПКС

Light machine gun | РПКС-СП № 2 | РПКС-СП № 3 | ||||||||

Applicable cartridge | 7,62x39 | 5,45X36 | ||||||||

Tape weight without stores, g | 280 | 200 | ||||||||

Number of stores in the cassette, pcs. | 4 | 3 | ||||||||

The weight of the replaceable part of the power system (the weight of the cassette with stores of various materials) | Shops | Absolute | "Dead" | Absolute | "Dead" | |||||

Yomk | Mat. building | is empty. | snr. | РіСЂР ° Рј | % | is empty. | snr. | РіСЂР ° Рј | % | |

30 | Steel | 1600 | 3544 | 13,33 | 82,30 |

|

|

|

| |

30 | Plastic | 1260 | 3204 | 10,50 | 64,8 | 800 | 1745 | 8,88 | 84,7 | |

30 | Easy alloy | 1040 | 2084 | 8,06 | 53,5 |

|

|

|

| |

40 | Steel | 1920 | 4512 | 12,0 | 74,1 |

|

|

|

| |

40 | Plastic | 1780 | 4372 | 11,12 | 68,7 |

|

|

|

| |

40 | Easy alloy | 1080 | 3672 | 6,75 | 41,7 |

|

|

|

| |

45 | Plastic |

|

|

|

| 1040 | 2458 | 7,70 | 73,4 | |

To create a satisfactory power supply system, it is necessary to change the principle of supplying ammunition, move away from simple, single-level feed and move on to complex, multi-level feed. Of the complex Power Systems, the simplest are the two-tier Systems, characterized by the presence of a feed on two levels - upper and lower. At the lower level, the delivery of ammunition from “devices for placing ammunition”, made in the form of clips, packs, shops, cartridge belts, etc., is known. At the upper level, “two or more” pre-loaded “devices for ammunition placement” are supplied in the Armory of the Complex to the so-called "power position". Feed paths at both levels can formally be of any complexity, but in practice, the shortest paths that are close to straight lines should be used. This approach provides:

- in the "devices for the placement of ammunition" - their minimum weight and maximum compactness;

- maximum compactness and minimum weight of devices that provide the supply of "devices for the placement of ammunition."

When powered by automatic cartridges, all this creates prerequisites for the successful creation of Power Systems that have capacities within 80 - 200 cartridges with quite acceptable mass-dimensional indicators. Such Systems may well become an alternative to tape power.

This idea is not new, although little known even to specialists. In the serial automatic rifle weapons for the first time such Power systems were applied on the Italian 6,5-mm machine guns of the Perino system arr. 1909 and the "Revelli-Fiat" arr. 1914 g., As well as on the German 9-mm submachine gun MP-40 / I arr. 1942 (also known as GERAT 3004).

In our country, various aspects of the construction of two-tier Systems were quite seriously worked out and outlined in the “Power supply system of automatic and semi-automatic firearms”, compiled in 1984 at the insistence of Colonel Semyonov Vyacheslav Vladimirovich - at that time the head of the BRIZ of the USSR Academy of Commerce.

One of the main issues discussed in the aforementioned work was the problem of using two-tier power systems on light PKK-type light machine guns. First of all, I was interested in the fundamental possibility of using such power systems on RPK machine guns, as well as the capacitive, weight and dimensional characteristics of the resulting products. The mock-up products were counted - the mass-size models of both machine guns and the power systems installed on them. Unfortunately, combat prototypes have never been built and have not been subjected to operational tests. Some materials from the work "The power supply system of automatic and semi-automatic firearms," adjusted for the latest data, are used in this article.

To use a two-tier power system with regular box magazine in the PKK machine guns, regardless of caliber, the following changes must be made:

1. Run through the transverse notch in the receiver near the receiving window;

2. To provide fastening on the receiver of the U-shaped rails in the block with the feeder of the cassette with magazines;

3. To provide accommodation in the so-called “pocket” of the receiver of the stepping mechanism for controlling the supply of the cassette with magazines;

4. Change some parts of USM - in particular the fuse, self-timer and enter the shutter stop;

5. To abandon the monolithic folding stock, and make it skeletal (frame);

6. Change the configuration of the bolt carrier.

These transformations do not require large material costs, especially since the shutter has already been shut down on some Izhevsk and Yasnaya Polyana products, the shutter handle is planned to be changed, the frame butt is produced in at least two forms and you only need to slightly change its geometry near the shoulder rest, well and finally, on some products, a fuse of almost the required type is installed.

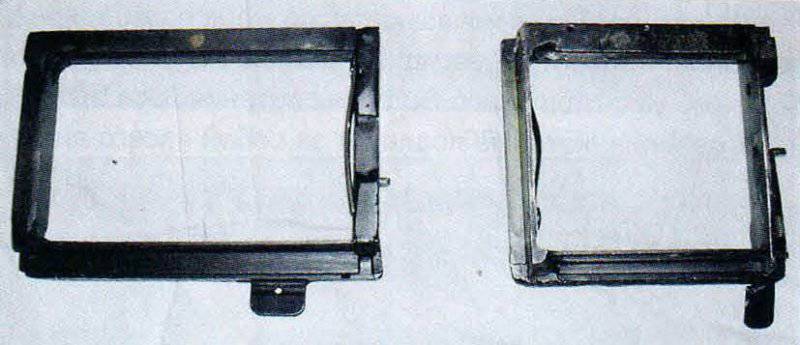

The power supply system developed for the RPKS machine gun chambered for 7,62x39 mod. 1943, designed for the placement of four regular box-type stores with steel, plastic or “light alloy” cases of 30 or 40 cartridges. This system bears the conditional index "РКСКС-СП №2". It is attached to the chute of a standard PKK receiver and is shown in Fig. 1 without stores.

Power system for RPKS machine gun chambered for 5,45x39 mod. 1974 was designed to accommodate three regular box stores with plastic cases with 30 and 45 cartridges. It bears the conditional index "РПКС-СП №3", and is also attached to the receiver RPK-74М and is presented in Fig. 1 with stores.

In both cases, the receiver has standard overall dimensions. The changes are in the presence of cuts on the sides and bottom in the receiving window area to ensure the unimpeded movement of the cassette with stores through the receiver in the transverse direction - from right to left and vice versa.

Both Power Systems include a non-replaceable part - non-detachable from a machine gun when reloading ammunition and a replaceable part removed from a weapon for the convenience of filling cartridges. For each machine gun, the non-replaceable part is presented in a single copy, while the replaceable parts for convenience of operation may include several (two or more) in the product package.

The non-replaceable parts of both Power Systems are almost identical and include U-shaped guides attached to the receiver at the cut-outs, a spring-type cassette feeding mechanism attached to both guides and the bottom of the receiver, and a cassette feed control mechanism. The feed control mechanism is step-by-step, plunger-type and differs only in the controls — in the “RPX-SP No. XXUMX” product it has a lever, and in the “RPX-SP No. XXUMX” with a button.

Replaceable parts of both models are also slightly different and consist of a cassette with three or four box-shaped stores. Frame type cassettes, steel; stores move their mouths in the cassette with its door open. The latter closes and closes with a latch, securely holding the stores inside the cassette. Magazine with stores manually moves from right to left in the guide and moves through the receiver to the leftmost position. At the same time, the cassette feed mechanism spring is compressed, and the step-by-step feed control mechanism runs idle until the right-most magazine in the cassette takes up a place in the machine gun receiver that allows the cartridges to be fed from the magazine to the receiver box to the feed position. Note: all the above manipulations with the cassette and magazines moving along the guides through the receiver box are possible only when the slide frame of the machine gun retracted to the rearmost position, therefore, it became necessary to stop the bolt. Correspondingly, the equipped magazine also carries out the change of the emptied store with the bolt carrier retracted to the extreme rear position; to move the cassette with magazines from left to right, press and release the button or lever of the cassette feed control mechanism.

The total weight of the array of ammunition entered into the power system

Cartridge | 7,62x39 | 5,45X39 | |

Amount of cartridges, pcs. | 1 | 16,2 | 10,5 |

30 | 486 | 315 | |

40 | 648 | 420 | |

45 | 729 | 472,5 | |

60 | 972 | 630 | |

75 | 1215 | 787,5 | |

90 | 1458 | 945 | |

100 | 1620 | 1050 | |

120 | 1944 | 1200 | |

135 | 2187 | 1417,5 | |

160 | 2562 | 1680 | |

The characteristics of the 7,62-mm machine gun of the Degtyarev system. Arr. 1944 RPD-44 - chambered for 7,62x39. In addition to a number of positive qualities, especially operational ones, this machine gun is distinguished by a capacious and easy replaceable part of the Power System - a box with empty cartridges for 100 cartridges weighs only 800 g. Of course, since the main nodes of the ammunition feed mechanism are installed on the machine gun and are an irremovable part of the System power supply, in general, it has a more impressive weight, but due to the enviable simplicity of the automation of this machine gun, its total weight together with the Power supply system without cartridges of all 7400 g and 9020 g with cartridges.

The dependence of the weight on the capacity of the replaceable parts of the Power supply system of the products "РПКС-СП №2" and "РПКС-СП №3" are marked in the graph with 6, 7, 8 and 9 curves. Replaceable parts are designated respectively "SP №2" and "SP №3".

The proposed power supply systems can use regular box-type shops with cases of various materials and different capacities, which is marked on the chart and in the tables with numbers 2, 3, 4. Table 4 is a summary, it contains all the data we are interested in on machine guns of the RPCS type, both with standard Power Systems and with experienced RPS-SP No. 2 and RPX-SP No. XXUMX.

Practice shows that a light machine gun with a power supply system equipped with cartridges should not exceed the weight in 9000 - 9500. That is why the RPD-44 machine gun is taken as the standard; all weapon versions exceeding its weight should hardly be considered acceptable.

Table 5 shows the data of the most successful versions of machine guns of the type RPS with power systems of maximum capacity with weight of samples in the equipped state, not exceeding 9500 g.

At the same time, for the RPCS-SP No. 2, chambered for 7,62x39, the author excluded from consideration the options with the light alloy shops (most likely silumin), since they are very rare. Box stores with steel cases are also excluded - since in our country they have practically become obsolete.

Analysis of results

One glance at the 5 table is enough to establish - increasing the absolute weight of the machine gun “RPX-SP No. XXUMX” relative to the RPX with the 2-cartridge magazine on 75 kg is justified by more than one and a half times (2 cartridges!) Increase in capacity. And this is with very good indicators of “dead” weight - it is reduced by 120. Compare with RPD-20: the weight of an empty “RPX-SP No. 44” is less on 2 g, in the curved state between them there is less 200 g difference, and in capacity “RPX-SP No. 100” on 2 cartridges (on 20%) surpasses the RPD-20, and even on the “dead” scales it is ahead of the standard.

The situation with the RPCS-SP №3 is quite good. When comparing it and RPKS-74 with the newest 60-cartridge plastic store, we see that the absolute weight of the RPX-SP No. 3 in running condition is more on 1900 g, but the capacity of the Power System is more than twice as high (135 versus 60 !) At the same time "dead" weight is reduced by half.

Let's compare “RPSKS-SP No. 3” and RPD-44 - although this is not entirely correct due to the large difference in tabular weights of cartridges (7,62x39 munition weighs 16,2 g, and 5,45X39 weighs 10,5 g). Even here it is noticeable that the capacity is increased by 35 cartridges, the weight in curbed condition per kilogram and a quarter less, and the "dead" weight in percent is almost the same.

Thus, it was proved that according to the weight characteristics, the machine guns “РКСКС-СП №2” and “РПКС-СП №3” have very good indicators on the ratio

"Weight-capacity", and surpass them in existing machine guns such as RPS. It should also be noted that the proposed products, at least, do not lose to the RPD-44 machine gun.

Those interested can check the validity given in the calculation tables.

In the process of working on samples "РПКС-СП №2" and "РПКС-СП №3" it was found that the dimensions of the main parts, assemblies and assemblies of AK-47, AKM, AK-74 machine guns and RPK type machine guns remain unchanged. The above prototypes were created only to clarify the fundamental possibility of creating new power systems, and therefore had a minimum margin of safety. When developing on the basis of these models of military weapons, revisions and changes are inevitable. Thus, the profile of the guides is likely to change without a noticeable increase in weight, the weight of the receiver and parts of the trigger is likely to remain the same or slightly more, the weight of the cassette will significantly decrease due to the optimization of profiles and the use of light alloys and plastics, perhaps the design will change Cassette feed and feed control mechanisms. In other words, the usual correction of weight characteristics will occur. But this will not change the fundamental side of the issue. What conclusions can be drawn from the results obtained?

Well, firstly, it is quite possible to create “complex” “multi-level” power systems. Like any phenomenon, they have very specific characteristics, and therefore their strengths and weaknesses.

Secondly, the fact of their existence of the “RPSKS-SP No. XXUMX” and “RPSKS-SP No. XXUMX” devices confirms not only the possibility, but I’m not afraid of this word, the need to modernize the Kalashnikov small arms system.

Thirdly, the RPSKS-SP No. XXUMX and RPKS-SP No. XXUMX devices fit so well and harmoniously into the M. Kalashnikov small arms system that they did not even need to change the basic sizes of the samples. And this, first of all, is the advantage of not the above-named devices, but evidence of the plasticity, vitality and enormous design potential incorporated into Kalashnikov rifle systems. This indirectly, but very eloquently, indicates that attempts by some officials in the Russian Ministry of Defense to abandon Kalashnikov assault rifles and machine guns are irrational.

Obsolete is not the Kalashnikov machine gun and his machine guns. Over the past 20 years outdated in the methods of management and in the views on the problems of the state almost everything, including the military, the bureaucracy of the Russian Federation. Therefore, the problem of Complex Power Systems is a purely technical problem; it threatens to turn into a political problem that can only be solved by top officials of the state.

Information