Titus is alive!

Demonstration of cars to journalists at the site near Paris

New car from Nexter can take on board 14 people

The squad leader watches the situation from the outside from his central place, a little in-depth compared to the other two front seats. To his left, the driver uses the car’s full power, easily overcoming obstacles (the ride is surprisingly smooth), and to the right, the commander / gunner controls a medium-caliber gun, being fully prepared for any possible threat. Behind, ten paratroopers are ready to join the battle and disembark through the stern ramp, which contains a surveillance and embrasure device for firing.

If not for some photographs attached to the article, the previous paragraph could describe a ride on a typical 8x8 armored personnel carrier. But no, we are on board the newest machine in the 6x6 configuration, developed by Nexter, a French company that looks like Mrap, but represents a significant step forward compared to its counterparts. Looking at the state of the market and the accumulated experience of developing its XP2 6x6 technology demonstrator, Nexter decided that it was time to fill the gap between Aravis and VBCI and thus meet the needs of those armies that need to replace their fleet of armored personnel carriers and at the same time adapt to the changing combat situation. Most importantly, this includes the current hybrid nature of existing conflicts, which, as recent operations confirm, may include a wide range of military operations, coupled with an unbending stance on reducing overall costs for the entire service life. Strategic and operational mobility plus operational flexibility are set aside, it is necessary that in less rich countries the term “inexpensive” prevails as opposed to the term “cheap”, and it should also be understood in first-tier countries whose military budgets are constantly decreasing.

This vehicle (formerly XP3) has transformed all of these aspects into modularity, life-cycle cost control and a highly efficient chassis with a well-deserved reputation. Subsequently, the vehicle received the more majestically "imperial" name Titus (Titus, the ancient Roman emperor), which actually means the Tactical Infantry Transport & Utility System (tactical infantry transport and support system). With a dead weight of 17,5 tons, its combat weight for mixed conflicts is usually about 23,3 tons, although its maximum total weight can go up to 27 tons.

Good visibility for the front seated squadron and some paratroopers sitting in the rear cabin

Driver's seat

Mobility

For an all-terrain military vehicle, the key factor of mobility is the constancy of grip. This in turn entails a corresponding (in fact, the maximum possible amount of load) load distribution and “long legs” in order not to lose traction with the ground in the most difficult conditions. When distributing the load, tires do a lot of work, which in this case is entrusted to Michélin 16.00R20 - comfortable wide “shoes”, the pressure in which may vary depending on the nature of the terrain.

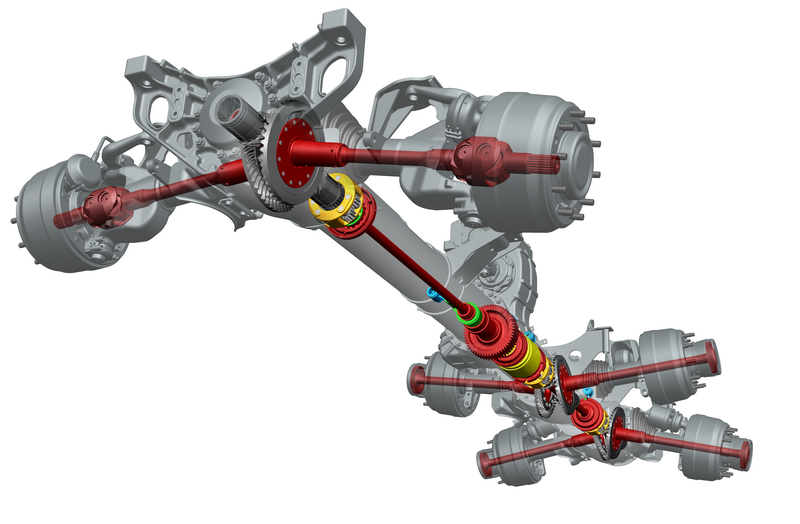

Another component that greatly influences grip is, of course, the chassis. There are several (but not many) ways to provide the necessary wheel travel down. One of them is to allow the chassis to arbitrarily curl, as it is very effectively done by a well-known German company. But if the chassis has to be a long, heavy and rigid cab, then such a scheme has a big disadvantage, negatively affecting the payload. The second, nominally perfect scheme, is a rigid chassis lying on a fully independent suspension with a long stroke, working on overhead wishbones, and which is as good as the road, especially over a certain tonnage. The ideal answer could give the principle of swinging semi-axes. It may be old, like the independent suspension itself, but its shortcomings, such as yaw (angular movements of the aircraft, ship, car relative to the vertical axis - approx. Lane), were brilliantly solved by Tatra company at the beginning of the 20-s. Since then, the company has had many victories in various races, including in the truck class at the unforgettable Paris-Dakar rally, starting from 1988, when Czechoslovakia was on the other side of the Iron Curtain. The uniqueness of the Tatra chassis, which was chosen by the company Nexter, lies in its central carrier tube (ridge frame) and independently swinging semi-axes. The torque is transmitted by the longitudinal shaft running inside the frame, and the main gear consists of two bevel gears mounted on the end of this shaft and engaging with the rims of the gears of each axle shaft (see the Tatra chassis and video that speak for themselves).

The operating principle of Tatra suspension with swing bridges; in the figure for the standard wheel arrangement 6 x 6 in which each differential semi-axle in a tubular casing swings around the corresponding drive gear

Video demonstration of the principle of operation of the Tatra chassis

However, the first thing Nexter did was to change the layout of the Tatra 6x6 chassis axles. The second bridge, usually located closer to the third bridge, was placed exactly midway between the first and third bridges. Of course, this is brilliant in terms of the distribution of the load and axle load when overcoming rough terrain, but makes the car poorly controlled, since the front wheels break the linear stiffness of the other two bridges when turning. The Nextxt company solved with no less success by placing a second differential steering gear on the third axle.

Wheels that are in positive continuous contact with the ground, provide good cross-country performance. The upgraded Tatra chassis fully meets this requirement.

What is very important, it not only added maneuverability, but also provided an unprecedented turning circle for trucks 13 meters, while modern passenger cars hardly fit into the mark 12 meters! The second advantage of this dual steering is to reduce the side skid when the wheels are completely locked. It must be said, however, that driving on a highway with a wagging "tail" is unacceptable. Therefore, the security system reduces the angles of rotation of the rear axle with increasing machine speed. The angles of rotation of the wheels to the speed of 10 km / h are the same as those of the front axle, with an increase in the speed, they gradually decrease, and when the 45 km / h is reached, the rear axle actually becomes uncontrollable.

The mobility of the vehicle is also largely dependent on the power of the power unit. To this end, the company Nexter went for the engine abroad and stopped on a Cummins engine with approximately 440 HP. and an automatic Allison six-speed transmission. As a result, with phenomenal effective engine power, the car is very sensitive and smoothly reacts to the accelerator pedal. Sea trials not far from Paris were quite difficult, but the engine always had enough engine power, although its combat weight was more than usual. Despite the impressive huge ruts dug at the site, there has never been any noticeable impact or loss of traction. It was only when there was a problem with the power reserve in the sand that journalists were told that an engine with an 550 hp power was considered as an option.

DEF

Nexter's goal is to provide the customer with what is really needed to increase protection. The base machine has the level of protection of the engine hood Level 1 and bullet-proof glass, the level of protection of the crew’s steel capsule is Level 2 (ballistic and anti-mine), and the machine is able to withstand an IED (improvised explosive device) weighing 50 kg. These levels, of course, can be easily raised by installing additional armor; Titus was created from the very beginning to make such decisions. Currently, the company Nexter is considering increasing the levels of protection: engine hood and bulletproof glass - Level 3, ballistic and mine - Level 4, protection against 150-kg of the SVU charge and 155-mm shell splinter; of course intermediate levels are also available.

As stated at the outset, full customer satisfaction is seen as a key task, even at a lower cost, to a large extent, the concept of modularity contributes to this. However, the modularity itself can raise the cost of the product and thus, here you need to take into account the wishes of the customer, all the pros and cons. This means that if the buyer finds that he will need to add some components later, the machine will be equipped to make such decisions. Conversely, if the buyer is fully confident that his car will not change, then solutions that allow adding modular elements will not be taken into account and the purchase price of the car will become lower. These concepts should be illustrated and described in detail, and a chart of successive options with many variable characteristics should be presented to the buyer.

Situational awareness

As mentioned above, in the cockpit the driver sits on the left and the commander / gunner on the right, in the left front corner of the roof of the prototype, the remote-controlled Nexter ARX20 combat module is installed. Behind the cockpit in the central position is a seat for the commander of the landing. Such a vantage point allows him not only to observe the situation on the big screen of the battle management system on the left and the sub screen on the right, but more importantly to keep a direct overview of the frontal sector in 120 ° through a large one-piece windshield - a key feature that guarantees maximum situational awareness.

The wide windshield also allows troops, especially those who are sitting in front, to observe the external situation. On each side of the car can be installed on three windows of armored glass. The current prototype was not equipped with such windows (but was ready for this), instead of them an opaque protection Level 3 was installed. Situational awareness is complemented by four cameras that provide an all-round view of 360 °.

Ergonomics

When creating Titus, Nexter conducted thorough ergonomic research, first made a wooden model and embodied all the experience gained with previous machines. The hull does not interfere with the passage over the entire length, its internal volume is 1,4 м3, you can add storage for it with 2,4 м3 volume inside the machine and 1,5 м3 outside, the latter is divided between six compartments, three on board.

The bottom of the car is high enough from the ground, the stern ramp and intermediate stage facilitate access to the car, the door is fenced with two side rails, which make it easier to get in and out of the car. We repeatedly checked the entrance and exit of the car: the ramp falls lower than, for example, at VBCI, and the intermediate stage plays an important role for the convenience of entry and exit. On the sides of the troop compartment are two rows of energy absorbing seats. The maximum number of 14 passengers, this includes two crew members in the front cabin and two rows of six seats in the rear without a squad leader. When installed for him in the middle of the seat, the number of rear seats in each row is five; accordingly, in this case the number of passengers is 13 people. The smaller number relates to personnel equipped with Felin systems, and the larger number to soldiers with light equipment.

Overall height is solid 1,37 meters, while each paratrooper has at its disposal 570 mm in width, a lot of attention in the car is given to comfort. It is worth noting one of the features that for armies equipped with individual soldier systems like the Felin, Nexter has developed wider side doors for the driver and commander to facilitate embarkation and disembarkation. There is also an option without the front right door. Depending on the level of protection and the corresponding increase in mass, the front doors can be equipped with electric drives. The commander of the vehicle and the compartment has hatches, and in the rear of the hull, on the upper corners of the module for carrying troops, there are two more hatches for access to the settings of light machine guns. The stern ramp can be replaced with two doors.

If comfortable conditions allow passengers to disembark in relatively good condition after a long drive over rough terrain and, consequently, immediately engage in combat, then comfort can be safely attributed to an integral part of ergonomics. The soldiers who took part in the current tests on this extremely harsh, if not extreme, area, previously participated in the hostilities in the former Yugoslavia and Afghanistan. They unequivocally confirmed the opinion of the journalists present that Titus utterly surpasses any combat vehicle on six wheels and can hardly be surpassed by the "eight-wheeled". In fact, we never got into a critical situation and never heard loud “protests” of the chassis when it seemed to the driver that they were aiming at us from an RPG. The strengths of the Tatra chassis cushioning system are enormous.

The machine is configured for 13 people, two rows of five seats plus three seats in the front cabin

options

The aforementioned modularity defines various configurations and variants. First of all, the BTR variant can be equipped in accordance with the level of threat and combat mission. Nexter offers six different kits with successively increasing weight and complexity; Depending on personal equipment, the seat layout remains 2 + 13 or 2 + 11.

The base version is used for patrol missions, its only weapon is a remote-controlled turret 7,62-mm machine gun for self-defense. The machine also has on each side three side windows with embrasures for shooting, the same is with the other two options for carrying out tasks of low intensity: one to maintain public order, and the second to disperse the crowd. The loudspeaker, the Galix non-lethal grenades and the front fence distinguish the option for maintaining public order, while the crowd-control machine also has scissors for cutting wires and cables, a Molotov cocktail counteraction system and bulldozer blades for demolishing barricades. All of these options, the patrol and two for internal troops, have a mass of about 19 tons.

For traditional warfare, mass increases to about 22 tons, remotely controlled weapons are replaced by heavier ARX20 turrets. The protection level of the crew compartment is raised to Level 3 (or even 4), side windows give way to additional armor, a shot detection system, an infrared silencer, a laser warning system receiver, a multi-touch warning device and a friend-to-friend identification system can also be added. plus can be installed front winch. Rebel control configurations include an 12,7 / 7,62-mm combat module, mounted RPG anti-RPG screens (eg, Nexter PG-Guard), a 360 ° all-round camera system, a silencer, and of course, all Level 4 protection with the greatest possible protection against roadside bombs; in the stern of the machine, two light machine guns are installed and it is quite possible in connection with the “gained Afghan experience”.

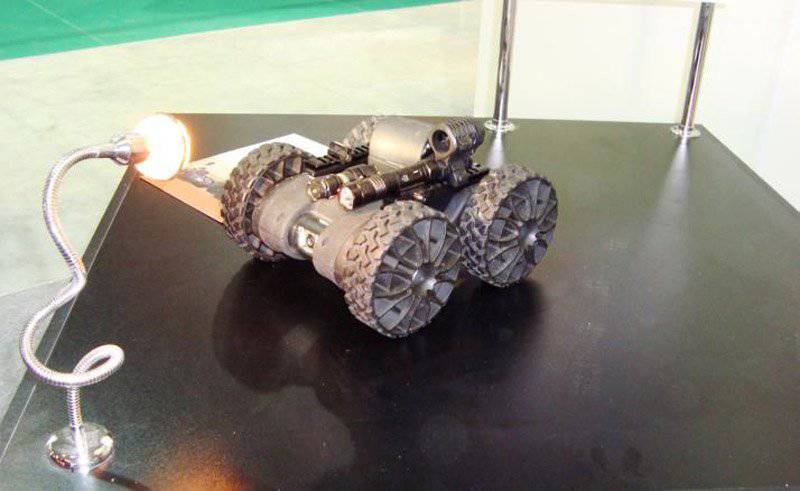

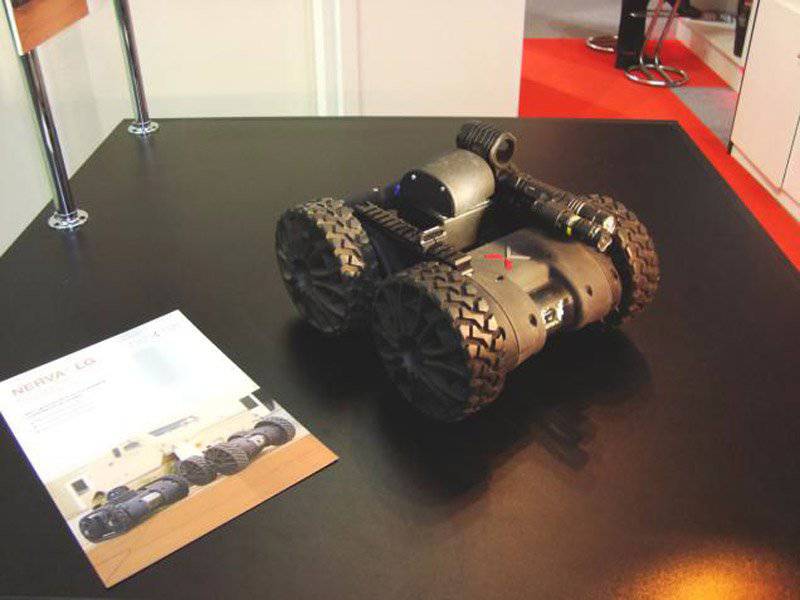

Such an option can also be equipped with a tactical ladder on the roof, so that special forces can directly storm buildings from higher floors. Of course, it is necessary to remove all equipment from the roof. The last two configurations increase the mass to 23 tons, which is a ton less than the heaviest option for urban combat. This is essentially a counter-insurgency variant with a dozer blade and a Nexter Nerva microrobot for conducting reconnaissance.

Three external boxes on each board provide additional 1,5 m 3 for storing individual equipment and compartment equipment. The Nexter Nerva micorobot laid at the rear of the Titus can usually be used in urban environments for short-range intelligence

The Nexter Nerva micorobot at the RAE 2013 exhibition in Nizhny Tagil

Nexter has already outlined the development of several functional kits that transform Titus into various support machines. These include an 81-mm mortar set-up with 80 rounds of ammunition, an anti-tank set-up with 12 missiles and two embrasures for firing and a sniper machine for two sniper groups with 12,7-mm and 7,62-mm rifles; All these cars have a crew of three people and, depending on the variant, a corresponding group of three or four specialists. The modifications, in the full sense of the word, include a sanitary version with four stretchers, engineering, easy evacuation and supplies (can carry NATO standard pallets and is equipped with aft doors), a control station with three jobs and an artillery observation vehicle. Last modified with Margot mast surveillance system. Even these machines are based on functional kits and can be reconfigured in the troops, depending on the tasks performed.

The only option that requires serious refinement of the machine is a mortar conveyor armed with an 120-mm rifled mortar TDA A 2R2M, which fires through two open hatches on the roof.

The principle of functional kits will simplify the support of the Titus machine from a logistics point of view. In this way, Nexter is developing an increasingly efficient logistics system, which ranges from parts supply to complete, comprehensive logistics. According to Nexter, being a combination of a Mrap type machine (with enhanced mine protection) and a wheeled BMP / BTR, Titus must perform more than 85% of BMP combat missions and all BTR tasks in mixed conflicts, which opens up significant market share for this French novice.

The picture clearly shows the work of steering the rear wheels. At low speeds, the angles of rotation are the same for the front and rear axles. At speeds above 40 km / h, turning the rear axle is blocked

The combination of a lowered ramp and an intermediate stage in front of it greatly simplifies embarkation and disembarkation. Such a decision will be highly appreciated by soldiers in heavy body armor.

Market

Nexter officials said they started the project more than two years ago after evaluating the scope of two main factors. On the one hand, this is the number of obsolete armored personnel carriers and infantry fighting vehicles that need to be removed from service, and on the other hand, the development of mixed conflict scenarios, in which a number of opportunities will be lost due to the too high cost of such large vehicles as VBCI and Boxer. These studies allowed the company to estimate the potential market volume in approximately 1000 machines.

The machine presented in the article is the first prototype, but it is planned that the second prototype will receive the inevitable improvements (some of them will also be implemented on the first prototype), and perhaps even a more powerful engine. The Titus machine is fully compliant with the standards for public roads and enters the Atlas A400M transport aircraft without any problems. It may be ready for production at the beginning of December 2013 (there is no information on 1 in January 2014).

Nexter ARX20 remotely controlled combat module has a rather convincing firepower

In the configuration of the struggle with the rebels on the Titus machine can be installed two light machine guns, for example, FN Minimi (pictured)

TITUS machine specifications

Own weight 17,5 tons

Combat weight (3 Level) 23,3 tons

Gross weight 27,0 tons

7,55 meter length

2,55 meter width

Height 2,73 meters

Track 2,55 meters

Cummins engine 440 HP, optional 550 HP

Max speed 110 km/h

Power reserve > 700 km

40 ° front overhang angle

Rear overhang angle 60°

Ground clearance 0,29 - 0,49 meters (0,38 meters standard)

Slope 60%

Side slope 30%

Horizontal obstacle 1,2 meter

Vertical obstacle 0,65 meters

Ford 1,2 meters without preparation

Titus presentation video at DSEI 2013

Information