Hitler saw and her heirs (from MG.42 to MG3)

Nearly six decades ago, World War II ended. Became property stories her battles in which the warring parties used the newest for the time weapon and military equipment. As always, the war stimulated the intensive development of the means of destruction, it was during this period that military technology received rapid development. Now the absolute majority of these technical creations have taken their places in museums. Some of them are already hopelessly outdated, others have served as the basis for the creation of new, more advanced weapon systems. Looking at some modern models of weapons, one can unmistakably guess their distant ancestors from that military past. Obviously, their developers turned out to be very far-sighted, having managed to correctly identify the development trends of their offspring. But such a weapon, which has survived to the present day and in almost unchanged form continues to be used in the armies of developed countries, almost no longer exists. With very few exceptions. Such an exception is the German machine gun MG.42.

Attempts to create a machine gun, which could be used in several "guises" (manual, easel, anti-aircraft, aviation), refer to the First World War. In Germany, the basis for such work was the MG.08 / 15 light machine gun, the lightweight MG.15nA machine gun, and the experienced MG.16 experienced. Success, however, could not be achieved. A careful assessment of military experience confirmed the opinion of this weapon, as the main weapon of the infantry units, from the detachment to the battalion. The German field manual required that machine guns in all types of combat should be as close as possible to the units and support them with their fire. The Armaments Directorate was inclined to abandon the division of machine guns into light and hand-held ones and to develop a single, or universal machine gun, (Einheitsmaschinen-gewehr) comparable to manual maneuverability and easel firepower.

The problem of a single machine gun involved in other countries, but by the beginning of a new big war to create a truly successful single machine gun could only in Germany. It was 7,92-mm MG.34, which appeared as a result of the efforts of designers of a number of firms and officially adopted 1939 in January. It was used in the following variants: manual on a bipod (with a dual-drive magazine on 75 cartridges or a tape on 50 cartridges) (on a folding tripod machine and with a tape on 250 cartridges) and, moreover, as a tank and anti-aircraft. Although on the whole MG-34 proved to be a sturdy and reliable weapon, it was not without flaws. Exact fit of the parts (especially the shutter and parts of the trigger) increased sensitivity to contamination, plus parts and lubrication, which was especially evident on the Eastern Front in the winter of 1941-1942.

The main drawback was the complexity of production in wartime conditions, when intensive saturation of troops with automatic weapons was required, and the growing demand for it could no longer be met by the cumulative release of MG.34 and Czech machine guns, as well as the use of trophy samples. Simplification and acceleration of the production of a single machine gun has become paramount. Attempts to simplify MG.34 (modifications MG.34S and MG.34 / 41) did not fundamentally solve the problem. It turned out to be more rational to force the work that was already under way on a new single machine gun.

Back in 1935, long before the MG.34 was officially put into service, the infantry weapons department of the Army Armaments Directorate (Heerswaffenamt) drew attention to the complexity and high cost of its production. In 1935-1937. under the direction of Dr.-engineer A. Peter, the possibility of producing a simplified machine gun using stamping was investigated, against which, however, production workers who were accustomed to more accurate metal machining processes objected.

In February, 1937 by Rhinemetal-Borzig! (more precisely, its branch in Sommerod), "Stübgen" (Erfurt) and "Johannes Gross-spuss Metal-und Lakirvarenfabrik" (Dobeln) received an order for the development of a machine gun, simple in production, but meeting strict tactical technical requirements. The works were among the priorities and were tightly controlled by the Wehrmacht and the Luftwaffe.

Rheinmetall proposed a variant with a gas engine of automation (the system of L. Shtanga, which later created the automatic rifle FG.42), and Stübgen chose the same principle. But the Arms Directorate insisted on the recoil engine - they played their role and the success of MG.34, and the practice of the First World War, when machine guns with automatics gas engines required thorough cleaning after 3000 shots (and then it was reduced to 6 minutes of intense combat). And although this experience had become obsolete, a machine gun with a sliding automation engine went into further development. The main task for the manufacturers of machine guns was the creation of designs with a wide use of stamping, large tolerances on the dimensions of parts, reliably working in any conditions. This approach, quite new for the German arms industry, was tested on machine pistols (note that this practice was also approved in the USSR).

October 26 1937, the company "Grossfuss-Werke" presented the layout, and in April next year, the first experienced machine gun. Until then, this company did not carry out work in the field of weapons, but had a wealth of experience in the technology of stamping metal parts, riveting, spot welding, high-temperature soldering. Dr. Grunov, a specialist in mass continuous production, primarily for stamping and welding metal parts, became the head of the arms industry "Grossfuss" (irony of fate can explain the consonance of the names of the designers of the two machine guns that appeared almost simultaneously and became the well-known Soviet machine design Goryunov and the German uniform Grunova). Strictly speaking, MG.42, like most of the samples of those years, was developed collectively, and it would be wrong to attribute its scheme to one designer, even one company. Some researchers prefer to attribute the creation of the MG.42 to the Infantry Weapons Division (WaPrnf?) Of the Land Forces Armaments Administration.

In July, the 1938 machine gun "Grossfuss" was tested with several hundred shots. The idea of placing automation components and basic mechanisms in a posted position inside a box of two stamped halves and the use of the relatively simple roller locking system was something the military liked.

After testing the fourth sample in February 1939, the design of the Grossfuss bypassed even the version proposed by the Rhine-Mixell. However, only the fifth EXPERIMENT sample was declared ready for final testing and received the designation MG.39. He was tested in the infantry school in Doberitz. Finally, the 20 of March 1941 of the High Command of the Land Forces demonstrated the MG.39 / 41 machinegun, which was followed by an order in the number of 1500 units. This batch of machine guns passed military tests under combat conditions until the end of 1941 (experienced MG.34 / 41 was tested a bit later). After completion at the beginning of 1942, the machine gun was adopted under the designation MG.42.

MG.42 device

Automation operated on the basis of recoil of the trunk with a short stroke. The firing cycle began with a cocking with the help of a large bolt handle, which became a combat platoon. A machine gun in this position could be fused. The length of the barrel with breech was 565 mm. The impactor-type impact mechanism worked from a reciprocating combat spring, the shot was fired from the rear sear. When the trigger was pressed, the whisper's nose dropped, releasing the bolt from the platoon, which, moving forward, removed the cartridge from the tape and sent it to the chamber.

The most original in the machine gun was the locking assembly. For the first time, the locking system with the help of rollers raised to the sides was patented by Mauser (Germany, 1910). and Barresi (Italy, 1928 g.), and then in a developed version of E. Steke (Poland). Finally, in 1937, Mr. Grunov used this system in the locking node of an experimental machine gun (the current version that the locking node was taken from a prototype captured in 1939 in Poland is refuted by the timeline for the development of MG.42). The fighting larva of a lock on both sides had figured cuts, in each the locking roller was obsessed. When moving the bolt forward, the wedge of the bushing of the hammer, connected with the stem supported by the reciprocating spring, pushed the rollers through the notches to the sides and back. When the battle larvae rested against the breech breech, the pressure on the rollers from the wedge increased. The rollers entered the breech grooves and occupied the most advanced position in the cutouts of the combat larva, propping up the larva from behind. So did the grip of the barrel and bolt. Before locking, the rollers prevented the drummer from escaping from the sleeve, as soon as the rollers dispersed, the striker’s striker passed between them and pricked the cartridge cap. Thus, a shot was prevented when the barrel bore was not completely locked. The rollers ensured smooth operation, without delays and considerable friction, as well as a sufficient support surface area and a small length of the locking assembly.

After the shot, the barrel and bolt moved back. To give the trunk additional energy of motion served as a recoil amplifier in a muzzle, playing the role of a guide sleeve, a recoil amplifier and a flame arrester.

The regulator of the muzzle allowed to change the rollback speed of the mobile system, and thereby change the rate of fire or adapt the automation to work in different conditions. At the beginning of the rollback, the rollers kept the battle larva in engagement with the breech breech. Then on the rollers acted curly straps of the cage of the box, and they were pressed inward along the breech grooves and cutouts of the combat larva. In this case, there was some preliminary shift of the liner in the chamber, and the rollers pressed on the wedge of the bushing sleeve, and it moved back along with the stem of the bolt. Accelerating the recoil of the bolt after disengaging from the barrel was realized quite simply. The rollers simultaneously moved in the breech slots and battle larva cutouts, but since the breech mortise length was longer than the larva cutouts, the latter accelerated relative to the trunk. The barrel, after unlocking, passed some more distance, after which the return spring of the trunk returned it to the forward position. The cartridge case was held by a spring-loaded ejector mounted at the bottom of the gate larvae. The reflector was a rod mounted in the battle larva of the bolt, which was supported by a pusher. When the bolt moved back, the stem of the bolt rested against the buffer of the butt plate, the pusher advanced the reflector, it moved forward to the level of the breech cut, turned the sleeve and removed it down. The buffer of the butt plate softened the blow of the bolt in the back, and also gave it an initial impulse to move forward. A strong recoil spring returned the bolt to the front position at high speed. Although the operation of the automation was considered relatively smooth, the blow in the forward position was still strong.

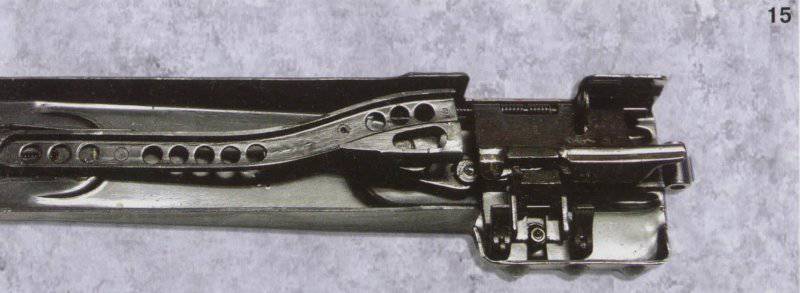

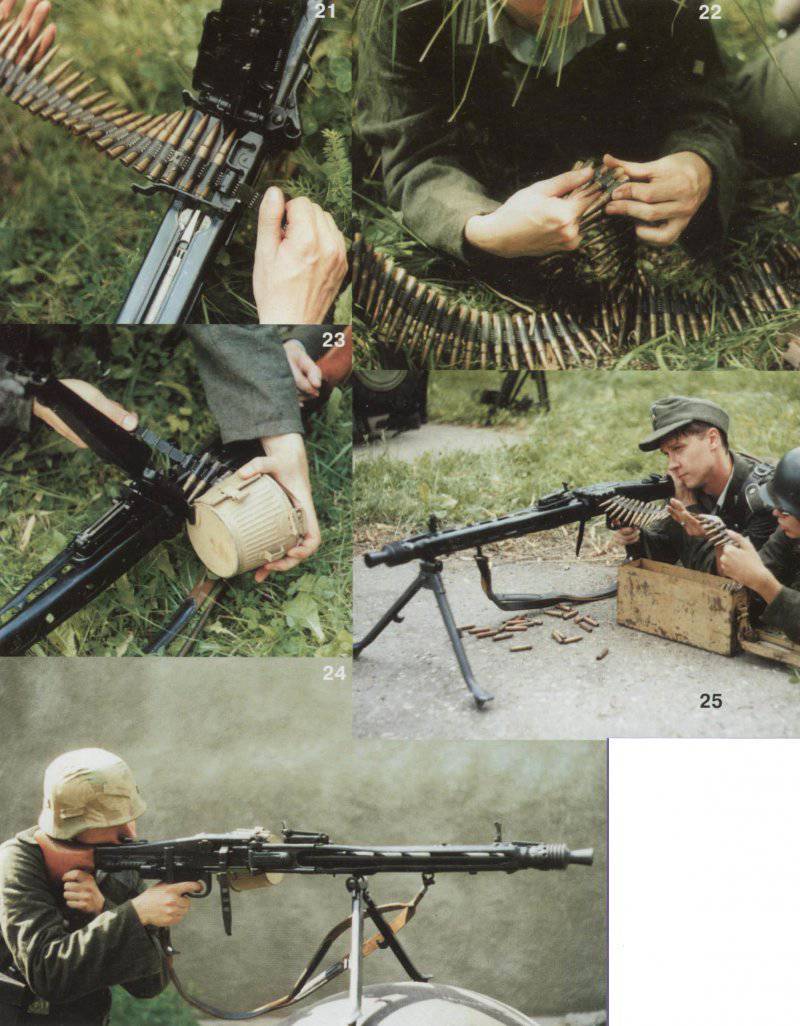

The machine gun was powered by cartridges from the standard Gurt34 / 4I metal tape with an open link, which was already used in MG.34 and had a successful design. The feed of the cartridge from the link of the tape is direct, since the configuration of the 7,92x57 “Mouser” cartridge completely allowed it. The steel links of the tape were fastened with wire spirals into pieces (pieces) of 50 cartridges each. Identical pieces were connected to each other by a cartridge, as well - by a cartridge - from one end of the ribbon was attached a shank, which facilitated the loading of the machine gun. The ribbon on the 50 cartridges was placed in a conical box that was attached to the box on the left (it was used in the version of the manual machine gun); The 250 tape was placed in a separate steel or aluminum box. The ribbon feed from left to right was provided by a roller in the back of the stem of the bolt moving in the curvilinear groove of the feed lever. This relatively long lever was mounted under the cover of the box (also known as the cover of the receiver) and could rotate around its rear part. The receiver's slider had two sets of hinged fingers mounted on each side of the central slider hinge. Each set of fingers advanced the ribbon by approximately half a step (two successive sets of fingers were previously used in the power supply mechanism of the MG.I3I aviation machine gun). When the shutter moves backward, the front of the feed lever, turning to the right, with its own roller, actuated the intermediate lever attached to the receiver slide. The inner fingers of the ram moved to the right, pushing the tape, and the outer fingers idled to the left. The next patron stood up opposite the longitudinal window of the receiver and pressed against the window with a tray under the receiver's lid, the cartridge was yielded to the barrel chamber by the crest of the battle larva of the bolt moving forward. The shutter roller moving along the feed lever turned it the other way, the lever front moved to the left, respectively, the inner fingers went to the left, making idle, and the outer fingers went to the right, moving the tape. Such a division of the load made the tape feed more uniform, eliminated its jerks, reduced the forces acting on the tape and the feed mechanism and ensured the correct supply of cartridges even at a high rate of fire. The window for ejection of spent cartridges was closed with a protective lid, which was opened when the weapon was cocked.

To load the machine gun was required: open the lid by pressing the latch in the back of it; Place the tape on the receiver tray with the open side of the links down so that the first cartridge in the tape is located to the left of the receiver's stop approximately the width of the cartridge; move the feed lever to the left position, close the lid; pull up the charging handle and return the handle forward. The machine gun was ready to fire.

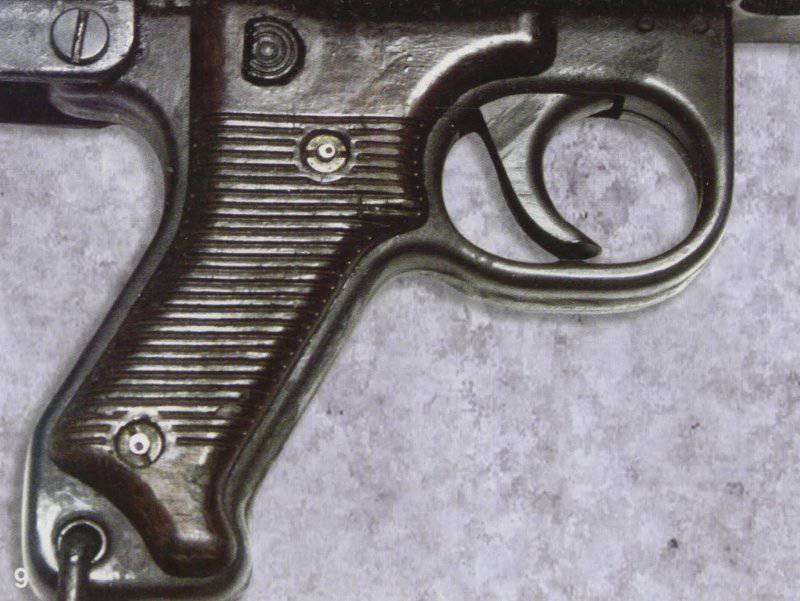

The trigger mechanism was mounted in the pistol grip frame and set only continuous fire mode.

The high rate of fire was associated with a high shutter speed, and this threatened to damage the trigger and the cocking of the bolt when they collided after the machine gunner released the trigger. To avoid this, it was necessary to ensure full contact between the working surfaces of the sear and the combat platoon when the bolt moves forward. To this end, the trigger mechanism had a “controlled” sear that rose to a certain point in accordance with the position of the moving shutter. The trigger was connected to the disconnector, the spring of which pushed him forward. The tail of the whisper passed through the disconnector, and the T-shaped rod at its end limited the turn of the disconnector forward. The front part of the disconnector had a projection. When the machine gunner pressed the trigger, the latter rotated on the axis and pushed the tail whispered up, the nose whispered lowered down, releasing the bolt action platoon that was going forward. The spring turned the disconnector, the disconnector protrusion appeared under the T-bar

tail whispered. When the machine gunner released the trigger, the whisper's tail sank down on the ledger's ledge. Therefore, the whisper nose could not rise to intercept the platoon of the bolt. The rotation of the trigger pushed the disconnector attached to it upward to the slide rolling above it. When rolling back, the bolt hit the disconnector head and turned it back. This freed the fighting platoon from under the tail whispered, the whisper tail descended, and the nose rose and stood in the path of the movement of the bolt. By the time the bolt started moving forward again, the whisper's nose was raised completely and substituted its entire front plane to the combat platoon.

A folding front sight was mounted on the front end of the barrel casing, a sector sight with graduations from 200 to 2000 m through 100m on the receiver cover. The aiming line was 430 mm. For anti-aircraft firing on the casing fixed fixed ring sight. The butt of the characteristic fishtail shape with a figured nape, like on MG.34, was raised to the axis line of the bore and allowed it to be held with the left hand when firing from a bipod.

One of the results of the growth rate of firing and cheapening of production was the reduction of barrel survivability to 3500-4000 shots, however, this characteristic was slightly increased by starting to chrome-plate the barrel. In addition, the barrel was replaced simply and for just 4-6 with. The day of this machine gun cocked, and the barrel lock, located on the right side of the barrel cover, leaned forward. The breech barrel breech was extended outward to the right with a lock and the machine gunner removed the barrel back. The new barrel was inserted through the retainer into the casing, the breech was placed through the transverse hole vertically, the retainer was closed. The method of replacing the barrel resembled that of the Italian manual machine gun "Breda" model 30, but it was more convenient. True, a mitten or rag was required and here it was necessary to take on the heated metal. To maintain ballistic qualities, the barrel had to be replaced after every 150 shots (three 50 tapes of ammunition). The spare barrel was worn in a special container behind the back of the second calculation number. Overheating of the barrel at a high rate of fire often led to the impossibility of removing the cartridge case from the chamber. The survivability of the breech was higher than the barrel itself, therefore the waste trunks were sent to the plant, where conditional breeders were selected and put on new trunks.

The barrel casing was protected by the arrow from burns and allowed to fire on the go. Foldable bipod fastened in front of or closer to the center of gravity, changing the shape of the casing required and changing the mounting bipod compared with MG.34. The hinge mount bipod allowed to put the machine gun on the ground in position and quickly raise to the fighting position. The carrying strap was attached below the case and the pistol grip. Due to relatively high tolerances and a rational locking system, the weapon was relatively insensitive to dust and dirt - MG.42 worked reliably in the African desert, and in the steppes and snows of the Eastern Front. Although the dispersion at such a high rate of fire and rapid heating of the barrel was greater than that of the MG.34, the accuracy of the MG.42 was considered sufficient at the usual range of the machine gun. Vibration was partly compensated for by the mass and balance of the weapon, and the machine’s controllability did not cause serious complaints. Caring for MG.42 was also much easier than for MG.34, the machine gun turned out to be less sensitive to the condition of the lubricant, and could shoot without it. For carrying with a machine gun cartridges and spare parts served steel and aluminum boxes. For equipment tapes used typewriter models "34" and "41". The problem for the machine gunner was to control the length of the queue - after all, the 20 bullets were released per second.

Marking machine gun included on the left side of the box near the back plate "MG42", the serial number and the code of the company s - and the manufacturer.

The basis of success MG.42. like many other samples of wartime, was a successful combination of service, production, economic and operational qualities. Precise metalworking was required only for the manufacture of the barrel, the locking assembly, the muzzle, the yoke and the sear, most of the other parts were made by stamping (however, with rather stringent requirements) and casting; riveting and spot gas welding were used for rigid fastening of parts. This greatly reduced the time and cost. The production of one MG.42 cost on average in 250 Reichsmarks - against 312 Reichsmarks for one MG.34. About the production of MG.34 was about 49 kg of raw metal and 150 man-hours, on MG.42-27,5 kg and 75 man-hours, respectively.

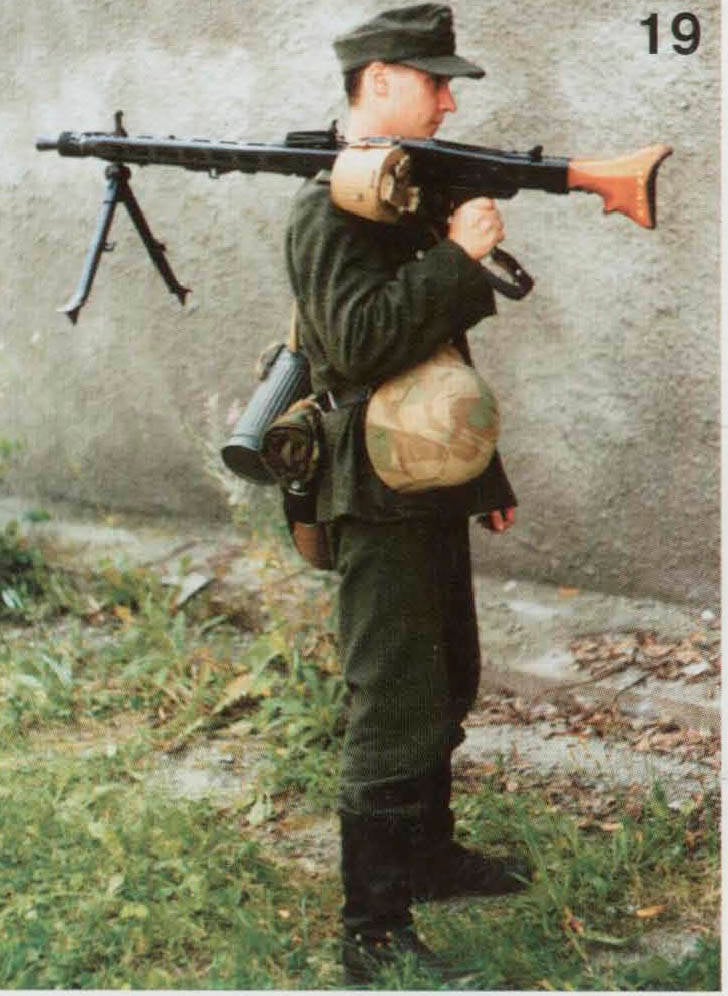

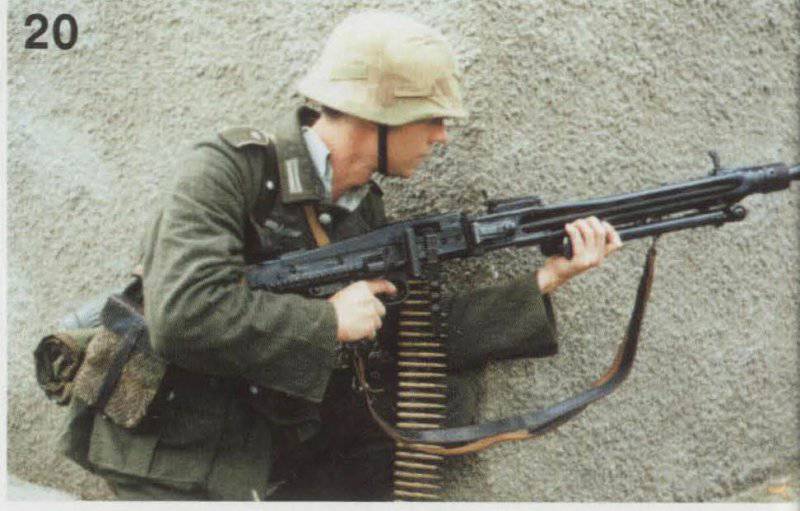

The calculation of the machine gun (manual version) in the infantry department consisted of the machine gunner and his assistant, they were attached to the shooter with a carrier of ammunition. In the German army, in order to speed up movement and reloading, it was also practiced to carry machine gun belts in combat on the shoulder, especially since they tried to take more ammunition for MG.42.

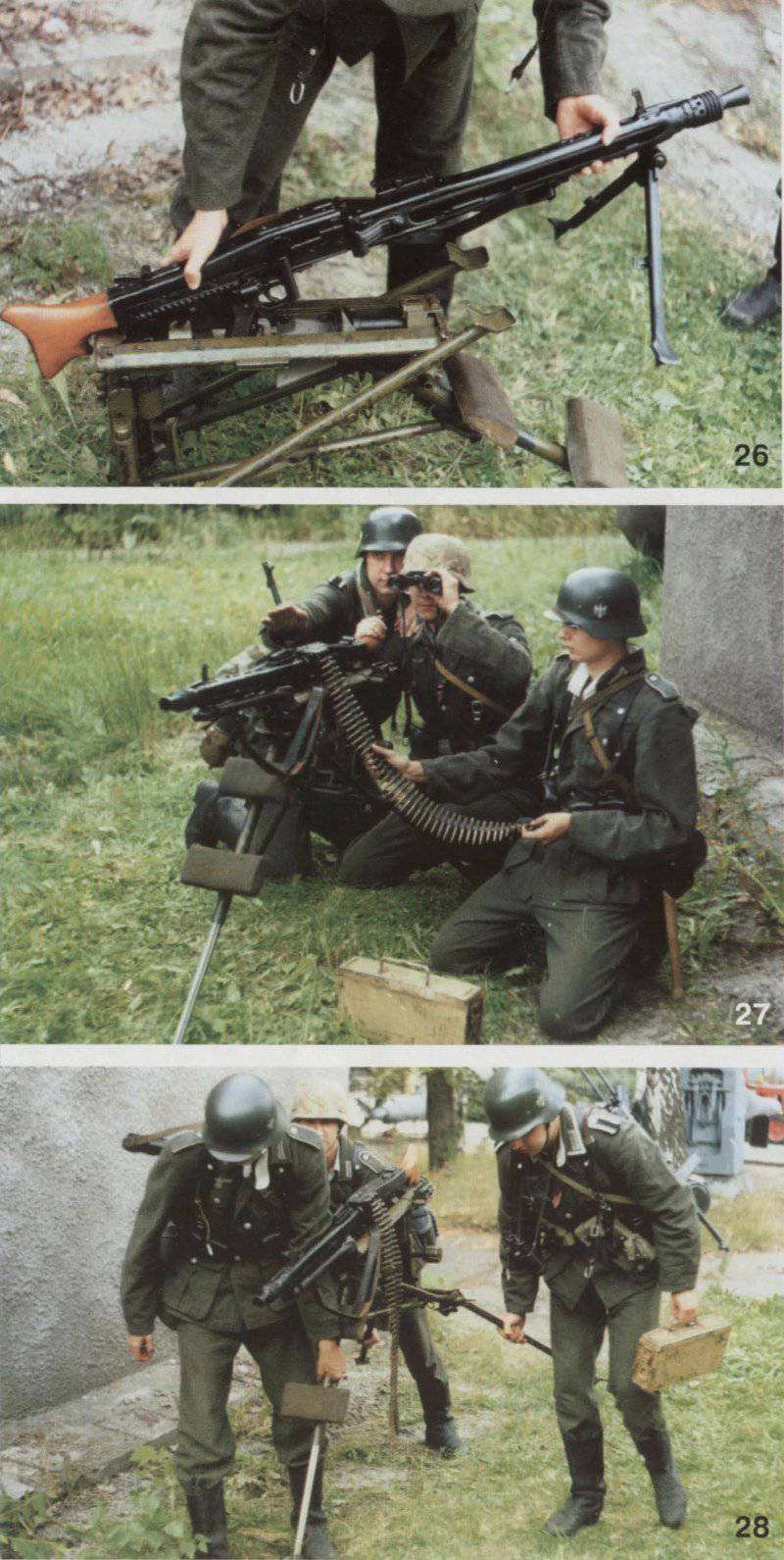

In the easel version of the shooting was carried out with a modified and lightweight tripod machine gun MG.34 (Lafette 42, and then 43). The machine consisted of a base with a pin swivel and details of the horizontal guidance mechanism; rotary and swinging parts, on which the slide was assembled with a device for quickly changing the barrel directly on the machine and a buffer device, a screw lifting mechanism and an automatic dispersion mechanism. The buffer, which included two coil springs, reduced the “jump” of the machine under the effect of recoil and increased the accuracy of shooting. The legs of the rear and telescopic front, connected with the rear telescopic stretching, were attached to the base of the machine. Legs were fixed with clamps and had openers. Shooting from the machine could be carried out with the emphasis of the butt in the shoulder. The machine gun was mounted on the skid of the machine with a bipod fixed in the front part of the

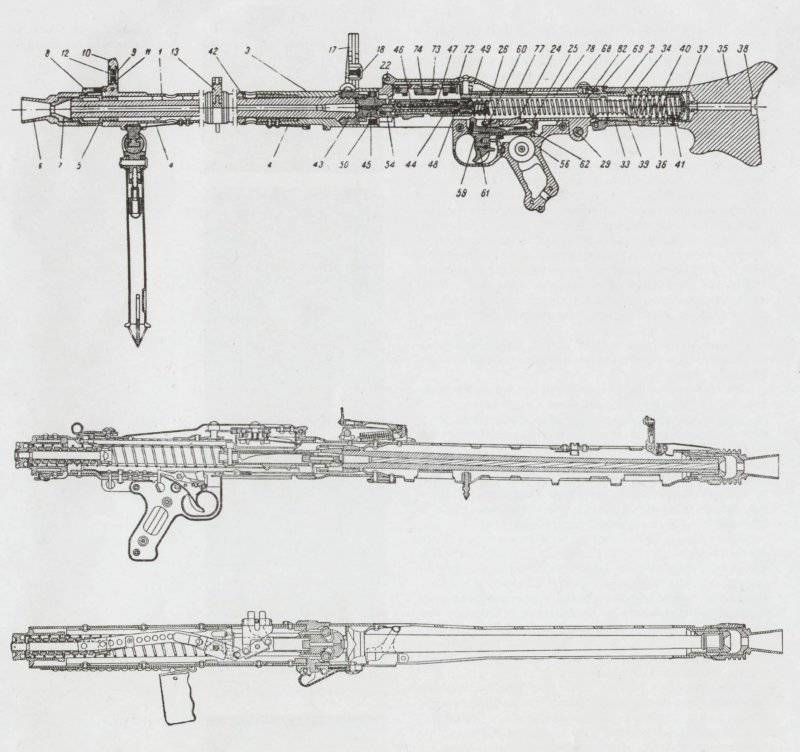

Machine gun section along the axis

1-casing, 2-box, 3-rear collar housing, 4-spring bipod, 5-guide sleeve muzzle, 6-arrester, 7-regulator, 8-latch the muzzle with the axis and the spring, 9-base front sight with the axis, 10 -hair 11-stop of the base of the front sight, 12-spring of the stopper, 13-base of the ring reamer with fonts, 17-rack of the sight, 18-engine, 22-stop axle of the cover with spring and pin, 24-release lever with axis and spring, XNUM-pin, 25-release lever with axle and spring, XNUM-pin, 26-release lever with axle and spring, XNUM-pin, 29-release lever with axis and spring, XNUM-pin, 33-release lever with axis and spring, XNUM-pin, 34-release lever with axis and spring, XNUM-pin, 35-release lever with axle and spring, XNUM-pin, 36-release lever with axle and spring, XNUM-pin, 37-release lever with axle and spring, XNUM-pin lever with axle, 38-fuse, 39-pin, 40-latch butt with axle and spring, 41-butt-plate, 42-butt, 43-butt latch with axle and spring, 44-butt cup, 45 -gun-holder, which has a set of bore, which has a set of bore, and a 46-bore butt-piece, which is 47-butt-holder, 48-bore, which has a set of bore, and a 49-bore butt-piece. bushing buffer, 50 buffer spring, 54-buffer spring with washer, 56-barrel, 59-barrel coupling, 60-gate frame, 61-combat Fragment, 62 drummer, 68 combat spring, 69 combat spring stop, 72 drummer nut, 73 rollers with locking springs, 74-automatic descent with axle and spring, 77-base of the control handle with connecting parts, 78 spindle and spring, 82-base of the control handle with connecting parts, XNUMX spindle, XNUMX-base of the control handle with connecting parts, XNUMX spindle, XNUMX-base of the control handle with connecting parts, XNUMX spindle, XNUMX-base of the control handle with connecting parts, XNUMX spindle, XNUMX-base of the control handle with connecting parts, XNUMX spindle, XNUMX-base of the control stick with connecting parts, XNUMX spindle with spring and rod, XNUMX uncoupler with axle and spring, XNUMX-translator with axle and spring, XNUMX-trigger pull, XNUMX-lid base, XNUMX-latch latch, XNUMX-receiver, XNUMX-slider, XNUMX-falling finger with an axis and springs, XNUMX-two-armed lever, XNUMX-feed lever for left-feeding, XNUMX-bolt spring.

beetle. The machine had its own trigger with a rate of fire translator, the trigger handle allowed work in mittens. The machine was intended for shooting from a prone position (with the hind legs folded and the front legs retracted), sitting and kneeling at ground targets, and when installing a removable telescopic anti-aircraft rack and at air targets. In the latter case, a circular anti-aircraft sight was attached to the casing of the machine gun. The folded machine was worn by the straps, the cushions on the front leg made it more comfortable to carry behind the back. When installed on the machine gun with a prismatic telescopic sight MGZ.34, the aiming range reached 3000 m direct fire and 3500 m indirect fire, when using MGZ.40 - 2200 m direct fire. The vibration of the machine gun at a high rate of fire made the fire from the machine less heap than the MG.34, but a special mechanism made it possible to halve those - 600 rds / min - due to the "skipping" of automatic cycles (like synchronizers aviation machine guns). During anti-aircraft fire, this mechanism was disabled.

Sometimes MG.42 adapted to other machines - on the Italian front, for example, it could be the machine gun "Breda".

The high rate of fire led to the widespread use of the MG.42 as an anti-aircraft gun. Actually, this characteristic was incorporated into the task, taking into account the requirements of the Luftwaffe, who wanted to get a light anti-aircraft weapon for the infantry (as well as an effective means of fire support for paratroopers). MG.42 was also mounted on single or twin tank anti-aircraft installations. It was used, like the MG.34, and on the Lafette 36 (Zwillingssokel 36) coaxial anti-aircraft machine-gun mount with circular fire and elevation angles from -10 to + 90 °. In this case, an upper machine with a seat for a machine gunner, a curved shield and a frame was attached to the pedestal support. The frame housed two machine guns without butts and cartridge boxes with ribbons. The machine guns had a single descent, the annular anti-aircraft sight was mounted on the bracket. The machine gunner could fire on air targets from a machine gun in the manual version from the shoulder of his assistant, who at the same time held the machine gun by the bipod - this technique, after the war, was practiced in the Bundeswehr.

In the design of MG.42, the influence of the experience of the Eastern Front was clearly visible - here both increased gaps between the parts, and a large charging handle, and a lid of the box cover, which allowed working in warm gloves. Also for the conditions of the Eastern Front to the MG.34 and MG.42 a “winter” descent was developed, which allowed firing in mittens. He was a stamped part, hinged on a pistol grip using an unshank, a pair of hinged levers with leaf springs, easily made by the arms workshops; there were also a number of devices for mounting a machine gun on a tree stump, bipod supports for snow shooting, sleigh installations, etc. For the "indirect" shooting from the entrenchment of the trench on an inclined arm was attached a separate butt, trigger, and all this was complemented by a simple periscope sight.

At the end of the war on MG.42, we tested the installation of a muzzle attachment (with a deflection angle of 30 °) for armored vehicles and fortifications. However, there were more effective and efficient attachments for weapons under the intermediate cartridge ("Kurtzpatron") with a relatively short bullet and less pressure of powder gases.

Several large enterprises and a number of small contractors were involved in the production of MG.42. The manufacturability of the new model contributed to a sharp increase in the production of machine guns: in I943, it amounted to 224,8% of the 1942 release. The assembly was carried out at five enterprises: Grossfuss in Dobeln, in the Berlin branch of Mauser-Werke AG, and in Berlin, Maget on "Gustlov-Ver-ke" in Suhl and on "Waffenfabrik Steyr" in the Austrian city of Steyr.

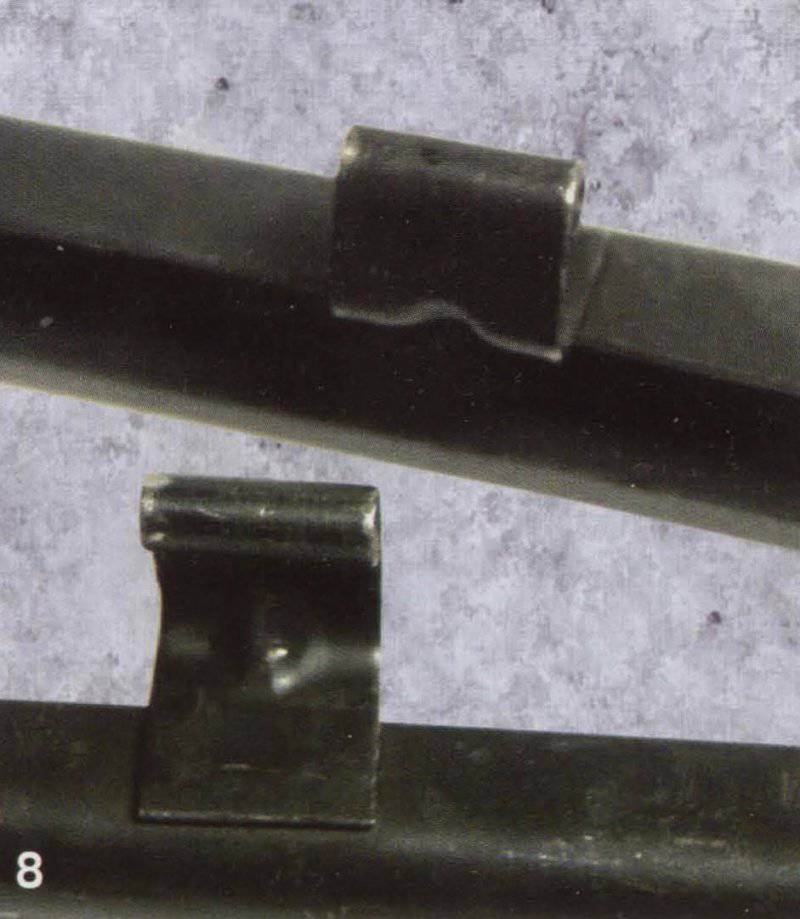

It is alleged that for the first time the serial MG.42 were used against British troops in Tunisia in the autumn of 1942, and by the end of the year mass production of this machine gun had been launched, and it soon appeared on the Eastern Front. For a high rate for infantry weapons, the rate of fire (up to 1200-1300 rds / min) and the characteristic sound that was published was sometimes called Hitler’s saw. The Anglo-American allies called MG.42 "Spandau", however, they called many German machine guns from the time of the First World War on behalf of the old German state arsenal plant. As of March 1945, the German troops had 153 712 units MG.42. It was produced separately by the orders of the Wehrmacht, Luftwaffe, Kriegsmarine and the SS troops. For the Wehrmacht, the 414 964 MG.42 machine guns were made (approximately 17% more than MG.34, and this is half the time). At the same time, the Luftwaffe was supplied 4014, Kriegsmarine - 2402, the SS forces - 225 units. The machine gun was produced before 1945 - just before the end of the war, MG.42 launched more than 400 000. Changes in the design made in the production process were insignificant. So, the first batch of machine guns had a wooden butt, which was soon replaced by a plastic one. By the end of the war, the loading handle was made folding. The fastening of the folded bipod to simplify production was performed not on the pin of the casing, but on its notch. The kickback amplifier with a flame arrester became different.

MG.42 quickly took the place of the main and in armament and production on the orders of all the armed forces. While in 1942, the MG.42 accounted for about 20% of machine guns commissioned by the army, in 1943, about 70%, and in 1944, more than 75%. Adopted at the beginning of 1944, the "infantry weapons program" was intended to bring the monthly output to 30 000. Even with the loss of production capacity due to the offensive of the Red Army and allies and the bombing, the level of production of artillery and small arms remained high, and in particular for light infantry weapons plans were fulfilled. This was facilitated by existing reserves and a decrease in metal consumption of products, but steel production in the second half of 1944g. fell by 40%, and this take-off of production was the last.

MG.42 is considered the best machine gun of the Second World War and in fact marked the beginning of a whole generation of single machine guns created in the postwar years. A significant component of the success of MG.42 was not only a rational design, but also a rational tactic of their application. Machine guns in the German army were considered as one of the most important weapons of the units in battle. If at the beginning of the war a machine gun company of three platoons each had two machine guns entered the infantry battalion, then in 1943 m. In accordance with the principle of decentralization, a branch of heavy weapons with machine guns was introduced into the infantry companies. In the German army, as in the Red Army, they also sought to reduce the number of personnel while increasing the power of automatic fire. Already in 1944, the German infantry regiment had 118 light and 24 heavy machine guns, most often MG.42. If in 1941-1942. Wehrmacht infantry division in defense could launch 1 25 bullets per minute on 073 km front, then 1944 42 832 at the end of XNUMX g.

MG.42 was also transmitted to various nationalist formations in the Wehrmacht and the SS: Norwegian, Danish, Dutch, Baltic, and Croatian. Retreating from the occupied territories, the Germans left their machine guns to conduct a "guerrilla" war against the USSR. The NKVD bodies only during the operation to evict the Crimean Tatars in May 1944, among other weapons, seized 622 various machine guns (enough for an infantry division).

Opponents of Germany often used captured MG.42, and this was not only partisans or sabotage groups, but also linear units at the front. The soldiers of the Red Army, even with enough of their own machine guns, willingly used the German ones, although they were supposed to be handed over to trophy teams. The commanders, in the presence of ammunition, replenished the arsenals of the divisions with the German MG.34 or MG. 42. In the USA, they even tried to make a copy of the latter, having failed with a copy of MG.34, for their own .30-06 cartridge - already in June 1943 the documentation was ready, in October, Seginav Gear, a division of General Motors I ", made the first sample of T24. I This project, costing 25 400 dollars, ended in failure. Finland also intended to release I MG.42, but the plans were not implemented. But at the end of the war, the construction of a number of MG.42 units was used in different countries in the development of their own single pu-lemets - features of its power supply system, for example, I can be found in the single machine guns of the Belgian I MAG family or the American M60.

Performance characteristics MG.42

Patron: 7,92-mm "Mauser" (7,92x57)

Body weight of the machine gun with a bipod: 11,60 kg

Full body length machine gun: 1219 mm

Body length machine gun without butt: 1080 mm

Barrel length: 533 mm

The length of the threaded part of the barrel: 476 mm

Grooves: 4 right

Barrel weight with breech: 1,80 kg

Initial speed of the bullet: 750 m / s

Effective range: 800 m with bipod,

2200 m from the machine

Power system: 50 tape or 250 cartridges

Tape weight with 250 cartridges: kg 6,90

Weight of empty steel cartridge box: 2,4 kg

Rate of Shooting: 1200 fps / min

Mass of the Lafette 42 machine: kg 20,5

A single machine gun MG.42v (MG.45)

Comparative performance characteristics of some machine guns during World War II

Features | Light machine guns | Machine guns | ||||

Machine gun | MG.42 | "Bran" Mk1 | DP-27 | MG.42 | М1919А4 | SG-43 |

Country | Germany | England | the USSR | Germany | USA | the USSR |

Cartridge | 7,92x57 | 7,7x56 (.303) | 7,62x53R | 7,92x57 | 7,62x63 | 7,62x53R |

Mass of weapon with cartridges, kg | 12,6 | 11,5 | 10,6 | 32,1 | 21,55 | 40,4 |

Machine body length, mm | 1219 | 1150 | 1272 | 1219 | 1041 | 1150 |

Initial speed of a bullet, m / s | 750 | 745 | 840 | 750 | 853 | 865 |

Rate of fire, rds / min | 1200 | 660 | 600 | 1200 | 500 | 500-700 |

Capacity of shop (tape), cartridges | 50 | 30 | 47 | 250 | 250 | 250 |

In 1944, a widespread rearmament program, known as the "infantry weapons program", began in Germany. The specialists understood the extreme limitedness of the remaining resources, and the demand for cheap production and the saving of materials became decisive for the new single machine gun.

With the use of parts and components MG.42 a machine gun with a fixed barrel and a semi-free gate was created. The barrel with the breech was fixed in a box (receiver). The gate consisted of a combat larva, two rollers bred to the sides, a stem and a drummer moving inside the stem and fitted with a front hub and an inertia weight. The larva, moving back under the effect of recoil, used its rear bevels to spread the rollers, thus slowing down its withdrawal. The rollers retreated back with the larva, ran around the walls of the breech, were reduced to it by bevels and pressed on the inclined surface of the bushing of the drummer, forcing it and the stem to retreat rapidly, relative to the larva. Such a redistribution of recoil energy, together with the inertia of the stem and the initial dilution of the rollers, ensured a slowdown in unlocking the bore. When the bolt came back, the stalk brought the larva to the breech-cut, then the inertial weight advanced the drummer, who smashed the cartridge primer. Simultaneously, the firing pin bushing spreads the rollers to the sides, braking the bolt in the breech. In a slightly different way, the same principle of roller deceleration was implemented in the experimental machine SG.45, but the successful implementation of a semi-free shutter required the creation of a new generation of weapons.

After the war, roller deceleration was embodied in the CETME, Heckler and Koch systems, the MG710 Swiss machine gun and the Spanish Amelie (by the way, both with the other system borrowed the MG.42 design features). The tape was used regular.

The first prototype was released in June 1944, the second and third - in September and November, settled on the fourth version of the experienced machine gun. This machine gun with a rate of fire from 1000 to 1350 shots / min (and even before 1800 shots / min) was designated MG 42v, but is also referred to as MG.45. In its construction was used mainly low-grade steel.

It was possible to reduce the mass of the machine gun to 6,5 kg, that is, according to this characteristic, it was closer to the light machine gun completely serviced by one soldier. Externally, the MG.45 (MG.42v) was distinguished primarily by the shortened barrel casing and, accordingly, the backward attachment of the bipod. The distribution of orders for parts was assumed for small subcontractors; the main manufacturers were to produce the most important parts and carry out the assembly. With the achieved standardization and thoroughness of constructive study, this would be quite realizable if it were not for the rapid advance of the Red Army and the Allied bombardments. They didn’t have time to put the machine gun into mass production; only 16 could produce 10 units planned for wider tests.

The machine gun with a semi-free shutter with a mechanical deceleration (due to the inertia of the flywheel spun when rolling in) and a ribbon receiver from MG.42 was developed by Barnitske, the chief designer of Gustlov Werke, but also remained experienced. Given the rapid approach of the collapse of Nazi Germany and the apparent illusiveness of production programs, it can be assumed that these machine guns were among those projects that the leaders of German industry hoped to offer to the Western powers after the end of the war.

Performance characteristics MG.45

Patron: 7,92-mm "Mauser" (7,92x57)

Machine gun body weight: 6,5 kg

Full length "body" machine gun: 1219 mm

Barrel length: 533 mm

Effective range:

800 m from bipod, 2200 m from the machine

Supply system:

50 tape or 250 cartridges

Firing Rate: 1000-1350 rds / min

To be continued

Information