155-mm self-propelled howitzer XM1203 NLOS-C (Part 1)

The abbreviation NLOS-C comes from the phrase Non-Line-of-Sight - Cannon - "howitzer for firing from closed positions (out of line of sight)." It is designed to provide fire support at the battalion level from closed firing positions with all types of conventional and prospective ammunition, including 155-mm high-precision guided missiles. The development of howitzers NLOS-C ХМ1203 are conducted by BAE Systems Land and Armament, General Dynamics, and others. It is the first manned ground vehicle platform developed under the Future Combat System (FCS) program. For several years, FCS has been the largest, most complex and costly new development program for the armed forces in stories the American army, which was spent according to some estimates already around 300 billion USD. It included not only the creation of innovative platforms weapons, but also the development of digital data transmission equipment, connecting with each other in a single information network both weapons platforms and any user from soldier to general.

The NLOS-C self-propelled artillery installation (SAU) project is by far the most advanced part of the FCS program concerning the development of ground crew vehicles. Despite the closing of the 2009 program in the summer, special attention is paid to this project because, according to the developers, this artillery system can have independent commercial success if you carry out certain work to adapt it to market requirements.

In accordance with the requirements of the program, it was assumed that the main advantage of this system over its competitors would be its high strategic and operational mobility. Strategic mobility was to be provided with the ability to transport the howitzers by the C-130 Hercules American military transport plane to anywhere in the world, followed by launch into battle on the move. To do this, it was planned to make it as easy as possible, with a mass less than 20 t. Operational mobility was planned to be ensured by integrating into an information network that allows you to exchange data with other units in real time. In accordance with this concept, it is envisaged to unite the heterogeneous forces and means dispersed in a wide combat space - personnel; organs and points of command of combat support; Arms and military equipment of land, air and sea bases - in formations, informationally connected by a complex network architecture - global and local information networks. Data exchange between consumers will be carried out in real time not only “vertically”, but also “horizontally”. In this way, all participants will be able to obtain comprehensive information about the state of the battlefield. It is expected that the operational capabilities and combat effectiveness of military formations with a network architecture will increase many times over the existing ones.

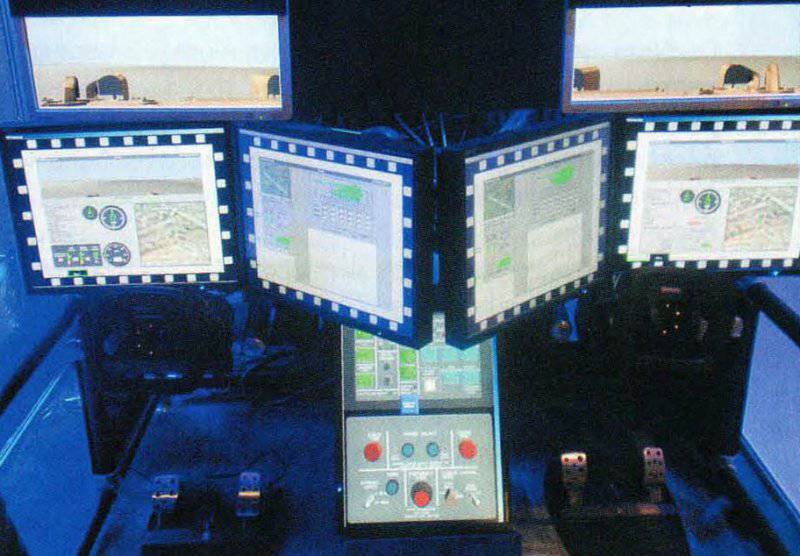

The possibility of inclusion in the network structure by introducing advanced information technologies into the troops was planned during the creation of all components of the “Combat System of the Future”. The howitzer will be able to independently and centrally receive information and target designation from various ground sensors and UAVs. In particular, the coordination of the fire means of the FCS brigade was supposed to be carried out centrally from a command and staff vehicle capable of retargeting self-propelled guns located in different places, Tanks and tactical missile launchers for general purposes. The gun commander almost instantly receives information about the newly discovered targets and orders from a superior, which provides a sharp reduction in the timing of fire missions. After evaluating the combat situation, the NLOS-C commander will be able to open fire no more than 30 seconds after receiving the target designation and “deliver the projectile to the target in less than one minute with high accuracy”, with a covered area of about 4 thousand km2.

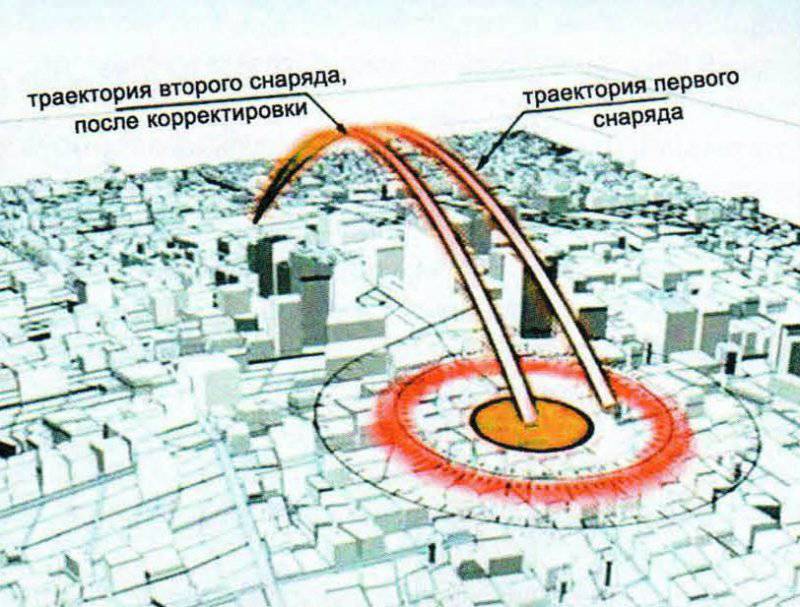

Targeting, location of the gun and the routes of advancement should be carried out in the same geographical coordinates by GPS. The howitzer will be able to work both “by squares” and by individual targets. The use of GPS-guided precision guided projectiles, such as the Excalibur 155-mm projectile, for example, will allow the howitzer to not only ensure extremely high firing accuracy even at very large distances, but also to transfer fire from one target to another without introducing the GPS coordinates of the new target into the projectile. In addition, the NLOS-C self-propelled gun is equipped with a projectile flight tracking system, which, in combination with an automatic loader and a fully automated firing system, significantly improves the accuracy of firing conventional ammunition. This is especially important when conducting combat operations in urban environments, as it will help to reduce collateral damage and will not give the enemy the opportunity to escape from the shelling. Also, network-centric targeting will improve the speed of firing and reduce the loss of their troops from their own artillery, which often happens in a rapidly changing tactical environment. It is assumed that the combat effectiveness of one howitzer HM1203 will be comparable to the 2-3 howitzer М109А6 Paladin.

Upgraded 155-mm howitzer M109A6 Paladin (PIM)

Today in the USA, due to the expiration of the life of the 203-mm howitzer М110 and 175-mm gun М107, the only self-propelled unit in operation is the 155-mm howitzer М109. Since its adoption in service in 1961, the howitzer has been repeatedly improved. One of the latest modifications was the M109А6 Paladin with the МNNUMX barrel with the 284 length and the range of 39 km firing with conventional projectiles, and the 24 km with active-rocket projectiles. The weight of the ACS М30А109 without fuel, equipment and crew is 6 t, and in the combat position - 28,8 t. The firing rate of 32 in / min. The crew of five people. From the moment production began in 4 to the end of 1991, 1999 systems were supplied to the US Army. In the artillery batteries of each M950A109, one M6 ammunition conveyor was attached, carrying 992 projectile, 93 charges and 99 fuses. Under various designations, reflecting the program of modifications to which this ACS was subjected, a howitzer was adopted by many countries.

In many armies of the world, the M109А6 Paladin howitzers have already been replaced by more advanced ones, with the exception of the US Army itself, in which this ACS is the main one. Recently, it has undergone further refinement. With 2007, BAE Systems is implementing a howitzer modernization program called the M109A6 Paladin Integrated Management (M109A6 PIM). It will be a semi-automatic howitzer equipped with an air conditioner and an electronic artillery fire control system. The main armament of the M109А6 PIM remains the same, but the turret structure has been changed and improved, and the outdated chassis components have been replaced with new ones from the Bradley infantry fighting vehicle. Also, some technologies were taken from the NLOS-C developed howitzer, including a system of automatic loading of the projectile and modern artillery system electric drives, instead of the old hydraulic one. According to the estimates of the US Army Command, the upgrade will significantly improve the tactical and technical characteristics of the M109 ACS and extend their service life up to 2050.

155-mm howitzer XM-2001 Crusader

Design engineers know that, despite repeated upgrades, sooner or later there will come a time when it is no longer possible to accommodate the improvements required by the time in the old concept. In this connection, in the USA, attempts were also made and are being made to create a new, promising 155-mm self-propelled howitzer to replace the M109-X6 Paladin. These attempts led to the creation by United Defense Industries of prototypes — the Crusader system, consisting of the XM-2001 howitzer and the XM-2002 ammunition supply vehicle. The first firing tests of the Crusader howitzer began in February 2000 at the Hume range in Arizona. In November 2000, the rate of 10,4 shots per minute was reached. In the process of development, it was possible to reduce the mass of the howitzer from 60 to 38 — 41. This made it possible to transport two Crusaders on one C-5 or C-17 aircraft. The maximum range of XMUMNEXX297 2 calibers with a barrel length could reach the usual 56 km shells, and with a bottom gas generator - up to 40 km. Ammunition howitzer 50 shells. The crew of three people. The howitzer is distinguished by a large number of innovations, among which are: an automatic loader, which ensures the maximum rate of fire of 48 in / min; the use of so-called "modular" artillery charges; laser ignition system of powder charge; interlayer cooling of the barrel, etc.

Using his technical capabilities, Crusader could realize a “multiple simultaneous strike” shooting scheme, i.e., deliver eight shells to the same target at once. To this end, the digital fire control system calculates the firing parameters separately for each of the eight projectiles and automatically changes, respectively, the calculated values, the tool pointing angles so that the first and all subsequent projectiles fly to the target simultaneously. The howitzer is also equipped with an integrated active protection system. Receiving and sending information occurs in real time through an advanced battle management system. New LV100-5 gas turbine engine with 1500 horsepower allows the machine to reach speeds of 67 km / h on asphalt and 48 km / h over rough terrain. It is believed that in general the Crusader is twice as efficient as the howitzer compared to the M109A6 Paladin. The production of the first versions was to begin in 2006. The commissioning of the howitzer was planned with 2008g. It was supposed to put in the army eventually 800 new machines. However, in 2002, this program was discontinued because Crusader was considered to be too heavy and too expensive a system, and did not meet the required mobility and firing accuracy specifications. But the technologies developed for the Crusader were used to create the lighter and more mobile 155-mm howitzers NLOS-C.

155-MM GAUB NLOS-C

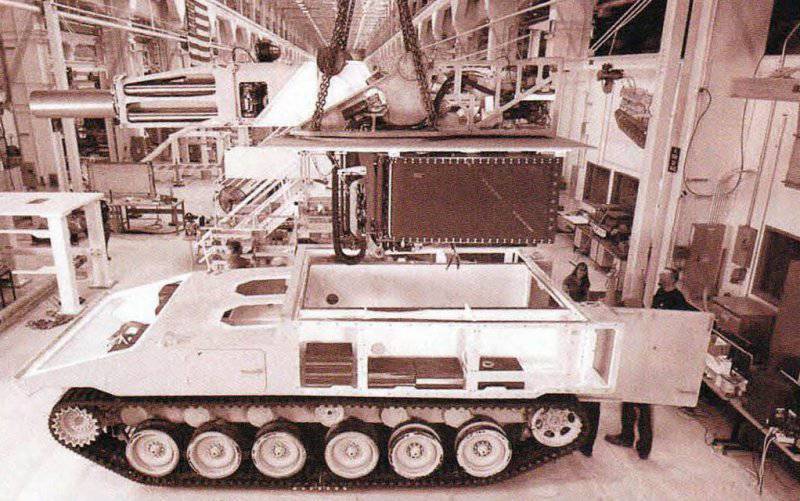

The beginning of the development of the NLOS-C howitzer can be attributed to May 2002, when the Ministry of Defense decided to accelerate the development of the Fighting System of the Future. After conducting preliminary research, in 2003, the corporation United Defense Industries, which developed the Crusader howitzer, received a new contract for the development of ground crew vehicles for the FCS program. In accordance with the contract, the corporation was responsible for the development of five (out of eight) crew vehicles developed under the FCS program, including the NLOS-C howitzer. For the first time, the demonstration model of the NLOS-C system - the “Technology Concept Demonstrator” (CTD) left the production facilities in 2003 six months after the closure of the Crusader project in 2002. From Crusader, the NLOS-C CTD demonstrator inherited an automatic loader, modular artillery charge-free MACS (Modular Artillery Charge System) with a fully burning body, a laser ignition system for modular charges (which will be described in the following publications), and some electronic components. Although at first glance it may seem that the demonstrator looks like a ready-made platform for the army of the future, in fact it was not even the prototype of NLOS-C. This is just a conglomerate of technical solutions, designed to prove the principles underlying the creation of a future howitzer NLOS-C. Most of the technologies developed for the demonstrator were later transferred to NLOS-C.

Initially, the demonstrator was equipped with a tool similar to the towed 155-mm howitzer М777, developed by the British company BAE Systems. The gun had a barrel length 39 calibers and dual-chamber muzzle brake. The main feature of the howitzer is a small weight - 4218 kg (for comparison, the weight 152mm of the domestic towed howitzer 2А65 "Msta-B" is 6,8 t.). This allows you to use a CH-47 helicopter or a MV-22 Osprey vertical take-off and landing aircraft to quickly move and deploy the battery. The maximum range of howitzer M777 conventional shells 45 kg weighs 24,7 km. The firing range of active-jet projectiles 30 km. When firing a M982 Excalibur guided missile with a bottom gas generator, the range can reach 40 km. In this case, as shown by the Excalibur projectile tests, when firing a 777 14 series howitzer at 24 km, the circular probable deviation was 5. The M777 howitzer is considered revolutionary because of its low weight and high accuracy. The design of the gun used alloys of titanium and aluminum, which allowed to reduce its weight to 4,2 t, this caused the use of the barrel group howitzers for NLOS-C.

In August, 2003, the NLOS-C CTD demonstrator, launched its first projectile. Two months later in October, 2003 g. He completed the test for the possibility of shooting at a rate of four, five and six rounds per minute, and then completed several other tests with a slower rate of shooting. By the end of October, 2003 from the NLOS-C CTD had already fired 140 shells. In subsequent years, in order to ensure the deployment of the NLOS-C together with a quarter of the main ammunition on board the C-130 transport aircraft, measures were taken to reduce the weight and size of the howitzer. According to the developers, the struggle was literally for every kilogram. One of these measures was to reduce the length of the trunk. In May 2004, the army and field artillery developers made key decisions on the NLOS-C barrel. Based on a thorough analysis, it was decided that the howitzer should have an 155-mm barrel with a length of 38 gauges and provide shooting with four MACS modular charges. In July, 2005, the company BAE Systems, which this year acquired the corporation United Defense, continued further testing with the new XM38 barrel, which was reduced to 324. However, the firing range of the M549 active-rocket projectile was reduced by 4 km - from 30 to 26 km. With the same barrel length 39 caliber from August 2003 to July 2005 1193 shots were made.

In September, 2006 g. BAE Systems announced the start of firing tests of the new version of the future NLOS-C howitzer - Firing Platform. The fire platform, unlike the demonstrator, outwardly began to look more like a self-propelled artillery installation, had a slightly modified swinging part and barrel XM324 38 length caliber

with a new muzzle brake. By early October, 2007 shots were fired from the NLOS-C firing platform. The maximum range of the M799 projectiles using four MACS modular charges (795 Zone) was 4 km. Shooting the “fire platform” was the first step towards the development of prototypes of NLOS-C P (Prototype). 26,4 June 11 in Washington, DC, on Capitol Hill in the National Alley in front of the Congress building, an exhibition was organized of the most advanced components of the Fighting System of the Future, among which was presented the first prototype NLOS-C Р2008 howitzer (see the photo on the article's splash screen). A similar exhibition was held near the Pentagon building 1 June 13. In September 2008, at the Yuma test site, the US Army began firing tests of the first NLOS-C Р2008 prototype. In total, in accordance with the test program, the P1 prototype at the end of 1 and at the beginning of 2008 was supposed to execute 2009 shots. According to the results of fire tests SAU NLOS-C was to be certified for safety.

In February, 2009, the company BAE Systems successfully conducted tests for the possibility of firing from the NLOS-C P1 howitzer with an Excalibur projectile, firing a projectile model corresponding to the mass-output characteristics of the original.

Until December 2008, the number of fully functional prototypes in the basic configuration was brought to five units, and in the first quarter of 2009, three more advanced samples arrived at the Hume test site. In total, the test program involved 18 SAU NLOS-C.

A comprehensive check of the future howitzers in the field and the development of combat tactics will make the necessary changes to their design prior to the production of serial samples, the first batch of which should go to the troops in 2014 — 2015. Carrier. The howitzer has a common for chassis machines developed under the FCS program, a unified tracked chassis (Common Chassis), made of metal alloys and composite materials. This chassis will have 75 — 80% in common with other crew vehicles. The car is the lightest in its class and will be able to develop maximum speed on the 90 — 100 highway km / h with a power reserve of 750 km and 56 km / h in rough terrain. One of the main features of the chassis is a hybrid power plant (GSU). Its principle of operation is based on the fact that the diesel engine through the generator recharges the batteries, which run the electric motors of the tracks, as well as all other systems, including the drive of the instrument, the automatic charging system, computers, communications and data exchange.

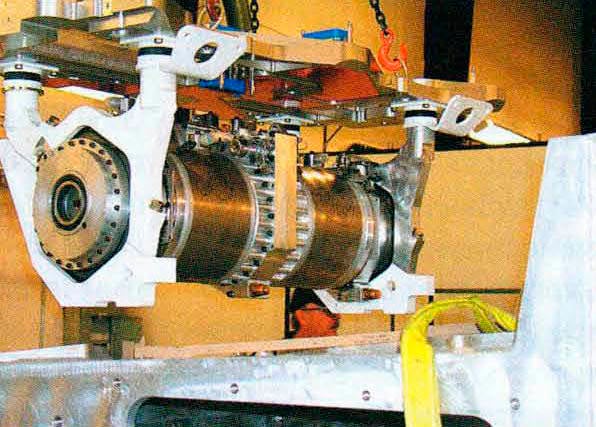

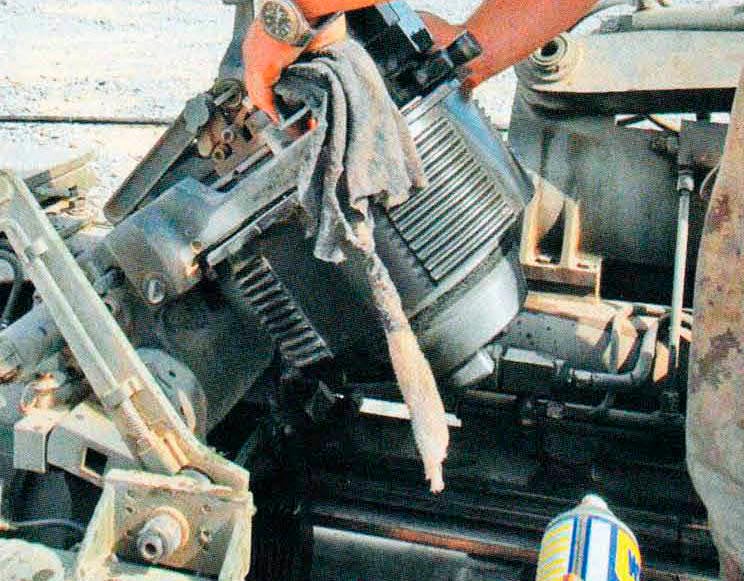

The use of GPS in the combat systems of the future is due to several reasons. One of the most important reasons is that modern self-propelled guns have electric actuators for pointing weapons and much more electronics, which leads to an increase in electricity consumption. In the future, power consumption in combat vehicles will only increase, and the power of conventional generators and batteries will not be enough. These needs can satisfy hybrid power plants with more powerful generators and energy accumulators that can provide not only the work of machinery and electronics, but also the movement of the machine at high speeds. Another important reason is that the GSU allows you to maximize power and save fuel. Compared with conventional vehicles with an internal combustion engine, fuel savings can be 10 — 30%, and compared with military tracked vehicles even more. The estimated fuel consumption of an American Abrame tank with a gas turbine engine is 350 liters per 100 km, a German tank Leopard 2 with a diesel engine 240 liters per 100 km, and a domestic T-80 tank with a gas turbine engine more than 430 liters per 100 km. Given that today military vehicles consume a huge amount of fuel, the transition to hybrid power plants will lead to less fuel dependence, cost savings and, ultimately, to a reduction in oil purchases. In addition, the use of GSU makes the howitzer less visible in the thermal range and low noise. In the event that stealth is required, it can drive on some 20 min batteries, not including diesel, which is especially important when driving in urban environments. The NLOS-C hybrid propulsion system consists of a five-cylinder diesel engine rated at 444 kW, coupled with an 300 kW generator that charges lithium batteries. Accumulators provide energy for gun drives, automatic loaders, electronics and tracked drive engines from QinetiQ. GSU can develop power up to 560 HP at peak load and almost twice the acceleration than traditional systems, while consuming only half the fuel. In 2004, to evaluate the ride quality of a hybrid power plant, the NLOS-C demonstrator drove more than 800 km on asphalt roads and on terrain with a variety of terrain. On some batteries, the demonstrator was able to drive 4 km at a speed of about 30 km / h.

Howitzer has a specific layout. In front of the machine is a compartment with batteries. Below is the power drive. This arrangement of the drive and batteries allows for additional protection of the crew in case of penetration of frontal armor.

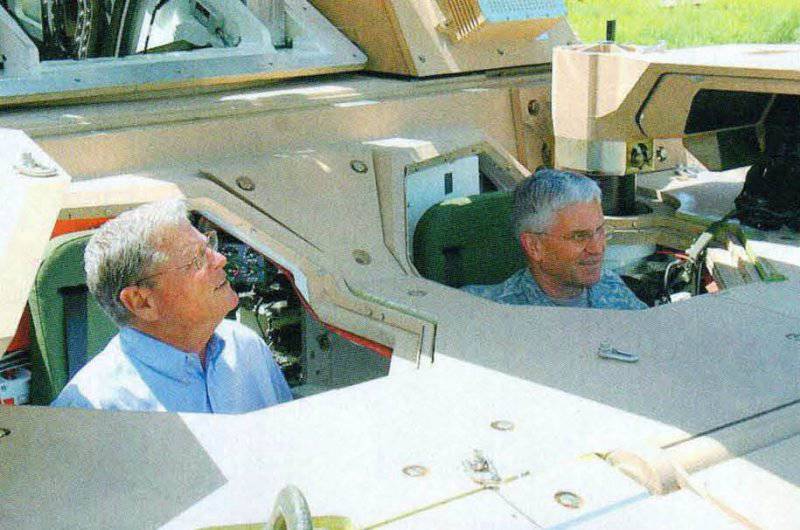

Behind the compartment with batteries is the crew compartment, which is closed at the top with two massive hatches. The hatches have a periscopic surveillance system, giving each crew member a good panoramic view. Inside the compartment in front of the driver and the commander there are two touch screens, which display all the incoming information about the combat situation and the state of the howitzer systems. The howitzer will be equipped with a complete self-test kit. Computers will simplify the work of the crew as much as possible, report on specific faults in the system and possible solutions.

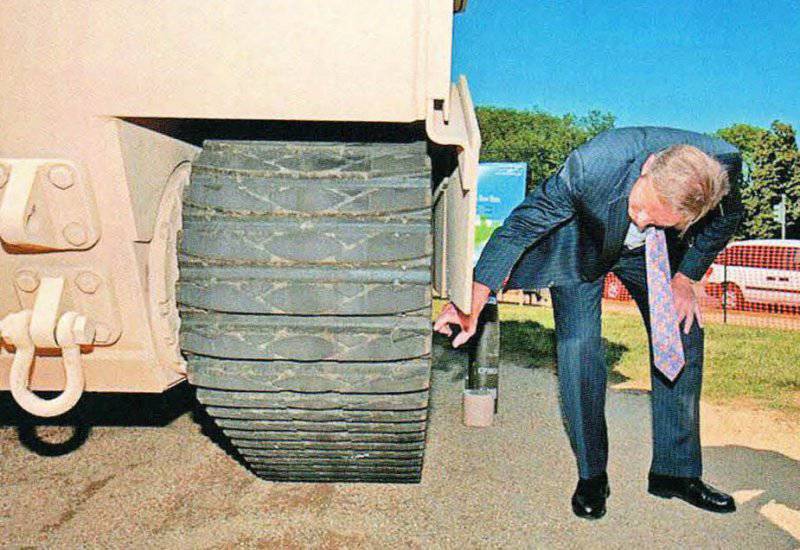

In an effort to minimize the weight of the machine, the developers have achieved further weight loss due to rubber tracks, which are twice as lighter than steel ones, move around the suspension components smoothly and with minimal vibration and noise. Solid rubber reinforced tracks provide a smoother ride, can significantly reduce noise and dust, increase survivability and, along with reduced rolling resistance, improve machine maneuverability. In the future, rubber tracks, due to their high performance in their manufacture and low operating costs, may be an alternative to metal tracks traditionally used for tracked combat vehicles. Other improvements include the installation of an active protection system instead of heavy armor. The active protection system, the sensors of which are located around the perimeter, detects a shot from a grenade launcher, from a tank gun and other different shots. It captures the target, leads it and then can either turn on the interference, if it is a guided missile, or launch a projectile or missile that will destroy the target before it reaches the machine. In addition, the active protection system will warn nearby machines, allowing you to strike a joint blow at the enemy. It is also intended to equip the howitzer with melee weapons, such as a modified M2 machine gun of the 50 caliber, to combat stationary or moving targets at a distance of up to 1500 m. It is also equipped with a system of protection against weapons of mass destruction. Passive protection is provided by the use of reinforced aluminum armor, composite materials, as well as specially developed ceramic armor. Armor machine is removable and is a separate block-modules that can be removed or worn, depending on the combat mission. Composite armor around the crew provides significantly better protection than on the Paladin howitzer. The layout of the car, the thoughtful arrangement of components and assemblies provides additional protection for the crew and vital systems, even in the event of penetration of ammunition for armor.

However, in order to protect the crew, first of all, they will try to avoid detection and direct collision with the enemy by controlling the thermal, visible and acoustic signatures. In addition, FCS combat vehicles will have a number of sensors for navigation, situational awareness and detection of the threat of destruction. Sensors will be passive and active, operating in the infrared and visible spectrum. Further improvements will allow vehicles to automatically recognize and classify targets, detect their sensors and target illumination devices, and exchange information with other FCS vehicles. Behind the crew compartment is the central compartment and two side. In the central compartment is a tower with an automatic loader and ammunition. On the right side along the machine are projectiles, on the left - modular charges.

Barrel group XM324. Consists of a barrel with a muzzle brake and a breech with an upward-opening piston bolt. The barrel does not have an ejector and, accordingly, nozzle and valve openings, which reduce the strength of the barrel. This and the use of high-quality steel alloys with increased strength characteristics (steel grade M47-2C with a yield point of 131 kgf / mm2) allowed the French manufacturer Aubert & Duval to significantly reduce the barrel weight. In addition, due to the use of high-quality alloys, it was also possible to reduce the size of the breech by 30% compared to the M777 howitzer.

However, despite the absence of a crew in the turret, the blowing of the barrel bore and ventilation of the internal space is still necessary, since powder gases accumulated in a closed, poorly ventilated space can ignite, that is, a reverse flame will occur. For this, the ACS is equipped with two powerful electric fans for ventilation of the internal space of the tower and cooling of the diesel engine.

Unlike the Paladin howitzer, when firing from the NLOS-C, it is not the capsular charges that are used, but the modular artillery charges MACS developed recently for the 155-mm howitzers. HM324 barrel chamber is made under the maximum charge, consisting of four modular charges MACS М232. The service life of the barrel to complete wear is 875 shots, equivalent to a full charge, at a rate of six shots per minute.

The maximum range of howitzer firing with a M107 high-explosive fragmentation projectile with a mass of 43,1 kg using three MACS M232 modular charges is on the order of 14 km, and using four MACS M232 M549A1 projectile XNNXX The maximum firing range when using Excalibur M43,5 guided missiles with a GPS system exceeds 26,5 km. New designs of hybrid high-explosive fragmentation shells are being developed, for example, the M982E30 Hybrid RA / BB projectile (Rocket Assist / Base Bleed - auxiliary rocket engine / blowing in the bottom area, bottom gas generator) 795 kg in mass. That is, being an active-projectile projectile, it additionally also has a bottom gas generator. This allows you to hit targets at ranges up to 1 km when firing a howitzer with a barrel in 48,1 calibers, which is 37 km more than when firing a M39X7 projectile. When firing the same active-reactive projectile and NLOS-C, but the barrel in 549 calibers with four charges of MACS M1, the maximum firing range can be 38 km.

Specialists from BAE Systems note that although the size of the bureaucrat and piston diameter are almost two times smaller than the M777 howitzer, they nevertheless withstand the pressure levels that are formed by the six modular charges of the MACS M232. This opens up the possibility of staging a new artillery barrel of greater length with an increased firing range, which will help expand the export prospects of the NLOS-C howitzer.

The measures noted above, as well as the use of a new effective muzzle brake and a number of other measures, made it possible to reduce the weight of the XM324 stem group by 620 kg compared to the 155-mm howitzer М109А6 Paladin.

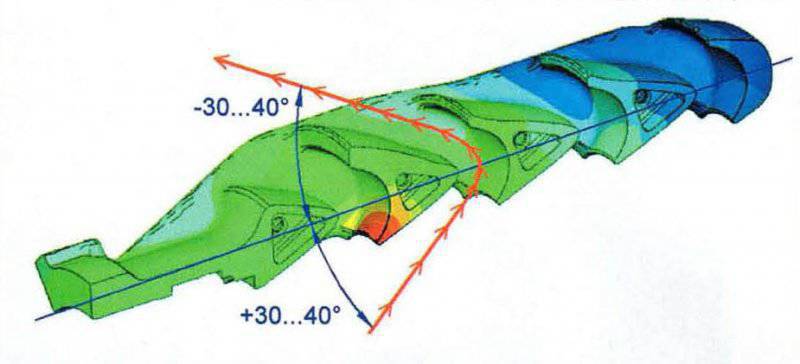

Muzzle brake. The original design of the muzzle brake, with which the howitzer was presented in 2008 at an exhibition in Washington opposite the US Congress building, draws attention to itself (see the photo on the splash screen). The muzzle brake in the artillery system is an important unit, as it allows to significantly reduce the load on recoil devices and carrier, which ultimately will lead to increased stability and lower machine weight. At the beginning, the howitzer was tested with a classic two-chamber muzzle brake, similar to the M777, M109A6 Paladin howitzer muzzle brakes. Then, a more compact tube (length 3,5 caliber) tubeless muzzle brake with four rows of side windows appeared on the NLOS-C P prototype. A distinctive feature of it is the shape and variable angle of the side channels. At the input it is (+ 30 ... 40 °), and at the output (-30 ... 40 °). This design of the side windows makes the muzzle brake very effective. Although the design of the muzzle brake with variable angles of inclination of the side windows has been known for a long time, previously it was not practically used due to the complexity of manufacturing, as well as due to the fact that the powder gases discharged back at a large angle create a high overpressure in the field of gun design. However, with the development of technology and given that in this case the crew is protected by armor, the manufacture of muzzle brakes with side channels of this form and angles of inclination became possible.

Another modification of the muzzle brake design, with which the howitzer was presented at the exhibition, was a muzzle brake with six rows of side windows with three windows in each row. Moreover, one window is directed vertically upwards and the other two down to the side at an angle of 120 °. Essentially, the design represents a set of plates connected by bridges, which makes it extremely light. From the videotape of the tests it is clear that the flow of gases expires from the side windows back at an angle of minus 30 — 40 °. In addition, when shooting, there is practically no flame.

Similar designs were offered by domestic developers for implementation in production more than 20 years ago. The masses of experimental structures proposed for the introduction, with the same energy efficiency with the muzzle brakes of the existing domestic artillery systems, were 5 — 6 times smaller. The fieryness of the shot was also significantly reduced, as was the case with the last version of the NLOS-C howitzer muzzle brake. But, unfortunately, due to technological problems, the proposed designs did not go into the series.

In the NLOS-C howitzer, another relatively recent design solution has been applied. Instead of two anti-recoil devices - recoil brakes and knurled ones, located on the top or bottom of the barrel, there are four of them on the NLOS-C - two recoil brakes and two knurlers diametrically located on both sides of the barrel. A similar arrangement of recoil devices is applied in the domestic 125-mm tank gun 2-46-M. This design allows you to compensate for the moments from the forces arising in recoil devices, reduce barrel oscillations and improve shooting accuracy.

Automatic loader. Holds 72 modular charge and 24 projectile of various types. It not only allows you to change the type of ammunition on the go, depending on the nature of the target, but also to use different types and number of modular powder charges when firing at different ranges. Automation tools eliminated the heavy physical work of the loader and for the first time in world practice for such systems reduce the calculation from five people, like the howitzer М109А6 Paladin, to two, and the reloading time is reduced almost twice. Since a similar automatic loader was already tested on the Crusader howitzer, the developers hope to get the maximum rate of fire the same as hers - about 10 rounds per minute. Achieving such a high rate of fire is a rather difficult technical task, because you need to perform a number of operations, such as installing a fuse, turning and transferring to the filling line, sending a projectile and then charges, polyethyleneglycol injection, locking and unlocking the barrel, etc. ., which takes time. Loading the ammunition of this howitzer will also be automated. For these purposes, an ammunition supply vehicle is being developed, which will allow the crew of the howitzer, without leaving the vehicle and not leaving its jobs, to load ammunition in less than 12 minutes.

Thanks to the automatic loader, which provides a high rate of fire, and an automated firing system, the NLOS-C howitzer, like the Crusader system, can implement a “multiple simultaneous strike” firing scheme, i.e. strike one howitzer at the target with several shells simultaneously.

Multiple simultaneous hit - Multiple Rounds Simultaneous Impact (MRSI scheme). If one projectile is fired at the enemy, in the event of a miss, the enemy will have time (6 — 10 с) before the next projectile arrives, and he can have time to hide in a shelter from which it can no longer be reached. The scheme of striking MRSI is as follows. The howitzer, its computing complex and software allow you to automatically, releasing one projectile after another, each time to change the angle of elevation of the gun so that the projectiles either simultaneously cover a certain area or arrive at one point. If you release a projectile at a high angle, it will fly to the target longer than a projectile fired at a lower angle. If you start from high and slightly lower the barrel after each shot, you can calculate the shots so that up to five shells fall on the target almost simultaneously. Although this is simple in principle, such a blow is very difficult to inflict, and only very sophisticated systems are capable of it. For example, the Crusader self-propelled gun can deliver eight shells simultaneously to the target, the German PzH2000 self-propelled guns - five shells, the Swedish Archer howitzer - six shells. With such a tactic, several howitzers, in the range of about one second, can bring dozens of shells at the enemy, preventing anyone from hiding. They will not even have time to hide in a trench or in a shelter.

At the end of August, 2005 at the test site of Hume, Arizona, from the NLOS-C demonstrator was successfully made four series of six shots according to the MRSI scheme. In the course of each episode, all six projectiles fell into the target within 4 s. The firing range was conducted in the 2 (5 — 12 km) and 3 (8 — 20 km) zones. Moreover, when shooting in the 2 zone, shooting began with the M232 modular charges, and ended with the M231 charges. That is, for the first time, the US howitzer implemented the MRSI method with more than one type of standard powder charge, which shows the perfection of an automatic loader able to work quickly with two types of modular charges.

A demonstration of the MRSI method was carried out in order to prove the viability of the architecture and functionality of the NLOS-C howitzer fire control software. According to engineers, already at this stage of testing, the software of the system was sufficiently developed to attempt an early demonstration of the MRSI method, although initially these tests were not planned. The software and automatic loader needed not only to select a certain number of charges of the same type and calculate the pointing angles, but to ensure the choice of shooting parameters and hitting the same target when switching to a different type of charge, which was successfully demonstrated during the tests. The ability to fire several types of charges MACS gives the howitzer the ability to conduct on the battlefield more flexible fire, allows you to provide faster and more accurate greater firepower with greater destructive consequences than before. Projectile Tracking System (PTS). The PTS system greatly improves the accuracy of shooting. It allows you after a shot using a radar with a phased antenna array that generates a narrow beam of radio emission, measure the muzzle velocity of the projectile, monitor its flight to the highest point of its ballistic trajectory, calculate the point of incidence and compare the deviation with the starting point of aiming before the projectile drops to the ground. On the basis of this, an adjustment of the tool pointing angles is made automatically from shot to shot. The interferometric tracking system is made on a series of conformal lattices installed in front of the tower. In general, the tracking system has an acceptable weight and dimensions and slightly increases the weight of the ACS. The system can accompany the projectile almost all the way to its flight. Circular probable deflection of shells when shooting from NLOS-C on 33-50% less than when firing from the M109-6 Paladin howitzer.

Tests According to the requirements of the military, the reliability of the NLOS-C ACS must be 10 times higher than that of modern military equipment of this class. Since the NLOS-C howitzer has unprecedented reliability requirements, in the past few years, BAE Systems has been conducting intensive tests to verify its reliability both on bench equipment and in field conditions. According to the results of the howitzer check, the developers intend to make the necessary changes to its design.

In order to thoroughly check the NLOS-C for mobility and fire in a short time, BAE Systems has developed a special vibrating table, the Mission Equipment Vibration Table (MEVT), which makes it possible to evaluate how the howitzer produces vibrations from movement and firing, taking into account extreme climatic conditions and shelling by the enemy. The MEVT booth development, completed in September of 2006, was undertaken as a way to identify and reduce system failures at the beginning of the NLOS-C development cycle to achieve unprecedented reliability. The focus is on the early detection of failures by imitating shots from a shot, vibration, under various thermal conditions, humidity, dust and pollution, creating a certain environment. The stand allows you to simulate the movement of all types of terrain and the overcoming of various obstacles in the form of trenches, pits and other obstacles, in conditions of high positive and negative temperatures. MEVT is the first of its kind stand, capable of testing components and assemblies of combat vehicles weighing up to 12,25 tons.

Another stand allows you to simulate the load acting on the power drive while driving on rough terrain. In general, during the reliability tests, the howitzer “passed” 10000 virtual miles, experienced loads from 2000 shots, and the turret with a simulator gun “traveled” more than 20000 km in order to assess the reliability in operational conditions. Thanks to a specially developed vibration test program using bench equipment, it was possible to simulate the 20-year life cycle of the howitzer for 12 — 18 months. This allows developers to quickly identify and eliminate any reliability problems in place, and make design changes to the prototypes they create, in order to speed up their development, rather than waiting for problems to occur during field trials or in combat.

Information