South Africa and Rhodesia vs min. Part I

The first anti-mine weapons were homemade “kits” that appeared in South Africa and Rhodesia at the very beginning of the seventies. Under the bottom of any suitable car hung a metal sheet, designed for partial absorption and discharge in the direction of the energy of the explosion. On the floor of the passenger compartment or on the bottom of the truck body, various containers filled with sand or water, also designed to take over some of the impact, were placed. Finally, in the event of overturning, on the roof of the transport were fixed the usual tires, which served as improvised shock absorbers. Despite its pronounced handicraft character, such protection adequately coped with the tasks assigned to it. According to some data, after the start of mass use of such “sets of additional protection”, the loss of people during mine explosions decreased by about three times - from 22% to 7-7,5%.

With all its advantages over unequipped equipment, such improvised armored vehicles, protected from mines, had one major drawback. When reworking the base car, it was necessary to take into account the different features of its design, which made it difficult to massively refine the machines. In addition, the economic blockade Rhodesia and South Africa could not count on the help of third countries. In this regard, already at the very beginning of the seventies, the first projects of armored cars began to appear, which preserved and improved the protective capabilities of previous machines, but at the same time were suitable for mass construction in the prevailing conditions. Consider some light armored vehicles created by the designers of South Africa and Rhodesia during the war.

Hyena

The first combat vehicle that can be considered a full-fledged representative of the class of vehicles (Mine protected vehicle - “Mine protected vehicle”) or MRAP (Mine resistant and ambush protected - “Mine resistant vehicle and protected from ambush attacks”) became a sample called Hyena ("Hyena"). Developed in South Africa, the car was based on the chassis of one of the Land Rover jeeps. Thanks to this, the lightly armored “Hyena” with the 4 × X4 wheel formula could accelerate on a good road to 127 kilometers per hour and overcome off-road conditions. Production armored Hyena engaged in the industry of the Republic of South Africa. Before 1974, about 230 of such machines were assembled; about a hundred and fifty were sent to Southern Rhodesia, where they served until the end of the war.

First full MPV class armored car - Hyena

The first full-fledged South African armored car capable of withstanding a mine explosion, had several characteristic features, preserved in one form or another on a later technique of South Africa and Rhodesia, and then passed to modern MRAP machines. So, Hyena patrol armored car received a characteristic narrow body with sides diverging to the top. The lower part of the hull fits perfectly into the dimensions of the chassis frame, because of which the seats for the transported soldiers had to be placed at the sides, sideways in the direction of travel. However, this inconvenience was compensated by security: when a mine was blown up under the wheel, most of the energy of the explosion and the fragments passed along the side, almost without damaging it. The driver and the landing were placed in the same volume, since the hull was not divided into several compartments. An interesting fact is that the armor "Hyenas" did not have a roof. Instead, a fabric awning was stretched on a metal frame or a light metal roof was installed. For self-defense, the shooters had to get up to their full height and fire from personal weapons through the gap between the awning / roof and the hull. Landing and leaving the car was carried out through the door in the feed sheet.

Wolf

Almost simultaneously with the Hyena armored car, another mine-protected machine called the Wolf appeared. A larger car was made on the base of the Unimog chassis and, as a result, had a greater load carrying capacity. The stock capacity used to create a new armored hull. The side panels of the “Wolf” hull converged downwards at a large angle in comparison with the “Hyena”, which led to an increase in resistance to explosions. In addition, perpendicular to the sides provided additional horizontal panels that diverted part of the explosion energy to the sides. On top of the troop compartment for eight people covered with a light metal roof. Like the Hyena armored car, Wolf did not have wheel arches, which allowed the shock wave of the mines, damaging the wheel and suspension, to go up without causing much harm to other units of the vehicle.

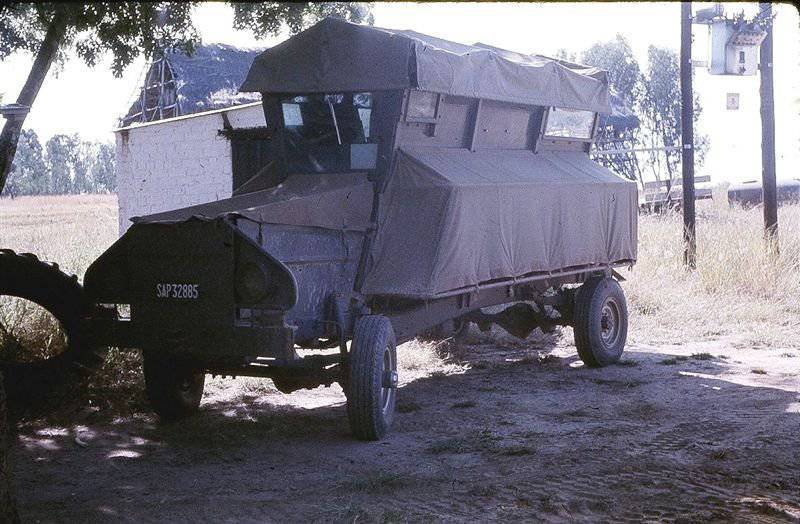

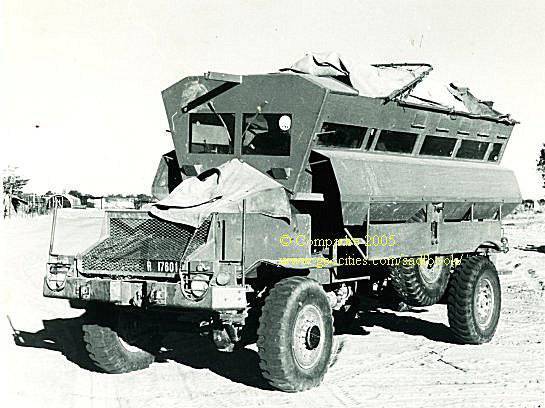

Armored Wolf

Unfortunately, the exact number of assembled armored vehicles "Wolf", as well as their exact characteristics, are unknown. Based on information about the base chassis, you can draw appropriate conclusions about the approximate characteristics of the car Wolf. They were probably at the level of a loaded Unimog truck. Cars "Wolf" actively used in the first half of the seventies, but their number is constantly reduced, because the repair after the explosion was too complicated and, moreover, not always possible.

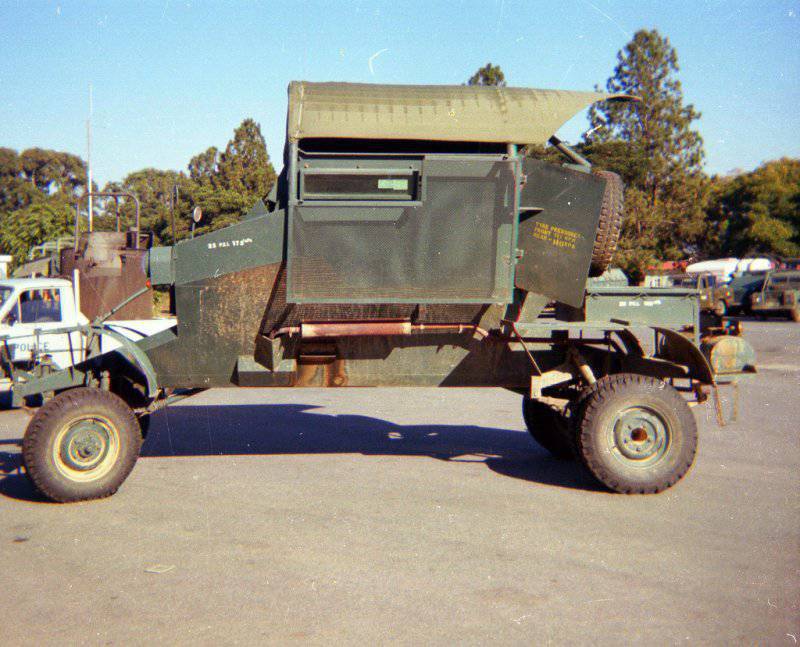

Hippo

Further development of the ideas embodied in the project Wolf, became the armored car Hippo ("Hippo"). At this time, the original armored hull of characteristic shape was installed on an English Bedford truck chassis. The armored corps expanding to the upper part contained ten seats for fighters with weapons and two crew seats. "Hippo" was the first South African specialized armored car, equipped with full-fledged onboard armored glass. The car had rear doors for embarkation and disembarkation of the crew and landing force. On some Hippo armored cars mounted devices for installing a machine gun. In addition, the landing force could fire from personal weapons, removing a light canvas awning from the frame. The armored vehicle with a curb weight of about 9,5 tons had an 134-strong engine and could accelerate on the highway to 80-90 km / h.

Hippo

Construction of "Hippos" was conducted from 1974 to 1978 years. In total, about two hundred armored vehicles were actively used during the war in Southern Rhodesia, and then in other armed conflicts in southern Africa. The measures used to increase resistance to mine explosions used in the Hippo design, as before, had an ambiguous result. The loss of personnel was minimal, but the vehicles were often not recoverable. At best, the blown-up armored car could be used as a source of spare parts for repairing less damaged cars.

Leopard

Despite the loss of technology, South Africa and Rhodesia, in an effort to save the lives of soldiers, continued to operate their MPV armored vehicles. A common feature of all armored vehicles created in the first half of the seventies was the use of ready-made chassis. This feature of the technique prevented the full use of the potential of the available developments in the field of increasing the resistance of the transport to mine explosions. In 1974, the Rhodesian engineer E. Konshel, having lost a close relative when the machine was blown up, began to study MPV-class equipment and know-how applied to them. As a result of the research and the design that followed, a new armored car Leopard (“Leopard”) appeared.

Like the previous armored cars, the Leopard was based on some units borrowed from the equipment available at that time. The basis for the armored car was a German minivan Volkswagen Kombi. The Conchel project also implied the use of several original innovations. First of all, the absence of the usual frame with the power plant, transmission, etc. units installed on it is striking. Her role on the “Leopard” was played by the carrying body with the original contours and the V-shaped bottom that had already become the standard for such equipment. In the front and rear parts of the body were attached chassis units, divided into two blocks. This arrangement has allowed to significantly increase the clearance of the machine, reducing the risk of damage to the body during an explosion. Both axles of the undercarriage were made in such a way as to collapse during an explosion, absorbing part of the energy of the shock wave. This idea also allowed to facilitate the repair of machines, including in the field. The car turned out quite easy - its dry weight did not exceed 1760 kg.

To improve the safety of the crew, E. Konshel took several interesting steps. Perhaps the most interesting of them is the safety arches surrounding the car body and not letting it fall over on its side or onto the roof with serious consequences for passengers. In addition, the driver and five soldiers were obliged to fasten to the seats when driving. The Leopard’s armored hull did not have a roof, which, firstly, simplified its design and, secondly, contributed to the rapid equalization of pressure inside and outside the hull in the first moments after the explosion. Finally, the engine with a light jacket, fuel tank and batteries were placed above the rear axle, outside the armored hull. The tank was mounted on controlled detachable mounts. With the help of these mechanisms, the driver after the explosion could have dumped the 40-liter (on earlier versions of the armored car, later the tank was increased one and a half times) the fuel tank and protected the car from fire.

Construction of armored vehicles "Leopard" on the basis of already existing German cars began in 1975 year. In four years, 725-750 of such MPV machines was assembled. During the last years of the war in Southern Rhodesia, only 67 Leopards were blown up by enemy mines. In this case, armored vehicles clearly demonstrated the need for Conchel's inventions. Thus, during the 67 explosions, only six people died, and a number of armored vehicles were subsequently restored and returned to service.

Rhino

Rhino

A peculiar attempt to combine the level of protection "Leopard" and the simplicity of the assembly of previous machines of the class MPV was the project Rhino ("Rhino"). Land Rovers jeeps were chosen as the basis for this armored car. They were installed lightweight body, at the same time resembling the corresponding units of machines Hyena and Leopard. At the same time, as at last, the case was raised to the highest possible height and equipped with tubular safety arcs. No sophisticated fixtures such as the fuel tank discharge system or the properly destructible elements of the Rhino undercarriage did not receive. Apparently, the authors of the project expected to provide the customer in the face of the police with not only a safe, but also an inexpensive armored car. According to some sources, several “Rhino” armored vehicles were sold to private individuals and used as personal vehicles.

Cougar

Another development of technical know-how, which appeared in the Leopard project, was the Cougar armored car (“Cougar” or “Puma”). In its basic features, this car resembled the previous one, but at the same time it had a number of noticeable differences. First of all, it is much larger. In connection with the use of units of a base machine (according to some data, it was a Unimog truck), the layout of the armored hull changed. In front of it, we have reserved the reserved volume for the engine and some transmission units. The fuel tank was still at the rear of the chassis. The hull shape with a V-shaped "mine bottom" has changed slightly, and thanks to the use of thicker and more durable armored panels, the safety bars were now only at the top.

The first Cougar was built only in 1978-79, but despite this, it managed to become the basis for several modifications. Thus, in the Organ version, the armored car carried several remote-controlled smooth-bore guns designed to suppress an enemy trying to fire a car from an ambush. The Panther armored vehicle (“Panther”) received other own weapons, namely, a swiveling turret with a machine gun on the roof. Finally, based on the MPV Cougar, several completely unexpected cars were manufactured - these were railway armored cars. They differed from the base model in a different chassis intended for movement on rails.

Cougar, additionally armed with guns

Panther armored car with turret

Cougar version for railway patrols

Kudu

Another embodiment of the concept embodied in the Leopard armored car was the Kudu family of vehicles (Kudu is the common name for two types of antelopes). Again, the Land Rover model car 3S Long, available in Rhodesia and South Africa, became the basis for the armored vehicle. The new armored car received an armored engine cover with a characteristic elongated inclined hood and armored hull with recognizable outlines. It is noteworthy that in the project “Kudu” they applied an original technical solution, designed to increase the level of protection of the hull from small arms bullets. On its sides and aft, special structures were installed, consisting of overlaid metal panels. Such multi-layered armor damaged bullets and changed their trajectories, thereby reducing the risk of damage to the hull and crew.

Since the Republic of South Africa or Rhodesia could not buy any equipment abroad, and there were several versions of Land Rovers in the countries, we had to create two versions of the Kudu project. Their main difference was in the wheelbase and the layout of some units. So, a short armored carriage carried fuel tanks on the sides, between the wheels. In the long-wheelbase, the only fuel tank was located in the same place as the Leopard and some other MPV class cars. On the basis of both versions of the armored car, they also assembled Ojay vehicles designed for patrolling the railways. If necessary, the standard car wheels were replaced by rail and the armored car could move along the rails.

"Railway" armored car Ojay

Crocodile

A characteristic feature of all South African and Rhodesian armored vehicles was a specific appearance, because of which they resembled some kind of creation by craftsmen, not professional engineers, even if limited by industry. Only in the second half of the seventies, Rhodesia and South Africa were able to get rid of this problem and create an armored car with an "exterior" that truly resembles similar equipment from leading world manufacturers. This project was named Crocodile ("Crocodile").

"Crocodiles" of the first parties

As a base for such armored vehicles, several models of five-ton trucks made in Japan were used. The cab, body and a number of other systems were dismantled from the chassis of Toyota, Isuzu and Nissan cars. In place of the cleaned units installed original armored hull with an open top. As before, a relatively light casing was mounted in front of the case with rather thick bronel sheets that covered the engine. Depending on the base chassis, one of two housing options was used: with a fully V-shaped bottom or with a flat bottom and inclined panels on the sides. On the frontal sheet of the main body there were two armored glass, and the left commander could, if necessary, be covered with a metal sheet. On the upper panels of the sides there were windows with bullet-proof glass that could be opened for firing from personal weapons.

The own armament of Crocodile armored cars consisted of several machine guns. Almost on all machines of this model, the FN MAG machine gun was installed above the commander’s workplace. Also, if necessary, machine guns or machine guns could be mounted in the embrasures on the sides. There was a version of the machine called the E-Type, designed to accompany the convoy. From the base model of the Crocodile, he was distinguished by the presence of a light turret (because of the shape it was called the “trash can”) with one or two Browning M1919 machine guns. For the safety of the machine gunner and the crew as a whole, three U-shaped safety arcs were installed on the upper part of the hull.

Crocodile armored cars successfully served in the troops of South Africa and Rhodesia until the very end of the war, and then were divided between several countries. So, around 35-40 "Crocodiles" are still serving in the army of Zimbabwe and in the foreseeable future, it seems, will remain in it. In addition, it is known that in the early nineties, during the fighting in Somalia, a number of former Rhodesian armored vehicles were used by US marines.

Past and present

This is not all armored vehicles created during the war in Southern Rhodesia. Due to the nature of the conflict, many enterprises and commercial structures tried to create their own versions of MPV class cars. Not all of them managed to bring their development to mass production and, moreover, to the construction of a large series. However, regardless of the number of units of equipment produced by a particular model, all or almost all such projects have significantly reduced the loss of personnel. At the cost of damage or destruction of armored vehicles by the end of the war, losses among their crews decreased, according to various data, to 1,5-2 percent.

It should also be noted that the designers of South Africa, helping their troops and friendly Rhodesia, have gained tremendous experience in creating armored vehicles capable of protecting people not only from bullets, but also from mines or improvised explosive devices. A few years after the end of the conflict, this led to the finalization of the overall look of a new class of technology - MRAP. South African armored vehicle manufacturers from Land Systems OMC (now a division of BAE Systems) are still actively using old practices and creating new ideas, which allows them to be one of the world's leading manufacturers of armored vehicles that are resistant to mines and protected from ambushes.

On the materials of the sites:

http://rhodesians.ru/

http://shushpanzer-ru.livejournal.com/

http://armourbook.com/

http://casr.ca/

http://rhodesianforces.org/

Information