Kinetic shells and rockets

The basis of modern ground forces is armored vehicles, presented tanks and infantry fighting vehicles, whose weight has already exceeded 70 tons, respectively (Abrams M1A2 SEP v2, Challenger-2, Merkava-Mk.4) and 40 tons (Puma, Namer). In this regard, overcoming the armor protection of these vehicles is a serious problem for anti-tank ammunition, which includes armor-piercing and cumulative shells, missiles and rocket-propelled grenades with kinetic and cumulative warheads, as well as striking elements with an attack nucleus.

Among them, the most effective are armor-piercing sub-caliber shells and rockets with a kinetic warhead. Possessing high armor penetration, they differ from other anti-tank ammunition with their high approach speed, low sensitivity to the effects of dynamic protection, relative independence of the guidance system weapons from natural / artificial noise and low cost. Moreover, these types of anti-tank ammunition can be guaranteed to overcome the active protection system of armored vehicles, which are becoming increasingly common as an advanced line of interception of striking elements.

Currently, only armor-piercing sabot shells are adopted. They are fired mainly from smooth-bore guns of small (30-57 mm), medium (76-125 mm) and large (140-152 mm) calibers. The projectile consists of a two-bearing master, the diameter of which coincides with the diameter of the barrel bore consisting of sections separated after departure from the barrel, and the striking element - an armor-piercing rod, in the nose of which a ballistic tip is installed, in the tail end - an aerodynamic stabilizer and a tracer charge.

Ceramics based on tungsten carbide (density 15,77 g / cc) and metal alloys based on uranium (density 19,04 g / cc) or tungsten (density 19,1 g / cc) are used as the material of the armor-piercing rod. The diameter of the armor-piercing rod ranges from mm 30 (obsolete models) to mm 20 (modern models). The higher the density of the material of the rod and the smaller the diameter, the greater the specific pressure the projectile exerts on the armor at its point of contact with the front end of the rod.

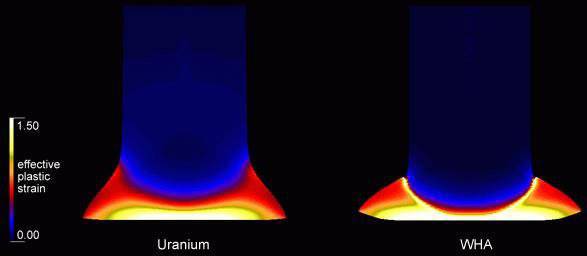

Metal rods have much greater bending strength than ceramic, which is very important when the projectile interacts with the shrapnel elements of active protection or throwing plates of dynamic protection. At the same time, the uranium alloy, despite its somewhat lower density, has an advantage over tungsten - the armor penetration rate of the first is more by 15-20 percent due to the ablative self-sharpening of the rod in the process of armor penetration, starting with the speed of the 1600 impact of m / s provided by modern cannon shots.

Tungsten alloy begins to show ablation self-sharpening, starting at a speed of 2000 m / s, which requires new ways to accelerate projectiles. At a lower speed, the front end of the rod flattens out, increasing the channel of penetration and reducing the depth of penetration of the rod into the armor.

Along with this advantage, the uranium alloy has one drawback - in the event of a nuclear conflict, neutron irradiation penetrating the tank induces secondary radiation in the uranium that affects the crew. Therefore, in the arsenal of armor-piercing shells, it is necessary to have models with rods made from both uranium and tungsten alloys, designed for two types of military operations.

Uranium and tungsten alloys also have pyrophore - the ignition of heated metal dust particles in the air after armor penetration, which is an additional damaging factor. This property is manifested in them, starting with the same speeds as the ablative self-sharpening. Another damaging factor is the dust of heavy metals, which has a negative biological effect on the crew of enemy tanks.

The leading device is made of aluminum alloy or carbon fiber, the ballistic tip and the aerodynamic stabilizer are made of steel. The master device serves to accelerate the projectile in the barrel bore, after which it is discarded, so its weight should be minimized by using composite materials instead of aluminum alloy. The aerodynamic stabilizer is exposed to heat from the powder gases formed during the combustion of the powder charge, which can affect the accuracy of fire, and therefore it is made of heat-resistant steel.

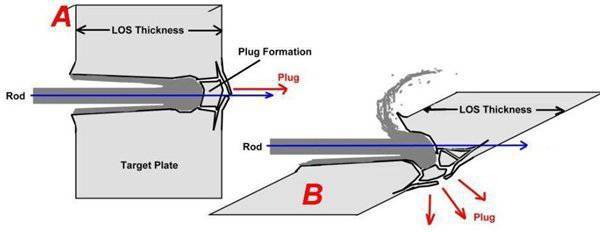

The armor penetration of kinetic projectiles and rockets is defined as the thickness of a plate of homogeneous steel, installed perpendicular to the axis of flight of the striking element, or at a certain angle. In the latter case, the reduced penetrability of the equivalent thickness of the plate is ahead of the penetrability of the plate, installed normal, due to large specific loads at the entrance and exit of the armor-piercing rod to / from the sloped armor.

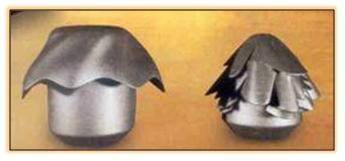

When entering sloped armor, the projectile forms a characteristic roller above the penetration channel. The blades of the aerodynamic stabilizer, when destroyed, leave a characteristic “star” on the armor, by the number of rays of which it is possible to determine the belonging of the projectile (Russia has five rays). In the process of armor penetration, the rod is intensively grind down and significantly reduces its length. When leaving the armor, it elastically bends and changes its direction of movement.

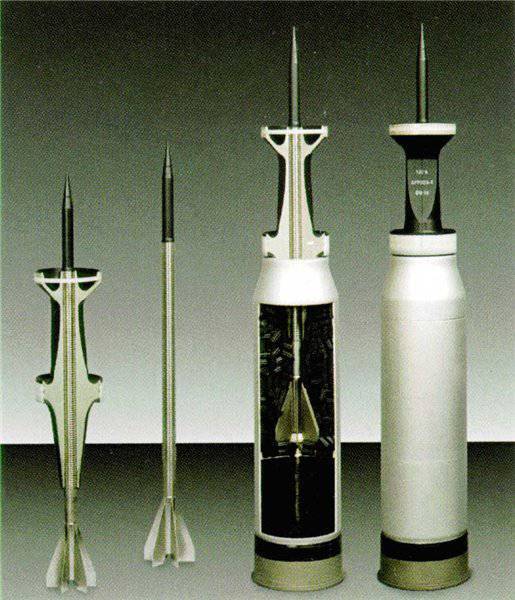

A typical representative of the next-to-last generation of armor-piercing artillery ammunition is the Russian 125-mm snapshot of the second-round snapshot 3BM19, which includes the 4Ж63 sleeve with the main propelling charge and the 3BMXNNXX sleeve, which contains additional propellant charge and its own design and subdivisions of the design of the design of the original projectile and the 44BM3M sleeve containing the extra propelling charge of the projectile charge, and the 42BMXNNXX sleeve containing the extra propelling charge and the design of the projectile and the projectile of the projectile, which contains an additional projectile charge and its own design of the projectile, which contains an additional projectile charge and part of the design of the design of the design of the projectile and the 2BM46M cartridge containing the extra propelling charge of the projectile. Designed for use in gun 1А90МXNUMX and newer versions. Shot dimensions allow you to place it only in the modified versions of the automatic loading of tanks T-XNUMX.

The ceramic core of the projectile is made of tungsten carbide, placed in a steel protective case. The master device is made of carbon fiber. As the material of the sleeves (except for the steel pallet of the main propellant charge) used cardboard impregnated with trinitrotoluene. The length of the sleeve with the projectile is 740 mm, the length of the projectile 730 mm, the length of the armor-piercing rod 570 mm, diameter 22 mm. The weight of the shot is equal to 20,3 kg, sleeves with a projectile 10,7 kg, armor-piercing rod 4,75 kg. The initial velocity of the projectile is 1750 m / s, armor penetration at a distance of 2000 meters along the normal 650 mm of homogeneous steel.

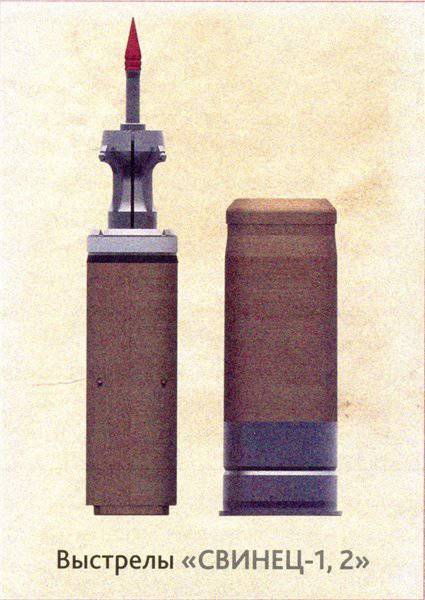

The latest generation of Russian artillery The main propellant charge is fitted into the 125IX3 "Ozone-T" sleeve.

The dimensions of the new shells coincide with the dimensions of the Lekalo projectile. Their weight is increased to 5 kg due to the greater density of the material of the rod. For acceleration of heavy projectiles in the barrel, a more bulk main propelling charge is used, which limits the use of shots, including Lead-1 and Lead-2 shells, only with the new 2А82 cannon, which has an increased charging chamber. Armor penetration at a distance of 2000 meters along the normal can be estimated respectively as 700 and 800 mm of homogeneous steel.

Unfortunately, the Lekalo, Lead-1 and Lead-2 projectiles have a significant structural disadvantage in the form of centering screws located along the perimeter of the bearing surfaces of the driving devices (visible in the figure are the projections on the front bearing surface and points on the surface of the sleeve ). The centering screws are used to stably projectile in the barrel, but their heads have a destructive effect on the surface of the channel. In foreign designs of the last generation, precision screw rings are used instead of screws, which five times reduces barrel wear when fired by an armor-piercing sabot projectile.

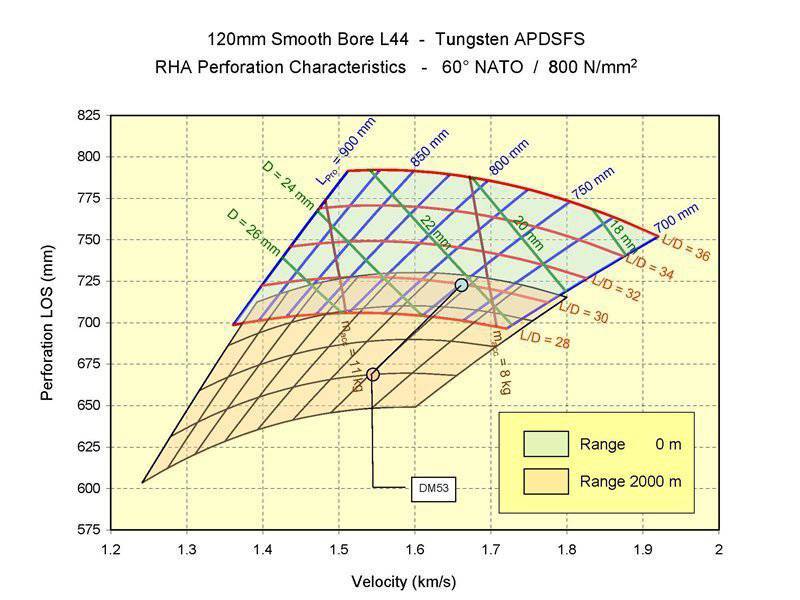

The previous generation of foreign armor-piercing piercing shells is represented by the German DM63, which is part of the unitary shot to the standard 120-mm smooth-bore NATO gun. The armor-piercing rod is made of tungsten alloy. The weight of the shot is equal to 21,4 kg, the weight of the projectile 8,35 kg, the weight of the armor-piercing rod 5 kg. The length of the shot is 982 mm, the length of the projectile 745 mm, the length of the core 570 mm, diameter 22 mm. When firing a gun with a barrel length in 55 calibers, the initial speed is 1730 m / s, the speed drop on the flight path is stated at the level of 55 m / s for every 1000 meters. The armor penetration at a distance of 2000 meters is normally estimated to be 700 mm of homogeneous steel.

The latest generation of foreign armor-piercing piercing shells refers to the American M829-X3, which is also part of the unitary shot for the standard 120-mm smooth-bore NATO gun. Unlike the D63 projectile, the M829А3 projectile armor-piercing rod is made of uranium alloy. The weight of the shot is equal to 22,3 kg, the weight of the projectile 10 kg, the weight of the armor-piercing rod 6 kg. The length of the shot is 982 mm, the length of the projectile 924 mm, the length of the core 800 mm. When firing a cannon with a barrel length 55 caliber, the initial speed is 1640 m / s, the speed drop is declared at the level of 59,5 m / s for every 1000 meters. The armor penetration at a distance of 2000 meters is estimated at 850 mm of homogeneous steel.

When comparing the latest generation Russian and American subcaliber shells, equipped with uranium alloy armor-piercing cores, one can see a difference in the level of armor penetration, largely due to the degree of lengthening of their attack elements - 26-multiple at the core of the Lead-2 projectile and 37-multiple at the rod projectile M829A3. In the latter case, a quarter is provided with a large unit load at the point of contact between the bar and armor. In general, the dependence of the value of armor piercing projectiles on the speed, weight and elongation of their striking elements is presented in the following diagram.

An obstacle to an increase in the degree of lengthening of the striking element and, consequently, the armor penetration of Russian projectiles is the automatic loader device, first implemented in 1964 in the Soviet T-64 tank and repeated in all subsequent models of domestic tanks, which provides for horizontal projectiles may exceed the internal width of the shell, equal to two meters. Taking into account the diameter of the liner of Russian projectiles, their length is limited to the value of 740 mm, which is 182 mm less than the length of American projectiles.

In order to achieve parity with the cannon armament of a potential enemy for our tank building, the priority task for the future is the transition to unitary shots located vertically in the automatic loader, whose shells have a length of at least 924 mm.

Other ways to increase the effectiveness of traditional armor-piercing shells without increasing the caliber of the guns have practically exhausted themselves due to restrictions on the pressure in the barrel charging chamber developed during the combustion of the powder charge, due to the strength of the weapon steel. During the transition to a larger caliber, the dimensions of the shots become comparable to the width of the tank hull, forcing the projectiles to be placed in the aft niche of the tower of increased dimensions and a low degree of protection. For comparison, the photo shows a shot of caliber 140 mm and a length of 1485 mm next to the layout of the shot caliber 120 mm and a length of 982 mm.

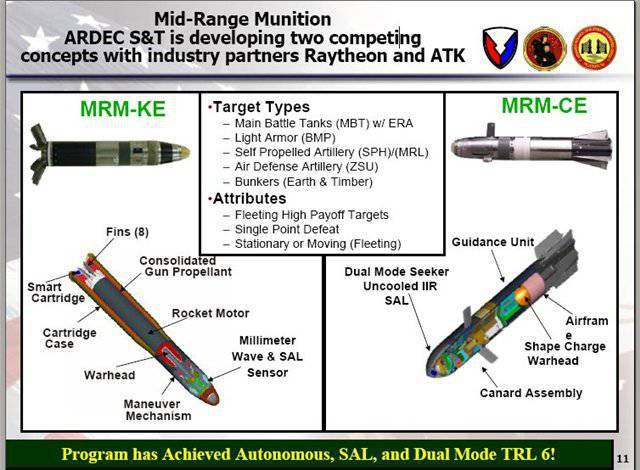

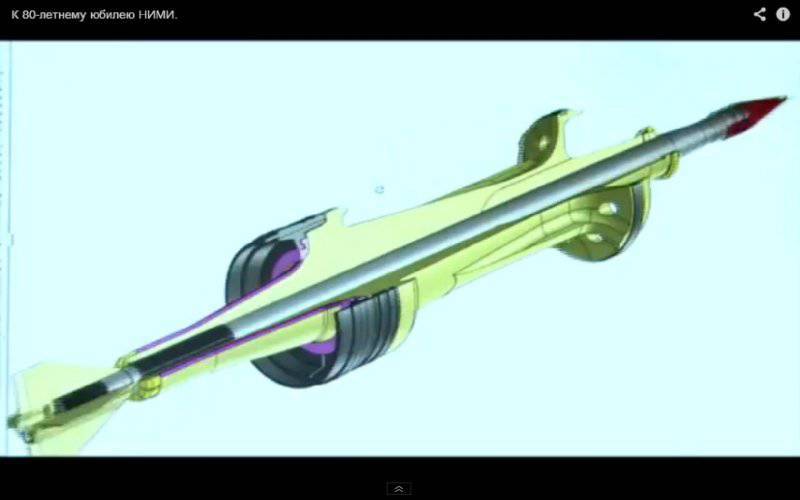

In this regard, in the USA, the MRM-KE active-rocket projectiles with kinetic warhead and the cumulative warhead MRM-KE have been developed in the USA as part of the MRM program (Mid Range Munition). They are fitted into the sleeve of a standard 120-mm cannon shot with a propellant charge of gunpowder. In the caliber shell shells are located radar homing head (GOS), the striking element (armor-piercing rod or shaped charge), impulse trajectory correction engines, booster rocket engine and tail unit. The weight of one projectile is 18 kg, the weight of the armor-piercing rod 3,7 kg. The initial speed at the level of the muzzle is 1100 m / s, after the completion of the work of the booster engine, it increases to 1650 m / s.

Even more impressive figures were achieved in the framework of the creation of the anti-tank kinetic rocket CKEM (Compact Kinetic Energy Missile), whose length is equal to 1500 mm, weight 45 kg. The rocket is launched from the transport and launch container using a powder charge, after which the rocket is accelerated by an accelerating solid-fuel engine to a speed of almost 2000 m / s (Mach 6,5) in 0,5 seconds. The subsequent ballistic flight of the rocket is carried out under the control of the radar homing and aerodynamic control surfaces with stabilization in the air with the help of tail tails. The minimum effective firing range is 400 meters. The kinetic energy of the striking element - the armor-piercing rod at the end of the jet acceleration reaches 10 mJ.

During tests of MRM-KE projectiles and CKEM missiles, the main drawback of their design was revealed - unlike sub-caliber armor-piercing projectiles with a detachable master, inertia flight of attack elements of a caliber projectile and a kinetic rocket is assembled with a large cross section and increased aerodynamic resistance, which causes a significant drop in speed on the trajectory and a decrease in the effective firing range. In addition, the radar homing, pulse correction engines and aerodynamic control surfaces have low weight perfection, which makes it necessary to reduce the weight of the armor-piercing rod, which negatively affects its penetrability.

The way out of this situation is seen in the transition to separation in flight of the caliber shell of the projectile / rocket and armor-piercing rod after the completion of the rocket engine, by analogy with the separation of the master and the armor-piercing rod, which are part of the sabot projectiles, after their departure from the barrel. Separation can be done using expelling powder charge, triggered at the end of the upper stage of flight. The reduced GOS should be located directly in the ballistic tip of the rod, while the flight vector control must be implemented on new principles.

This technical problem was solved in the framework of the BLAM (Barrel Launched Adaptive Munition) project to create small-caliber guided artillery shells, made in the Auburn Adaptive Aerostructures Laboratory of the AAL Adaptive Aerostructures Laboratory of the United States Air Force. The aim of the project was to create a compact homing system, combining in one volume a target detector, a controlled aerodynamic surface and its drive.

The developers decided to change the direction of flight by deflecting the projectile to a small angle. At a supersonic speed, deviations in fractions of a degree are enough to create a force capable of executing a control action. The technical solution was proposed to be simple - the ballistic tip of the projectile rests on a spherical surface, which plays the role of a spherical support; several piezoceramic rods arranged in a circle at an angle to the longitudinal axis are used to drive the tip. Changing its length depending on the supplied voltage, the rods deflect the tip of the projectile at the desired angle and with the desired frequency.

The calculations determined the strength requirements for the control system:

- acceleration acceleration to 20 000 g;

- acceleration on the trajectory to 5,000 g;

- projectile speed up to 5000 m / s;

- tip deflection angle to 0,12 degrees;

- the drive response frequency up to 200 Hz;

- drive power 0,028 watts.

Recent advances in the miniaturization of infrared radiation sensors, laser accelerometers, computational processors, and lithium-ion power sources that are resistant to high accelerations (such as electronic devices of guided projectiles — the American Excalibur and the Russian Krasnopol ”) make it possible to create and Adoption of kinetic shells and missiles with an initial flight speed of more than two kilometers per second, which will significantly increase the effectiveness of anti-tank combat ripasov, and will eliminate the use of uranium as a part of their submunitions.

Information