German projects of tank gas turbine engines

Until a certain time, Hitler's Germany did not pay much attention to the projects of gas-turbine power plants for ground vehicles. Thus, in 1941, the first such unit for an experimental locomotive was assembled, but its tests were quickly turned down due to economic inexpediency and the availability of higher-priority programs. Work in the direction of gas turbine engines (GTE) for ground vehicles continued only in the 1944 year, when some of the negative features of the existing technology and industry were especially vivid.

In 1944, the Arms Directorate of the Land Forces launched a research project on the subject of gas turbine engines for tanks. In favor of the new engines, two main reasons were cited. Firstly, German tank building at that time took a course towards heavier combat vehicles, which required the creation of an engine of high power and small dimensions. Secondly, all available armored vehicles used to some extent scarce gasoline, and this imposed certain restrictions related to operation, economy and logistics. Promising gas turbine engines, as German industry leaders then calculated, could consume less high-quality and, accordingly, cheaper fuel. Thus, at that time, from the point of view of economics and technology, gas turbine engines were the only alternative to gasoline engines.

At the first stage, the development of a promising tank engine was entrusted to a group of designers from Porsche, headed by engineer O. Zadnik. Several related enterprises were supposed to assist the Porsche engineers. In particular, the SS Engine Research Department, headed by Dr. Alfred Müller, was involved in the project. Since the mid-thirties, this scientist has been working on the subject of gas turbine installations and participated in the development of several aviation jet engines. By the time the creation of a GTE for tanks began, Müller completed the turbocharger project, which was later used on several types of piston engines. It is noteworthy that in 1943, Dr. Müller repeatedly made proposals regarding the start of the development of tank gas turbine engines, but the German leadership ignored them.

Five options and two projects

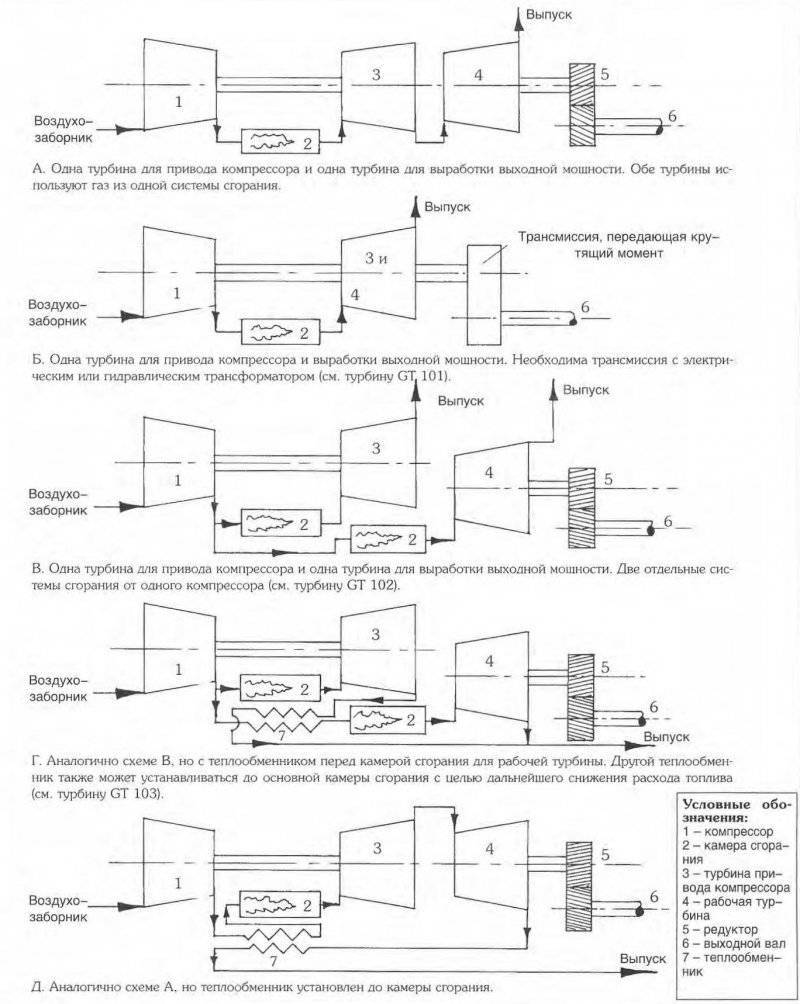

By the time the main works began (mid-summer 1944 of the year), the lead role in the project was transferred to the organization headed by Muller. At this time the identified requirements for prospective GTD. He was supposed to have a capacity of about 1000 hp and air consumption about 8,5 kilos per second. The temperature in the combustion chamber was set by technical task at the level of 800 °. Due to some characteristic features of gas turbine power plants for ground equipment, before the development of the main project had to be created, several auxiliary ones had to be created. A team of engineers led by Muller at the same time created and reviewed five versions of the architecture and layout of the CCD.

The schematic diagrams of the engine differed from each other in the number of compressor steps, the turbine, and the location of the power turbine associated with the transmission. In addition, several options considered arrangement of the combustion chambers. Thus, in the third and fourth versions of the layout of the CCD, it was proposed to divide the air flow from the compressor into two. One stream in this case had to go into the combustion chamber and from there to the turbine, which rotates the compressor. The second part of the incoming air, in turn, was injected into the second combustion chamber, which gave hot gases directly to the power turbine. Also considered options with different position of the heat exchanger for preheating the air entering the engine.

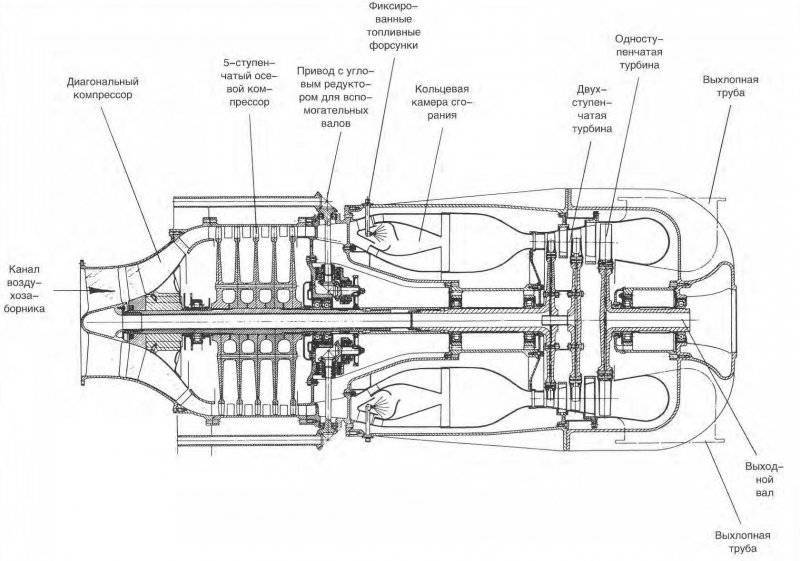

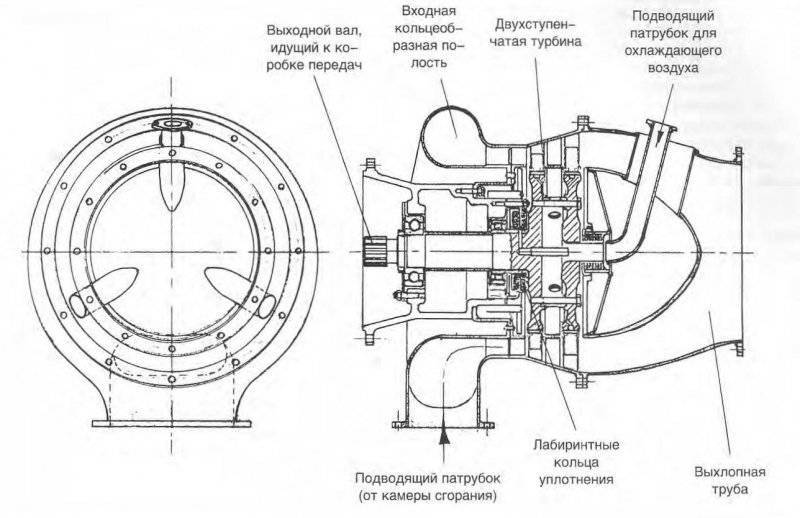

In the first variant of the promising engine, which reached the stage of full-fledged design, the diagonal and axial compressors, as well as the two-stage turbine, should have been on the same axis. The second turbine was supposed to be placed coaxially behind the first and connected to the transmission units. In this case, the power turbine, which supplies power to the transmission, was proposed to be mounted on its own axis, not connected with the axis of the compressors and the turbine. This solution could simplify the design of the engine, if not for one serious flaw. So, when removing the load (for example, during gear changes), the second turbine could spin up to such speeds at which there was a risk of destruction of the blades or the hub. It was proposed to solve the problem in two ways: either to slow down the working turbine at the right moments, or to divert gases from it. According to the results of analyzes, we chose the first option.

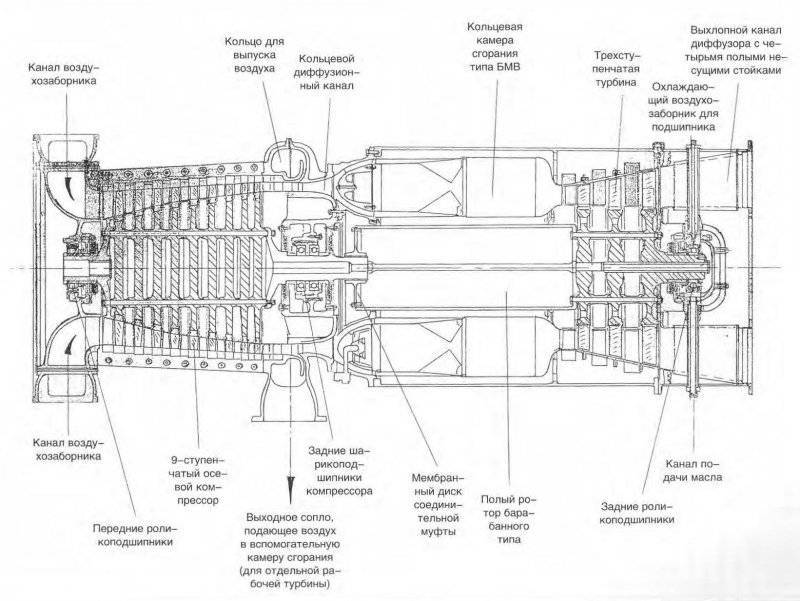

And yet the modified first version of the tank GTE was too complicated and expensive for mass production. Muller continued further exploration. To simplify the design, some original parts were replaced with corresponding units borrowed from the Heinkel-Hirt 109-011 turbojet engine. In addition, several bearings were removed from the design of the tank engine, which held the engine axles. Reducing the number of supporting elements of the shaft to two simplified the assembly, but forced to abandon a separate axis with a turbine that transmits torque to the transmission. The power turbine was installed on the same shaft, on which the compressor impellers and the two-stage turbine were already located. In the combustion chamber provided the original rotating nozzles for spraying fuel. In theory, they allowed fuel to be more efficiently injected, and also helped to avoid overheating of certain parts of the structure. An updated version of the project was ready in mid-September 1944.

This option was also not without flaws. First of all, the claims caused difficulties with maintaining torque on the output shaft, which was actually a continuation of the main shaft of the engine. The ideal solution to the problem of power transmission could be the use of an electric transmission, but the shortage of copper made us forget about such a system. As an alternative to electrotransmission, a hydrostatic or hydrodynamic transformer was considered. When using such mechanisms, the power transfer efficiency decreased slightly, but they were significantly cheaper than a system with a generator and electric motors.

GT 101 Engine

Further elaboration of the second version of the project led to the next changes. Thus, in order to preserve the efficiency of the CCD under shock loads (for example, when a mine exploded), a third shaft bearing was added. In addition, the need to unify the compressor with aircraft engines led to a change in some of the parameters of the tank GTE. In particular, air consumption increased by about a quarter. After all the improvements, the draft of the tank engine received a new name - GT 101. At this stage, the development of a gas turbine power plant for tanks reached the stage where it was possible to begin preparations for the construction of the first prototype, and then the equipped GTD tank.

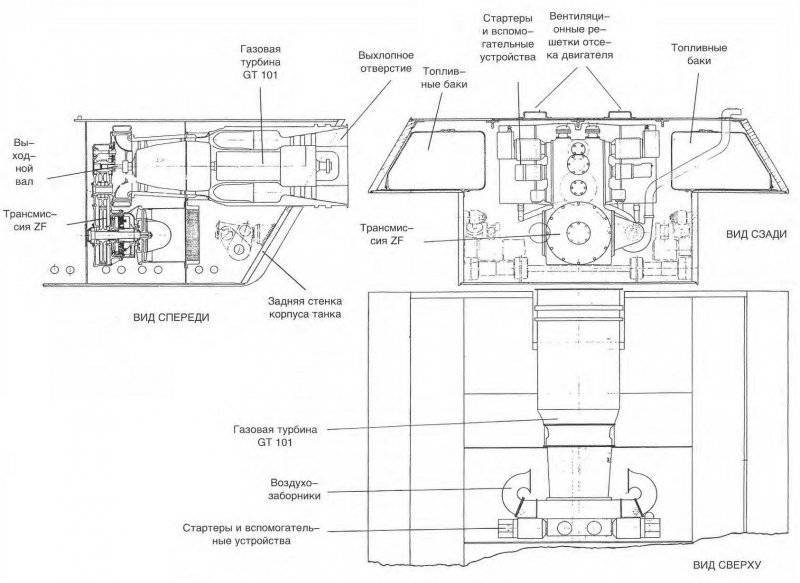

However, the engine refinement was delayed and by the end of the autumn of 1944, work on installing a new power plant on the tank had not begun. At that time, German engineers worked only on locating the engine in existing tanks. It was originally planned that the base for the experimental GTE will be a heavy tank PzKpfw VI - "Tiger". However, the engine compartment of this armored car was not large enough to accommodate all the necessary units. Even with a relatively small volume, the GT 101 engine was too long for the Tiger. For this reason, it was decided to use the PzKpfw V tank, also known as the Panther, as a base testing machine.

At the stage of finalization of the GT 101 engine for use on the Panther tank, the customer, represented by the Army Armaments Directorate and the project performer, determined the requirements for an experimental vehicle. It was assumed that the CCD will bring the specific power of the tank with a combat weight of about 46 tons to the level of 25-27 hp. per ton, which will significantly improve its driving performance. At the same time, the requirements for maximum speed almost did not change. Because of the vibrations and shocks that occur when driving at high speeds, the risk of damage to parts in the undercarriage significantly increased. As a result, the maximum allowed speed of movement was limited to 54-55 kilometers per hour.

As in the case of the "Tiger", the engine compartment of the "Panther" was not large enough to accommodate the new engine. Nevertheless, the designers, under the leadership of Dr. Miller, managed to fit the GT 101 GTE into the existing volumes. True, the large exhaust pipe of the engine had to be placed in a round hole in the stern armor plate. Despite the seeming oddity, such a solution was considered convenient and suitable even for mass production. The GT 101 engine on the experimental "Panther" was supposed to be placed along the axis of the hull, with a shift upwards, to the roof of the engine compartment. Next to the engine, in the fender shelves of the hull, in the project put several fuel tanks. The place for transmission was found directly under the engine. Air intake devices brought to the roof of the hull.

Simplifying the design of the GT 101 engine, due to which it lost a separate turbine-related transmission, brought about a different complexity. For use with the new GTE had to order a new hydraulic transmission. The organization ZF (Zahnradfabrik of Friedrichshafen) in a short time created a three-stage torque converter with an 12-speed (!) Gearbox. Half of the gears were intended for driving on roads, the rest - for overcoming off-road. In the engine-transmission installation of the experimental tank also had to enter the automation, which monitored the engine operating conditions. A special control device had to monitor the engine speed and, if necessary, raise or lower the transmission, preventing the GTE from entering unacceptable modes of operation.

According to the calculations of scientists, the GT 101 gas turbine unit with transmission from ZF could have the following characteristics. The maximum power of the turbine reached 3750 hp, 2600 of which was selected by the compressor to ensure the operation of the engine. Thus, on the output shaft remained "only" 1100-1150 horsepower. The speed of rotation of the compressor and turbines, depending on the load, ranged from 14-14,5 thousand revolutions per minute. The gas temperature in front of the turbine was kept at a given level in 800 °. Air consumption was 10 kilogram per second, specific fuel consumption - depending on the operating mode of 430-500 g / hp.h.

GT 102 Engine

Having a uniquely high power, the GT 101 tank gas turbine engine had at least a remarkable fuel consumption, approximately two times higher than the similar figures available at that time in Germany for gasoline engines. In addition to fuel consumption GTE GT 101 had several technical problems that required additional research and correction. In this regard, the new GT 102 project began, in which it was planned to preserve all the successes achieved and get rid of the existing shortcomings.

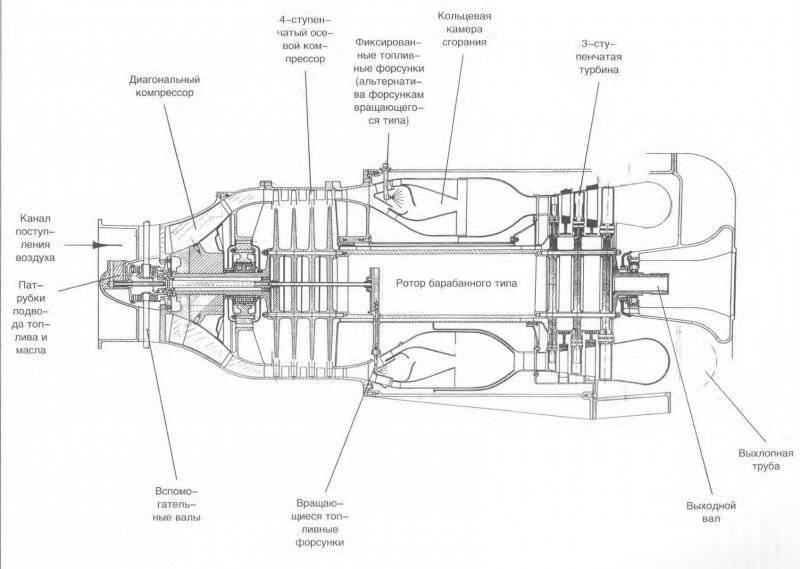

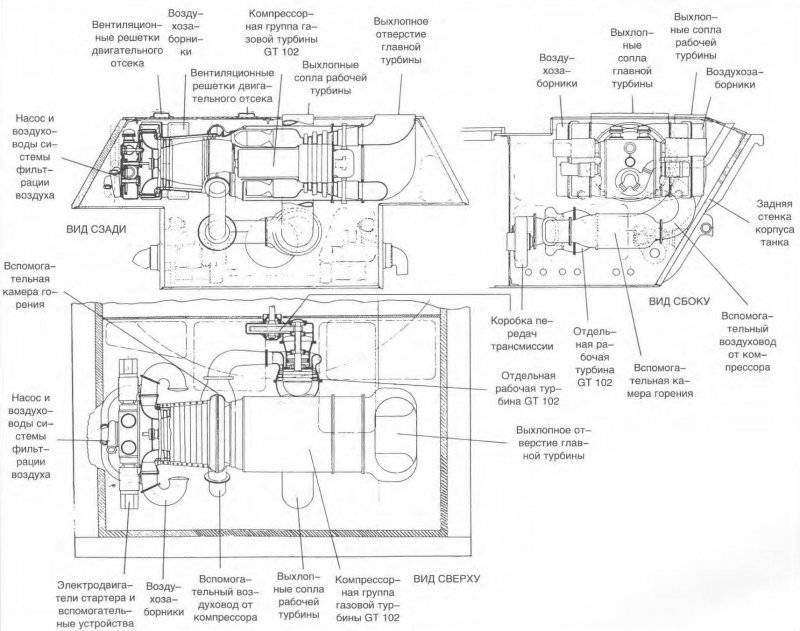

In December, 1944, the team of A. Muller came to the conclusion that it was necessary to return to one of the early ideas. To optimize the work of the new GTE, it was proposed to use a separate turbine on its own axis, connected to the transmission mechanisms. In this case, the power turbine of the GT 102 engine should have been a separate unit, not placed coaxially with the main units, as previously proposed. The main unit of the new gas turbine power plant was a GT 101 with minimal changes. It had two compressors with nine stages and a three-stage turbine. When developing the GT 102, it turned out that the main unit of the previous GT 101 engine, if necessary, can be placed not along, but across the engine compartment of the Panther tank. This was done when assembling the units of the experimental tank. The air intake units of the CCD are now located on the roof at the left side, the exhaust pipe at the right side.

Between the compressor and the combustion chamber of the main engine block, a pipe was provided for taking air to the additional combustion chamber and the turbine. According to calculations, 70% of the air entering the compressor had to go through the main part of the engine and only 30% through an additional one, with a power turbine. The location of the additional unit is interesting: the axis of its combustion chamber and the power turbine should have been located perpendicular to the axis of the main engine block. The units of the power turbine were proposed to be placed below the main unit and equipped with their own exhaust pipe, which was removed in the middle of the roof of the engine compartment.

The “congenital disease” of the gas turbine engine scheme used in GT 102 was the risk of excessive unwinding of the power turbine and its subsequent damage or destruction. It was proposed to solve this problem in the simplest way: to place valves for flow control in the pipe supplying air to the additional combustion chamber. At the same time, calculations showed that the new GT 102 GTE may have insufficient acceleration due to the peculiarities of the relatively light power turbine. Estimated technical characteristics, such as power at the output shaft or the power of the turbine of the main unit, remained at the level of the previous GT 101 engine, which can be explained by the almost complete absence of major structural changes, except for the appearance of a power turbine unit. Further improvement of the engine required the use of new solutions or even the opening of a new project.

Before starting the development of the next GTE model called the GT 103, Dr. A. Muller attempted to improve the layout of the existing GT 102. The main problem of its design was the fairly large dimensions of the main unit, which made it difficult to place the entire engine in the engine compartments of the tanks available at that time. To reduce the length of the engine-transmission installation, it was proposed to run the compressor as a separate unit. Thus, inside the engine compartment of the tank it was possible to place three relatively small units: a compressor, a main combustion chamber and a turbine, as well as a power turbine unit with its own combustion chamber. This version of the GTE was named GT 102 Ausf. 2. In addition to removing the compressor in a separate unit, attempts were made to do the same with the combustion chamber or turbine, but they did not have much success. The design of the gas turbine engine did not allow to divide itself into a large number of units without noticeable loss in performance.

GT 103 Engine

An alternative to the GT 102 Ausf gas turbine engine. 2 with the ability to "free" layout of units in the existing volume has become a new development GT 103. At this time, the German engine builders decided not to do the convenience of placement, and work efficiency. The structure of the engine equipment introduced heat exchanger. It was assumed that with its help, the exhaust gases will heat the air entering through the compressor, which will allow to achieve tangible fuel economy. The essence of this decision was that the preheated air would give the opportunity to spend a smaller amount of fuel to maintain the required temperature before the turbine. According to preliminary calculations, the use of a heat exchanger could reduce fuel consumption by 25-30 percent. Under certain conditions, such savings were able to make the new GTE suitable for practical use.

The development of the heat exchanger was entrusted to the "accessory" of the company Brown Boveri. The chief designer of this unit was V. Hrinizhak, who had previously participated in the creation of compressors for tank GTE. Subsequently, Hrinigak became known as an expert in heat exchangers and his participation in the GT 103 project was probably one of the prerequisites for this. The scientist applied a rather bold and original solution: the rotating drum made of porous ceramics became the main element of the new heat exchanger. Inside the drum were placed several special partitions that provided the circulation of gases. During operation, hot exhaust gases passed through the inside of the drum through its porous walls and heated them. This happened within half a turn of the drum. The following half-turns were used to transfer heat to the air flowing from the inside to the outside. Thanks to the system of partitions inside and outside the cylinder, the air and exhaust gases did not mix with each other, which excluded the engine from malfunctioning.

The use of a heat exchanger has caused serious controversy among the authors of the project. Some scientists and designers believed that the use of this unit in the future will allow to achieve high power and relatively low air flow rates. Others, in turn, saw in the heat exchanger only a dubious means, the benefits of which could not significantly exceed the losses from the complexity of the structure. In a dispute about the need for a heat exchanger, supporters of the new unit won. At some point, there was even an offer to complete the GT 103 GTE with two devices at once for air pre-heating. The first heat exchanger in this case was supposed to heat the air for the main engine block, the second for the additional combustion chamber. Thus, the GT 103 actually represented the GT 102 with the heat exchangers introduced into the design.

The GT 103 engine was not built, which makes it necessary to be content with only its design characteristics. Moreover, the available data on this CCD was calculated even before the end of the creation of the heat exchanger. Therefore, a number of indicators in practice, probably, could be significantly lower than expected. The power of the main unit, produced by the turbine and absorbed by the compressor, had to be 1400 horsepower. The maximum design speed of rotation of the compressor and turbine of the main unit is about 19 thousand revolutions per minute. The air flow rate in the main combustion chamber is 6 kg / s. It was assumed that the heat exchanger will warm the incoming air to 500 °, and the gases in front of the turbine will have a temperature of about 800 °.

According to calculations, the power turbine was supposed to rotate at a speed of up to 25 thous. Revolutions per minute and give the power of the 800 hp to the shaft. The air flow of the additional unit was 2 kg / s. The temperature parameters of the incoming air and exhaust gases, as expected, should have been equal to the corresponding characteristics of the main unit. The total fuel consumption of the entire engine with the use of appropriate heat exchangers would not exceed 200-230 g / hp.h.

Results of the program

The development of German tank gas turbine engines started only in the summer of 1944, when Germany’s chances of winning the Second World War melted away every day. The Red Army advanced from the east to the Third Reich, and the troops of the United States and Great Britain marched from the west. In such conditions, Germany did not have sufficient opportunities to fully manage the mass of promising projects. All attempts to create a fundamentally new engine for tanks rested in the shortage of money and time. Because of this, by February 1945, there were already three full-fledged projects of tank GTEs, but none of them even reached the stage of assembling the prototype. All work was limited to theoretical studies and testing of individual experimental units.

In February, 45-th event occurred, which can be considered the beginning of the end of the German program for the creation of tank gas turbine engines. Dr. Alfred Muller was removed from the post of head of the project, and his namesake Max Adolf Muller was appointed to the vacant seat. M.A. Mueller was also a prominent specialist in the field of gas turbine power plants, but his arrival at the project slowed down the most advanced developments. The main task under the new head was the finishing of the GT 101 engine and the beginning of its mass production. Until the end of the war in Europe, less than three months remained, which is why the change in project management did not manage to lead to the desired result. All German tank GTE remained on paper.

According to some sources, the documentation on the projects of the GT line fell into the hands of the allies and they used it in their projects. Nevertheless, the first practical results in the field of gas-turbine engines for ground-based machines, which appeared after the end of World War II outside Germany, had little in common with the developments of both Dr. Mullere. As for the GTE, designed specifically for tanks, the first production tanks with such a power plant left the assembly shops of factories only a quarter of a century after the completion of German projects.

Based on:

http://alternathistory.org.ua/

http://shushpanzer-ru.livejournal.com/

http://army-guide.com/

Kay, E.L. History development and creation of jet engines and gas turbines in Germany. - Rybinsk: NPO Saturn, 2006

Information