80 years to Chelyabinsk Tractor Plant

The sketch design of ChTZ was drawn up in the spring of 1930 at a special design bureau of Leningrad. Realizing that the construction of an enterprise of such a level as the Chelyabinsk Tractor Plant is possible only with the application of all the accumulated world experience, the country's leadership decided to conduct the final revision in the United States. In Detroit, the center of the American automotive industry, the design bureau Chelyabinsk Tract Plant was created. Twelve American and forty Soviet specialists made many changes to the initial sketches. Instead of the planned twenty separate buildings, it was decided to establish three workshops: mechanical, blacksmith and foundry. To be able to change production facilities, the reinforced concrete supporting structures of buildings were replaced with metal ones. Later, during the war years, this made it possible to quickly switch to production at the plant tanks. On June 7, 1930, the ChTZ master plan was completed, and by August 10, workshops were laid.

The first builders met with great difficulties: there was no equipment, housing and medical care. There was a shortage of materials, and by the end of 1930, funding for the construction site had sharply decreased. Of the forty-three thousand workers who arrived here on 1930, thirty-eight thousand people left by the end of the year. The construction was threatened. However, 11 may 1931 of the year I.V. Stalin declared that the Chelyabinsk tractor falls under the special supervision of the Central Committee of the CPSU (b). After that, the construction of the plant went at an accelerated pace. In 1932, a comprehensive installation of production equipment began, with three hundred and seven companies from the USA, Germany, France and England, as well as more than one hundred and twenty domestic factories participating in the delivery. In general, the share of Soviet equipment was more than forty-three percent. What was done in three years was amazing. The endless field turned into a growing city. There, where recently there was one dirt, there were brick houses and huge workshops, there were asphalt roads. In the factory area there was a kitchen factory, a club, a cinema and a training complex.

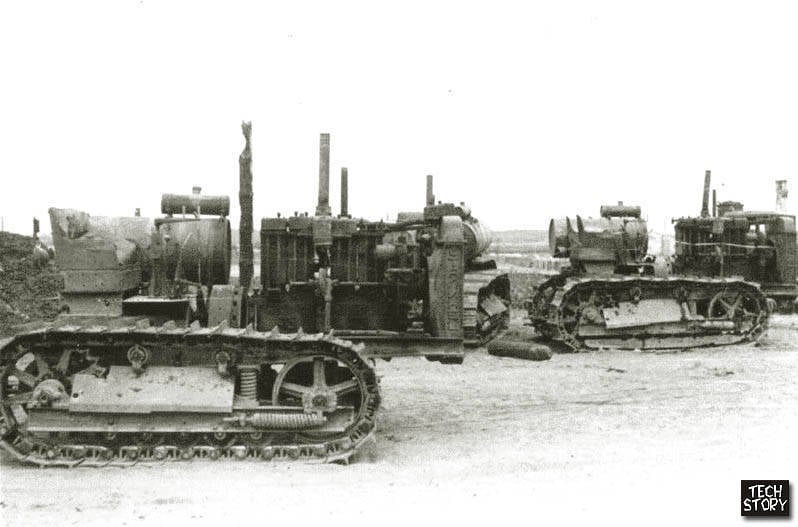

The first tractors produced ChTZ them. Lenin, worked on naphtha fuel, and only after a significant renovation in the 1937 year, the company launched the production of new diesel vehicles created on the basis of C-60, but five horsepower more than its predecessor. Already in May of the same year, C-65 became the winner of the Paris World Exhibition, receiving a well-deserved diploma "Grand Prix" from its organizers. The serial production of these fuel-efficient machines was established at ChTZ 20 on June 1937 of the year, thanks to which the company became a pioneer in the domestic tractor industry, producing diesel tractors. In total, from 1937 to 1941, the plant produced about thirty-eight thousand C-65 tractors.

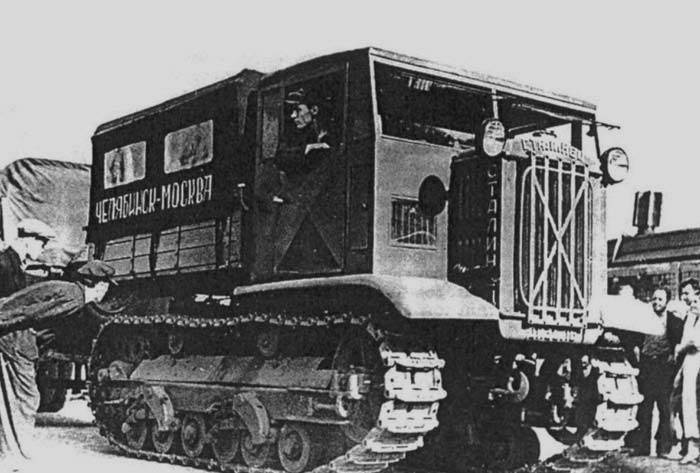

In the 1939 year, the company expanded its product range, having mastered in parallel the production of a tractor for artillery C-2 or Stalinets-2. Its power was already one hundred and five horsepower. The 30 day of March of the 1940-th Chelyabinsk plant marked a new achievement: the 100-thousandth tractor rolled off its assembly line that day. The meticulous statisticians calculated that the total power of all the machines released up to this point on the plant was six million horsepower, which is approximately equal to the power of ten DniproHES.

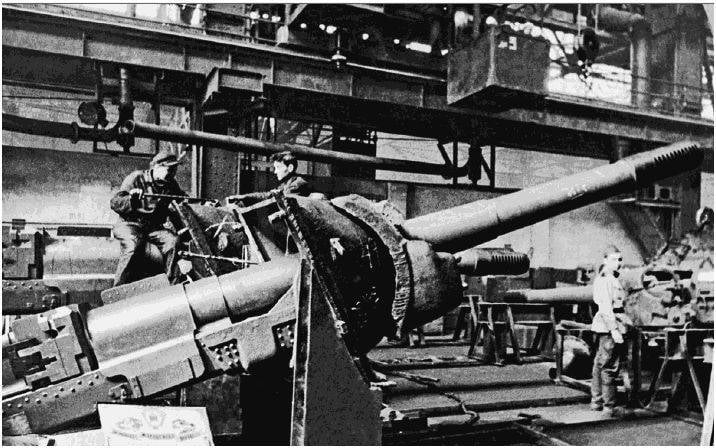

Waiting for the war in the air required a reorientation of production, and in 1940, at ChTZ, intensive research and preparation for the production of heavy tanks (such as KV) were carried out together with the designers of the Kirov factory in Leningrad. At the same time preparing to release a fuel pump for the engines of T-12 bomber planes. The first tank was received at the CTZ by the state commission on the last day of 1940.

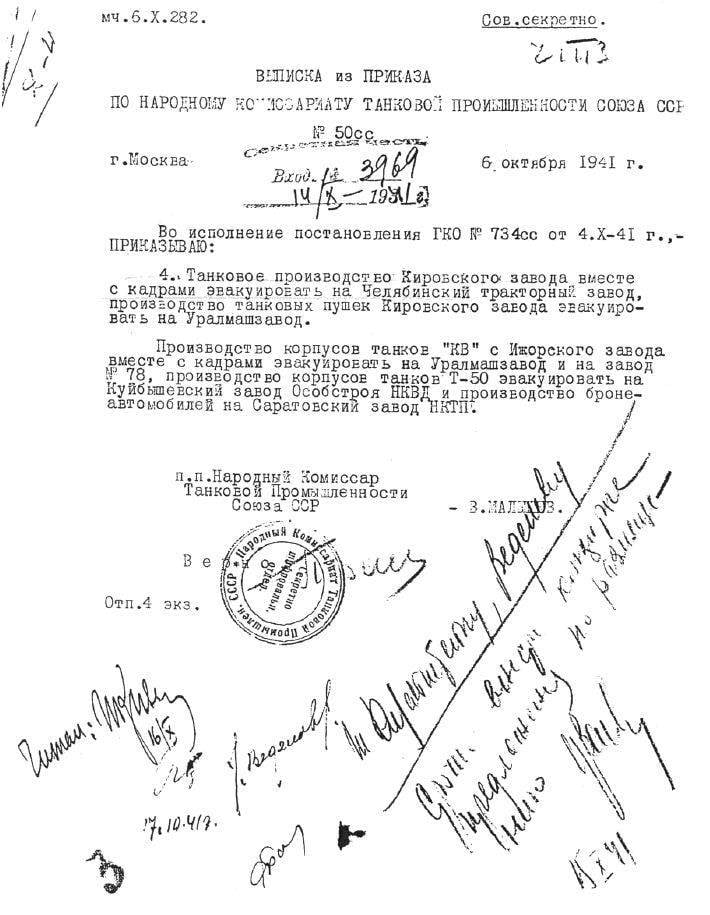

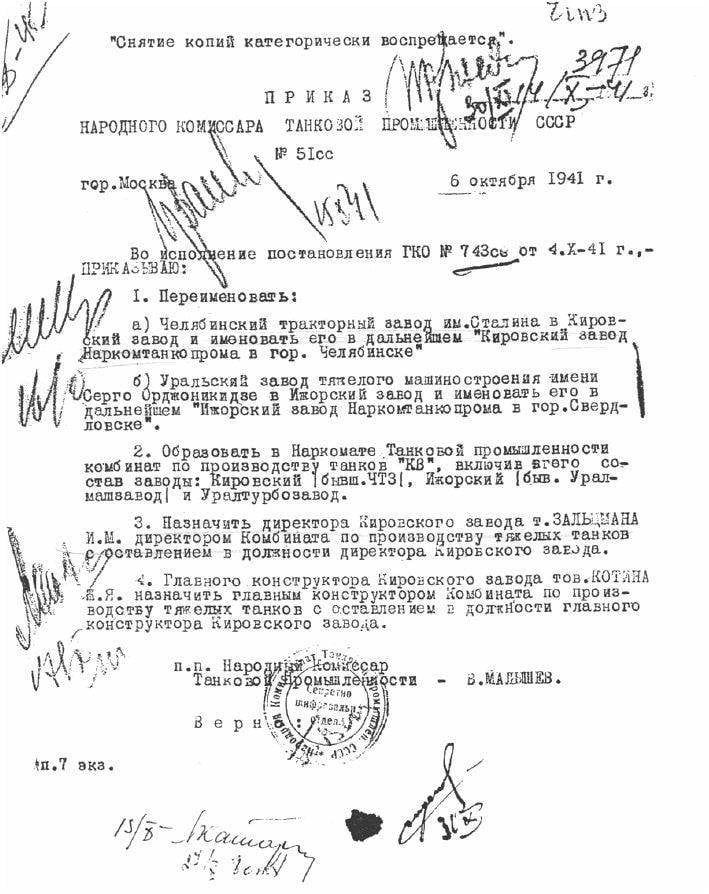

The beginning of the invasion of the fascists and their rapid advance on our territory in 1941 forced the country's leadership to conduct an urgent evacuation of all large enterprises deep into the USSR, in particular to the Urals. The main production shops and specialists of the Kirov Plant were shipped to Chelyabinsk from Leningrad as soon as possible. The production was deployed on the territory of CTZ. Later, the Kharkov Motor Plant and five more enterprises, evacuated from the territories already captured by the enemy, were added to it. On the move, in the cold, among the snowdrifts, people unloaded the equipment, immediately put the machines on the foundations and started up. Only later were the walls erected around the equipment and the roof was erected. In the shortest possible time, seventeen new workshops were built and launched. As a result, on the site of the former Chelyabinsk Tractor Plant, the largest machine-building plant for the production of military equipment and weapons under the conditional name "Tankograd".

Officially, from October 6, 1941, the enterprise became known as the Kirov Plant of the People's Commissariat of the Tank Industry. Even after the end of the war, for twenty years, Chelyabinsk people produced their products under the Kirov factory brand.

Production of tanks was started from one or two a day, but soon this number was brought to twelve or fifteen. All workshops worked on the barracks position. In cold rooms, people worked sixteen to eighteen hours, systematically malnourished and lack of sleep, with full dedication. No one left their seats until they fulfilled two or three norms per shift. Truly the essence and meaning of the life of the collective of the plant were the words: “All for the front! All for the victory! The company's specialists managed to put on stream the assembly of the EC-1, EC-2, EC-3 and KV tanks. The Chelyabinsk Kirov Plant slowly became the country's main military supplier, producing the latest and best military equipment, without which it would have been impossible to resist such a well-trained and equipped enemy as the German army. The ISs represented all the best that domestic heavy tank building could offer. They harmoniously combined speed, armor and weapons. It is lighter than the heavy tanks of the Germans, with thicker armor and a more powerful gun, they had no equal in maneuverability. After ISa appeared on the battlefields, the command of the Third Reich forbade its tankmen to contact them in open battle.

In addition to heavy tanks, the plant produced the most famous and widely used T-34, as well as the SU-152 (SAU). In total, in wartime, Tankograd produced and sent to the front eighteen thousand self-propelled artillery systems and tanks of various types, eighteen million billets for ammunition and forty-nine thousand diesel engines for tanks. Despite the tension of the situation, the engineering minds of the enterprise fruitfully worked, which during the war created thirteen new types of self-propelled guns and tanks, as well as six types of diesel engines for these combat vehicles. The Red Banner of the State Defense Committee, as the winner of the All-Union competition, was awarded thirty-three times for selfless labor and outstanding achievements to the plant team for the entire war period. Two banners were even left in the company for eternal storage. 5 August 1944 year for achievements in the development and production of new types of equipment and invaluable assistance to the army, the plant was awarded the Order of the Red Star and the Order of Lenin. The second Order of Lenin Design Bureau of the plant received for achievements in the development and production of tank diesel engines 30 April 1945-th year.

At the end of the war, the work of the enterprise re-entered the peaceful course, and on 5 on January 1946, the plant launched its first post-war brainchild, the Stalinet-80 tractor or C-80, which already used a closed type cabin. Since mid-July, 1946, the company has started mass production of this indispensable machine for the post-war economy, which was subsequently widely used not only during the development of fallow virgin lands, but also during the construction of the largest and most large-scale facilities of the Soviet Union. By the way, from the entire fleet of machines that carried out earthworks during the construction of the Volga-Don Canal, the ChTZ tractors made up more than half of the available equipment and performed most of the work.

Historical for Chelyabinsk Tractor Day is June 20, 1958, when the company was finally returned to its original name. By that time, the plant had already mastered the production of the new T-100 machine, which in 1961 won the gold medal of the international exhibition. The T-100 tractor (popularly nicknamed "weaving") was distinguished by a high level of comfort inside the cab for the sixties, it had a soft seat, lighting, and forced ventilation. A number of machines of this type are still in operation. The tractor was produced by the enterprise until 1963, when its improved model T-100M (108 horsepower) was introduced into production, also awarded the highest international award in 1968.

By the 1964 year, ChTZ had already produced twenty-two models of the T-100M tractor, among which a significant part was occupied by machines with increased productivity and reliability for work in the marshland, the permafrost zone, and also on sandy soils. And in January 1961, the Chelyabinsk plant launched into production a completely new type of diesel-electric tractors DET-250, with a capacity of three hundred and ten horsepower and three times later awarded with medals at international exhibitions (in 1960, 1965 and 1966 th)

Without stopping the production of tractors, in the late sixties a major reconstruction of the enterprise began and its complete re-equipment in accordance with the new requirements of the time and preparation for the manufacture of tractors of the new generation T-130. The construction of new facilities and the reconstruction of ChTZ 26 on May 1970 received the status of the All-Union Komsomol construction site. And already on 22 on January 1971, the plant received another award, the Order of Lenin, for excellent performance in fulfilling the tasks of the five-year production development plan. It was on the basis of this plant on November 10 of the 1971 of the year that the first production association in the history of Soviet engineering was created, ChTZ im. Lenin ”, uniting four more production branches.

31 of May 1983 of the year to the anniversary of the establishment of the company received the Order of the Red Banner of Labor, and 1 June in the square in front of the plant on the pedestal was installed the first-born CTZ and the first domestic tracked vehicle C-60. To the golden date, the plant specialists timed the release of the world's first heavy-duty tractor T-800, used to disassemble the rocks in particularly difficult conditions, where explosives are powerless. The significant for ChTZ became the 3 day of November 1984 when the millionth tractor rolled off the production line with the label of the company. And September 1988 of the year was marked by another unusual achievement: the T-800 bulldozer-ripper was entered into the Guinness Book of Records for the highest performance and gigantic dimensions.

With 1992, a new stage began in the life of CTZ. First, on April 30, the Government of the Russian Federation decided to privatize it. Then, on October 1, the production association turned into the OJSC URALTRAC. But after three and a half years, 27 on April 1996, the same meeting decided to change the name to Chelyabinsk Tractor Plant OJSC. The difficult situation in the country, the wrong financial policy, despite the demand for the company's products on the market, led in 1998 to the recognition of ChTZ as bankrupt and its complete reorganization. However, the legendary enterprise managed to survive; after the changes that had been made, a new machine-building giant appeared in the market, called ChTZ-Uraltrak LLC.

The celebration of the seventieth anniversary of the 1 plant on June 2003 of the year took place in a solemn ceremony, when a whole column of cars proceeded from the gate of the enterprise to the townspeople, in which all tractor models produced at different times were displayed. The C-65 legend, and later modernized tractors brands, participated in the parade of tractors. Among the samples of military equipment could be seen as "old man" T-34, and in the arsenal of the modern Russian army BMP-1 and T-72. The column that followed along the main street of Chelyabinsk enabled the residents of the city to see firsthand the engineering vehicles produced by the plant, wheeled and small-sized vehicles. In the future, this interesting exposition was installed on a prepared demonstration site, which was visited by several tens of thousands of residents and guests of the city in a few days.

Separate models of tractors created at ChTZ repeatedly became winners of a well-known competition among domestic manufacturers under the name “100 best goods of Russia”: in December 2004, the DET-320 model was awarded this honor, in December 2010, the T13 tractor and loader PC-65, and in 2011-ohm - bulldozer B-8. In addition, the company itself was awarded awards for high quality products. Another evidence of recognition of the credibility of the plant was the election of the Director General of ChTZ V. Platonov to the post of head of the committee of the Russian Chamber of Commerce and Industry in July of 2006.

Obtaining a European quality certificate for one of the models produced by the enterprise (11 bulldozer) in June, 2009, and a certificate of labor protection in June, 2010, opened the way for CTZ to the European market with the possibility of organizing joint production. The result of the fruitful cooperation with the Italian partners was the foundry mini-plant launched in September of the 2010. And in January of the same year, the company began to test the latest bulldozers using the GLONASS satellite navigation system.

In March, 2011 of the year Uralvagonzavod Corporation acquired a controlling stake of CTZ (63,3%), which in total with the shares already owned by this company amounted to about 80%. The agreement between UVZ and ChTZ was rightly called the “2011 Deal of the Year.” The main direction of production of the plant as part of UVZ was the production of civilian road-building equipment. Thus, today ChTZ is one of the largest industrial associations in Russia, which can offer Russian and foreign consumers not only high-quality tractors, bulldozers and engineering vehicles, but also high-capacity pipe layers, vibratory rollers, loaders and diesel engines, as well as diesel engines. generator sets and diesel-hydraulic stations, spare parts for own-produced tractors, mini-tractors and utility machines. In recent years, the plant’s products were introduced not only in the former Soviet republics, but also in sixteen foreign countries, including the states of Eastern Europe, Vietnam, India, Indonesia, the United Arab Emirates and many others. Large export orders for foreign countries, as well as domestic orders of Rosleskhoz, oil and gas corporations allowed the company to finally solve all financial problems and resume recruitment of personnel for the first time in many years.

Information sources:

http://chtz-uraltrac.ru/news/topics/233.php

http://www.bronetehnika.narod.ru/stalinec-60i65/stalinec-60i65.html

http://www.t-magazine.ru/Reviews/HISTORI_CHTZ/

http://www.minpromtorg.gov.ru/special/65/6

Information