Continuous earth-moving machines of the engineering troops of the USSR

The high-speed trenching machine BTM is intended for fragments of trenches and lines of communication in soils up to category III, inclusive, with a dump of excavated soil on both sides of the trench being torn off. As the working equipment applied rotor ...

Multi-bucket excavators (continuous)

Continuous excavators are earth-moving machines that develop and transport soil continuously. In this case, both operations - digging and transportation of soil - is performed simultaneously. Unlike single-bucket excavators, continuous excavation provides higher output, however, the main drawback of continuous machines is their low versatility. Each digger, whether chain or bucket wheel trenchers, excavators - drenoukladchiki, rotary snow and two-rotor backhoe kanalokopateli, reclamation, multi-bucket excavator cross-digging, and even more so - the major career multi-bucket excavators - they are designed to perform specific operations and can not be used on other works.

High-speed trenching machines BTM

The high-speed trenching machine BTM is intended for fragments of trenches and lines of communication in soils up to category III, inclusive, with a dump of excavated soil on both sides of the trench being torn off. As a working equipment, a rotor with 8 th buckets with a capacity of 160 l was used.

Maximum machine capacity with a trench width at the top of 1,1 m, at the bottom - 0,6 m and at a depth of 1,5 m - 800 m / h. The machine was developed on the basis of the 409U Product, or, alternatively, a heavy artillery tractor AT-T, designed by the Kharkov machine-building plant named after Malyshev under the guidance of the famous Soviet tank builder A.A. Morozov (AT-Ts were produced from 1950 to 1979). On the tractor is a diesel engine A-401 power 415 hp, allowing you to reach the transport speed to 35 km / h. The fuel reserve is enough for 500 km or 10-12 operating hours in the ground. The cabin is sealed, equipped with a filter-ventilation installation, the crew - human 2. Machine weight - 26,5 t.

Production of trenching machines BTM started with 1957 in the Dmitrovsky excavator plant. The rotor was raised and lowered by a troso-block system using a U-shaped frame. Buckets were closed, which affected the performance of the machine: when working on clay and wet soils, buckets were clogged with earth and were not cleaned in an upright position, so it was necessary to clean them manually. Presumably, this disadvantage is eliminated on the modification of the machine BTM-2, which used buckets with chain bottoms. On a further modification of the BTM-3, the mechanism for raising and lowering the rotor was changed, and such machines were produced until the end of the 70s.

Machine BTM-4 - a prototype; The AT-T tractor was used as the base. Later a new MT-T multi-purpose tracked tractor was used. Serial production under the index BTM-4M.

Trench high-speed machines BTM entered service with the engineering troops of the USSR Armed Forces. For national purposes, the BTM-TMG (rotary) and BTM-TMG-2 (chain) machines were developed and produced.

High-speed trenching vehicle BTM based on the AT-T tractor. The machine is installed on a pedestal near the Ministry of Emergency Situations of Ukraine. Photos made RIO1.

The high-speed trenching vehicle BTM-3 on the basis of the AT-T tractor in the transport position is under test. Photo from the archive of the Kharkov Morozov Design Bureau.

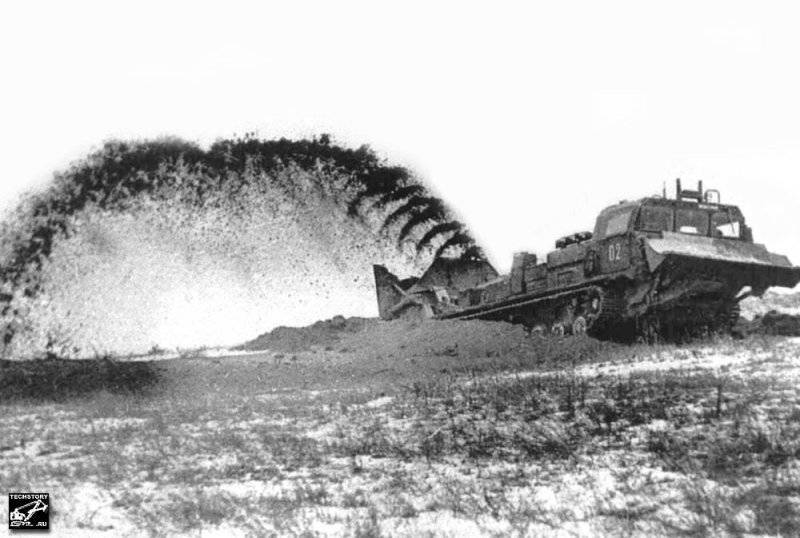

High-speed trenching machine BTM-3 based on the AT-T tractor in operation. Photo from the archive of the author's website techstory ru.

High-speed trenching vehicle BTM-3 based on AT-T tractor. Photos were taken on the basis of the Emergencies Ministry Madzhivka in the Leningrad region F. Shilnikov.

BTM-3 machines. Photos from the archive of the author's website techstory ru.

High-speed trenching machine based on the MT-T tractor (prototype 1978). Photo from the archive of the author's website techstory ru.

TMK trenching machines

The trenching machine TMK is a wheeled tractor MAZ-538, on which a working body for fragments of trenches and dozer equipment are mounted. The machine allows the passage of trenches in soils up to category IV, inclusive. The separation of trenches in thawed grounds at a depth of 1,5 m is carried out at a speed of 700 m / h, in frozen soils 210 m / h.

The working body is rotary, free-flow type. The working equipment includes a mechanical transmission drive and a hydraulic mechanism for raising and lowering the working body. On the frame of the working body are installed retractors of the passive type, ensuring the formation of inclined trench walls. The soil raised from the trench is thrown by throwers on both sides of the trench.

Installed auxiliary dozer equipment with a blade width of 3,3 m allows land leveling, backfilling of holes, ditches, digging of pits, etc.

The basic all-wheel drive wheeled tractor MAZ-538 is equipped with the D-12А-375А engine with the HP 375 power.

TMK machines were manufactured from 1975, at the Dmitrovsky Excavator Plant. Later on the TSKT-538DC wheeled tractor produced a modernized trenching machine TMK-2.

Trench machine TMK-2 on the basis of all-wheel drive tractor КККТ-538ДК. Photos taken by E. Bernikov.

Trench machine TMK-2 based on KZKT-538DC 1982 tractor unit. Photo from the archive of the author's website techstory ru.

Pit cars MDK and MKM

With the transfer of production in 1946 to the T-54 tank, the designers of the Kharkov Design Bureau named after A.A. Morozov, under the leadership of M.N. Shchukin and A.I. Avtomonov, began to develop the tractor ed.401 based on this tank. These works were carried out on the instructions of GAU and TsAVTU. The tractor was successfully tested, and in 1953 the first production samples of the AT-T (heavy artillery tractor) were released.

The MDK-2 excavation machine (MDK-2m) is an earthmoving machine based on the heavy artillery AT-T tractor (produced from 1950 to 1979 in Kharkov. Malyshev Machine Building Plant) and is intended for excerpts of pits of 3,5 X 3,5 size and any length various soils up to category IV inclusive. The dozer equipment available on the machine allows to plan the site before the fragment of the excavation, to clean and level the bottom of the excavation, to fill holes, ditches, trenches and excavations and so on.

With a passage of excavations, the excavated soil is laid in one direction to the right of the excavation in the form of a parapet at a distance of 10 m. In one pass, the recess is 30-40, see. Type of tool - milling cutter with a thrower; technical performance - 300 m3 / h; vehicle transport speed - 35,5 km / h.

The digging machine MDK-3 (the first, prototype) is intended for extracts of excavations with a width of 3,5 m and a depth of up to 5 m for hiding equipment. The basic tractor is an AT-T tractor with an additional power unit, with the result that the installed engine power reaches the HP 1115 !!! Machine productivity on grounds II - III categories - 1000 - 1200 м3 / h. Machine weight - 34 t.

The MDK-3 excavation machine (late, serial version) is a further development of the MDK-2м machine and is intended for extracts of trenches and shelters for equipment, excavations for fortifications. The base machine is a multipurpose heavy tracked carrier conveyor MT-T, developed by the Kharkov Design Bureau named after. A.A. Morozov and graduated from 1976 to 1991. Kharkov machine-building plant them. Malyshev.

When digging pits, the developed soil is laid in one direction to the left of the pit in the form of a parapet. In contrast to MDK-2, the pit excavation machine MDK-3, with a passage excavation, moves backward, tearing the excavation depth to 1,75 m in one pass. The auxiliary equipment is powerful dozer equipment and a ripper for frozen soils, which significantly increased the capabilities of the machine compared to the previous one. Technical performance of the machine - 500 - 600 m3 / h; transport speed - 65 km / h.

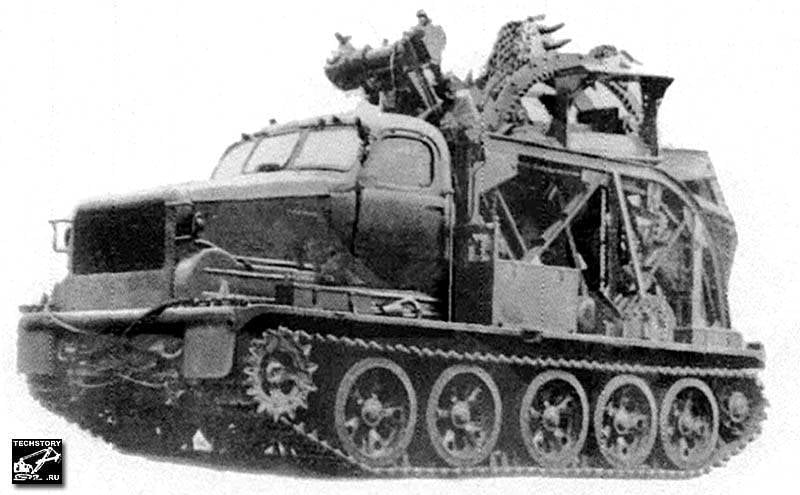

Experienced excavation machine MKM based on the AT-T tracked tractor in the transport position. Photo from the archive of the author's website techstory ru.

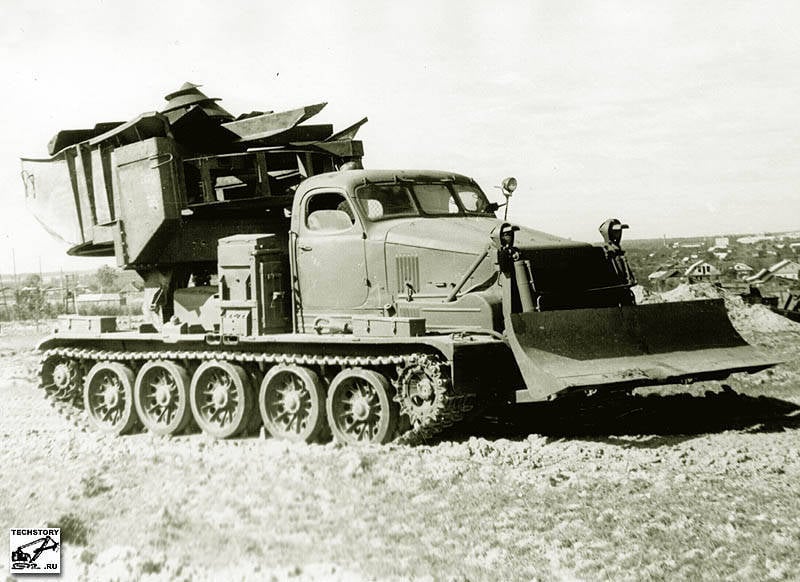

Boiler MDK-2 on the basis of the AT-T tracked tractor in the transport position. Photo from the archive of the author's website techstory ru.

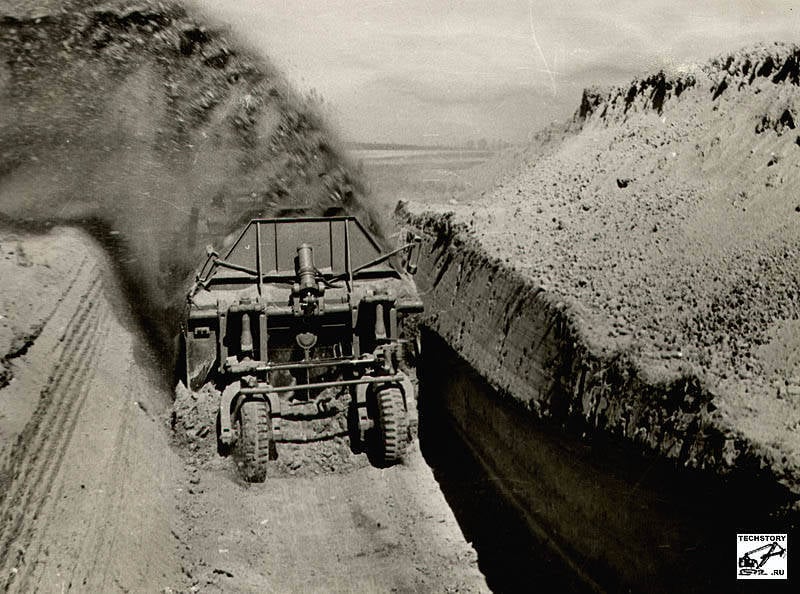

Extract of the pit machine MDK-2. Photo from the archive of the author's website techstory ru.

Boiler MDK-2m on the AT-T tracked tractor in the transport position. Photo from the archive of the author's website techstory ru.

Boiler MDK-3 on the basis of the AT-T tracked tractor in the transport position, front view. Prototype. Photo from the archive of the author's website techstory ru.

The pit mine MDK-3, front view. Prototype. Photo from the archive of the author's website techstory ru.

Excerpt boiler machine MDK-3. Photo from the archive of the author's website techstory ru.

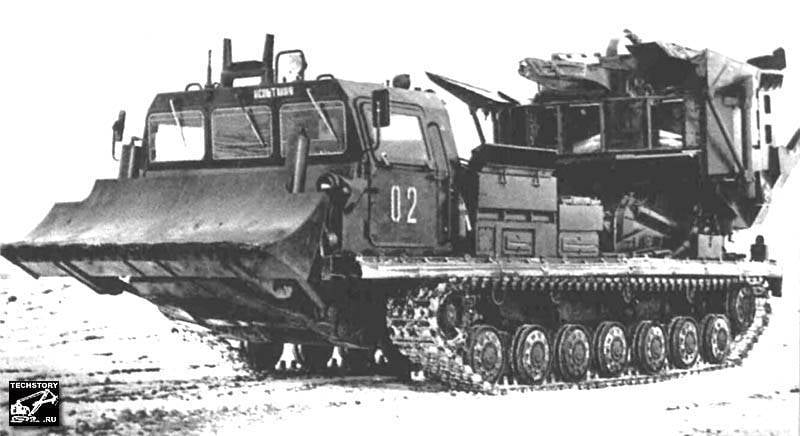

The pit mine MDK-3 on the MT-T tracked tractor in the transport position is under test. Photos from the archive of Kharkiv Design Bureau named after AA Morozov.

The pit mine MDK-3 on the MT-T tracked tractor in operation. Photos from the archives of the Kharkiv Design Bureau named after AA Morozov.

The pit mine MDK-3 on the MT-T tracked tractor. Author photo A.Kravets.

DZM and PZM earth-moving machines

The regimental digging machine PZM-2 refers to trench-trenched machines intended for fragments of trenches and ditches for fortifying equipment of positions, areas of troops and control points. In thawed ground, the machine provides a fragment of trenches and pits, in frozen ground - only trenches.

Working equipment of the machine - chain free-flow with rotary thrower. Technical performance with a pit excavation - 140 м3 / h, trenches - 180 м3 / h. The dimensions of the trench to be torn off: width 0,65 - 0,9 m, depth - 1,2 m; dimensions of pits: from 2,5 to 3,0 m to a depth of 3 m.

Bulldozer equipment can be used for backfilling trenches, ditches and holes, as well as for cleaning roads in winter. The winch with traction force 5 t is used for self-pulling and to provide the necessary tractive effort when extracting pits and trenches in frozen soils with a wetted surface.

The PZM-2 earthmoving machine is mounted on a T-155 tractor tractor of the Kharkov Tractor Plant. It is equipped with an SMD-62 engine with an 165 horsepower.

The divisional earthmoving machinery DZM is a prototype of a trailed trench-trench machine equipped with two chain-free working bodies. A wheeled MAZ-538 is used as a tractor.

The PZM-2 earth-moving machine based on the T-155 1991 tractor. Photos from the archive of the author's website techstory ru

The PZM-2 earth-moving machine based on the T-155 tractor. Photo from the archive of the author's website techstory ru.

Earthmoving machines PZM-2. The photo was taken in the city of N.Novgorod by O. Chkalov.

Earthmoving machine PZM-2. Photo from the archive of the author's website techstory ru.

Opening of the trench using the PZM-2 excavator. Photos provided by I. Drachev, Director of Bryansk Department of Mechanization of Special Equipment, Ltd.

PZM-2 earthmoving machine based on BOOM. Photo courtesy of I.Drachev, Director of Bryansk Department of Mechanization of Special Machines.

DZM earthmoving machine in transport position. Photo from the archive of the author's website techstory ru.

The author would appreciate any information and photos of these machines.

Information