Mi-28 - combat helicopter

To achieve high tactical and technical indicators comparable to the characteristics of attack aircraft. AN-56A was equipped with a pushing propeller, a wing, a rigid rotorless rotor, as well as a complex set of aiming and flight-navigation equipment.

The resolution of the Central Committee of the CPSU and the Council of Ministers of the USSR on the creation of the Mi-6 adopted by 1968 in May included, among other things, the development on its basis of a promising model of a rotary-wing attack aircraft with a higher flight speed, good stability and maneuverability. By the end of the year, the first project of the Mi-24 rotary-wing was completed in the advanced design department of the cost center, which was a further development of the Mi-28 without an airborne cargo cabin, but with a rigid main rotor, additional propulsion means and reinforced armament. Unfortunately, the customer’s lack of clear ideas about the appearance of such a device, the large workload of the company with current work, as well as the illness and death of ML Mil, did not allow for the immediate implementation of a new concept.

To the in-depth design development of a combat rotorcraft Mi-28 (product 280), the MVZ cost center employees. ML Mil under the direction of the new Chief Designer M.N. Tishchenko returned to 1972, when in the USA research was under way in full progress on a program similar to that of the AAN attack helicopter. The lead designer in the early stages was MV Olshevets. The command of the Soviet Air Force had formed by this time the basic requirements for a promising vehicle. The helicopter was supposed to serve as a means of supporting ground forces on the battlefield, destroying tanks and other armored vehicles, escorting helicopter assault forces, and combating enemy helicopters. As the main weapons it was supposed to use guided missiles of the Sturm anti-tank complex (up to eight missiles) and an 30-mm movable gun. The total weight of the combat load was estimated in 1200 kg. The cockpit, consisting of the pilot and operator, and the main components of the helicopter were to be protected from weapons of caliber 7,62 and 12,7 mm, flight-navigation complex - to ensure operation at any time of day and in any weather conditions. The maximum speed of the car was planned 380-420 km / h.

The cost center designers to them. Mil M. conducted aerodynamic, strength and weight calculations of promising projects, worked out various versions of power plants, schemes and layouts of Mi-28. Since the customer required equipping the helicopter with an emergency escape system, and the practice of flight tests conducted at Mil showed the difficulty of ensuring safe blades ejection, the developers considered the twin-rotor type rotary-wing scheme as a priority. He not only guaranteed safe ejection outside the screw disks, but also allowed the inclusion of a rotor wing in the design. In 1973, a project of such a machine with an take-off weight of up to 11,5 t, equipped with two TVZ-117F engines with an 2800 hp power, was made. each with two rotors with a diameter of 10,3 m and a pushing propeller. Pilot production has built an appropriate layout, units and systems were worked out in the OKB departments.

In the middle of 70's. The customer has revised the concept of using military helicopters. The tactics of combat operations (by analogy with attack aircraft) at relatively high altitude and speed gave way to tactics of actions at low altitudes with rounding of the terrain, which provided the helicopter with a high survival rate on the battlefield. In this regard, the cost center designers at the beginning of 70-s, as an initiative, developed technical projects of a number of combat helicopters without additional propulsion means. Among them are helicopter versions: a twin-screw transverse scheme with main rotors with a diameter of 8,25 m and two GTE-UFP engines with a power of 1950 hp. each; single-rotor scheme with the diameter of the main rotor 14,25 m and two engines GTD-SFM; single-rotor scheme with a rotor with a diameter of 16 m and two TVZ-117F engines. The last option was recognized as the most promising for the Mi-28. Milevtsy did not consider the two-screw coaxial scheme because of the fear of the possibility of the propeller blades catching during combat maneuvering.

The rejection of the rotor wing scheme allowed to significantly increase the weight and combat load, as well as simplify the design. The adoption of tactics of warfare at low altitudes allowed, moreover, to abandon the installation of the ejection system. Studies have shown that when a helicopter was hit at low altitudes, the crew did not have time to eject - they had to rely only on the strength of the vehicle’s hull and the means of survival. The concept of using safely deformable structures, energy-intensive chassis and energy-absorbing seats, which originated in the same years, created the prerequisites for ensuring the survival of the crew of a wounded helicopter without the mandatory ejection. Based on this, the designers chose to return to a constructively simpler classical single-rotor scheme. As the power plant, they chose to modify the powerful, reliable and already mastered by the industry TVZ-117 engines.

The search for the most rational appearance of the helicopter was accompanied by the harmonization of requirements for the weapon system, sighting and flight-navigation complex and other components, purging models in the wind tunnel, the formation of assessment methods and determining ways to increase combat survivability and survival, reduce visibility, carried out in specialized scientific research, development and flight testing organizations, the main among which from the very beginning of design have become TsAGI, NIIAS, LII, VIAM, GNIK Air Force. Kolomenskoye Design Bureau of Engineering, TsKB Sokol, Ramenskoye Instrument Design Bureau of MAP and others. Every year more and more customer organizations and ministries were involved in the development of a promising sighting, flight and navigation complex and weapons for combat helicopters aviation, defense, radio engineering and other industries. The design of the Mi-28 gradually took on the character of a national comprehensive program comparable in complexity of tasks to the construction of a new promising combat aircraft.

By 1976, the features of the appearance of the Mi-28 were mainly defined. All work on the combat vehicle was headed by the Deputy Chief Designer A.N. Ivanov, MV Weinberg was appointed responsible lead designer. He obeyed a whole group of leading designers, each of whom was responsible for a separate direction of the ambitious program. Designed at the cost center for them. ML Mile technical proposal received a positive customer evaluation. Formed a circle of co-executives on systems and complexes.

At the same time with the Milovsk project of a combat helicopter B-80 proposed to the government Ukhtomsky helicopter plant them. N.I. Kamova. Experts of the Kamov Design Bureau, having experience in using helicopters of a twin-screw coaxial scheme on ships, concluded that the devices of such a scheme would also be effective in solving the problems of fire support of ground forces. Kamovtsy proposed the original concept of a single-crew attack aircraft. The functions of the second crew member to a large extent had to take over the electronic complex.

16 December 1976 of the Central Committee of the CPSU and the Council of Ministers of the USSR adopted a resolution on the development of Mi-28 and B-80 helicopters (hereinafter Ka-50) on a competitive basis, and both companies started sketch projects. Since there was no specific tactical and technical assignment from the Air Force, the specialists of the cost center and the UVZ received wide discretion. Began unprecedented in stories aviation competition, in which the creators of rotary-wing machines had to invent and develop the concept of combat helicopters, based on their own understanding of the tasks facing the machine, and how to perform them, and then prove the viability of their concepts to the customer. As a result, firms began designing machines of a completely different class, differing in aerodynamic configuration, take-off weight, crew, weapons, equipment, etc. In contrast to the unparalleled Kamovsky B-80, the Mi-28 helicopter was designed at the MVZ cost center. Mil Mila in accordance with the concept of a two-seater combat vehicle with a clear division of functions (piloting, observation, target recognition, aiming, communication and weapon control) between two crew members, which was accepted all over the world and confirmed its viability in real combat operations. As a prototype Milovets took the Mi-24 and the best foreign helicopter of a similar class - the American AN-64 Apache, which was to be surpassed by the main indicators.

When creating the Mi-28, the designers of the Mil Mil Helicopter Center in order to achieve weight perfection with the necessary strength, reliability and combat survivability applied new methods of optimal design that were tested when creating the heavy truck Mi-26. The sketchy design was accompanied by the elaboration of numerous layout options, including the original fuselage layout with the so-called "central core", i.e. with the placement of all vital parts and systems in the central longitudinal power frame, on the sides of which there were compartments with equipment and secondary units. However, the calculations showed the difficulty of achieving the necessary vibration and strength characteristics, the vulnerability of the equipment and forced to abandon the attractive scheme and return to the traditional layout of the all-metal semi-monocoque fuselage.

When creating the Mi-28, the designers of the Mil Mil Helicopter Center in order to achieve weight perfection with the necessary strength, reliability and combat survivability applied new methods of optimal design that were tested when creating the heavy truck Mi-26. The sketchy design was accompanied by the elaboration of numerous layout options, including the original fuselage layout with the so-called "central core", i.e. with the placement of all vital parts and systems in the central longitudinal power frame, on the sides of which there were compartments with equipment and secondary units. However, the calculations showed the difficulty of achieving the necessary vibration and strength characteristics, the vulnerability of the equipment and forced to abandon the attractive scheme and return to the traditional layout of the all-metal semi-monocoque fuselage.The combat survivability of the designers decided to provide duplication of units with their maximum separation and mutual shielding, wired up more important aggregates with less important ones, combining reservations, choosing materials and dimensions of the structure that exclude catastrophic damage to the structure in case of damage in sufficient time to complete the task and return to the base.

One of the key elements was the layout of the cockpit. Milevtsy immediately abandoned the location of the crew members nearby, since such a scheme did not provide the necessary viewing angles to the pilot and operator, and also complicated the emergency escape of the helicopter. The “tandem” scheme was recognized as the most successful (the pilot’s position was elevated above the operator’s position), i.e. scheme proven life on the Mi-24. In the future, the correctness of the choice was confirmed by international experience. During the design of the Mi-28, the pilot production cost centers built many layouts and models, including successively six full-size helicopter layouts that made it possible to optimally assemble the combat vehicle.

The most important element that fundamentally distinguished the Mi-28 from the Mi-24 was the separation of the engines. This event, firstly, guaranteed against simultaneous destruction of both engines, and secondly, the engines were an additional screening element that protected the main gearbox and helicopter control system.

By the end of 1977, the designers of the MVZ them. ML Mil completed the conceptual design, as well as coordinated with all affiliate companies all the programs for creating component systems for equipment and armaments. The next year and a half went to agree with the customer on all aspects of the tactical and technical tasks for the helicopter and its complex, and in 1979, the OKB began working on the design of the rotary-wing machine and tested the first experimental samples of the units and systems.

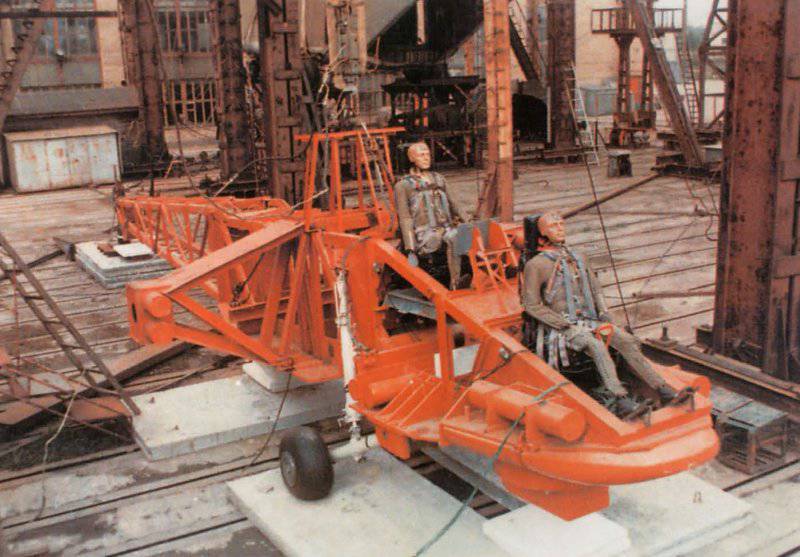

When designing the helicopter units, various design schemes and design solutions were worked out, new materials were widely introduced with strict observance of weight and strength control. In particular, as alternatives, the cost center specialists designed and built two types of fundamentally new bearing rotors of the Mi-28: elastomer and torsion, and also tested, along with the tail rotor, which has the traditional method of controlling the blade pitch, the experimental steering screw with a controlled flap , transmission shaft of carbon fiber. The selection of the most promising solutions was accompanied by comprehensive testing of the units on the stands. In total, the 54 stand was created, including a full-scale stand, an automatic static test stand, an electropower stand for testing the main gearbox, stands for testing elements of bushings, blades and other units, a unique stand-model for testing the crew’s survival system during emergency landings, and stand for the study of the effects of overload on humans and working out rescue systems.

For carrying out preliminary flight tests of the units (elastomer and torsion bushings and main rotor blades, tail rotor, TVZ-117BM engines) and systems (autopilot, aiming and navigation and piloting complex and guided missile weapons), pilot production converted four helicopters Mi- 24, and then several Mi-8.

The cost center designers to them. Mil M., together with subcontractors from specialized design bureaus and scientific research institutes, conducted experimental studies on programs to ensure high combat survivability and low thermal conspicuity, in particular ballistic tests for survivability of the crew cabin, fuel tank, propeller and steering rotor blades, transmission shaft, control rods and hydraulic systems. According to the results of these tests, the design and placement of armor protection was optimized. For the first time in the domestic helicopter industry, the characteristics of the thermal radiation of a helicopter were experimentally determined at all azimuths. In addition, joint efforts were carried out a set of experimental and computational studies to create a system of passive protection for the crew of the helicopter, tested the performance of safely damaged means of emergency depreciation and fixation - the chassis, impact-resistant seats, moving floor, etc.

In August, the 1980 Committee of the Presidium of the Council of Ministers of the USSR on Military-Industrial Issues, having familiarized itself with the development of the advanced Mi-28 combat helicopter, decided to build two experimental models without waiting for the approval of the final layout. A positive conclusion of the mockup commission followed only at the end of next year, when the assembly shop of the plant had already transferred the first model of the helicopter to static tests and built the first flight copy. Therefore, the first model of the Mi-28, assembled in July of the 1982, was refined to the required level in the process of fine-tuning and flight tests.

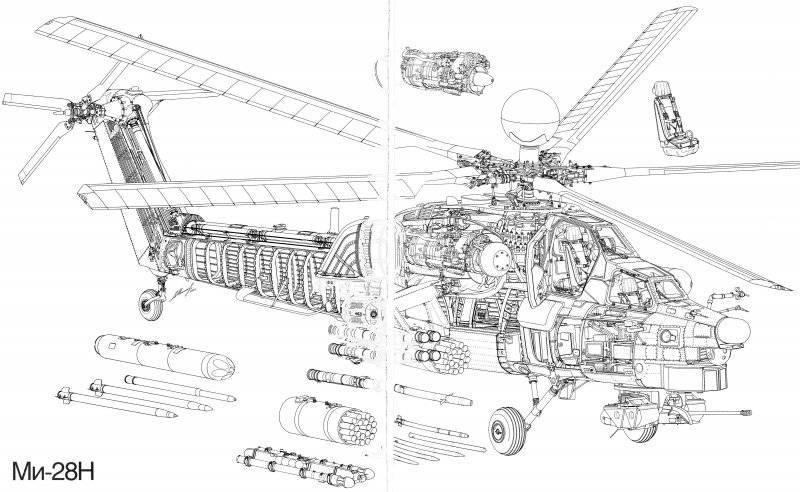

The twin combat helicopter Mi-28 was built according to the classic single-rotor scheme and was designed to search and destroy armored vehicles, enemy manpower in open and rough terrain, and low-speed air targets with visual visibility in simple and limited weather conditions. The dimensions of the helicopter made it possible to transport it on Il-7b military transport aircraft with minimal disassembly. Constructive solutions and layout of the main units ensured the autonomy of the conduct of hostilities from sites outside the airfield during 15 days.

The fuselage of the Mi-28 included the nose and central parts, as well as the tail and keel beams. In the bow there were two separate armored cockpit compartments, in which the navigator-operator's seat was located in front, and the pilot's seat behind and above. A combined observation and observation station KOPS and a gun installation were attached to the front and bottom of the nose. Under the pilot's floor, there were blocks of electrical equipment and an aerobatic-navigation complex.

To increase the helicopter's combat survivability and crew survivability, armor protection was provided for the cabin, which included a set of ceramic tiles pasted on the frame of the forward fuselage. In addition, the protective role was performed by silicate bulletproof glass. The pilot and navigator were separated by an armored partition. The navigator's door was on the left side, and the pilot was on the right. Doors and windows were equipped with emergency reset mechanisms. During an emergency escape of cabins under the doors, special ladders were inflated, protecting the crew from hitting the chassis.

The main gearbox, the fan, the auxiliary power unit, the hydraulic unit and the air conditioning units were mounted on the ceiling panel of the central fuselage. To the right and left of the symmetry axis on the ceiling panel and cantilever elements of the frames were installed engines and angle gears, as well as wing consoles. At the bottom of the fuselage was a container of fuel tanks, on the upper panels of which there were equipment blocks. The placement of the heaviest units and systems near the center of mass contributed to increasing the maneuverability of the Mi-28. The rear compartment of the radio equipment had ample free volumes that allowed it to be used as cargo (for transportation of airfield equipment when relocating a helicopter or evacuating the crew of another helicopter). The simplicity and convenience of maintenance of various systems and equipment of the helicopter provided numerous doors and hatches on the sides of the fuselage. The lower location of the tail boom eliminated the possibility of grazing the main rotor blade with it during a sharp maneuver. The rear part of the keel beam was made in the form of a fixed steering wheel, inside which the cable wiring of the steering screw and stabilizer, mounted in the upper part of the keel beam, stirred. The stabilizer control was connected to the handle of the common pitch of the main rotor. Under its lower part was the tail landing gear.

The wing of the helicopter is free-landing with four pylons, intended for the suspension of rocket, rifle-gun, bomb weapons and additional fuel tanks. On the pylons of the wing installed modern girder holders DBZ-HC. Their feature is a removable lock, which made it possible to place in the wing a built-in armament suspension system that does not require special ground equipment. At the ends of the wing in the fairing were located devices for shooting interfering cartridges. In an emergency, the wing could be dropped.

The system of passive protection of the helicopter was to ensure the safety of the crew members during an emergency landing at a vertical speed of up to 12 m / s. In this case, the magnitudes of the overloads decreased to the level of physiologically tolerable. The mechanisms that triggered the protection system were installed on the shock absorber cylinders of the main landing gear supports. With their help, the drawdown of the energy-absorbing crew seats and the forward deflection of the handle of the longitudinal-transverse control were carried out, which excluded the possibility of injury to the pilot. Energy-absorbing seats, descending on the 30 cm, protected the crew from overloading during an emergency landing. In an emergency, forced safety of the pilots to the back of the seat with a tethered system was also provided.

The choice of the Mi-28 chassis scheme - three-support with a tail wheel, was due to the need to place a turret cannon installation with a wide firing sector under the nose of the helicopter, as well as a restriction on the dimensions of the vehicle related to its transportation conditions. The design of the landing gear were included hydropneumatic shock absorbers with an additional emergency course. The main support lever type allowed to change the clearance of the helicopter.

The blades of the five-lobe main rotor had a profile recommended by TsAGI and a rectangular shape in plan. Spar blades - from polymer composite materials formed the nose in the shape of the profile. To it were attached tail compartments, made in the form of plating of polymer composite materials with polymer-plastic filler. The main rotor hub was a titanium case with five rendered spherical elastomer hinges. Metal-fluoroplastic and fabric bearings were widely used in movable bushings. Such “maintenance free”, i.e. not requiring constant lubrication, sleeves were first used in the domestic helicopter. The elastomer sleeve not only made it possible to reduce the labor costs for servicing the helicopter, but also provided increased machine maneuverability and controllability. (The use of an alternative torsion bush on the Mi-28 was refused.)

The four-blade tail rotor for noise reduction and increased efficiency was designed in an X-shaped pattern. His sleeve consisted of two modules installed one above the other on the hub spitz. Each module was a joint of the two arms of the blades. The blade included a fiberglass spar and a tail part of the cell block and fiberglass plating.

The blades of the main and tail rotors were equipped with an electrothermal anti-icing system.

Unfortunately, the development of the X-shaped tail rotor was tightened and the first experienced Mi-28 to 1987 were used. The steering screws from the Mi-24 were used.

The power plant included two TVZ-117ВМ turbo engines, hp 1950 power. each whose independent operation provided the ability to perform a flight with one engine running. At the entrances of the engines were mushroom dust protection installation. The engines were equipped with screen-exhaust devices that reduce the thermal visibility of the helicopter. The water injection system ensured the smooth operation of the engines when launching unguided rockets.

As an auxiliary power unit, an AI-9B engine was used, which also provided for the drive of systems during ground tests and the supply of warm air for heating the cabs. In the engine compartment of the gearbox compartment, above the ceiling panel of the central part of the fuselage, there was a fan and oil radiators.

The fuel system Mi-28 was made in the form of two independent symmetric power systems of each engine with automatic cross-feeding and pumping. It consisted of three tanks (two consumables for each engine and one common), which were in the container of fuel tanks, the walls of which were protected by foam rubber. The fuel tanks themselves were filled with explosion-proof polyurethane foam.

A feature of the helicopter's transmission was the presence of two angular gearboxes UR-28, which serve to transfer torque from the engines to the main gearbox BP-28 and are the first stages of the reduction.

In the control system, four combined steering gears installed on the main gearbox were used, which served as hydraulic boosters and autopilot steering gears. The hydraulic system of the Mi-28 consisted of two independent systems serving to power the combined steering gears of the control systems and the hydraulic damper in the track control system.

The equipment of the helicopter also included a pneumatic system, air conditioning system and oxygen equipment.

A set of instrumentation equipment was installed on the Mi-28 helicopter, which made it possible to fly a helicopter and solve air navigation problems at any time of day and in any meteorological conditions.

To solve combat missions, as well as perform flights, the helicopter was equipped with: a complex of guided missile weapons. including a combined observation and sighting station (KOPS) developed by the Cherkassy Plant -Photopribor- designed for the navigator-operator search, recognition and tracking of the target during the launch of guided missiles and firing from the gun; helmet-based target designation of the pilot, providing control of the gun; aim-flight-navigation complex PrPNK-28. For aiming and shooting from stationary weapons in the cockpit, an indicator was mounted on the windshield of the ILS-31. The PrPNK-28 complex created by Ramenskiy instrument-making design bureau provided aimed shooting and bombing, improved flight performance, flight along a predetermined trajectory, fixed hanging over a given point, stabilization of altitude, and continuous positioning. The complex consisted of sensors of primary information, two on-board computers and control and display devices. The following sensors were used as sensors: vertical information systems. course, altitude-velocity parameters, Doppler velocity and drift gauge and helmet-mounted target designation system. The structure of the control and display devices included: automatic tablet, navigation instruments and information display system.

The armament of the Mi-28 consisted of the non-removable mobile gun unit NSPU-28 with a powerful 2A42 gun of the caliber 30 mm developed by the Tula Instrument Design Bureau and a detachable weapon system suspended from the beam holders of the wing pylons. Like most helicopter gunships in the world, the Mi-28 was equipped with a cannon that could be turned at high angles, which allowed firing various weapons simultaneously on two targets at different azimuths (the gun is similar to the BMP-2 infantry fighting vehicle installed on the combat vehicle). The fixed mobile cannon plant NPPU-28 was developed by the specialized enterprise MMZ Dzerzhinets. The peculiarity of the GSPU-28 was the simplicity and reliability of the supply of projectiles to the gun. The 2А42 gun had selector power supplied from two sides, in connection with this, the installation provided two independent shell boxes, rigidly connected to the receiving windows on the gun. When moving the gun barrel in elevation and azimuth, the slug boxes repeat its movement. When operating boxes can be equipped with two different types of shells. The deviation range of NNPU-28 was: in azimuth ± 110 °; by elevation + 13 - 400. Ammunition cannon in 250 shells. The removal of ammunition increased the reliability of weapons and the survivability of the helicopter. The external girder holders provided for the suspension of the Ataka-V anti-tank guided supersonic 16М9 missiles of the Ataka-V complex or 120М9 of the Sturm-V complex (with radio command guidance systems) deployed on APU-114 / XNX launchers mounted on 4. Guided missile armament -Ataka-B- was developed by the Kolomna machine-building design bureau, designed to destroy not only ground targets, but also low-flying low-speed aerial targets. Blocks of unguided rockets B-8В5, B-35В8 or B-20Л13, unified helicopter GUD in machine-gun and grenade launchers could be mounted on the inner holders. On the holders it was also possible to carry small-sized KMGU-1 containers with mines, 2 caliber bombs and 250 kg bombs or additional fuel tanks. In the following years, the Mi-500 arsenal was replenished with heavy unguided C-28B rockets, cannon containers UPK-24-23 and incendiary tanks ZB-250.

According to the security characteristics, the Mi-28 helicopter has no equal in the world helicopter industry. The crew cabin is made of aluminum sheets on which ceramic tiles are glued. Cabin doors have two layers of aluminum armor and a layer of polyurethane between them. Cabin windshields are transparent silicate blocks 42 mm thick, and side windows and door windows are made of the same blocks, but 22 mm thick. The cockpit is separated from the operator's cabin by an aluminum armor plate, which minimizes the loss of both crew members with one shot. Fire tests have shown that the sides withstand the hit of shell fragments of the American Vulcan 20-mm cannon, the windshield with 12,7 mm caliber bullets, and the side and door glass with 7,62 mm.

Protection against destruction by guided missiles on the Mi-28 was provided by: equipment for jamming radar stations and guided missiles with infrared and radar homing heads; helicopter irradiation warning equipment by enemy radar and laser target designators; the device for shooting off the HC-26 jamming cartridges for protection against missiles with thermal homing heads.

Equally important in the development of the helicopter attached ease of maintenance in the conditions of autonomous basing. Compared to the Mi-24, the complexity of maintenance has been reduced by about three times.

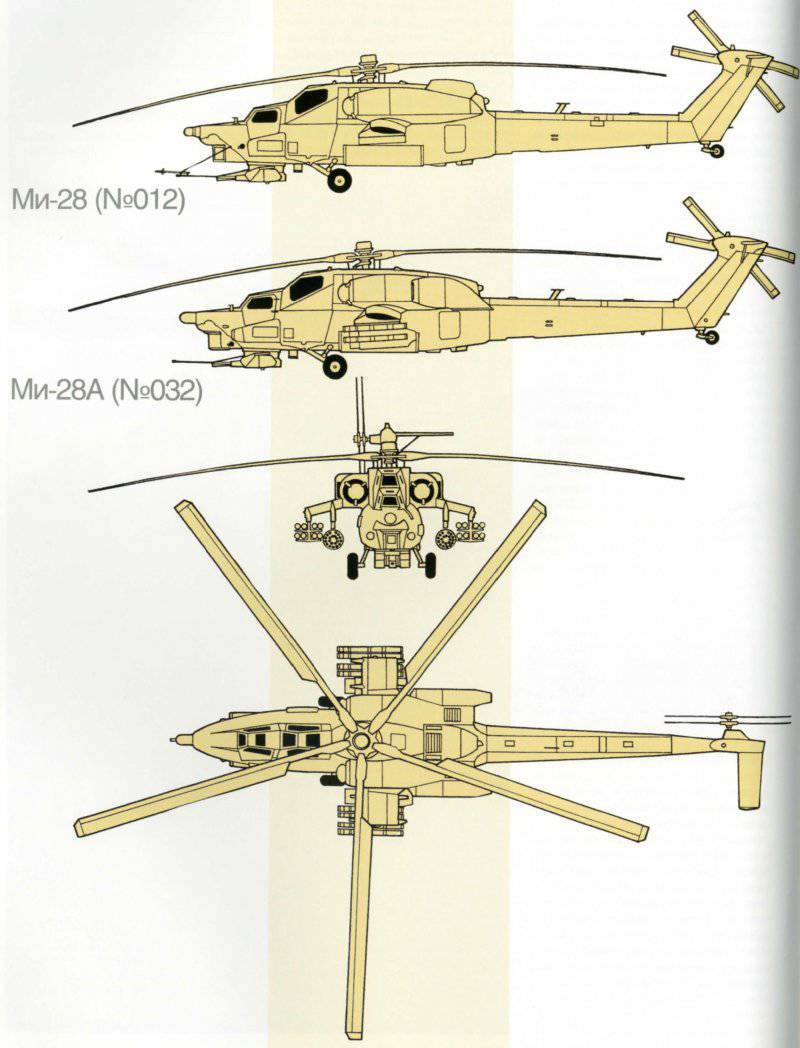

A few months after the assembly was completed, ground crews of the first Mi-28 and 10 in November 1982 took place on the ground, the crew consisting of the leading test pilot of the plant G. R. Karapetyan and test navigator V. V. Tsygankova for the first time tore off the new helicopter land, and 19 December of the same year - made the first flight in a circle. All parts and systems of the helicopter worked satisfactorily, and the very next day the official transfer of the helicopter to the first stage of the joint comparative state tests took place. They ended successfully in 1984, and the helicopter entered the Air Force Institute at the second stage of the SSIG (Air Force stage). A great contribution to the testing of a combat helicopter was made by factory pilots Yu.F.Chapaev, V.V. Bukharin, V.I. Bondarenko and B.V. Savinov, navigator V.S. Cherny. The leading flight test engineers were V. G. Voronin and V. I. Kulikov.

The first model of the Mi-28 was intended primarily for the removal of flight performance and did not carry weapons systems. It was installed on the second flight copy, the assembly of which the pilot production cost center completed in September 1983. All the comments of the Air Force model commission were taken into account in its design. The second flight copy at the end of the year entered the test sites for weapons of the SSGI. At first, the flight tests of both machines were complicated by the insufficient transmission resource and carrier system, but then the designers brought the life of the main units up to several hundred hours and thus ensured the successful completion of the SIPS program.

In the course of comparative joint tests of the first flight model of the Mi-28 to 1986, all specified flight performance was confirmed, and even exceeded in some parameters. The customer's wish was only to expand the range of permissible overloads due to the fact that the helicopter control stocks allowed to perform maneuvers with higher values. After appropriate revision of the blades and hydraulic system, this problem was also solved. As a result, the vertical overload in the -Hork mode was 2,65 at the height of 500 m and 1,8 at the height of 4000 m. The maximum speeds of the flight "sideways" and "tail forward" also increased significantly.

In the second instance of the flight in the same year, all work was completed on fine-tuning the special helicopter complexes and ensuring compatibility of the weapon with the machine. Successfully passed tests of weapons at the Gorokhovetsky testing ground, including the first experimental night launch from a helicopter of guided missiles at ground targets.

After the 1987 was installed on the first flight model of the X-shaped tail rotor, the appearance and equipment of the combat helicopter were finally determined.

The impressive results of the first tests of the Mi-28 allowed the Ministry of Aviation Industry in February 1984 to decide on the preparation of its mass production at the Arsenyev Aviation Production Plant. With good luck, the Soviet Air Force could have received the first Mi-28 already in 1987, however, this was not to be. Despite the fact that studies conducted in the United States proved the impossibility of creating a full-fledged single-seat combat helicopter at the current level of development of American electronics, Soviet military experts came to the opposite conclusion, believing that our instrument-makers could create an automated complex that allows a single-seat combat helicopter to operate effectively near the ground. In October, the customer made his choice of 1984, preferring the B-80 helicopter for further development and mass production in Arsenyev.

In April, 1986 held simultaneous tests of the Mi-28 and B-80 for the detection, recognition and imitation of defeat targets, during which the Mi-28 proved its advantages. Nevertheless, the customer’s specialists, without waiting for the end of the comparative tests, on the basis of theoretical calculations, came to the conclusion that B-80 has a greater development prospect and requires less expenditure on the creation and maintenance of a helicopter grouping. To improve the efficiency of detecting and recognizing targets, the military proposed a method for instrumental target designation for B-80 from a special reconnaissance helicopter or ground guidance systems. However, such a double target designator helicopter was still to be built, and the instrumentation equipment and armament of the B-80 was to be brought to working condition. Therefore, no one decided to close the Mi-28 program, only the amount of funding was reduced. -Contest- continued, but in unequal conditions. Despite this, the Mi-28 successfully completed a significant part of the state tests, proving the high efficiency of its onboard systems and weapons. Taking into account the positive results of the SSGI, the Central Committee of the CPSU and the USSR Council of Ministers issued a Decree of 14 on December 1987 on the completion of tests on the Mi-28 and the start of serial production at the Rostov helicopter plant. A further helicopter improvement program envisaged the creation of the upgraded Mi-28А helicopter at the first stage, and then its “night” version of the Mi-28Н capable of conducting combat operations in adverse weather conditions at any time of the day.

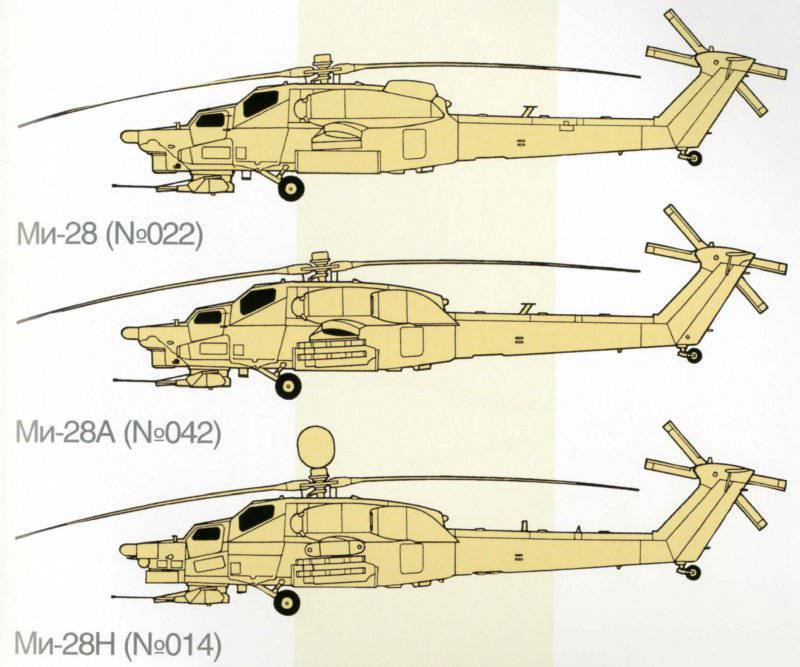

The construction of the third flight instance of the Mi-28, the design of which took into account all the customer’s remarks and changes made to the experimental samples as they were refined, the pilot production of the MVZ them. M.L. The mile began in 1985. The upgraded helicopter received the name Mi-1987А in 28. It differed from the first experimental samples by the upgraded TVZ-117ВМА high-altitude engines with the 2225 hp power. each, with improved instrumentation, a modified design of ejector exhaust devices and a modified main gearbox. At the ends of the wings, containers with infrared and radar passive jamming cassettes appeared (they were not installed on the first two Mi-28s).

The tests of the modernized Mi-28A began in January 1988 g. They passed safely, and the following year the helicopter was first demonstrated at the Le Bourget air show in Paris and at the exhibition in Red Hill near London, where it enjoyed great success with visitors. In the same year, the first experimental helicopter Mi-28 was first officially presented at home during the aviation festival in Tushino. In January, 1991, a second Mi-28A, assembled by a pilot production cost center, joined the test program. In September, 1993, during an all-arms exercise near Gorokhovets, the helicopters brilliantly demonstrated their flying qualities and combat superiority over their competitors. The feasibility of choosing a double layout has become apparent to all.

The Mi-28А helicopter was highly appreciated by both domestic and foreign specialists. It fully complied with its purpose and exceeded in many respects all helicopters of a similar class. Aerobatic and maneuverable characteristics ensured a high degree of survival in air combat. With the exception of his younger brother, the lightweight sports training Mi-34, the combat Mi-28 is the only helicopter in Russia capable of performing aerobatics. 6 May 1993. Test pilot G. R. Karapetyan for the first time performed on the Mi-28 Nesterov-loop, and after a few days - a “barrel”.

The Rostov Helicopter Production Association began preparations for serial production of a flying tank, and in 1994 began to build the first production model at its own expense.

The leadership of the armed forces of many foreign countries became interested in the Russian military helicopter. In the autumn of 1990, an agreement was concluded with Iraq on the sale of Mi-28 helicopters, and subsequently on their joint production (Mi-28L - licensed) in Iraq, but these plans were hampered by the outbreak of the outbreak of the Gulf War. In the fall of 1995, the Ministry of Defense of Sweden selected the Russian Mi-28A and the American AN-64 -Apach- among various types of combat helicopters to conduct comparative tests. Our rotary-wing machine fully completed the test program, including live firing, and proved to be very reliable and well adapted to field conditions.

In 1993, after the end of the first stage of the state tests of the Mi-28A, the preliminary conclusion of the customer on the release of the installation batch of helicopters was received. Military test pilots began to develop the Mi-28A. However, due to insufficient funding, the work was delayed, and the equipment of competing helicopters had by this time become morally obsolete. In this regard, M.Vaynberg, who had already become the General Designer of the cost centers, with the consent of the customer, decided to stop the development of the Mi-28A at the final stage of state tests and concentrate all forces and financial capabilities on the development of the combat helicopter Mi-28Н (-Н- - night, export designation: Mi-28НЭ) - round-the-clock and all-weather, with a fundamentally new integrated fifth-generation on-board equipment complex. The helicopter is considered as a kind of response to the creation of an all-weather-flying tank by the American firm McDonnell-Douglas - AH-64D Apache-Longbow. Subsequently, the correctness of the decision was indirectly confirmed by the tests of the Mi-28A helicopter (in Sweden in October 1995), when the only additional requirement was placed on it - the presence of systems in the future that allow to conduct combat operations at night.

Taking into account that the layout and design of the Mi-28, its armament, protection systems met the most modern requirements, it was decided to develop only new equipment on the advanced element base and gearbox. At the beginning of 1993, the customer’s mock-up commission and acceptance of the conceptual design were carried out, after which, despite a strong lack of funding, the development of the Night Hunter Mi-28H began.

The Mi-28Н / Mi-28НЭ helicopter is equipped with an integrated fifth-generation avionics and instrumentation equipment complex. All equipment communicates via a single interface - a multiplex information exchange channel. The onboard equipment controls are integrated into a single compact control system, which made it possible to reduce their number to a reasonable minimum and place them in relatively small crew cabins.

The on-board radio-electronic complex provides the use of weapons and the solution of flight and navigation tasks day and night in simple and complex meteorological conditions at extremely low altitudes (10-50 m) with automatic rounding of the terrain and the overlying obstacles using cartographic information. The complex allows you to detect and identify targets, use weapons; control helicopter groups with automated distribution of targets between them; to conduct bilateral exchange of information on targets between helicopters and air or ground command points. The complex also provides control over the operation of the power plant, transmission, fuel, hydraulic and air systems; voice notification of the crew about emergencies and telephone communication.

The complex of on-board radio-electronic equipment includes: navigation system, aerobatic complex, on-board computer system (BTsVM), information and control system; multifunctional information display system, weapon control system, operator’s sight and sight station, pilot thermal imaging station, on-board circular radar station, rocket armament control system, night-vision goggles, communications equipment, radar and laser radiation warning system and radio identification equipment.

The Mi-28Н navigation is provided on the basis of a high-resolution map information system based on a digital data bank on the terrain of the combat area, a high-precision satellite navigation system, and an inertial navigation system.

The tasks of search, detection and recognition of targets are solved on the Mi-28Н due to the presence of the latest observation and sight station with gyro-stabilized fields of view. The station has an optical, low-level television and thermal imaging surveillance channels. All channels, with the exception of optical, have the ability to digitally provide information with the issuance of it on the screen. The laser range finder and the missile control system are constructively combined with the observation and sighting station. All generalized information comes to the indicators of the navigator-operator. An unofficial competition was held in the development of the sight-sighting station, which was attended by: Krasnogorsk Mechanical Plant, Ural Optical-Mechanical Plant, Cherkassy Photoprior Bor Plant and Kiev Arsenal Plant. The winner of the competition was recognized as the Krasnogorsk plant.

An onboard radar station located in a spherical spinner on a hub of a rotor operates in search and detection modes for small-sized ground and air targets, with issuing relevant information for indication and in digital form to the target recognition automation system. Mi-28H can search for targets, hiding in the folds of the terrain or behind the trees, putting out for shelter only his - cushion-. The station also provides information on the obstacles ahead, including detached trees and power lines, in digital form and as a television signal for indication, allowing round-the-clock flight at extremely low altitude 5-15 meters even in adverse weather conditions.

The aerobatic thermal imaging station of the pilot “Stolb” developed by the Geofizika CDB worked both in the control mode from the on-board computer and in the manual mode. The station was also equipped with a laser range finder. At present, the Stolb pilot station has been replaced by a more advanced TO-ES-521 station developed by the FSUE “UOMZ”.

All the generalized information is fed to the multifunctional liquid crystal indicators - two in the cockpit and two in the cockpit of the navigator-operator.

The airborne communications complex provides on-land and in-flight two-way telephone radio communication between helicopters and ground command posts of the Air Force and the Ground Forces; data exchange between helicopters and ground stations; internal telephone communication between crew members in flight and with ground support personnel during pre-flight training; crew voice notification of emergency situations; as well as recording telephone conversations of the crew on external and internal radio communications. Accordingly, the Mi-28H helicopter has the equipment for obtaining external target designation.

The airborne communications complex provides on-land and in-flight two-way telephone radio communication between helicopters and ground command posts of the Air Force and the Ground Forces; data exchange between helicopters and ground stations; internal telephone communication between crew members in flight and with ground support personnel during pre-flight training; crew voice notification of emergency situations; as well as recording telephone conversations of the crew on external and internal radio communications. Accordingly, the Mi-28H helicopter has the equipment for obtaining external target designation.The Mi-28H mastered a unified computing environment consisting of two central on-board computers and a number of peripheral computers that significantly simplified on-board software. An extensive internal control system has been introduced on the helicopter, which allows for autonomous preparation for departure, post-flight maintenance and the search for failures without the use of special aerodrome test equipment.

The onboard integrated radioelectronic complex allows the crew of the Mi-28Н / Mi-28НЭ to work at low altitudes, in combat formations, to conduct assault operations with landing at intermediate sites, to solve combat missions using guided missile weapons from behind cover, without entering direct contact with the aim and without putting the helicopter at risk of destruction. The radio command guidance system of the supersonic high-precision “Ataka-V” guided missile provides enhanced noise immunity in front of the laser: it is more adapted to work in smoke, dust, and heavy fog. ATGM 9М120В "Attack-B" affects all types of tanks, including with dynamic protection of armor. Having determined the targets and their type, distributing them according to need between the group’s helicopters, selecting an object for attack, the crew of the Mi-28H vigorously come out of ambush and “process” the target with weapons or direct attack aircraft or other group helicopters.

The defense of the Mi-28Н / Mi-28НЭ from enemy aircraft and helicopters, in addition, is enhanced by the placement of air-to-air guided missiles “Igla” on it. These missiles are used around the clock in the mode of starting up - forgotten, that is, they are fully autonomous after launch.

The combination of a multifunctional integrated airborne electronic and instrumentation equipment complex, powerful armament and an unparalleled passive protection system make the Mi-28Н / Mi-28НЭ - Night Hunter - unique in terms of combat effectiveness and survivability by the rotorcraft of combat operations, which have no analogues among the propeller aircraft .

In addition to the new equipment and weapons complex, the cost center designers installed on the Mi-28Н and a number of new parts of the design, such as, for example, the new multi-threaded main gearbox BP-29 and engines with an upgraded automatic control system. The program for creating the Mi-28H was headed by the chief designer VG Shcherbina. In August 1996, the first Mi-28H was assembled, and on November 14 of the same year, the crew consisting of test pilot V.V. Yudin and navigator S.V. Nikulin performed the first flight on it.

Factory flight tests of the Mi-28H began on 30 on April 1997, and, despite the difficult economic situation of the leading enterprise developer, they were successfully completed four years later. The helicopter entered the state tests.

Given the great need for military vehicles of this type, the command of the Russian Air Force in 2002 adopted the Mi-28H as the main prospective combat helicopter of the future, without waiting for the completion of the tests. The summer of next year was followed by the order of Russian President Vladimir Putin on the adoption of the Mi-28H into service as the main attack helicopter. The Rostov Helicopter Plant OJSC Rosgvertol began to master its serial production.

Given the great need for military vehicles of this type, the command of the Russian Air Force in 2002 adopted the Mi-28H as the main prospective combat helicopter of the future, without waiting for the completion of the tests. The summer of next year was followed by the order of Russian President Vladimir Putin on the adoption of the Mi-28H into service as the main attack helicopter. The Rostov Helicopter Plant OJSC Rosgvertol began to master its serial production.4 March 2006 The State Commission, chaired by the Commander-in-Chief of the Air Force, issued an opinion on the release of the Mi-28H installation batch, which officially authorized the plant to carry out the serial production of the Mi-28Н helicopters, and to operate them for the customer’s subdivisions. Before 2010, the Russian Armed Forces plan to adopt 50 of such vehicles. In total, the domestic Air Force are going to buy at least 300 "Night Hunters".

The Mi-28H “Night Hunter” helicopters in the summer of 2006 took part in the joint military maneuvers of the “Union Shield” 2006, where they received high marks from the joint Belarusian-Russian command. Equally high was the score of the Night Hunter and the military attaches of foreign countries who were present at the maneuvers. According to their responses, the real combat readiness and effectiveness of the Mi-28H demonstrated during the exercise exceeded all expectations. Interest in the acquisition of "Night Hunters" was expressed by the military ministries of several foreign countries.

The Mi-28H “Night Hunter” helicopters in the summer of 2006 took part in the joint military maneuvers of the “Union Shield” 2006, where they received high marks from the joint Belarusian-Russian command. Equally high was the score of the Night Hunter and the military attaches of foreign countries who were present at the maneuvers. According to their responses, the real combat readiness and effectiveness of the Mi-28H demonstrated during the exercise exceeded all expectations. Interest in the acquisition of "Night Hunters" was expressed by the military ministries of several foreign countries.With the installation of an onboard radio-electronic equipment complex on the Mi-28 helicopter, which allows to conduct combat operations around the clock and in adverse weather conditions adequately to the actions of the Ground Forces, the Armed Forces of the Russian Federation received a reliable "shield and sword" in the air, and Russia - a new competitive combat helicopter on the world arms market .

Designers of JSC “Mil Moscow Helicopter Plant” continue to work on improving the Mi-28H “Night Hunter”, introducing the latest achievements of domestic and global helicopter science and technology into the design of its units and systems. A number of new modifications of the helicopter are being prepared for the Russian Air Force and for export deliveries, including variants with foreign-made units and systems.

Flight performance of Mi-28 helicopters | |||

Basic data | Mi-28 | Mi-28A | Mi-28N |

Year built | 1982 | 1987 | 1996 |

Crew, pers. | 2 | 2 | 2 |

Capacity of the evacuation compartment, pers. 2-3 * | 2-3 * | 2-3 * | |

Engine type | TVZ-117ВМ | TVZ-117ВМА | TVZ-117ВМА |

Engine power, hp | 2x1950 | X 2 2200 | X 2 2200 |

The diameter of the rotor, m | 17,2 | 17,2 | 17,2 |

Weight of empty helicopter, kg | 7900 | 8095 | 8660 |

Take-off weight, kg: | |||

normal | 10 200 | 10 400 | 11 000 |

maximum | 11 200 | 11 500 | 12 100 |

Weight of combat load, kg: | 2300 | 2300 | 2300 |

flight speed, km / h: | |||

maximum | 300 | 300 | 305 |

cruising | 270 | 265 | 270 |

Static ceiling | |||

excluding land influence, m | 3470 | 3600 | 3600 |

Dynamic ceiling, m | 5700 | 5800 | 5700 |

Practical flight range, km | 435 | 460 | 500 |

Ferrying range, km | 1100 | 1100 | 1100 |

'In the radio equipment compartment | |||

Information