The seventh "Flower" in the artillery "bouquet" and its unified heirs "Peony"

In the second half of the 1960's. The cannon artillery was “rehabilitated”; a number of programs were launched to create new artillery complexes, including self-propelled ones. Staging in stories domestic barreled artillery became 1967 year. In 1967-1969 work began on the creation of a series of artillery systems of various calibers and purpose. GRAU MO assigned development codes ciphers for color names, and the resulting self-propelled artillery mounts (ACS) received indices "2С":

- 2С1 - 122-mm self-propelled howitzer of the Ground Forces "Gvozdika";

- 2С2 - 122-mm self-propelled howitzer of the airborne troops "Violet";

- 2SZ - 152-mm self-propelled howitzer "Acacia";

- 2С4 - 240-mm self-propelled mortar "Tulip";

- 2С5 and 2А36 - 152-mm instrument of increased ballistics "Hyacinth", respectively, in self-propelled ("Hyacinth-S") and towed ("Hyacinth-B") versions;

- 2С7 - 203-mm self-propelled gun "Peony";

- 2С8 - 120-mm self-propelled mortars "Astra" (for the Ground Forces) and "Lily of the valley" (for the Airborne Forces).

SAU "Violet". "Astra" and "Lily of the Valley" remained experimental, but the rest of the "bouquet" of modern artillery systems entered service with the Soviet Army. The relevance of these systems is preserved to our days. The seventh "flower" - "Peony", became the strongest in this "artbook".

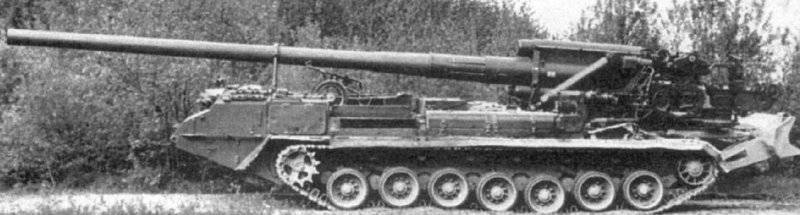

Self-propelled artillery 2C7 "Peony"

SAU 27 "Peony" was created with 1967, as a powerful weapon for firing both conventional and tactical special ammunition. A large caliber (203,2 mm - the historically established caliber corresponding to 8 inches) was chosen because by the time the tool was developed, advances in designing special projectiles allowed the tactical nuclear (atomic) charge to be packed into this caliber. This opened up a unique opportunity to consider the Pion ACS as the most powerful field type artillery. A powerful long-range gun with a special charge was designed to solve a variety of fire tasks, including:

- the destruction and suppression of the means of nuclear attack and other fire weapons and equipment of the enemy;

- destruction of field and long-term fortifications;

- suppression of rear, points and command and control bodies, destruction of manpower and equipment in areas of concentration.

The 203-mm 2A44 gun itself was created in the design bureau of the Volgograd plant "Barricades", with which the designers of the KB-3 of the Kirov plant had long-standing creative ties. The layout of the self-propelled guns was not immediately selected. Under the leadership of one of the elders of KB-3 L.I. Gorlitsky - the creator of the famous artillery vehicles of the Great Patriotic War - a project was developed using heavy knots tank T-10, in which the gun was installed traditionally - in a heavily armored wheelhouse in the bow of the car. This option received the index "Object 216 SP1".

At the same time, calculations showed that with a large recoil force (and this tool had it around 135 t), using ready-made tracked chassis is difficult. The solution was found in the use of tracked chassis, developed according to a special scheme, but with ready-made units of serial tanks. In the new chassis used semi-suspension, rubberized tracked belts, rubber tires on supporting and supporting rollers. The design provided for the possibility of lowering the chassis guide wheels to the ground before firing and thereby increasing the bearing surface when fired, while rubberized rollers and a caterpillar, coupled with the operation of four pairs of energy-intensive telescopic shock absorbers, significantly reduced vibration and shock loads.

In order to reduce the mass of the machine in KB-3, the layout variant with the rear open position of the cannon and calculation work stations was adopted, which was placed in armored compartments of the hull during movement. Thus, the “216 cX2 Object” appeared, the development of which was carried out under the direction of G.N. Rybina and V.V. Kulagin. The aft layout of the open fighting compartment turned out to be preferable due to a number of advantages:

- the barrel is located within the length of the body (with slight advancement), which eliminates sticking it when moving over rough terrain;

- an optimal scheme of perception of forces when fired and maximum convenience of the crew’s combat work is created.

Perhaps the most important thing is that, thanks to the movement of the recoil parts of the gun outside the hull, a large recoil length is ensured, so as not to use the muzzle brake, and good stability when firing. Rollback length reaches 1400 mm.

When developing a self-propelled unit, the firing range was set at least 35 km, and the driving speed at least 50 km / h. Placing and ensuring the operation of high-powered guns required the appropriate dimensions of the hull and chassis; as a result, the Peony was not only one of the most powerful self-propelled units, but also the largest of modern production armored vehicles. The developers had to solve a lot of difficult tasks to ensure the car high driving performance and stability when shooting. But they were under the power of designers and artillery systems, and self-propelled with their rich experience.

The main tactical and technical characteristics of the ACS 2C7 "Peony"

Mass, t 46,5

Tool caliber, mm 203,2 Guidance angles:

- vertical 0-60 °

- horizontal 15 ° Maximum firing range, km 37,5 Minimum firing range, km 8,4 Mass of high-explosive fragmentation projectile, kg 110 Rate of fire, rpm

Ammunition, rds 8 Types of high explosive shells, high-explosive, special

Transfer time from traveling to combat, min 5

Calculation, pers. Xnumx

Engine power, hp Xnumx

Maximum travel speed, km / h 51

Cruising on highway, km 500

Angle of climb 25 °

Roll angle 15 °

Wade depth, m 1,2

Average specific pressure per pound, kg / cm2 0,78

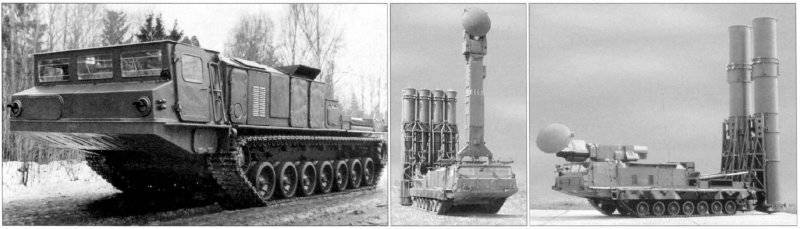

Unified C-300В self-propelled tracked chassis

Almost simultaneously with the development of the 2S7 self-propelled gun KB-3 of the Kirov plant, it was tasked with developing a unified tracked chassis for the S-ZOOV anti-aircraft missile system. The S-300V air defense system was created as a front-line air defense system and was intended to destroy aerodynamic and ballistic targets, including ground-based ballistic missiles (such as Lance, Pershing) and aviation (SRAM type), cruise missiles, strategic and tactical aircraft aviationjammers. The tasks posed to the air defense system imposed certain requirements on the base chassis:

- carrying capacity not less than 20 t with a total mass not exceeding 48 t;

- high maneuverability and throughput;

- maximum unification of chassis components for all types of vehicles;

- the ability to ensure the functioning of all systems in conditions of chemical and radiation contamination.

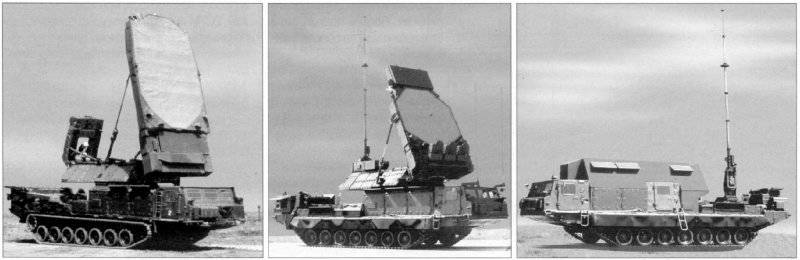

All these requirements were provided in the family of self-propelled tracked chassis (SGS) for C-300В facilities, which included:

- launcher of light missiles 9А83 - chassis "Object 830";

- launcher of heavy missiles 9А82 - chassis "Object 831";

- circular radar 9C15 - chassis "Object 832";

- multichannel station for guidance of rockets 9С32 - chassis "Object 833";

- radar station of the sector review 9С19 - chassis "Object 833-01";

- command post 9C457 - chassis "Object 834";

- 9А84 and 9А85 starting and charging machines - chassis "Object 835".

Means of the C-300B system on the basis of the above-mentioned GSSh have a maximum speed of 51 km / h (according to technical conditions, really - up to 55-60 km / h), the minimum turning radius is 5,5 m. The maximum chassis length is 11,5 m, the maximum height is 3,8 m , ground pressure - 0,84 kg / cm2. In the absence of roads with hard pavement, they provide movement in sands, loose soils, on wetlands, overcome water obstacles to a depth of 1,2 m and virgin soil with a snow cover with a thickness of 0,5 m.

The engine and transmission compartments of the SNGZ ZRS C-300В and SAU 2С7 are unified, but on the "830-835 Objects" under the terms of the logistics arrangement it is located in the rear part. The undercarriage SGS ZRS C-300В is made using the undercarriage units of the T-80 tank, the multi-fuel diesel B-46 (later B-84) is installed. An ejector-type cooling system provides the engine with 100% load at air temperatures up to + 40 ° C and with 80% at temperatures up to + 50 ° C, and the original preheater ensures reliable warm-up and engine start at temperatures to - 50 ° C.

The chassis has an autonomous power supply system driven by a gas turbine engine, which provides power supply to alternating (220В / 400 Hz) and constant (24 В) consumers, and there is also a backup generator, which is driven by a sustainer drive. The chassis is equipped with communication equipment, filtering unit. At the first chassis a turbo-refrigerating unit was installed to cool the hardware compartments, but then it was abandoned for reasons of economy. Air conditioning is installed to cool the habitable compartments (cockpit and operators).

For the development of SGS ZRS C-300В Deputy Chief Designer of KB-3 A.A. Magdenko was awarded the Lenin Prize.

The first samples of the chassis were made at the Kirov factory, and their mass production was organized at the Lipetsk Tractor Factory.

Since its introduction into service in 1983, the C-300В system (and with it the SGS) has undergone a series of upgrades and is still in demand both by the Ministry of Defense of the Russian Federation and abroad.

Multifunctional machines of high mobility and cross-country capacity on the basis of SAU 2C7 "Peony"

Changed in 1990-ies. The economic situation forced the developers to pay more attention to the dual-purpose technique. Moreover, during this period the demand for mobile energy-rich engineering machines increased significantly, capable of effectively and in a short time eliminating the consequences of accidents, terrorist attacks and technological disasters, especially in conditions of inaccessible and difficult terrain.

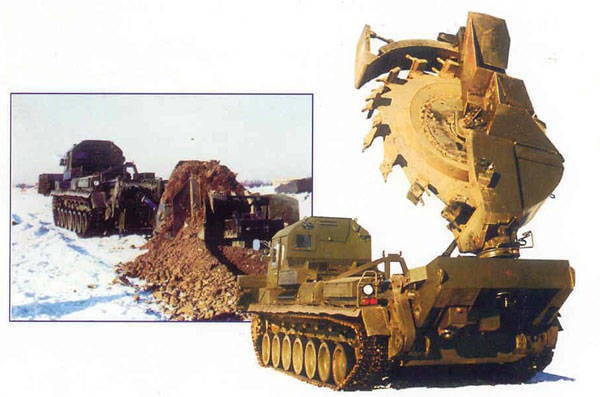

Thus, the unified range of machines started by the “216 Object” included the high-speed tracked trench machine BTM-4М (“Tundra”, 1997), self-propelled crawler cranes SGK-80 (1994) and SGK-80Р (1998) ) with a carrying capacity of 80 t and a CM-100 machine (2004 g.).

The crawler cranes and SM-100 were built by order of the Traffic Safety and Ecology Department of the Ministry of Railways of Russia (now OJSC Russian Railways) and were intended to eliminate the consequences of accidents on railway transport. BTM-4М was designed by order of the Directorate of the Engineering Troops of the Russian Federation and serves for digging trenches, message posts (including in frozen soils), device passageways, access roads, backfilling of ravines, etc.

These products constitute, in essence, a family of machines on a unified chassis, and during operation they confirmed the specified technical characteristics and safety for the operating personnel and the environment. If necessary, this family can be supplemented with other specialized machines with other functions and purposes. In addition to the use of such equipment to eliminate the consequences of accidents, it can be successfully used in the construction, installation of cable communications and pipelines, irrigation and land reclamation.

The equipment of all four types of machines is mounted on a seven-crawler tracked chassis with front-mounted logistics. The structure of the unified chassis includes: a housing with a cabin, a power plant, a transmission, a tracked undercarriage, an air system, electrical equipment, a ventilation system, and automated fire fighting equipment.

The main differences of these chassis are in the design of the case and associated with the installation of various working equipment. Despite this, their level of unification and standardization in relation to the ACS "Pion" - "Malka" is very high:

For BTM-4M

- parts unification - 41,3%

- unification of assembly units - 51,6%

For SGK-80

- parts unification - 72,8%

For SGK-80P

- parts unification - 54,7%

- unification of assembly units - 29,6%

For SM-100

- on unification of parts - 63,7%

- on unification of assembly units -37,8%

Engineering vehicle BTM-4M ("Tundra")

The engineering vehicle BTM-4M has expanded its fleet of dual-purpose military vehicles. This original machine for design solutions and performance was created under the guidance of General Designer N.S. Popova chief designer of the project V.P. Yakovlev, leading engineers F.F. Efimenko, V.N. Spiridonov and other specialists KB. The BTM-4М has working equipment installed at the Drrmash Research Institute (Kiev) and includes a rotary working body in the rear part of the machine and bulldozer equipment mounted in its forward part.

BTM-4M can dig trenches and pits, arrange earthen ramparts with the help of a rotary tool and dozer blade, as well as overcome contaminated terrain. In addition, it provides ballistic protection for the crew and is able to work in extreme meteorological conditions at any time of the year and day.

The rotor in the stowed position is placed on the roof of the chassis. When digging trenches, the rotor rotates with the help of the power shaft from the main engine through an intermediate gearbox and gearbox. The depth of the trench is determined by the installation of a special mechanism - a stripping shoe that serves as an additional support. Trenching is carried out when the machine is moving in the working mode on a hydraulic creeper, which provides for infinitely variable travel speeds.

The dump of soil when digging trenches is provided in both directions with the help of soil collectors under the action of backing pounds. The position of the rotary working body is regulated by means of hydraulic cylinders, which keep it in a constantly specified or in a floating position, which allows you to tear off the arc-shaped trench and type "snake". The bulldozer equipment consists of a blade and a frame, its position is regulated by four hydraulic cylinders. In the back of the blade there are shoes for snow removal work. Technical performance when digging a trench depends on the category of soil and its depth.

The diesel engine (as on the 2С7 “Peony” and 2С7М “Malka” ACS) was used as the power plant of the engineering machine, which ensures high transport and operating speeds. The machine can cross the ford with a depth of 1,2 m, rise to 25 °, roll 15 °, and ditches wide 2,5 m. Conversion from transport to working position takes about 5 min. Dimensions BTM-4M: length - 10,7 m, width - 3,38 m, height - 3,7 m (in transport position). Length in working position - 15,33 m, width - 4,01 m.

Main technical characteristics of the engineering machine BTM-4M

Mass, t 43,9

Crew, man 2

Dimensions profile detachable trench, m:

- depth 1,1; Xnumx

- width at the bottom of 0,6

- height of the parapet 0,3; Xnumx

- width over the top of 0,6; 0,9; Xnumx

- Berm width 0,2; 0,3 Technical performance, m / h:

- not frozen soil up to 1200

- frozen pound to 300 Dozer blade width, mm 4110 Movement speed, km / h:

- maximum 50

- working 0-2

- when moving the soil to 10 Average specific pressure per pound, kg / cm2 0,8

Engine power, kW (hp) 618 (840)

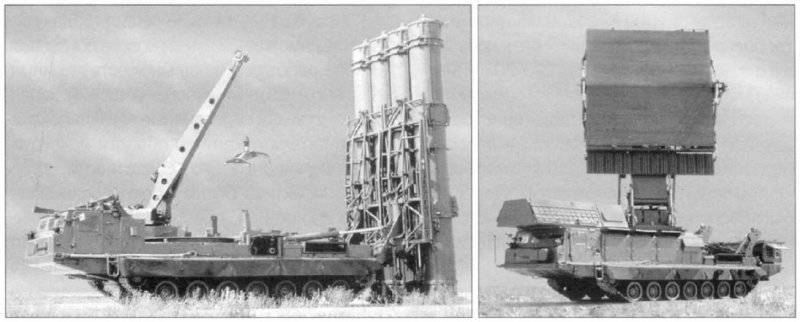

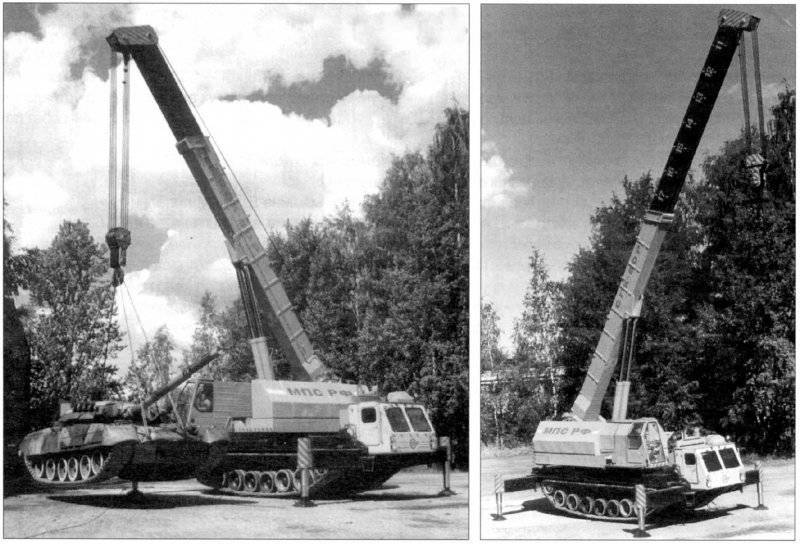

Self-propelled crawler cranes СГК-80 and СГК-80Р

The special purpose vehicles were Russian-German self-propelled crawler cranes SGK-80 of Russian-German and SGK-80Р - Russian production. The need for a self-propelled crawler crane is particularly felt due to the growth of various man-made accidents in transport and industrial facilities, often far from roads, in the outback, where such a crane can quickly get its way.

The development of these machines was carried out under the direction of V.P. Yakovlev and V.N. Spiridonov. The crane part of the SGK-80, created by the German company Schwarz-Machinebau Kirov (Leipzig), is mounted on a chase, equipped with a two-link telescopic boom and a polyspast hook suspension. The SGK-80Р crane is made entirely on the basis of domestic components and has higher technical characteristics, its price is almost 2 times lower.

Structurally both cranes consist of:

- tracked chassis equipped with a system of hydraulic outriggers designed for hanging, leveling and perceiving loads when lifting loads;

- a turntable, which allows to work around (angle of rotation 360 °);

- full-turn crane platform with its own power unit, crane operator's cabin, mechanisms for turning and lifting the telescopic boom;

- on-board computer providing safety interlocks, monitoring selected cargo characteristics and troubleshooting of operating mechanisms;

- hydraulic systems;

- heating systems for operation in winter conditions.

Non-standard design and technical solutions and techniques allowed the machine to be designed in such a way that with its own weight 65 t it allows you to lift a load with weight 80 t (when tested, the weight of the load reached 100 t), and the automated control system (using an on-board computer) takes into account the load the crane, boom reach, weight of the load and allows you to impose restrictions on the angle of rotation and height of lift, ensuring safety of work.

And finally, the technical autonomy of the crane part (with its own engine, hydraulic system and electrical equipment) allows separate production of the crane turning part (HRC) at specialized enterprises, without requiring technological connection with the crane manufacturer.

Main technical characteristics of self-propelled cranes

Model of the crane SKG-80 SGK-80P

Crane weight, t 65 65

Crew, man 2 2

Maximum lifting capacity, tons 80 80

Maximum load moment, tm 480 480

Maximum boom, m 13,5 15,5

Work sector 360 ° 360 °

Boom angle 47 ° 65 '

Maximum speed, km / h 25,4 25,4

Average unit pressure per pound, kg / cm2 1,4 1,4

Main engine power, kW (hp) 618 (840) 618 (840) Auxiliary engine power

chassis, kW (hp) Missing 22,1 (30) Crane engine power

parts, kW (hp) 154 (210) 154 (210)

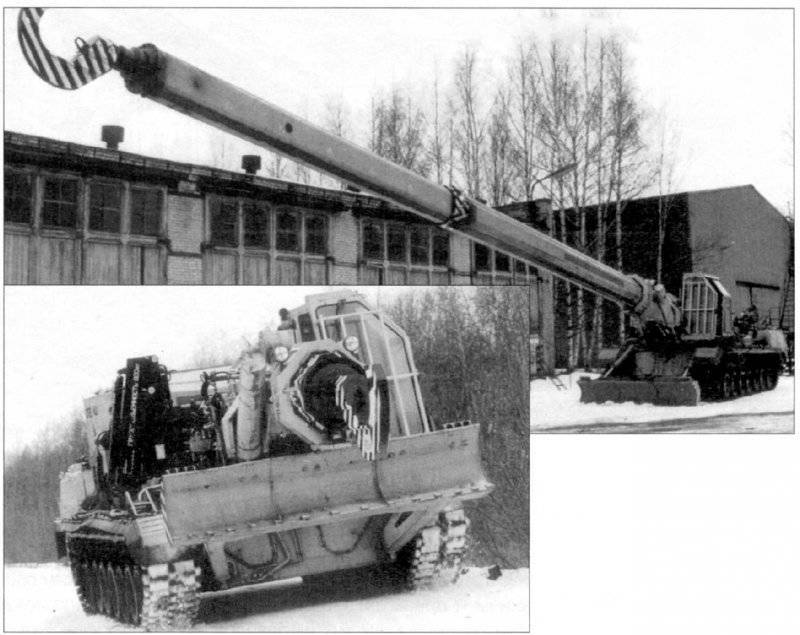

SM-100 self-propelled tracked vehicle

A characteristic feature of the machine CM-100, developed by V.N. Spiridonov and his colleagues in the design bureau, in comparison with other emergency and rescue means, is the presence of an operator controlled telescopic hydraulic power manipulator. This “smart hand”, which is located on the chassis length 11 m in the stowed position, is capable of advancing to 20 m and using a replacement tool, without direct human participation, to capture and move large-sized objects (including cars, diesel locomotives, etc.) with an effort up to 120 ts, which is especially important when dismantling debris located in areas that are dangerous for a person to stay. Telescopic arm of the manipulator (in the form of an octahedron in transverse

section) allowed to place in a limited volume of high-loaded roller bearings and perform metal construction of maximum strength. Relocation of objects is possible due to the application of pulling or pushing force. The power manipulator allows in a limited volume to realize high loads due to a turntable based on polyamide slide bearings.

In the aft part of the CM-100, dozer equipment is installed, which is used in clearing the debris and as an emphasis (coulter) when the power arm is operated. At the end of the telescopic boom has a hydraulic rotator that allows you to rotate the working tool for the convenience of capturing the moved objects. The machine is equipped with a circular lighting system with controlled spotlights and an 55 kW power generating unit, which provides energy for plasma cutting and welding equipment. Containers are installed on the machine for transporting replacement tools and equipment. Their loading and unloading, replacement of the replaceable tool on the rotator is performed by an auxiliary hydraulic winch with a crane working on both sides of the machine. Traction winch - 6 t, cable length - 65 m.

Giving an interview about the SM-100 self-propelled tracked vehicle during its tests, V.I. I. Spetmash, General Director Kozishkurt stressed that neither the world nor the domestic equipment had ever known anything like that, that such equipment would become an indispensable assistant for the rescuers not only of the Ministry of Emergency Situations and the Ministry of Emergency Situations (“Unique Push-Push”, St. Petersburg Gazette, №237 (3107), 26.12.03 g.).

When creating the considered machines, original design and technical solutions were found that required complex calculations using high-performance computing, mathematical modeling methods, operating models, materials research used for high-loaded structures. All solutions are protected by 13 patents. Among them:

1. Patent No.45331 from 4.12.1997 for the industrial design “High-speed trenching machine”.

2. Patent No. 42340 from 23.03.1995 for the industrial design "Self-propelled tracked crane".

3. Eurasian patent №002533 from 19.03.2001 g. "Method of braking a mechanical winch and gearbox for its implementation."

4. Patent for invention №2140584 from 7.08.1998 g. "Double telescopic cylinder", etc.

There is no doubt that the family of unified machines developed and put into operation corresponds to the strategic goals of the Russian Federation in the field of ensuring the security of various national economic structures. This is an example of the rational use of dual technologies, the introduction of the development of the military-industrial complex in the national economy without prejudice to the development and development of defense products.

Main technical characteristics of the CM-100

Machine weight, tons 48

Crew, man 5

Maximum departure of the manipulator, m 20,6

Maximum tractive effort, tonnage 120

Maximum pushing force, tf 25 The range of operation of the power manipulator:

- in the vertical plane 20 ... + 45 '

- in the horizontal plane ± 15 'Composition of the replaceable instrument, pcs .:

- 1 hook

- hook 1

- gripper for 1 automatic coupling

- 1 planning blade Auxiliary equipment:

- there is a bulldozer

- winch (pull force 5 tf) Yes

- manipulator (load capacity 800 kg) Yes

- equipment for air plasma cutting and welding

- Fuz containers, pcs. 2 Maximum speed, km / h 50

Information