TU-95. Target America (part of 1)

Initial data

In 1950, Mr. V.M. Myasishchev appealed to the government with a proposal to create a strategic bomber with a maximum speed of 950 km / h and a range of more than 13000 km, equipped with four AA Mikulin designs. The proposal was accepted, and the reconstructed OKB-23 Myasishchev was assigned to create the M-4 bomber capable of reaching the US territory with a nuclear bomb in 5 in the shortest possible time. However, Stalin, deciding to err, gave a similar task to Tupolev. The huge costs of the simultaneous development and mass production of two identical aircraft for the purpose did not bother him: the Soviet government seriously considered the possibility of a nuclear war with the United States in the middle of the 50s. and wanted to get a full guarantee of creating a strategic carrier.

To talk with the leader, Tupolev turned out to be well prepared: the search work on heavy aircraft with transonic speed began in his OKB-156 (strictly speaking, this designation was applied to the ANB Tupolev only in the period from the end of 50-x mid 60-s. Before all the documents were addressed to the plant number 156, and after - MMP "Experience." From the middle of 70-s, the company became known as MMP "Experience" named after A.N. Tupolev, from the second half 80- x years - ANTK named after A.N. Tupolev, and from 1992 - ANTK named after A.N.Tupolev) in the spring of 1948. It was then that Andrey Ni’s table olaevicha lay report "Study of flight characteristics of heavy jet with swept wings." Based on research conducted by the OKB, TsAGI, captured German developments, this report addressed the problems of choosing the main design parameters of an aircraft with a 80-160 t flight weight and 25-35 ° swept wing along the 1 / 4-chord line. The results of this study have already formed the basis of the Tu-16 project, now Tupolev decided to use the experience of using the swept wing to radically improve the characteristics of the Tu-85. Thus, the purposeful sequence of solving complex scientific and technical problems and taking into account the trends in global aircraft construction allowed the OKB-156 team to 1950 to shape the shape of the future high-speed long-range bomber, which received the 95 code. The aircraft was supposed to have a take-off mass of about 150 T and a wing swept 35 ° with an elongation around 9. By that time, this wing had been studied quite well at TsAGI. The fuselage of the new car on the layout and diameter repeated the fuselage of the aircraft "85".

To determine the type of power plant, the Kondorsky brigade worked out its various variants: with four turbofan engines of the AM-3 type; with four TVD type TV-10 and two AM-3; with four TV-10 and two TRD type TR-3A; with four TVD type TV-4 type TV-4 and two AM-3; with four tv-xnumx. During searches, the wing area varied from 10 to 274 m400, elongation from 2 to 6,8, sweep angles from 11,75 to 0 °. For the final comparison, we chose two close options: one with four turbofan engines, the other with four theater engines. Calculations showed that the most suitable for obtaining the flight range over 45 km was the variant with four theater engines with an 13000-12000 eHP power. and specific costs in cruise mode of the order of 15000 kg / ehp. at one o'clock. At the same time, the take-off weight of the aircraft reached 0,25 t, the estimated maximum speed at 200 m height is about 10000 km / h, the takeoff run length is 800 m. A similar plane with four turbofan engines using 1500 kgf (for example, AM-9000) would have If the maximum range is no more than 3 km and the length of the run is over 10000 m. Its only advantage would be the maximum speed of more than 2000 km / h. After studying the results of research and understanding that the main thing is to reach the target, Tupolev finally chose a power unit for theater for the new aircraft, although the leaders of the aviation industry and the Air Force command, having familiarized with the project of Myasishchev, insisted on using TRDs.

By that time, the TV-2-type TVD, developed at OKB-276 under the supervision of N. D. Kuznetsov based on the captured Jumo 022, had an 5000 e.s. Its prototype, originally designated TV022, passed a state bench test in October 1950. His forced version of the TV-2F had the power of 6250 eHP At the same time, OKB-276 began work on the TV-10 and TV-12 engines with a design capacity of 10000 and 12000 eHP, respectively. But these most powerful TVDs in the world could only be ready in 1,5-2 of the year, which delayed the work on the 95 aircraft. In search of a way out of this situation, Tupolev flew to Kuibyshev to Kuznetsov. As a result, OKB-276 urgently designed and manufactured the engine-pairing of two TV-2F, working on a common gearbox. The new theater received the designation 2TV-2F, and its total capacity reached 12000 eHP. The most difficult thing in this work was the creation of a gearbox, which had no analogues in world practice. It had no analogues and the implementation of similar power with a propeller. According to first estimates, its diameter exceeded 7 m, which was clearly unacceptable for layout reasons. The output was found in the use of two coaxial screws of smaller diameter with opposite rotation, which OKB-120 undertook K.I.Zhdanov to design. Kpd screw installation should have been at least 0,78-0,82, which also has not yet been achieved in the aircraft industry.

After a principled resolution of these crucial issues, Tupolev asked Stalin to re-accept him. The meeting took place, and the Chief Designer received a "go-ahead" for further work. 11 July 1951 issued a decree of the Council of Ministers of the USSR and an order of the aviation industry, according to which OKB-156 was instructed to design and build a high-speed long-range bomber in two versions: with four twinned XDUMX-2F ATC in September 2 g for flight tests in September 1952 g , with four TVD-12 theaters with a transfer period for flight tests of a second prototype aircraft in September 1953.

Four days later, on July 15. 1951, the technical projects department, under the leadership of S.M. Eger, began the conceptual design of the 95 aircraft. In August, the Air Force developed tactical and technical requirements for the bomber. The plane was supposed to strike at military bases, seaports, military industrial facilities, political and administrative centers in the rear of the enemy. In addition to a wide range of strategic tasks, the new machine was intended for setting mines, torpedoes and bombing attacks on ships in remote maritime theaters of operations. The aircraft to be built should have a practical range of 15000 km, a maximum technical range of 17000-18000 km, a cruising speed of 750-820 km / h, a maximum speed of 920-950 km / h, a practical ceiling of 13000-14000 m and a takeoff length of 1500-1800 .

According to the Eger department, the combination of high speed and high altitude with powerful defensive armament made the new bomber for enemy fighters almost non-vulnerable. Modern navigation and radio communication equipment made it possible to use the aircraft as part of the same-type machine mix, or singly, day and night, in adverse weather conditions. Its estimated maximum bomb load was 15 t, the normal one was 5 t, the maximum caliber of bombs was 9 t. Not only ordinary but also nuclear bombs, mines and high-altitude torpedoes could be placed in the thermally stabilized cargo compartment, up to four guided bombs.

Both variants of the bomber given by government decree were unified and differed only by engine type. For the second variant, OKB-276 promised to prepare TV-12 with a maximum take-off power of 12500 bhp, maximum at height - 12000 bhp. and nominal -10200 eHP With a bomb load of 9 t and 2TV-2F engines, the plane had to have a range of up to 6000 km, and with TV-12 engines - up to 7500 km. On the basis of the new machine, it was planned to create a global shock complex, for which it was supposed to install a wing refueling system in the air from similar tankers. At the same time, the calculated technical range reached 32000 km, which made it possible to strike at any point on the globe and guarantee a return to the base.

31 October 1951 The draft design of the "95" received a positive opinion from the Aviation Technical Committee under the Commander-in-Chief of the Air Force, although work on it was completed only in mid-December. 15 November, the Kuibyshev Aviation Plant No. 18 was tasked to proceed with the preparation of the mass production of the 95 aircraft with a deadline of 1 September 1952 for September. During 1954-55. the factory was instructed to transfer serial bombers to the 15 air force, and to the engine-building factory No. 24 (also located in Kuibyshev) to master the TV-12 engine in the series, which was designated as NK-12. At the same time, VMMyasishchev OKB-23 and the Moscow Plant No. 23 were hastily preparing for the serial production of the M-4. The estimated start of a nuclear conflict with the United States, 1954, was approaching.

Decision progress

In the process of designing and building a new bomber, the OKB-156 team, together with the developers of systems and units, successfully solved a number of the most complex scientific and technical problems. To coordinate this large-scale work, Tupolev appointed his closest assistant N.I.Bazenkov responsible for the theme "95", who later became the chief designer of the Tu-95 and his civilian version Tu-114 (in 70, he was succeeded .Kirsanov, and at the end of 80's - D.A.Antonov).

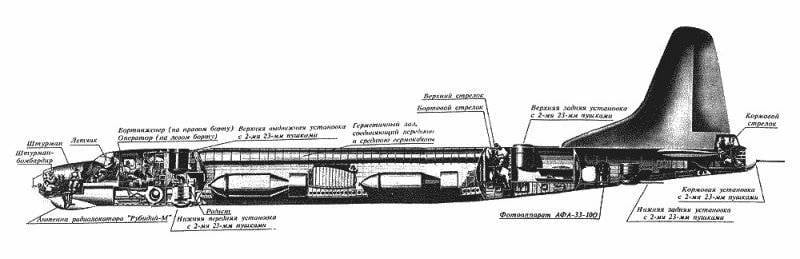

The aircraft "95" was equipped with the most advanced equipment, which only could give the Soviet industry. Its features, which then spread to all types of heavy aircraft, were the use of lighter aluminum wires in the power supply system and the introduction of electric anti-icing systems for the wing, tail, propellers and other surfaces. For the aircraft "95" created a new, more efficient system for launching powerful theaters. An important feature of the project was the lack of ejection seats. Eight crew members in an emergency left the car through the hatches and front landing gear compartment. This decision was justified by the relatively low velocity head, as well as significant weight savings and more comfortable crew accommodation conditions, which is especially important during a long flight. When creating a new aircraft, it was decided to maximize the use of semi-finished products and components from previous developments of the OKB. Subsequently, this allowed speeding up the process of mastering the machine in mass production.

During the development of the management system ideology, differences arose between OKB-156 and TsAGI. The Tsagists insisted on applying the novelty of that time - irreversible boosters, which were treated with disbelief at the Design Bureau, considering their installation to be premature. The OKB point of view won, and the control system had to be equipped with special devices that reduce the pilot's physical efforts to control the aircraft — various compensators, means of reducing friction, and so on. By the way, OKB-23 boldly put irreversible boosters on its M-4, and Tupolev people have long remained faithful to the statement of their boss: "The best booster is the one that stands on the ground."

From the very beginning of the development of the bomber "95" a large load fell on the strength department of the OKB, headed by A. M. Cheremukhin. Specialists of the department analyzed the power schemes of the aircraft as a whole and its individual units, determined the optimal location of the engines on the wingspan. After such thorough research conducted in OKB-156 together with TsAGI and OKB-23, they came to an unexpected decision: the safety factors regulated by the existing strength standards were found to be too high, leading to unjustified weighting of the structure. As a result, the methods for determining the design loads were revised, and the wings of the 95 and M-4 aircraft were significantly lighter. Additional complications in the work of the engineers introduced a parallel process of preparing serial production, which was in full swing at plant number 18, because the design changes they required led to a remake of the rigging and refinement of the prototype aircraft on the assembly line.

In order to accelerate the testing and fine-tuning of the 2TV-2F engine, one of the serial Tu-156 was transferred from the Air Force to the OKB-4 for conversion to a flying laboratory. By the middle of 1952, the TU-4LL was ready. On it, instead of the regular right neighbor to the fuselage of the engine, 2TV-2F was installed.

Working drawings of the aircraft began to be prepared in September 1951, and by the end of November they completed a full-size mock-up, which, during construction, was examined three times by Air Force representatives, making a lot of comments. A mockup was presented to the mockup, and in December, the Commander-in-Chief of the Air Force approved it. The construction of the first prototype aircraft "95-1" and the second instance for static tests began at the factory number 156 in October 1951.

Special case-1

By the fall of 1952, the construction of "95-1" was over. The undocked vehicle was transported to the flight test and development base (LI & D) in Zhukovsky, where it was finally assembled and 20 of September was transferred to factory tests. While the bureau was preparing for the first flight, the state security agencies took the strictest measures to ensure secrecy. A number of additional measures were taken to combat the leakage of information from the experimental design bureau and the pilot plant, introduced a strict mode of travel in the vicinity of the airfield on the right bank of the Moscow River, from where the runway and aircraft parking spaces were perfectly visible. All work on the prototype was carried out before the start of the movement of vehicles and electric trains on the Kazan Railway.

12 November 1952 crew consisting of the test pilot commander A.D. Perelet, the second pilot V.P. Morunov, the flight engineer AF Chernov, the navigator S.S. Kirichenko, the radio operator NF Mayorov, the electrician I. .E. Komissarov and flight mechanic L. Borzenkova lifted the car into the air. In the course of the 50 minute flight, the ninety-ninth reached the height of 1150 m. The normal refinement process began. After each landing, troubleshooting was carried out, and modifications were made. Only three flights took place before the end of the year, but from 13 in January the tests went more intensively. On April 17, on the 16 flight, the automatic installation of the pitch of all four propellers failed, and Perelet was hardly able to land an experimental car. At this point, the total 95-1 bloom was about 21 hours. The plane was on the ground again for almost a month, and the engineers of the OKB and TsAGI were looking for the causes of the defect.

The government and the Air Force command kept a constant check on the testing process. The results of each flight were reported to the government through the IAO and the Ministry of State Security, and the representative of the Air Force at plant No. 156, Sub-to S. D. Agavelyan, reported directly to Commander-in-Chief of the Air Force, Colonel-General P. F. Zhigarev. All participants in the tests were incredibly overwhelmed, both morally and physically. Many slept a few hours a day, spending the rest of the time at the airfield, at the OKB, or at the ministry.

11 May was a regular, 17-th flight. At the airfield was himself A.N. Tupolev. Everything was going fine, a constant radio communication was maintained with the test machine, and suddenly a restrained and maybe overly calm voice of the Flight was heard in the speakers: "I am in the Noginsk region. Fire of the third engine. Free the runway. I will sit right off the route." Two or three minutes later, the flight was on the air again: “They did not manage to cope with the fire, it grows, engine nacelles and chassis are burning. There are about forty kilometers left of you”. And then, after a while: "The engine has come off. The wing and gondola of the landing gear are burning. I gave the crew command to leave the plane. Watch ...".

The first was a telephone message from the Noginsk department of state security that the plane had fallen northeast of the city and was on fire. Tupolev and Agavelyan immediately left for the crash site. Behind them on several machines - employees of the experimental design bureau and test base. Directly to the site of the fall, we traveled through the marshy forest on foot, for Tupolev we got a horse. A terrible picture opened up to the eyes of the arrivals. The aircraft, having on board several tens of tons of fuel, crashed into the marshy undergrowth and exploded. A funnel was formed with a depth of 10 meters, at the bottom of which eight huge wheels of the chassis burned out. Scattered through the forest, people began to search. Found the remains of AD Perelet and paratrooped navigator S. S. Kirichenko. In addition to them, the flight engineer AF Chernov and the vibration test technician from the scientific research institute of aircraft equipment A. Bolshakov were killed. The second pilot V.P.Morunov, the boarding engineer N.F.Mayorov, the leading engineer N.V. Lashkevich, the assistant to the leading engineer A.M.Ter-Akopyan, the board electrician I.Ye. Komissarov, the board mechanic L. Borzenkov and the engineer LII K. I.Wyman was saved by parachute.

To clarify the causes of the catastrophe, a government commission chaired by the Minister of Aviation Industry, MV Khrunichev, was created. Representatives of the Ministry of State Security, the Air Force, the General Staff, the Party Central Committee, the Council of Ministers and many other organizations also participated in the investigation. First of all, the commission heard reports from surviving testers. Maiorov said: "... Having flown out in the morning, we carried out a task to measure fuel consumption. In the last mode of maximum engine thrust, at a height of 7300 m, a third engine fire broke out. I watched the car’s behavior through the upper blister. When I heard a strong click, I saw a hole In the front upper part of the third engine hood and a small flame beating out of it. I reported to the commander. The engine was immediately turned off, the screws were plugged. Fire extinguishing was turned on. The fire continued, parts of the aircraft fell off. The plane would not succeed. Descending to the height of 5000 m, Flight took the burning plane from the densely populated area to the forest and ordered everyone except the flight engineer Chernov to leave the plane. I waited. Looking down into the cockpit, I saw a calmly sitting commander. that he intends to land the plane in an emergency. At the height of 3000, I left the plane and started descending. I went down by parachute and only saw how some kind of strong fire appeared and a column of smoke appeared ... ". Lashkevich, descending on a parachute, saw the burning third engine separate from the plane, the screws of the fourth engine rose to the vane position, and the car began to fall in a steep spiral, almost vertically.

It was found out that Flight and Chernov died directly from the explosion, until the last moment trying to save an experimental car (in 1955, Mr. AD Pereletu was posthumously awarded the title Hero of the Soviet Union for his contribution to the creation of the Tu-95, and in Lennon Award in 1957. ). Kirichenko left the plane, but it was covered by a shock wave and a flame. Bolshakov also jumped out, but forgot to wear the parachute on which he was sitting (they said that he did not know how to use it)

The Air Force’s first reaction to the disaster was the decision of the Commander-in-Chief to prepare a submission for the trial of the military tribunal of the senior military representative at the factory No. 156 of Agavelyan as the main culprit of the disaster. The first version appeared, explaining its reason, supplemented and supported by OKB-276 and the engine department of the Experimental Construction Department aviation Air Force technicians. Everything was explained simply: the engine mount of the third engine was destroyed, the engine began to come off, a fuel leak began, which led to a fire. The cause of the disaster is the negligence of S.D.Agavelyan and senior military representative at TsAGI, Colonel Engineer A.I.Soloviev, who accepted the results of statistical tests of engines. The idea of destroying the engine mount was picked up by many and took on its final form in the Conclusion of the head of the aforementioned engine department, General Zaikin, who drafted the order of the Commander-in-Chief to bring both senior military representatives to court. However, after reading the draft order, Zhigarev realized that the matter would not end with the shooting of two officers. After all, he himself daily reported the progress of the tests to Stalin and knew how much attention Beria was paying to this. The Commander-in-Chief was sure that many generals and, possibly, he himself could soon be in the role of the defendants. Therefore, he summoned both military representatives, carefully listened to reports on their impeccable control over the development and testing of the engine mount, made a decision on the complete innocence of the officers, and did not sign the order.

Meanwhile, the commission continued its work. Many, including dvigatelisty, amicably blamed Tupolev. Some even said that it was impossible to trust the creation of a strategic bomber to the former "enemy of the people." Andrei Nikolayevich was silent, all his questions were answered by his deputies N.I.Bazenkov, S.M.Eger, K.V. Minkner and others. They defended a different version of what happened. The fact is that one of the soldiers, who had dug up the third engine's engine nacelle, found a large piece of gear gear. When he was transferred to CIAM, the largest specialist in the strength of aviation materials, RS Kinashoshvili, determined by the structure of the fracture, that the destruction was not of a shock, but of fatigue nature. However, most members of the commission did not agree with this conclusion, since the gear in the engine turned on the entire 10 watch, and insisted that it broke down due to the impact.

At a meeting of the commission, unexpectedly for engine builders, excerpts from the documentation of the technical control departments of OKB-276 and Experimental Plant No. 276 (At the request of Tupolev and Khrunichev, all documents on this issue were arrested by state security bodies and presented to the commission) were announced that 30- The 40TV-2F bench test hours and the 2 test bench gears were destroyed with the occurrence of fires in test boxes. Unperturbed until that moment, Kuznetsov, the chief designer of the engine, suddenly turned pale and fainted. The situation, however, softened Tupolev himself, stating that Kuznetsov should be reprimanded for concealing the announced fact, and more severe measures could harm the country's defense. He called for assistance to engine builders and to enable them to refine the engine. Further investigation established that the cause of the catastrophe was the destruction of the gear reducer gear due to its insufficient fatigue strength. This item was manufactured in violation of technology, the true culprit was found and convicted. Now it is among the exhibits of the museum of the Samara NPO Trud, on which the 2TV-2F engine was manufactured.

15 October 1953, the MAP issued an order in which, among the causes of the catastrophe, apart from the destruction of the gear, was the lack of effectiveness of onboard fire extinguishing agents. The chief designers Tupolev, Myasishchev, Kuznetsov, Mikulinu were charged with ensuring quality and trouble-free conduct of flight tests of the 95 and M-4 aircraft. Tupolev, Kuznetsov and TsAGI chief Makarevsky, before the second instance of the 95 bomber with TV-12 engines was launched, it was necessary to organize and carry out a motor test with a gondola, as well as additional static and vibration tests of the entire machine. Before Kuznetsov was required to install TV-12 on an airplane, to ensure reliable fine-tuning and testing of engines in bench conditions, as well as at the Tu-4LL flying laboratory. OKB-276 was decided to assist in various areas, in particular, to create standards for the strength of aircraft engines. In addition, it was prescribed to conduct special tests of the fire protection of 95 and M-4 bombers. In the order, obviously, for securing the engine-building OKB-19, which was led by Pavel A. Solovyov, the development of a new D-19 theater unit with an 15000 el.ns takeoff power was given, the nominal one - 12300 el. and specific fuel consumption at maximum mode 0,16 kg / ehp. at one o'clock.

Special case-2

The construction of the second prototype "95-2" with TV-12 engines ("understudy") began at the 156 plant in February 1952 and lasted until November. This made it possible to take into account the results of the first flights of the "95-1", as well as already had some experience in operating the Tu-16. As a result, the “doubler” turned out to be lighter than its predecessor (the weight of the empty “95-1” exceeded the calculated one by 15%, and the “doubler” - by 3%). In addition to the modified nacelle, it was notable for new structural materials, in particular, the use of the В95 alloy, and more advanced equipment. For a long time, until July, 1954, on an almost finished machine, modifications were carried out, and for almost half a year "95-2" stood in the assembly shop: there were no engines. OKB Kuznetsova this time did everything carefully, with the guarantee that the May 1953 tragedy will not happen again.

The MAP leadership, for its part, closely followed the fine-tuning and testing of the TV-12. In December, 1953 approved the general layout of the motor, and when it became clear that its components such as gearbox, oil system, torque and thrust measurement systems could not be brought, OKB-276 suggested working out the backup versions of these units. The take-off and maximum power of the TV-12 exceeded the declared values by 2-3%, but the specific fuel consumption also turned out to be higher by 2-3%. Experienced TV-12 installed on the Tu-4LL, and since the summer of 1954, he began to pass flight tests.

In December, 1954 on 95-2 was finally installed on TV-12 and transported to Zhukovsky’s airfield in early January. The 21 numbers the pilot machine was officially handed over to factory tests, and the February 16 crew led by test pilot M.A.Niuhtikov and co-pilot I.M.Sukhomlinin raised the bomber into the air. Flights and fine-tuning of the aircraft at the stage of production tests were carried out before 8 in January 1956. During this period, the “doubler” made 68 flights with a total flight of 168 hours. In general, the tests were normal, but one episode nearly broke the entire program of the 95 aircraft ".

In the summer of 1955, when the “doubler” was once again returning to the airfield, flight engineer Ter-Hakobyan announced on the radio that no landing gear was being produced, and not from the main power supply network, nor from the emergency one. Putting the plane "on the belly" meant with a high probability to destroy the second experimental car. An alarming situation was created in Zhukovsky. The bomber flew in circles, burning out fuel. Tupolev, Kerber and other leading employees of the OKB arrived from Moscow urgently. Kerber, with equipment specialists, laid out the electrical circuits on the grass at the remote gearbox and began to look for the cause of the non-release of the chassis when powered from the emergency network. Tupolev, in great excitement, walked around and hurried Kerber. So lasted about two hours. Finally, Kerber took the microphone and began to clearly send the command aboard the aircraft. He ordered Ter-Hakobyan to completely de-energize the car, and for a while the “backup” was left without radio contact with the ground. When the relay was turned on again, the chassis exhaust system was blocked and calculated by Kerber, the chassis was released, and the aircraft made a normal landing.

That summer, the “understudy” was presented to the Minister of Defense G.K. Zhukov and the head of the country, N.S. Khrushchev, who, sitting in the cockpit, discussed his further fate with Tupolev. The general public "95-2" was first shown on the traditional air parade in Tushino. The plane made a great impression on Western aviation specialists. In NATO, he received the code designation Bear (bear). For two years, the Western press believed that the bomber was created at the SV Ilyushin Design Bureau and called it IL-38. Only some time after the iron curtain, they identified the true creators of the aircraft, but assigned it the wrong designation Tu-20.

Tests "doubler" continued. In September, 1955 was the time for the main exam - a flight at maximum range with bomb dropping, photographing gaps and returning to the home airfield. The route began in Zhukovsky, ran through the entire territory of the USSR to Khabarovsk, then bombing on the Kamchatka training ground and return followed. In that flight, the take-off mass of the “doubler” was equal to 167,2 t, fuel - 84,44 t, cruising speed - 750 km / h, maximum reached 880 km / h, practical ceiling - 12150 m, takeoff run - 2300 m. Practical range reached 13900 km, which was 1100 km less specified in the terms of reference, but quite enough to reach the North American continent.

Solution found

While there were factory tests of experimental machines, the serial production of the bomber was deployed at the factory number 18, which was given the official designation Tu-95 (the open name is the product "B"). Already in 1955, the stocks of the first two series - zero and first, with five cars in each stood on the stocks. Serial Tu-95 had, in contrast to the "doubler", extended by almost 2 m fuselage, a large 5% weight of an empty aircraft and full equipment onboard equipment. 31 August 1955. The first serial machines No. 5800003 * (tail number "5") and No. 5800101 (tail side - "6") were released. Both of them passed factory flight tests from 1 in October 1955 to 28 in May 1956.

State tests of the Tu-95 were carried out on three airplanes - a "double" and the first two production vehicles - from 31 May to August 1956. The first to start the flights were the "double". It reached a maximum speed of 882 km / h, the ceiling was 11300 m, and the range was 15040 km. Serial, heavier cars, showed a smaller range and ceiling. The results turned out to be lower than those set in 1951 by a resolution of the Council of Ministers, so the aircraft 5800101 No. from 20 August 1956 to 21 February of next year was undergoing revision, during which the upgraded NK-12M engines with 15000 take-off power e.l. . The maximum take-off mass of the bomber increased from 172 t to 182 t, and the fuel supply from 80,73 t to 89,53 t. The aircraft received the designation Tu-95M (product "VM") and outwardly almost did not differ from the Tu-95, except for additional air intakes in the upper part of the nacelle designed for blowing electrical equipment. It passed factory tests in September-October 1957, reached a maximum speed of 905 km / h and a practical ceiling of 12150 m. The maximum technical range was 16750 km, and the practical exceeded 13000 km. Despite the fact that these data were lower than those specified by the Council of Ministers, on September 26, the aircraft was commissioned on 1957. By the way, the M-4 showed on the state tests the practical range of the entire 9050 km.

Between 1955 and 1957 Plant No. 18 built the Tu-31 bomber 95, and by the end of 1958 another 19 Tu-95. Subsequently, they were all equipped with NK-12M engines, and then - NK-12MB engines. In 70-s. these cars went through the whole cycle of improvements and improvements that allowed them to remain in service until the 80-s.

- Vladimir G. Rigmant, Efim I. Gordon

- TU-95. Target America (part of 1)

TU-95. Target America (part of 2)

Information