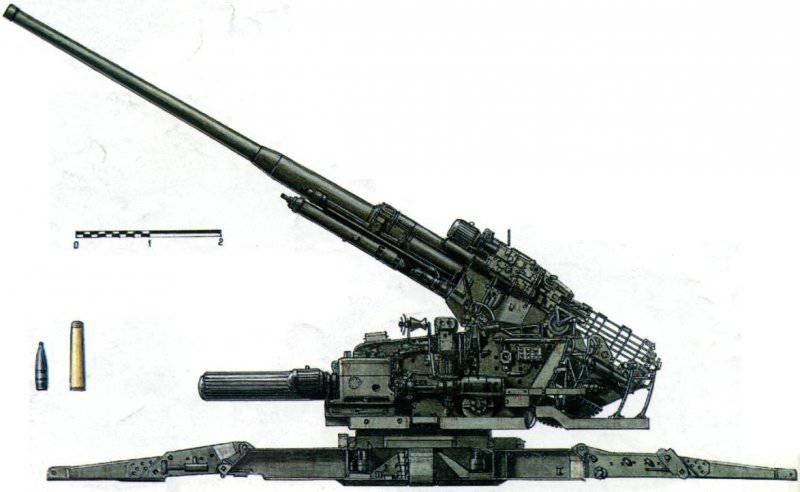

Soviet 130-mm anti-aircraft gun KS-30 (1948 g.)

In 1947, the design bureau of the plant No. 8 under the leadership of the chief designer L. V. Lyulyev developed those. 31410 project. This project was called "130-mm moving gun with SSP". The gun was designed to destroy air targets flying at a height of up to 19500 m. According to the project, it should have the following characteristics: Projectile mass - 33,4 kg; initial speed - 970 m / s; ceiling - 20 thousand. In the same year, the project was approved by the State Agrarian University and the Ministry of Arms. Gun assigned index KS-30. In the following year, 1948, Plant No. 8, produced a prototype of a KS-30 moving-type gun, which passed small factory tests in November of the same year. 25 December 1948 a sample was handed over to the customer, December 28 was sent to a research anti-aircraft artillery ground (NIZAP). 1948, the Kirov plant manufactured an experimental platform KS-30P. During 1949, a prototype of the platform and drawings were refined. In December 1949 of the year, four more platforms were manufactured and handed over to the customer.

5 - 17 April 1950. The experienced KS-30 battery (four guns with GSP-130) was factory tested without shooting at factory 8. However, the military acceptance of them refused to accept, because some of the mechanisms for them were not made. In addition, problems were noted: for example, on system No. 3 the tray swung incorrectly, there were failures of rammers, etc.

The second battery delivery was scheduled for June 1950. By this time, two ALD-100-2 (power units) deliveries of the Ministry of Electrical Industry had to be delivered. Their manufacture engaged plant number 686. Plant No. 172 was designated as the head manufacturer of the KS-30. Plant number 232 engaged in the manufacture of swinging parts for anti-aircraft guns.

Modifications

Plant number 232 in 1953 year began the manufacture of experimental trunks. In the new trunks, the rifled part was changed (the number of rifling was reduced from 40 to 28; the field width was changed from 4,2 mm to 6,29 mm; the width of the rifling - from 6,0 mm to 8,3 mm). This has improved the reliability, stability of the projectile, as well as reduce barrel wear.

Plant No. 172 20 April 1956. Sent a letter to the Main Artillery Directorate, proposing to improve the performance of the 130-mm anti-aircraft gun KS-30. In particular, it was proposed:

- increase the initial velocity of the projectile from 970 to 1100 m / s;

- increase the speed of the pointing drives: horizontal - from 25 to 40 degrees / sec; vertical - from 9 to 20 degrees / sec;

- to introduce into the design a mechanism for automatic correction of the angles of horizontal and vertical guidance of the instrument, taking into account the inclination of the axle axle of the cradle.

To obtain these characteristics, the plant offered to introduce a muzzle brake and a loading mechanism, to increase the power of the GPS, to introduce a partial lining of the barrel, or to use a composite pipe.

In addition, it was proposed to use the mechanized provision of ammunition from the cellar unified with the KM-52. The main objectives of this modernization was to reduce the time for re-loading the gun and to facilitate the work of the calculation.

Gun device

The barrel of an anti-aircraft gun consists of a pipe, a breech and a coupling. The pipe has 28 rifling (in pipes of early production - 40 rifling). In all pipes, the slope of the rifling is constant. The horizontal wedge valve has a semi-automatic copying (mechanical) type. After loading, the shutter is closed using an automatic closing mechanism. The impact mechanism of the shutter is activated automatically through a time relay (mechanical) in the trigger mechanism. The mechanical time relay with the tray is blocked in such a way that the shot is fired only after the tray returns to the upper position. The breech assembled throwing mechanism.

The cradle is a molded box with a pipe and a molded upper link welded to it. The front clip with rollers is fixed on the pipe, along which the barrel moves during rollback and roll forward. Hydropneumatic rammer is equipped with a hydraulic accelerator. The underride devices include a hydropneumatic retracting brake of a riveted type and two spring-hydraulic overlap brakes. When fired, recoil gears are still.

The welded machine, having a cast base, rotates on a spherical double row chase. Each row has 112 balls (diameter 40 mm).

The horizontal device is designed for mounting and leveling the rotating part of the gun. The frame of the device is mounted on a ball bearing and four jacks, which are mounted on the crosspiece. The frame of the leveling device with the help of jacks is moved relative to the cross on the angle 2 degrees in any vertical plane. The lifting mechanism has one sector. The rotating contact device provides unlimited rotation in azimuth.

Guidance mechanisms have a mechanical transmission from hydraulic drives, with the help of which automatic aiming is carried out. In addition to auto-navigation, with the help of GSP-130 drives, semi-automatic and manual guidance can be carried out according to the data of the anti-aircraft fire control device using indicator devices. The control of hydraulic actuators in the case of semi-automatic guidance is carried out by means of manual guidance mechanisms, while the shift knobs are set in the “Semiautomatic” position. The structure of the spring balancing mechanism of the pulling type includes two columns.

The welded cross has folding legs arranged crosswise. In the stowed position, the paws are folded and attached to the cradle, the crosspiece and the machine. The cross in the stowed position serves as a vehicle. Retractable forward and reverse gears in the stowed position are attached to the crosspiece and, when transferred to the combat position, are rolled back.

Moves - uniaxial carts with torsion suspension. For the reverse and forward gears, wheels from YAZ-200 with GK tires (12,00x20 inches) are used. Hydrojacks are used for lowering and lifting a weapon when transferring from a combat position to a stopping position and back. The gun is transported with the help of an artillery heavy tractor.

The complex includes:

- 8 or less guns;

- gun stations of power supply ESD-50 VSA, placed on two-axle trailers;

- control unit anti-aircraft fire;

- the system GSP-130, which serves to enter data into the execution units and ensure the operation of non-8 guns;

- DREAM-30;

- the cable network connecting all elements of the complex, while the central distribution box (CID) is connected to PUAZO and each tool with a line of 300 meters in length, consisting of four segments of cable 75 m.

Winemaking

Production at plant number 172 was supposed to start in the fourth quarter of 1951, according to the plan it was necessary to hand over the 8 guns, but the plant did not pass any. In the 1952 year, it was planned to produce 16 guns, but none were produced. In fact, the production of KS-30 guns began in the 1954 year - 24 units. (according to the 32 gun plan); 1955 year - 120 units (120); 1956 year - XNUMHed. (255); 250 year - 1957 plus one for the landfill (333). In total, including experienced ones, made 328 guns. Production ended in December 738.

Technical characteristics 130-gun KS-30:

Trunk:

Caliber - 130 mm;

Barrel length with breech - 63,6 klb / 8266 mm;

The number of rifling 28 (on early 40 samples);

The mass of the barrel with a bolt - about 4170 kg;

Carriage:

The angle of vertical guidance from -3 to + 88 degrees;

The angle of horizontal guidance - 360 degrees;

Vertical speed:

from GSP-130 - 9 degrees / s;

manually - 0,5 hail, for a turn of a flywheel;

Horizontal pickup speed

from GSP-130 - 25 degrees / s;

manually - 3,6 hail, for a turn of a flywheel;

Rollback Length:

at an angle of 0 degrees - from 1450 to 1650 mm;

at an angle of + 88 degrees - from 1300 to 1500 mm;

The height of the line of fire - 1960 mm;

Dimensions in the combat position:

weight - 23500 kg;

length - 10360 mm;

height at 0 ° - 2690 mm;

height at 88 ° - 10510 mm;

width - 9525 mm;

Dimensions in the traveling position:

weight - 29000 kg;

length - 11650 mm;

height - 3250 mm;

width - 3075 mm;

clearance - 330 mm;

radius of overturning of a trunk - mm 6900:

vehicle base - 5000 mm;

Performance data:

Rate of Fire - 12 rds / min;

Firing range - 27000 m;

Maximum reach - 19500 m;

Transfer time from marching to martial status - 60 min;

Maximum wagon speed:

on the highway - 20 km / h;

on the road - 10 km / h;

Gun crew - 10 man;

Ammunition: O-481 - frag remote grenade;

Grenade mass - 33 kg, including 3,634 kg of explosive;

Fuse - VM-45, response time - 44,3 with;

Charging - separate-sleeve;

Sleeve - steel or brass;

The mass of the sleeve - 27,9 kg, including 14,3 kg of charge.

Initial speed - 970 m / s.

Based on materials:

http://военконспект.рф

http://war-arms.info

http://armyman.info

http://www.xliby.ru

http://omop.su

Information