Possible way to improve the fighting qualities of the tank

Retaining the dimensions and weight characteristics of the predecessors, they dramatically increased the firepower, armor and speed. The study of the development of the design of tanks for the basic qualities shows its slowing down and a full stop. One of the significant reasons is the ever increasing insufficiency of the volume of the hull and the turret under the armor. It is known that the dimensions of the tank, especially its width, are strictly limited by the conditions of rail transport.

The booked volume is filled to the limit with mechanisms, aggregates. ammunition and fuel. The fight goes for every extra ammunition, for every extra liter of fuel. The tank was overgrown with various fire extinguishing systems, radiation and other types of protection, devices for overcoming water obstacles and self-digging. Many elements of observation, warning, protection are taken out and not protected. The developed design of the undercarriage does not allow a significant increase in the relief and ground-drawing maneuverability. The control system of turns of the car does not allow further increase of speed of movement on roads.

Increasing the destructive power of ammunition, the initial speed of their flight, increasing the resistance of armor without increasing its thickness and weight, increasing the power of the power plant without increasing its size and fuel consumption - all this is a reliable, but long-term path involving fundamental science, performing large and expensive research. Naturally, they must be connected with military doctrine and the concept of a tank as a combat vehicle. But you can choose a simpler and currently quite effective way to improve the fighting qualities of the tank. It is necessary to break the deadlock, which is created by adherence to the usual layout, when the tank has one monoblock case with two tracks and a limited length of the prop part of the propulsion unit that can withstand the favorable ratio between the gauge width.

A break from the deadlock can be found if you sacrifice one of the tank’s geometrical parameters - its length. Increasing the length of the hull will dramatically increase the amount of reserved space to accommodate an additional set of ammunition, fuel, increase the number of crew members.

When assessing the length of the tank is considered its length with a gun and body length. If you estimate the surface area of the side silhouette of the tank, excluding from it the area of the barrel, then this approach would be wrong. The modern six-meter tank gun, larger than 120 mm, is not a needle. The probability of damage is large enough. When turning the car, especially steep, the radius of the launching of the protruding parts will be determined by a muzzle cut. Determining the length of the tank only on the hull is the same as determining the length of the crocodile along the body, excluding its tail.

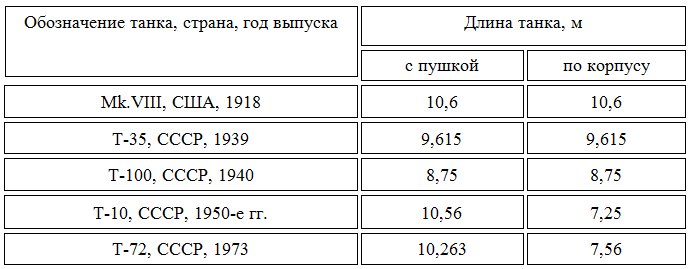

The table shows for comparison the length parameters of some heavy tanks.

It should be noted that the total length of the T-72 tank when the gun is positioned forward or backward varies little. The standard four-axle railway platform has a platform length of 13,8 m, which provides both side and end loading and transportation of a tank with a hull of up to 11,0 meters in length. With such a length of the hull, the length of the track support part can be more than 8,0 m. In T-72 it is 4,28 m. The longer the length of the propulsion surface, the greater the width of the moat is overcome by the machine, but it deteriorates the steering and turning ability of the tracked vehicle having a monoblock body resting on two caterpillars.

The elimination of this drawback is possible in the case of an articulated body, each part of which has its own tracks. This scheme was developed by Nodwell in the early 50-s. Especially positive, it showed itself in amphibious vehicles, dramatically improving their ability to get out of the water on land.

The articulated system (it is also called a two-link or a pairing) was successfully implemented as an all-terrain transport with a tracked propulsor. Known Swedish car BV206 and domestic DT-10P Ishimbay plant. There were attempts to create a combat vehicle. These include the light Swedish tank UDEX XX20, which has not developed further prototypes.

Experienced articulated tank UDEX XX20 (Sweden). The main armament is the German 120-mm smoothbore gun in the removed installation

Experienced articulated tank UDEX XX20 (Sweden). The main armament is the German 120-mm smoothbore gun in the removed installationIn the Armored Academy named after Malinovsky, work was carried out to substantiate the articulated tracked combat vehicle. But then the preparation of a scientific report did not matter.

All previously designed and built in the form of prototypes or serial articulated tracked vehicles were controlled at the bends in the kinematic manner. To obtain sufficient turning, the angle of rotation of one part of the two-cranks relative to the other reached 30 ° in each direction. And this circumstance complicates the communication of volumes of turned elements among themselves. All known structures have blind end walls facing the connecting device.

Developers Sparok, obviously, it was not known that the rotation can be done both in kinematic and on-board method.

Increasing the length of the tank hull will cause an increase in the length of the caterpillar and its supporting surface. In an articulated car, the number of tracks will double, but the distance between the front support roller of the head and the rear support roller of the tail will be significant and will interfere with the turning of the machine onboard. This interference in an articulated machine is easily eliminated. In modern articulated machines, body rotation is controlled in two planes. In horizontal for change of the direction of movement and in vertical for improvement of relief passability. Using the ability to rotate the body in a vertical plane, you can shorten the length of the supporting part from the driver’s seat and thus facilitate the implementation of sharp turns. This technique is used on some wheeled and tracked vehicles with a monoblock body and an onboard steering system. In particular, the Panar M8 cannon armored vehicle and the Swedish tank Shyudad.

Combat wheeled vehicle "Panhard" М8 (France)

Combat wheeled vehicle "Panhard" М8 (France)In an articulated tank, by connecting the front and rear of the hull with a hinged tunnel, you can communicate them, pass all communications and controls through it, and ensure their armor protection. An annular toroidal pneumatic seal will ensure the tightness of the hinge.

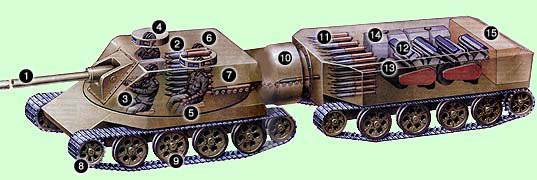

Thus obtained a significant additional amount of reserved space will allow the entire front part to take under the fighting compartment. In the tower of increased volume with a longitudinal armored partition in the left, along the way, the crew will be located, including the driver. In the right - the gun and its charging system with the current set of ammunition, in the back of the two-linkage will be located a stock of ammunition, a power plant, fuel tanks.

Chassis - track rollers, torsion bar suspension, tracked belts, tensioning devices, drive wheels interchangeable.

The numbers on the diagram denote: 1 - tower; 2 - crew quarters; 3 - current consumption; 4 - conveyor; 5 - ammunition stock; 6 - power unit; 7 - fuel tanks

Receiving additional moving articulated reserved volume makes it possible to:

- 1. Increased ammunition increased caliber 3 times.

- 2. Increase in power reserve with one refueling 3 times.

- 3. Increase the power of the power plant on existing engines 2 times.

- 4. Increased relief patency in overcoming the moat and threshold 1,5 times.

- 5. Increased soil-coupling permeability.

- 6. Increase the survivability of the chassis. The machine can move and be controlled even with the loss of three tracks. Move side step with complete loss of tracks.

- 7. Reducing the time for self-digging 10 times.

- 8. Reducing the time to prepare to overcome the water obstacle in 100 times.

- 9. Significant increase in safe highway speeds.

- 10. Conveniently controlled reversing.

All these and other not listed positive qualities can be obtained by design development using a significant number of ready-made assemblies and assemblies. The design of the machine fully fits into the existing technology and the state of the factories producing tanks.

At the beginning of 1999, the author made and tested a valid model in full size 1 / 7 in order to identify new driving characteristics of the articulated tracked chassis.

The members of the military-technical section at the cultural center of the Armed Forces of the Russian Federation, the department of tractors and amphibious machines and the department No.18 of the General Military Academy of the Armed Forces had a significant moral and organizational work to study the model.

According to the test results, it was revealed that the tunnel hull structure and the track of the articulated machine, which are extremely close to each other and connected by a spherical joint, provide sufficient steering when driving with the smallest turning radius to 16 m with the kinematic method of turning. Driving from the driver's seat, the change in the length of the support base with the Base / Track ratio = 40 to 4 values allows turning with a radius of 1,8-6,0 m. This corresponds to the parameters of the short-base monoblock tracked vehicle, which is performed by the onboard method.

For an articulated tracked vehicle, which is, as a rule, a long-wheelbase, the ability to make turns in two ways saves it from a significant drawback - understeer on a large radius and low steer. Tests of the model showed the real possibility of the articulated tracked vehicle to perform the stepping (lag) movement. During the tests, the high survivability of the undercarriage, which provides movement and controllability in the event of a breakdown or loss of up to three tracks, was confirmed. The results of self-digging were unfinished for a number of reasons.

It is supposed to continue testing the model in order to create a full-size model of the sample with a sharp increase in the parameters of the combat tracked vehicle.

Information