Crazy Juggler (PEAK3)

The ingenuity of the human mind is for me an immutable truth.

The ingenuity of the human mind is for me an immutable truth.For its history man has repeatedly proved that he knows how to extricate himself from the most incredible crises. Each time, when humanity fell into a deaf corner of a circular defense, it always found the “magic ladder” in the third dimension, again and again leaving seemingly unavoidable physical environmental restraints “with the nose”.

And the farther, the more this process reminds me of the tireless juggling of restrictions and limiters, when removing one of them immediately creates a dozen others - often as dangerous and ineradicable as the newly removed limiter of the previous stage of development.

I catch the first, I look at the second, I throw the third. And so - time after time, in an increasingly accelerating pace.

The situation with industrial metals is the same endless juggling of possibilities. Some metals leave the arena of human development, others immediately take their place.

The copper age is replaced by the bronze age, the bronze age passes into the iron age.

Every next century does not throw metals of the last century into the garbage heap of history. Copper Age with its copper swords invisibly lives with us and now - copper has simply left military affairs (although leaving its sister in brass shells - brass), but now it has taken the first and most important place in electrical engineering.

Now, without copper, electrical engineering is as difficult to imagine as military or construction - without iron (or rather, without steel). The closest competitor to copper - aluminum can only boast of its best prevalence in the world and, as a result, a lower price. Yet pure electrical quality of aluminum compared with copper "so-so". Aluminum in electrical engineering is ordinary paper on which everyone writes in the absence of stamped paper.

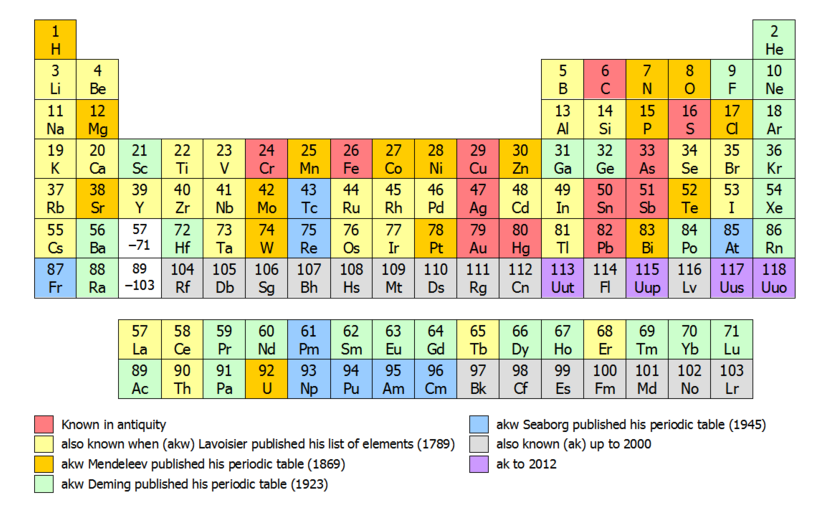

In general, the dynamics of the discovery of chemical elements can be estimated from this table:

As you see, in ancient times, humanity in general had a poor choice on pure elements - lead and antimony, mercury, gold, silver, copper, arsenic and tin.

The whole metallurgy of the Bronze Age spun around these industrial metals.

This metallurgy was provided by charcoal, which was practically pure carbon and was, perhaps, the first industrial fuel.

In the Iron Age, iron and chromium are added to this list. Even the use of these two additional "juggling balls" has significantly improved the capabilities of mankind and get away from the problem of the exhaustion of ancient copper and tin deposits.

Here is an ancient Chinese bronze a sword in which you can see one of the first uses of chromium for the purpose of obtaining a strong and hard alloy:

On the left - the wrought iron sword of the kingdom of Chu, on the left - two cast, chrome-plated swords of the kingdom of Qin.

Qin defeated Chu. It took more 300 years.

But, as a result, iron won bronze, “appropriating” the “juggling ball” of chrome and turning it into alloyed steel.

A crazy juggler continued to throw up and catch balls again.

By the end of the XVIII century, the number of newly discovered chemical elements passes for fifty.

Most of them at the beginning of their journey are no more than expensive toys and amuse the pride of the scientists who discovered them, but the farther away, the more our crazy juggler asks and asks for these new balls in his hands, tossing the old ones and taking from the shelf of discoveries new balls.

Besides the fact that the balls were becoming more numerous, the skill of mankind in handling the source material also grew.

The beginnings of metallurgy were native gold, tin, iron, copper. Virtually all metals known in antiquity are present in nature in the native form. It is already pure, recovered metal. Now there is almost no such thing - gold nuggets in the modern world, if they find it, are so rare that they themselves have already become a luxury item - they are left unchanged and exhibited in jewelry collections.

Most gold is now mined from very, very poor sources. For example, here so.

Well, the concentration of the useful element in such deposits is ridiculous. So, in the indicated gold deposit in Kazakhstan gold contains only 2 grams per ton of rock.

That is, this beautiful "Caterpillar" carries 200 grams. And not 100 tons, as you inadvertently thought:

It is clear that such blatant costs of obtaining a new metal bring to life the most sophisticated ways of returning the "prodigal sons" back to their home, that is, back to industrial and social (as in the case of gold) turnover.

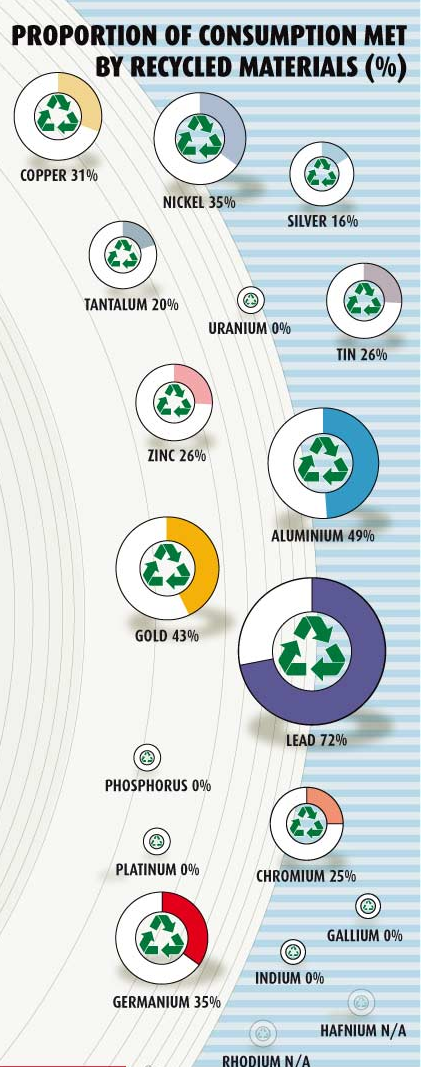

Here are data on the level of reuse of metals in modern industry:

As you can see, in some places, humanity is already very diligent in its approach to the issue of “preserving what has been dug out”. At the same time, what is interesting, the palm in industrial reuse is by no means gold, but in such seemingly not very expensive metals like lead and aluminum.

And the level of reuse of nickel, tin, zinc, copper and germanium is also very high, although it leaves much to be desired.

Why isn’t all 100% metals once involved in industrial circulation used and renewed?

In any process, in any cycle of use, as we remember, there are losses.

Some metals in the production cycle are literally lost. For example, uranium in a nuclear power plant is completely transformed into fission fragments, including unpleasant cesium and strontium, the first of which could not be completely separated from tanks and helicopters, and the second - from the bones of the liquidators of the Chernobyl disaster.

Therefore, strictly speaking, the opposite of uranium and its reusability is worthy of the proud figure “zero”. At this point, she died, so she died - for the second time uranium is not launched into circulation, unless, of course, we take into account breeder reactors.

As for the other metals and elements, the sad number “zero” stands against the chemical name, there are several stories.

For example, phosphorus, already somehow disassembled in materials from the PEAK series, until they are recycled solely due to the non-weak energy intensity of this process. Although - to collect separately what comes out of us from behind and what flows in front is possible without any problems right now.

In the men's toilets, it is generally easier to organize the “collection of phosphorus” (the equipment called “urinal” is quite suitable for this), and everything is already thought out for women. Here, admire the bright future looking at you straight from the depths of the toilet bowl:

In the case of other metals and chemical elements, the way out of the “zero return” situation is not so obvious.

Everyone, I think, knows the story of silver.

It is this metal that created photography and cinema. Despite the fact that now humanity has learned to re-use entire 16% silver, most of it was irretrievably lost in old photographs and films.

The first photographic materials were rather exotic. One of the first photographs was taken on a plate poured with organic matter such as tar; under the action of light, he hardened. Then, by washing away the unused and uncured material, it was possible to get something like a negative, and by smearing it with paint and stamping paper - to get something like prints. This technology has lived for quite a while as a rare artistic device, but very quickly the whole photo basically became silver - the photosensitivity of the salts of this precious metal remained unsurpassed. Both films and photographic paper carried layers of gelatin, filled with small crystals of silver salts, which darkened in the light.

They tried to replace silver with something cheaper for decades, non-silver photography was the same attractive theme for inventors, like a bicycle, a perpetual motion machine or a baldness remedy - but all in vain. Only silver salts. At the same time the photo process remained very wasteful. Silver was consumed in the process of manifestation. And its consumption was very high - out of the total consumption of silver in the world, photography was responsible for about a third of consumption (the rest is radio electronics, coinage and jewelry).

Even in the 1980-s, estimates were made: with modern consumption, modern reserves and the modern rate of exploration of new deposits, until the exhaustion of silver reserves there are thirty-five years left. That is, today we should have already lived in a "non-silver world."

The output was found in digital photography.

It would seem - the perfect solution. There is no scarce silver, there is no stupid limitation in 36 frames on one film, you can immediately see what you photographed and not make sure in two weeks that "she did blink."

... you can see. Stop stop stop.

And what are these wonderful LED and liquid crystal arrays made of, which have become constant satellites of digital technology?

From silicon? Yes, definitely. Silicon we have enough for a very long time. However, it is necessary to spend coal on its production, so clean, metallic silicon will never be free. Here, if that reportage for understanding the subject matter:

This is not steel, it is molten silicon.

Therefore, even now industrial silicon, despite its widespread prevalence in nature, already costs 2 500 euro per ton. Quite to itself at the level of other industrial metals and, for example, much more expensive than less common iron.

But the problem is not even in the LEDs themselves, but in a thin, transparent glass over the liquid crystal matrix. The thing is that to transmit an electrical signal to the LCD-matrix use transparent conductive coatings, which consist of an alloy India with tin. Here it is, handsome indium - shiny and soft, like plasticine:

Very expensive metal clay.

Prices indiumAs with many other metals for which new industrial applications are found, they change very much. For example, the price of a kilogram of indium in the 2002 year was only 60 dollars.

Along with the increase in the production of LCD monitors, the demand for indium also began to increase, and, accordingly, its price began to grow. By 2005, it already exceeded 950 dollars per kilogram. Then, due to the reduction in the cost of other types of monitors (plasma panels, electroluminescent displays), the growth in production of LCD panels stopped and in October 2006, the price of a kilogram of indium was already about 750 dollars.

Now indium costs about 500 dollars per kilogram, but it is interesting that there are deposits of it in the world. total about xnumx tons.

Do you want to know the whole truth about "economical LEDs" and LED matrices built on their basis?

LEDs other than indium are also gallium (1200 dollars per kilogram, 10 000 tons in zinc ores and 1 million tons in bauxite), germanium (the same 1200 dollars per kilogram, no global reserves data, the United States estimates its reserves as 450 tons) and hafnium (780 dollars per kilogram, world reserves - about 1 million tons).

That is, by juggling with materials in the desire to help humanity fix the happy moments of their lives on photographic film and seeing the lack of silver before their eyes - people invisibly created other restrictions for themselves, with several elements at once — indium, gallium, germanium and hafnium. Well, everything else is already on the little things - copper in the wiring, silicon in the chips, gold in the contacts and another ten other less valuable elements in the board and in the camera body.

The situation with a constant increase in the price of raw materials unfolds two interesting trends at once before our eyes: reserves of more and more poor metal ores are being included in mining reserves and at the same time the reuse of all industrial metals is increasing, both in the form of scrap metal and in the form of ready-made, restored products.

For example, in the United States, even a separate set of laws was adopted, designed to give all possible tax and customs exemptions in the matter. remanufacturing - restoration, repair and reuse of used products.

In the United States, the Automotive Parts Repair Association is active (APRA), which brings together over 1000 companies and about 20 thousands of engineers. The overall coordination in all industries is carried out by the Institute of Remanufacturing (TRI). In Europe, framing is supervised by the Fraunhofer Society (Germany).

Americans have already classified parts as new, used, repaired and remanufactured. Taking into account economic, social and other factors, remanufacturing is recognized as the most preferred mode of production — noble, in the terminology of companies that recognize the benefits of recycling metals, materials, and even whole spare parts.

Research at the Massachusetts Institute has shown that with this method of producing automotive components, energy savings are 85%, compared to the production of new ones. Thus, when renovating its injectors for large diesel engines, Caterpillar makes a profit of 500%, for one injector the renovation operation can be applied 4 times.

President Bush, at the G8 Summit in Evian in 2003, initiated the issue and agreed to reduce customs barriers to the flow of recycled goods. Within the United States, remanufacturing has tax breaks (up to -20%) and other incentive preferences.

However, despite the titanic efforts to ensure the reuse of metals, globalization processes worldwide lead to interesting trends. As the saying goes: "water finds a hole" and usually flows down. For example, China currently buys the largest scrap metal it is from the USA. In general, we wanted the best, but China turned out again.

And if you think that an export-oriented economy "aimed at exporting metal" in Russia and in India, then it will probably also be a surprise to you that both these countries are net importers in scrap metal.

In general, the situation with industrial metals is increasingly beginning to resemble an “arms race,” guerrilla actions, and even open war.

Have you heard of the abduction of copper from cell towers? About the multimillion-dollar losses of non-ferrous metals in the cut communication cables? About sewer manhole covers disappearing at night? No that's not Ryazan. This is California and Michigan.

What is it?

Juggler tired?

Have you ever traveled in a car with the gas pedal pressed into the floor itself?

The problem of controlling something in such modes, with the regulator almost on a stop, is simple — the machine (reactor, amplifier, locomotive, whatever, any object of regulation) already without control accounting is in some strange, unusual mode. Even if the basic parameters are normal, then something more / already close to the stop.

We drove on slippery road after a thunderstorm? Everything is in order - and suddenly it turns out that the usual pressing of the brake before a turn leads to (surprise!) Complete locking of all the wheels, entering this turn with the skid and going into the ditch.

In a normal market situation - the price is slightly up, the volumes of metals have increased, but now for some reason everything is quite the opposite - the price is not a little bit of a fig, but immediately to heaven, and the growth in the production of metals - from the bottom.

So the planes are fighting like that with all the crews and passengers, EXTREMELY breaking into a corkscrew (although it just flew, well, you will think that it is somehow slow and from a big angle), the reactors are screaming, the power systems of Moscow or New York are falling apart.

Yes, by the way, about the notorious "world crisis" everything is exactly the same - when that reactor, that airplane, that the economy starts inadequately, strongly and sharply, to react to impacts, and especially fun - if in the opposite expected direction.

And although it also keeps, creeps in the right direction and the glow continues on - this is the first sign that the white fur animal wanders somewhere nearby.

He has not arrived yet, but at any moment, from the careless pressing of a button or the sneeze of a sparrow flying by, the thin tin of the reactor building breaks, the power house card collapses, the small and insignificant trillion-another bucks evaporate from the inventory — and liberty evaporates forces and impacts for which it is all so pulled out at once, ugh and grind, no obstacle for penetrating a straight and knurled road to Ad.

Fuuuh .. let me go.

And yes, in our case, in the topic under consideration, this option is called "metal peak“Because in the modern world such a situation is very poorly treated and the juggler’s art may not be enough.

Therefore: "thanks for the fish and for now" can be one of the most likely options ...

Information