Submarines of the "Narwhal" type (project of the American company "Holland-31")

3 June 1909, the new tactical and technical elements were sent to domestic interested factories in order "to build submarines without fail in Russia".

The MTK Commission, headed by Captain First Rank Beklemishev M.N., 11 and 13 on July 1909, reviewed 16 projects. At the same time, projects were rejected in which it was envisaged the use of single engines, as well as containing proposals from factories that were not engaged in submarine construction. A specially created subcommittee, which included officers of scuba diving and led by captain-lieutenant Gadd A.O., 1 August 1909, preferred the projects of Nevsky (submarine with a displacement of 490 tons) and Baltic (displacement of 450 tons) plants. Experts of the ITC in discussing the protocol of the subcommittee joined the opinion of the divers; but September 11 captain of the first rank, assistant chief of MGS, Shtal A.V. demanded to increase the speed of submarines to 16 / 12 nodes.

The board of the Nevsky Shipbuilding and Mechanical Plant 6 on November notified MTK that the construction of a submarine having such characteristics is possible only if the displacement will be about 1000 tons. It was assumed that all preliminary design work will be performed only with the guarantee of the order. It also required three additional months for the manufacture and testing of the model in the experimental pool.

The 26.11.1909 board reported that each of the three submarines will have a displacement of 750 / 950 tons, with a total cost of 2 250 000 rubles.

The Nevsky Plant instead of the project stated only tonnage and cost, while the Baltic Plant presented quite specific designs of the submarine with a displacement of 600 tons. Such an unlawful act caused the energetic protests of Colonel IG G. Bubnov, who in a memorandum addressed to Major General A. Krylov, Chairman of the MTC, December 8 1909 of the year, categorically demanded that the order be transferred to the Baltic Plant. Vice Admiral Ebergard A.A. MGSH head supported the opinion of I.G. Bubnov, but MTK continued negotiations with the Nevsky Zavod, mainly thanks to Beklemishev M.N., who reasonably believed that it was absolutely necessary to study the best foreign analogues in practice - Holland-type submarines, who proposed to create a Nevsky plant. December 13 1909 of the year during a meeting with the Minister of the Marine Rear Admiral Voevodsky S.A. competitors reconciled, deciding to order each plant on three submarines. This decision was explained by the development of the Black Sea Fleet Enhancement Program at the MGSH (19 of May 1911 of the year was followed by royal approval), which involved the construction of six submarines.

The board of the Nevsky plant only 23.11.1910 notified MTK about the main engines for the surface run - two-stroke diesel engines with an 850 horsepower designed by the German company MAN (Mashinen-Augsburg-Nuremberg). It was assumed that the production of these engines will be established in Russia. 04.06.1911 presented a draft of the submarine "Holland-31A" with general layout drawings. A month later, the MTC meeting on the mine case was considered a draft of a submarine with a displacement of 650 tons and speed of 17 / 12 nodes. Also at the meeting it was considered appropriate to reduce the speed of the boat to 16 / 11 nodes in the surface / submerged position, increasing the range in the submerged position. The cost of each submarine was established in the amount of 1 600 thousand rubles, the period of construction with delivery through 28 months on the Black Sea. Maritime Minister, Vice-Admiral I.K. the next day, ordered to give outfit and insisted on reducing the period of construction to 2-x years. At the same time, rear admiral M.V. instructed MTC to require builders to submit detailed drawings, calculations and specifications for approval by the Committee within two months.

GUKiS 9 July 1911 of the year issued Nevsky Zavod outfit number 3413 for the construction of three submarines of the type "Holland - 31A" with a deadline for testing by 9 July 1913 of the year. The MTC meeting held on October 8 reviewed the board's request and gave permission to order main engines for surface running in Germany. It was stipulated that the plant would start producing similar diesel engines for itself and manufacture the first two at its own expense as experience. The Nevsky plant 27 July 1912 of the year entered into an agreement with the company MAN for the manufacture of six two-stroke 8-cylinder diesel engines with a power 850 hp. The total value of the contract is 850 thousand marks. The delivery time of the 1 diesel is 11 months, 5 and 6 months after 15 months after the start of construction.

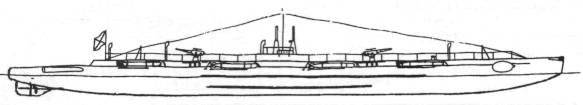

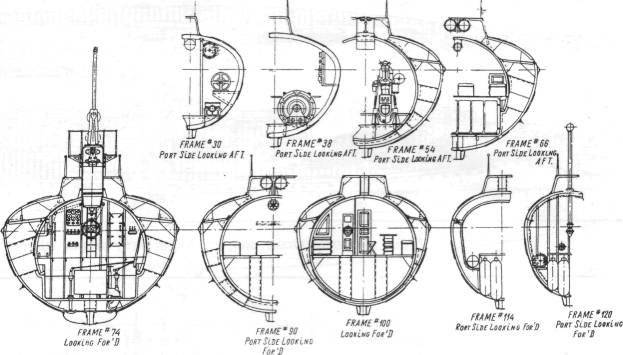

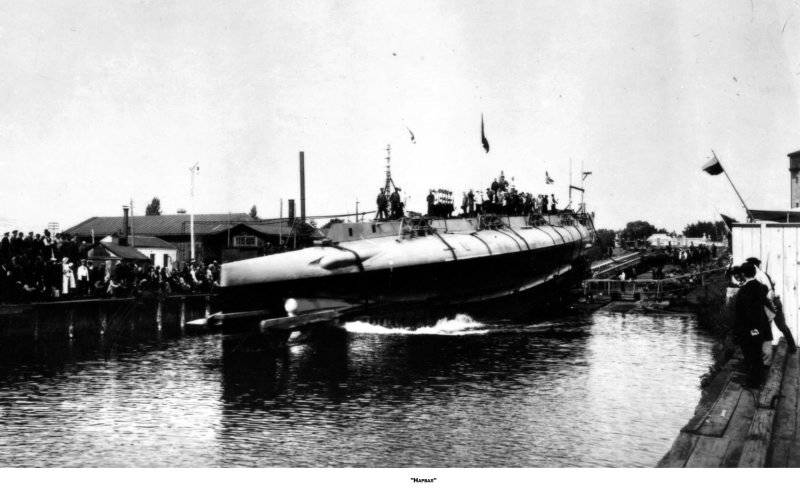

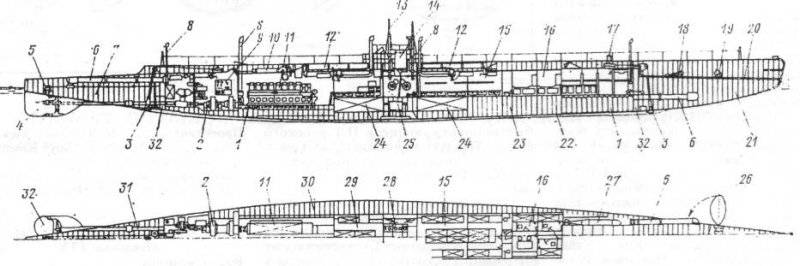

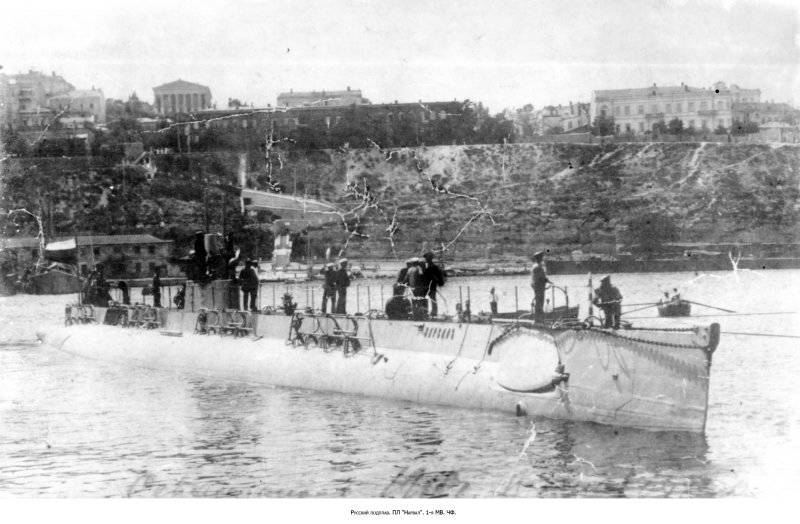

The main electric motors were ordered by the plant "Simmens and Galske". Schukkert and Co. and the Russian Society Universal Electricity Company supplied the rest of the electrical equipment. The order for rechargeable batteries was issued to the firm "Meto". Some orders were placed abroad: in the United States were made compressors, pumps and air guards, in Italy at the factory "Officino Gallileu" - periscopes. A certain financial benefit was also obtained from the use of foreign contractors, since deliveries along the line of orders for the maritime ministry were not subject to customs duties. At the same time, in Nikolaev the place for assembly was prepared. October 10 1913 was made the solemn laying of three submarines, called "Sperm Whale", "Whale" and "Narval". With a tonnage of 621 / 994 tons, a buoyancy margin of 45 percent, they were radically different from Bubnova I.G. submarines of the Bars and Morzh types. Submarines of the Narwhal type belonged to polutorakorpusny submarines, had a double hull in the middle part over the length of 44 percent. With the main dimensions 70,2x6,5x3,4 meters, the overall device looked like this: within the frames 122-150 (counting from the stern) the nasal tank of the main ballast No. 1 (ton capacity 49,2) was located. Nasal torpedo tubes and an underwater anchor were located in the lower part.

The bow tip above the waterline was divided by a waterproof horizontal deck, thus forming a superstructure to accommodate the drives of the bow horizontal rudders and the surface anchor.

The feed (0-26 frames) had a similar design and served as the main ballast tank No. 5 (49,7 capacity tons), through which the feed torpedo tubes and drives of horizontal and vertical feed handlebars passed. Closer to the midsection, right behind the extremities, between the two flat bulkheads (121-122 and 26-27 frames), there were differential bow and stern tanks (4,5 and 3,8 tonnes, respectively), calculated for the immersion depth of 100 meters.

The general location of the submarine type "Narwhal" (project "Holland 31 A"): 1 - air guard; 2 - rowing electric motors; 3 - underwater anchors; 4, 5 - vertical steering wheel; 6 - tubular TA; 7 - feed ballast tank; 8 - ventilation pipes; 9 is the main power station; 10 - gas exhaust manifold; 11 - diesel engines; 12 - rotary TA; 13 - periscopes; 14 - conning tower; 15 - command room; 16 - mess and officers cabins; 17 - spire; 18 - Parker anchor; 19 - drive horizontal rudders; 20 - waterproof deck; 21 - nasal ballast tank; 22 - boxed keel; 23 - fuel tank; 24 - rechargeable battery; 25 - surge tankers; 26 - nasal horizontal rudders; 27 - spare torpedoes; 28 - central control station; 29 - room conductors; 30 - double-breasted tanks; 31 - propeller shaft: 32 - trim tanks

Robust housing was divided into 7 compartments waterproof bulkheads. In the first of them (107-121 frames), there were air guards, breech parts of torpedo tubes, a spike motor, spare torpedoes, a torpedo loading bow. The second compartment was occupied by the crew - the saloon and the officers' cabins (95-107 frames), the lower-ranking corps (78-95 frames). A fuel tank with a capacity of thousands of liters of 58 and also a bow group of a battery consisting of 60 elements were located under the floor of the command department. The middle part served to accommodate the central post, where various instruments were concentrated, the control of vertical, aft and bow horizontal rudders. In the lower part of the compartment there was a middle leveling tank and two auxiliary tanks (5, 1,0 and 3,2 tons, respectively), designed for blowing at the maximum depth of immersion with the help of compressed air of maximum pressure.

In the third compartment (61 - 71 frames) there were also 60 battery cells, a galley, living quarters for conductors.

The sixth compartment (42-61 frames) was allocated for the main surface run engines, air guards, oil tanks.

In the seventh - electromotor - compartment there were rowing electric motors, main ballast pumps, compressors, main power station, and also breech parts of stern torpedo tubes.

The upper part of the strong hull was covered by a lightweight superstructure, which was filled when immersed, which improved the nautical qualities of the submarine. Above the main post (67 - 79 frames), a solid wheelhouse with fencing was installed, which served as a crew exit shaft.

There were also ventilation pipes for intra-articular intake ventilation, the upper flooring was a bridge in the surface position.

The robust 36 to 107 hull frames covered the second lightweight hull, and the annular space that was divided above the waterline with waterproof, powerful stringers was used as a tank ballast tank (132 ton capacity). The ballast tanks of the submarine were filled with gravity, which was an undoubted advantage compared with the submarines of the type "Leopard" and "Walrus". Tanks located in a sturdy casing were blown with compressed air, and from the rest of the ballast water was pumped out of the ballast through the box keel. In this case, the keel served as the main drainage line. This dive system allowed the submarine to move from position to submarine for 40-50 seconds.

Initially, submarines of the Narval type were to have two stern and bow torpedo tubes each, including a spare set of torpedoes and two rotatable twin torpedo tubes in the superstructure (behind and in front of the cabin). But since rotary torpedo tubes for submarines were not manufactured in Russia, during the discussion of the 4 project in July 1911, MTK obliged the plant to work out the possibility of replacing rotary torpedo tubes in case of their unsuitability by eight Torpedo tubes of the Dzhevetsky system or four torpedo tubes of the Dzhevetsky-Podgoro system.

At the Nevsky Zavod in November 1911 of the year they finished rolling the metal, in December the first 167 tons of steel were smelted on the stocks. If the auxiliary mechanisms and hull structures were made on time, then during the construction of diesel engines, experts encountered unforeseen difficulties from the very beginning. Major-General Yeliseyev EP, the head of the underwater part of the GUKiS, demanded to coordinate the development of all units and assemblies of diesel engines under construction. Such a "guardianship" was the reason that the 17 of May 1913 of the year, the plant's management appealed to the underwater part of the GUK and asked to urgently determine the type of clutch. This made the order of crankshafts impossible. In turn, the company MAN developed the drawings for a very long time, searched for suitable grades of metal, and organized the casting of blanks. As a result, only in May, the 1914 of the year produced the first pair of engines that were never delivered to Russia. Much time was spent on determining the type of tubular torpedo tubes. Major-General Remmert A.A., head of the mine department of the GUK, insisted on installing torpedo tubes manufactured by the G.Lessner plant, and the leadership of the Nevsky plant proposed Holland-type torpedo tubes. Given that the factory version allowed to win in the mass of 2600 kg, the meeting of the XUUM XUUM April 25 of the year decided to install American-type torpedo tubes by modifying their design.

MGSH striving to put submarines into operation as quickly as possible, made a number of proposals that IK Grigorovich approved 22 on July 1914 of the year. It was envisaged to install in place of the main engines 250-strong internal combustion engines, removed from the Amur gunboat tower type "squall"; to give Nevsky Zavod a work order for the production of round-the-clock emergency works. In the place of rotary torpedo tubes to install the apparatus of the Dzhevetsky system Make an emergency 72 torpedoes and batteries for the three submarines. Despite all the efforts, all the boats at the beginning of the First World War remained on the stocks.

HUK 1 November 1914 of the year entered into an agreement with the American company "New London" for the supply of twelve 160-strong diesel engines for submarines of the type "Narval". 28 January 1915, all the engines on the Tambov steamer of the Voluntary Fleet were delivered to Vladivostok. In revenge with the engines, a group of workers and technicians of the company arrived under the guidance of engineer Gilmore RB The engines brought to Nikolaev were installed in pairs so that the aft diesel of each side worked directly on the propeller shaft, and the nose engine was connected to it by means of two pairs of gears and a transmission shaft.

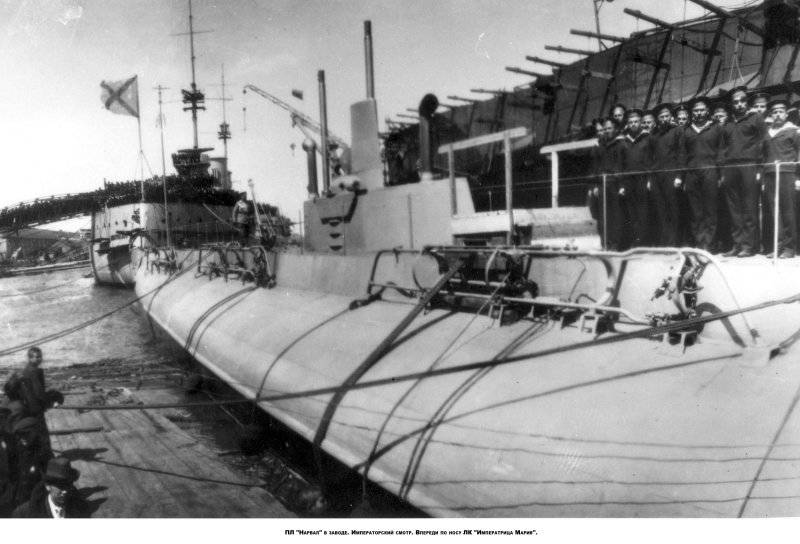

The commission, headed by Rear Admiral A. Belogolov, 20, June 1915 of the year began testing the submarine Narval, which, after 9 days, had to be interrupted due to turning the friction clutch of the aft left engine. She warmed up so much that wooden fists began to smoke.

The same happened to the starboard coupling. The commission made the following conclusion: "friction clutches that have this device represent an unreliable clutch". On July 4, the submarine developed the speed of 12 knots during the tests, but when the diesel engines stopped, the left side coupling could not be separated for 20 minutes. In the report, besides unreliability and danger, it was noted that "the transmission device is bulky, works with strong noise, the bearings are often loosened." The submarine Narwhal 18-19 July moved to Sevastopol from Nikolaev, where the tests were carried out until August 23.

In the submarine "Whale" similar defects were observed, but despite this, the command of the Black Sea Fleet insisted on the immediate incorporation of the submarine into service. The submarines Narwhal and Whale in the final version had four internal torpedo tubes and eight torpedo tubes of Dzhevetsky each. This weaponry allowed the submarine commanders to refuse to receive spare torpedoes, especially considering that their loading caused many difficulties. The submarine "Kashalot" in October 1915 of the year was put to the test with four torpedo tubes Dzhevetsky-Podgorny, and the submarines "Kit" and "Narval" were already in their first combat campaign. The combat capabilities of the boats were significantly increased by the installation of two 75-millimeter guns.

On the submarine "Whale" on the way to the Bosphorus 4 of October 1915, the compressors failed in stormy conditions, the crankshaft of the right diesel engine broke, the support bearing brackets burst. Three weeks later, a similar accident occurred on the submarine Narwhal. Both submarines had to be sent for repairs to Nikolaev. Causes of damage investigated specials. Commission headed by the captain of the first rank Y.S. Soldatov. American engineer Gilmore R.B. participating in the work of the commission tried to shift the blame on engine mechanics who allegedly violated the rules for operating engines, but when disassembling the mechanisms, shells and cracks of crankshafts, beds and foundations were found. New London's diesel engines were too weak to rotate propeller shafts, large propellers, couplings and electric motors.

The transfer device was dismantled on the recommendation of the commission; on submarines "Kashalot" and "Kit" ICE were connected "directly" through friction clutches, and the bow on the submarine "Narval" - with dynamos, which were delivered for submarines of type "AG" from the United States. At the same time, the GUK prohibited fodder and fore diesel engines from being used on the Kashalot and Keith submarines, prescribing that they should walk only under fodder diesel engines. Run nasal diesel engines were allowed only in exceptional cases. Due to the installation of random engines, the maximum speed decreased to 9,5 nodes, the battery charging time increased to 20 hours. The unreliability of mechanisms has become more pronounced. The only positive factor was an increase in the range to 3500 miles. Despite the shortcomings of surface engines, the submarine commanders noted a number of positive qualities of Narval-type submarines: good controllability, central control, convenient placement of batteries, good ventilation of engine rooms, improved living conditions in comparison with the Walrus submarines.

Black Sea-type submarines "Holland-31" after the entry into service, actively participated in the hostilities of the Black Sea Fleet. For example, the submarine Narwhal in the Kefken 16 lighthouse on October 1916 of the year destroyed enemy vehicles with a displacement of about 4 thousand grt, and the crew of the Kashalot submarine on 1 March 1917 of the year destroyed the 5 schooners loaded with coal with subversive cartridges.

After the end of hostilities, the Narwhal submarines were laid up in Sevastopol, where the British interventionists sank them in April 1919. EPRON in the 1934 year raised the submarine "Whale", and the submarine "Sperm Whale" and "Narval" rest on the seabed so far.

The construction of the one-and-a-body Narval type submarines, which were distinguished by good seaworthiness, increased survivability due to the presence of watertight bulkheads, immersion speed, became an important stage in stories domestic shipbuilding. Many design solutions that were first used on them have found application in projects that were presented at the 1916 competition of the year. On the other hand, the use of random engines for surfaced propulsion showed the weakness of the Russian machine-building industry, which failed in the shortest possible time to start production of diesel engines for submarines.

Information