Experimental aircraft NM-1 (PCP)

To make an extraordinary plane that would not only meet the requirements of the time, but is really necessary, while one that no one has ever had before, can only be done at the Design Bureau, which has a good experimental and production base. At that time, such a task was practically impossible to solve, or at least very difficult.

By the beginning of the 1950's. All planned Soviet pilot aircraft were concentrated in several large experimental design bureaus. The main designers of the teams remaining in the MAP (after the closure of the experimental enterprises in 1946-1949), “hand in hand” turned into an insurmountable monolithic wall. Having divided the spheres of influence, the CB with all available means tried to prevent the promotion of new competitors. Only a few managed to rank with them and in most cases only for a short time (in 1951, the VM Myasishchev OKB, which was engaged in strategic bombers, was re-established, and was stationed at plant # XXUMX). Among the exceptions was the OKB-23, which was located on the Moscow Sea in the town of Podberezye on the territory of Plant No. XXUMX (the Chetverikov Design Bureau IV used to work here, and after 256 of the year, German aviation specialists led by Baade B.V.). He was headed by Pavel Vladimirovich Tsybin (years of life 256-1947), the author of many experimental, sporting and landing gliders, which were built before the 1905 year. In order to form his own design bureau, he had to pretty much try to convince the government and the military elite of the need to build an airplane according to the preliminary project proposed to them. This preliminary development actually was those. offer Tsybin.

4 March 1954 of the year Tsybin P.V. sent a closed letter to the Kremlin with a proposal to build a new aircraft, which will be endowed with unprecedented properties. Its maximum speed was to be 3 thousand km / h, flight altitude - 30 thousand m and 14 range thousand km. To achieve the stated characteristics, many elements of novelty were proposed. The tail and wing were prescribed hex profiles with a very small relative thickness (from 2,5 to 3,5%), not used anywhere else for aircraft. For the fuselage, we chose contours of a similar style with straight lines forming rotational surfaces. An important condition for ensuring high flight data was the corresponding power supply. They were going to get it, firstly, thanks to the unprecedented lightening of the structure and the filling with efficiency - 80% and, secondly, the use of new, more powerful engines.

The question that this power plant needed to be created, for some reason, did not embarrass anyone in the early stages.

Preliminary work was started at BNT TsAGI by a small group of specialists who were temporarily seconded to P. Tsybin. These were O. Eliseev, I. Kostenko, A. Kondratiev, V. Shavrov. other. According to the preliminary design, the PC (jet) had an unusual aerodynamic layout. The device is quite elongated body shape (about 30 meters) with a trapezoidal wing of small elongation (area 65 m2, span 10 m, sweep along the leading edge 58 degrees) had two engines at the ends of the wing, nose and tail horizontal tail. The tail part was a peculiar highlight of the preliminary project, representing a winged "special cargo". At the command of the pilot (after an order from the Kremlin), it is separated in flight, turning into a shell. It was a winged bomb (the corpus of the ed. "244Н" was taken as the basis), which, after leaving the bomber's lock, planned for a target detected for 250 kilometers, being dropped from it for 50 kilometers. The part of the aircraft remaining at a height carried out a U-turn and, without entering the enemy air defense zone, returned ... without a tail. After the separation of "special cargo" "jet aircraft" turned into an aircraft "duck". To balance it with the new position of the center of gravity (since a ton of weight was removed from the stern), the nasal horizontal solid turning surfaces were included in the control system. From the moment of the start and before the division of the "trunk", the front horizontal tail worked in a feathering, slightly "overwrought" mode. The winged surfaces of the winged bomb, originally included in the control system of the aircraft as a stabilizer, after the separation switched to autonomous control, performing their function until the moment of meeting with the target. The targets could be Boston, London, New York, and so on.

The Kremlin promised the indicators so much that they became a powerful lure for the military and the governments of the post-Stalinist USSR, which made the proposal very serious, despite skeptical views about its viability.

The avanproject was handed over to proxies in the Ministry of Aviation Industry. His consideration and study for the overall assessment was conducted at the Central Aerohydrodynamic Institute. After discussion at the extended commission, which included representatives of industry and the Air Force, tech. the proposal was found to be competent and competent. Experts from the Aviation Industry Institute expressed doubts about the 80-percent weight return, and this led to the formation of a separate subcommittee, headed by I. Tsebrikov. (head of the weight brigade in the Sukhoi Design Bureau). The audit showed that for the proposed design and layout of the 80% apparatus are unreal, and you can only rely on 60% (in the practice of Soviet aircraft building, it was already possible to create an aircraft with a weight return exceeding 50%. A wooden bomber NB was created in the Polikarpov Design Bureau (BN) "T"), the weight return of which was 1943%). Taking into account the fact that such a result was promising, Tsybin’s proposal was given a “green street”. Thus, with all the pros and cons, enthusiasts achieved complete success.

Various commissions, inspections and inspections on private issues have artificially delayed the inspection of the "PC" facility for almost a year. And when there was nothing more to complain about, the innovators presented their "brainchild" at the expanded board of the Minaviaprom with the participation of officials from the defense department of the Central Committee of the CPSU. On May 5, 1955, P.V. Tsybin made a report. at the top, and on May 23 a government decree was signed on the creation of OKB-256 and the construction of "PC". The document was signed by the first 13 members of the government of the USSR and the Politburo: Malenkov G.M., Khrushchev N.S., Bulganin N.A., Kaganovich L.M., Mikoyan A.I., Suslov M.A., Zhukov G.K., Pospelov P.N., Voroshilov K.E. other. At the same time, they signed the estimate, the total amount was 224 million 115 thousand rubles. By February 1, 1957, the first flying machine was supposed to be ready, and a backup by April 1 of the same year. All work was given 1,5-2 years. Needless to say, Pavel Vladimirovich and his associates accomplished a real feat by creating a new business and opening an enterprise. The new design bureau was allocated a room and a production base of plant No. 256. Design Bureau management: P.V. Tsybin - Chief Designer, Golyaev A.G. - deputy. on general issues, B.A. Merkulov - deputy. on science and Yakovlev I.A. - deputy. for special equipment and systems. The famous aircraft designer V.B. Shavrov was appointed head of the design department (fuselage, empennage, wing, control, landing gear, and so on) and led individual teams specializing in the listed units. In addition, the new design bureau had a large number of other brigades and departments, to fill the staff of which a wide reception was opened. Other chief designers were instructed to allocate a certain number of people to Tsybin. Also, freshly baked young specialists from technical schools and universities were assigned to OKB-256. From the point of view of staff selection, Tsybin was not lucky since the recently recreated (1951-1952) OKB-23 of chief designer V.M. Myasishchev. absorbed unclaimed human resources, filling its own staff with specialists who were left out of work after the reduction in the second half of the 1940s. aviation enterprises. In this regard, very little qualified contingent remained for OKB-256. Naturally, the chief designers did not give the best workers from their staff (everyone tried to get rid of low-skilled and unwanted ones). Thus, the general professional level of OKB-256 employees was lower compared to other enterprises. However, this is not all. Almost all workers who came from outside believed that their wages could not be lower than at the previous place of work. In addition, in large development bureaus, as a rule, a bonus of up to 20% of the salary was paid every month, but in the new design bureau there was not yet anything to pay it for. Therefore, workers began to apply for an increase in grades and categories in order to bring their earnings up to the level of previous salaries. Considerable inconvenience in the recruitment of personnel was represented by the remoteness of the plant from Moscow, which became the reason for the costs with an already determined estimate. The chief designer was in a hurry to fill the staff for the early deployment of work on the product, and in some cases he went to overstate the categories and grades of designers and other engineers. For example, instead of the 2nd and 3rd category, they gave the 1st and 2nd, which in many cases did not correspond to the actual qualifications. In addition, the stratum of leading engineers and other "nondescript" leaders and officials, clerks and social activists with large salaries (heads of departments, groups, brigades, together with their deputies and assistants, as well as all kinds of trade union, Komsomol and party semi-liberated and liberated secretaries) were quite significant.

Meanwhile, the complexity and novelty of the tasks required required the presence of specialists of the first rank, starting with the management and ending with simple designers. Today we can safely say that the original intention was beyond the power of the executors of OKB-256. This affected the early stages of work. The consolidated team did not have a common labor reserve, that long joint preliminary work (when people get used to and get used to each other), giving the necessary knowledge.

With great difficulty, the final general view of the "Jet Plane" and even its scheme were made. For a long time (approximately the first two years) 5 general layout drawings were made on the 1 scale: 5, equally signed by Tsybin, but only partially based on detailed elaborations, since the subsequent views did not replace the previous ones, which were not canceled. And not one of the big questions was thought out. In the design teams there was no complete consistency. Especially a lot of changes were made because of the equipment, which was constantly changing in the order of its improvement, when one system, which did not justify itself, was replaced by another, as a rule, more complex and capacious. In addition, there were a lot of unnecessary work that arose in the heads of "initiative" deputies and assistants. For example, a lot of time was spent on air conditioning issues (even a proposal to dilute chlorella was considered). It was built, however, it was not finished, but rather its own thermal pressure chamber was abandoned at the beginning of work. They did, but did not assemble a dynamically similar model of the aircraft on the scale of 1: 10. Made from the finest energy in all details, it was intended to study future vibrations and deformations. In a word, much was done, attention was scattered, and the main issues remained unresolved. For a long time they could not get out of the state of various dead ends. Therefore, there is almost no talk about clear-cut developments and achievements over the first 2-3 of the year. The work entered the stable course almost at the end of the existence of the design bureau. But first things first.

Of course, there were numerous consultations with TsAGI, as well as other sectoral institutes of the aviation industry, under the supervision of the defense department of the Central Committee. The work of all the OKB services in making decisions shook from the painful linkages with the aggregate plants, the mechanics and the Nemanov departments and agencies. The case turned out to be new in such fullness and breadth, about which neither the customers, nor the developers of PC, nor the lawmakers even suspected. But over time, much has stabilized. A large number of calculations and purging were carried out, laboratory complexes, etc. were built. The initial "aces" idea of a detachable tail was soon abandoned due to the clarified difficulties associated with separation and auto-re-centering, with the overlapping of the problems of supersonic and subsonic aerodynamics inherent in a single aircraft and its isolated parts. As a result, the designers stopped at the normal scheme of the aircraft with tail, as well as a semi-submerged suspension under the “special cargo” fuselage. In this case, the layout, design and location of the retractable landing gear was revised, which, with the tail support, received the front position of the main leg and the modified side posts.

During the development of the draft "PC", it became clear that the weight of the aircraft exceeds the proposed one and one does not even have to think about the weight efficiency in 60%. By the end of 1955, it turned out that the maximum flight range would not exceed 7,5 thousand km. There was an idea about the suspension "PC" under the Tu-95H. The range of the joint flight was to be 3000-4000 km, followed by the disengagement and acceleration of the “Jet” with two twin accelerators (with a liquid-propellant rocket engine) in the climb mode. A further independent flight (after accelerator dumping) took place on two mid-flight supersonic direct-flow air-jet engines with a speed of 3000 kilometers per hour. Bomb dropping, as in the original version, was supposed to be made 50 kilometers from the target with its detection of an onboard radar at a distance of 200-250 kilometers.

The draft design of the aircraft "PC" in this form was released 31.01.1956 and approved by the chief designer P.V. Tsybin. Long before that, almost from the very beginning of development, in the OKB-670 Bondaryuk MM sent an official order to develop a supersonic ramjet engine. Two such SPVRD, which received the designation RD-013, at the calculated height developed the thrust 4400-4500 kgf each. The engines were supposed to provide a speed of 20 km / h at an altitude of 3000 thousand. The RD-013 had an adjustable external compression air intake with a central cone. The total length of the engine is 5,5 m, the diameter of the combustion chamber is 650 mm.

At about the same time, other design bureaus (SA Lavochkina and VM Myasishchev) developed alternative projects: ed. "350" and ed. "40". These were remote-controlled unmanned aerial vehicles, known as the “Storm” and “Buran”. The vehicles were also designed for speed in 3000 km / h and intercontinental (transpolar) range. They were equipped with direct flow engines RD-012U and RD-018А (respectively) designed by M. Bondaryuk. "Storm" and "Buran" differed vertical launch from the ground with the help of rocket boosters with liquid rocket engines.

The first launch of the intercontinental BR P-7 Korolev SP design, which took place 15.05.1957, and the launch of 21.08.1957 of the same missile at the calculated range contributed to the fact that work on the winged carriers of strategic nuclear weapons were soon drastically reduced.

For combat aircraft and aircraft came the dark days. The creators of the rocket technology were able to form the opinion of the top military and the government that the aircraft technician loses its value as the main strategic weapons. Widely advertised new ideas about military equipment, where missiles dominated. The era of radical restructuring of the military-industrial complex of the USSR began. The hotly supported and thoughtlessly dogmatic point of view (participants and partisan supporters of rocketry) was inflated with successes in astronautics, which led to the categorical statement: "Missiles will replace aircraft!", Which became the driving slogan, shifting the indiscriminately decision to military aviation tactical. Some aircraft design bureaux and the most powerful plants of the aviation industry were permanently transferred to the Ministry of Medium Machine Building. Their rigging, tech. the equipment and all the aircraft accessories were let under the pile driver. The culture of designing, designing, and manufacturing at various levels (starting from manufacturing parts and ending with the general assembly of products), which has remained from the aviation industry, played a significant role in the powerful development of the rocket engine building, rocket production and cosmonautics. The rocket ship once again literally robbed the aircraft industry and to date they have rested on their laurels, self-righteous. Suffice it to say that the factories No. 1 and No. 23 — the flagships of the Soviet aircraft industry — usurped the serial production of SP Korolev missiles. and Chelomey V.N. “It was a terrible time,” said V. Litvinov, Director of Plant No. XXUMX, twice Hero of Socialist Labor. “We, being airplanes to the core, were forced to obey the order of the Kremlin, and without any desire to destroy everything, starting something alien to the soul of the matter. Fresh banners and new appeals hung on the walls of the buildings than looked like appeals to suicide and nothing could be changed ... "

In those years, a large number of military aviation units, units and formations were deprived of the mat. parts and disbanded. Thousands of combat aircraft found their "last refuge" right on the ground under the gas cutters. Generated by the massive destruction of aircraft, on an unprecedented scale, aircraft cemeteries multiplied and grew. For howl history the world has not seen such unbridled vandalism about the results of the work of its people in their own country. Military aviators and aircraft builders were eliminated and were retrained in rocket and missile planners. Wing shoulder straps and blue buttonholes were innumerably replaced with black with cross-stitched overlays from the trunks. Only one example of restructuring plunges into real horror. So, for example, in the OKB Lavochkin, the former fuselazers developed the hull of space satellites, and yesterday's wing designers ... just by their external similarity (and only in the eyes of housewives or journalists) switched to designing solar panels ...

Simultaneously with the work on the PC object, the Design Bureau was engaged in the design and creation of other devices. One of the most promising was a strategic intelligence officer, designed to carry out operational work in the deep rear of a potential enemy and on possible theaters of military operations. The work on the winged carrier of a nuclear bomb, which had been developed and carried out earlier, became an aid for OKB-256, which helped keep it afloat during the period of decisive rocket domination. At that time, the creators of rocket and space technology had not yet thought of reconnaissance space stations and orbital spy satellites. Therefore, at the end of the 1950-s, an "atmospheric" reconnaissance aircraft could be quite relevant.

The initial design of the scout, known as "2PC", also included the use of two RD-013 supersonic air-jet engines, MM Bondaryuk. and air launch from under the carrier. The question of the suspension of a Tu-95H aircraft in the light of the then ideas about the carriers of strategic armament was forgotten. The topic was continued under the designation "RSR", that is, "reconnaissance jet aircraft". A new reorientation of the object, from a high-altitude start to an airfield independent take-off, turned out to be forced. The development of a suspension system for a carrier, which began in 1956, at the stage of layout and production of drawings of the general view of the PC bomber, was not completed for several reasons. The length of the scout "2PC" in connection with the installation of the tail antenna has increased compared to the prototype on 700 mm. This caused additional difficulties with its suspension under the fuselage of the Tu-95H bomber. Testing of the suspension system, the separation of the object in flight and the launch of the SPVRD was conducted in the OKB-156 A.N. Tupolev extremely slowly and reluctantly (first of all it was connected with the fact that Tupolev A.N. was the main opponent of the work of Tsybin). The matter did not go faster even after the government issued a resolution on the continuation of the mass production of the Tu-95 in Kuibyshev at plant No. 18 due to the need for carrier aircraft for the 2PC. These works at the Tupolev Design Bureau were soon unilaterally discontinued.

The refusal to create a carrier (and, consequently, from an air launch) led to the replacement of the power plant and the revision of the layout and design of the chassis in order to carry out full aerodrome operation of the aircraft (the former chassis was intended solely for landing).

31 August 1956 of the year issued a decree SM on the release of the aircraft "RSR", equipped with a pair of engines D-21 design Solovyov PA This aircraft was supposed to leave the assembly shop by the first quarter of 1958. The air force TTT formulated to it 15 January 1957 of the year. When fulfilling these requirements, the device would be the first all-daily aircraft with supersonic flight speed, designed for conducting reconnaissance at a distance of 1,7 thousand km from the airfield. The highest speed of the "RSR" in 2,7 ths. Km / h was required only with a cruising altitude of 25,5 km. The draft PCR project, which was completed on 26 June 1957 of the year and made very well, confirmed the reality of fulfilling both the customer’s requirements and the hopes of the Kremlin.

The height of 20 thousand meters by a reconnaissance jet should have been gained in 15 minutes from the moment of separation from the runway. The speed of sound was to be reached at an altitude of 8,5 thousand m after 4 minutes after takeoff. At an altitude of 10,7 thousand m at a speed of 1540 km / h, the overhead tanks were dropped and, at cruising altitude (25,5 thousand m), the "PCP" performed a long steady flight at supersonic speed corresponding to M = 2,65. The maximum flight altitude at speeds up to 2800 km / h should have been 26,7 thousand meters, and the flight range at altitudes above 20 thousand meters with a lower speed reached 3760 kilometers. According to the calculations, the takeoff run length was 1300 meters with flaps extended up to the separation speed of 330 km / h, at take-off angle up to 9 degrees and thrust in 9500 kgf. The reduction of "PCP" for landing was supposed to start 500 kilometers from the airfield. The path length at landing speed in 245 km / h was 1200 meters. Scout during the flight should be respected modes of radio and radar silence. To reduce radar reflection, specialists agreed with the designers to provide appropriate forms for the lower surface of the device, as well as the possibility of using porous radio-absorbing coatings for the skin. To evade enemy missiles, which were detected by airborne antennas, it was planned to perform anti-missile maneuvers with overloads up to 2,5 (for example, vigorously rising to a dynamic ceiling in 42 thousand meters or lifting with a left and right roll with a further sharp change in altitude), as well as creating passive and active radio interference in the working frequency ranges of detection of enemy air defenses. Interference was possible in the presence of a radiating locator, powered by a central turbine unit and equipped with two electric generators.

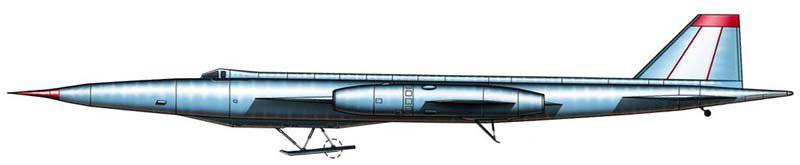

The RSP aircraft scheme was a single-seated midplane with a trapezoidal wing of small elongation and a full turning tail plumage similar to it. The profiles of the control and bearing surfaces were formed into symmetrical hexagons by straight lines. Hexagons on the rear and front edges are pointed. The fuselage assembled from cylinders and cones had a circular cross section with a diameter of 1500 mm in the central part. On top of the hull laid out invoice gargrot trapezoidal section, which stretches from the cockpit to the front edge of the vertical tail. This add-on was made not immediately, but during the design studies. Its main purpose was the wiring of communications along the fuselage from the cockpit from the controls to the deflected surfaces of the tail, for communication between hydraulic and electrical units and fuel tanks. The front part of the fuselage is a cone with a nasal lively Ccock. The tail part, also conical in shape, ended with a hemispherical radome of the radiation warning antenna at the rear end point. The lantern of a cabin was formed by transparent flat surfaces. This form was used to eliminate visibility distortion. The fuselage was divided into eight compartments: bow; instrument compartment; airtight cockpit cockpit; front carrying fuel tank; the middle part occupied by functional equipment; rear carrier tank consisting of two sections: the steering compartment and the aft fuel tank. The cabin compartment had thermal insulation and two shells. Also, in the fuselage there was one consumable tank of small capacity, a turbine unit, as well as a tank with supercooled propane, which was used to cool the instruments and some equipment in combination with thermal insulation materials. Kerosene tanks of welded construction were made of D-20 sheet duralumin. The diameter of the suspended tanks 650 mm, length - 11400 mm and contained 4,4 tons of fuel. For flights with a variable speed mode (subsonic-supersonic-subsonic speed), in order to avoid sharp longitudinal imbalances, automatic fuel transfer to the rear tanks of the fuselage from outboard tanks was provided, and a certain order of output was introduced. In this case, the optimum position of the center of gravity relative to the average aerodynamic chord of the wing was ensured.

The pilot, who was wearing a spacesuit, was in an airtight cabin, in which an internal pressure of 780 mm Hg was maintained on the ground, and at a working height, 460 mm of mercury. In the cabin, the air temperature was maintained at 30 degrees at an outside temperature of 60 degrees and fell no lower than - 5 degrees at a temperature behind the board to - 60 degrees. The pilot used an individual air-conditioning system that fed his spacesuit. The spacesuit in flight connected to the main air-conditioning system with the help of valves. In the case of cabin depressurization, the emergency system of the spacesuit's emergency system worked, providing an internal pressure that corresponds to the flight altitude 11,5 thousand meters, that is, acceptable living conditions for 15 minutes, during which the pilot could descend into the more dense layers of the atmosphere to return to his aerodrome.

During the flight, the accuracy of navigation on a given route when using radar landmarks every 500 km must be at least +/- 10 km m along the course, and during the exit to the target area to 3-5 km. These indicators were achieved using a number of automatic complexes: astro-inertial system with a vertical axis, flight-navigation equipment, a course stabilization system, an autopilot, and radar sight sights. The onboard electrical system consisted of a pair of GTS-6000 starter-generators installed on each motor and two EG-6000 generators, which were powered by a turbo unit. The turbo unit itself, installed in the fuselage and working by taking power from the compressors of the turbojet engines, was a stationary thermal reactor with an output nozzle, which was derived from the hull plating. From the turbine unit, three 15-strong hydraulic pumps, an air compressor with a capacity of 40 tons per hour (atmospheric operating pressure 2) and a cooling system fan with a capacity of 1000 tons per hour (atmospheric pressure 0,7-1) were driven.

The PCR’s defensive weapons and reconnaissance equipment included a radar scope with a photo attachment and a radio intelligence station, which were installed inside the front fairing. Their use was necessary for reconnaissance of industrial centers at the 250 km range and detection of enemy ground-based radar systems (at distances that correspond to 125-130 percentages of their detection range). After that, photographic equipment was introduced during the flight over the target at an altitude of up to 23 thousand meters. During the flight along the route, an optical sight was used, which serves to monitor the operation of photographic equipment, as well as the radar exposure warning station of enemy air defenses. If necessary, it was possible to use the equipment for setting passive and active radio interference.

In all variants of the aircraft, regardless of the destination, the idea was preserved that it was first necessary to test the possibility of flying an aircraft of this design and pattern with its unusual wing, and to study the characteristics of take-off, landing, behavior in the air, and other specific features. Scaled-down models, as well as similarity criteria associated with them, did not provide comprehensive data on the results of aerodynamic research. To obtain complete information, it was necessary to build and conduct flight tests of several full-scale models included in the estimate from the very beginning. However, the full-scale models were not interested in the government and were not reflected in the resolutions. However, as the work progressed, the need to create them became more and more obvious. In 1956, the development of a full-scale model No. 1 (HM-1) began in which the future PCR design was implemented: the chassis, glider, equipment placement, control, operation of some onboard systems and the effect of the systems on the external forms of the aircraft and the performance of its main tasks.

NM-1 - simplified "PCP", the aircraft having the same shape, piloted in research flights without load and equipped only with test instruments. In short, the laboratory, which was created for flights without achieving the specified flight performance with limited modes. Prior to receiving the standard turbojet engines (D-21), X-NUMX AM-2 engines with 5 kgf each were installed on the machine (the model was designed for subsonic speed), which imposed certain simplifications on the design of the vehicle and the nature of flight experiments. The bow of the NM-2000 is made much shorter compared to the combat option: for centering there they installed an animated pig with 1 weight of kg. Materials and design NM-700 consistent design and materials "PCP". The fuel system has been greatly facilitated, in terms of fuel volume and those. equipment (it was not necessary to pump the fuel back and forth, since the achievement of the wave crisis and the longitudinal unbalance associated with it was not planned). Management also had no fundamental differences from the "RSR". It included power boosters, hard rods, loading mechanisms and shafts. The chassis was completely different. It was made according to the type of the landing device of the “PC” outline design, that is, with the main support positioned in front of the center of gravity of the aircraft, but with considerable relief to match the smaller mass of HM-1. Instead of a two-wheeled landing trolley, a lightweight ski made of 1-mm duralumin plate with a length of 10 m and a width of 2,1 m was introduced. It was designed for several landings with further replacement with a new one. A wheel axle having two pneumatics, which was called the starting carriage, was attached to the side nodes of the ski for takeoff. Depreciation of the chassis during taxiing and during takeoff was carried out by compressing the high-pressure tires and the hydraulic cylinder rack. The flight was to be carried out in the following order: takeoff, accompanied by the separation of the wheel axle from the ski; climb in 0,1-1,2 thousand m and speeds from 1,5 to 480 km / h; flying in a box; landing with a landing on the ski. The time of the first flight should not exceed 500 minutes.

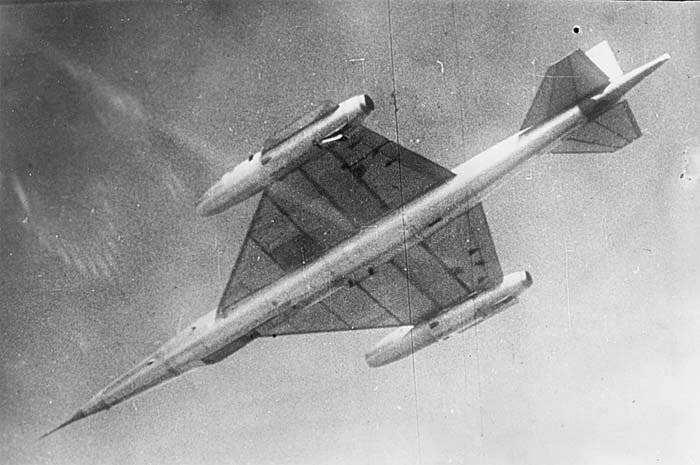

Basically, the construction of the NM-1 was completed by the middle of 1958, however, its rollout to the airfield occurred much earlier than its full readiness to demonstrate the accelerated pace of work and the implementation of the plan. Therefore, some finishing work was carried out in the open air, which delayed and complicated them, since the car needed to be rolled into the hangar during rain and overnight. The first trial taxiing conducted 01.10.1958. At the same time made the first approach into the air lasting 17 seconds. But permission for the first flight and the continuation of tests could not be obtained due to bad weather and some minor malfunctions in the work of the onboard systems. Then there were doubts about the strength of the boarding ski, and then winter came. “Good” on flights gave only in the spring of next year. 18 March 1959 made repeated taxiing, and on April 7 on 10: 53 test pilot Amet-Khan Sultan made the first flight on NM-1. The separation of the car from the runway was carried out as if in the 3 stage. At first, NM-1 at the speed of 285 km / h separated from the runway 26 seconds after the start of the run. Repeated separation occurred at a speed of 305 km / h on the 28 second. For the third time, the aircraft separated in 30 seconds after launch. At the end of the takeoff, the speed was 325 km / h, while the effort on the handle was 15 kg (reduced by the CSSC trimmer with 26 kg). The takeoff was performed with a smaller angle of attack and some over speed, and therefore the launch car, dropped at a speed of 400 km / h from a height of 40 meters, crashed against the runway. According to measurements made by the accompanying Yak-25 aircraft, the NM-1 speed was up to 500 km / h, and the height of the flight was 1,5 km. In flight, the pilot felt the weak swaying of the machine by the roll, compensated by the ailerons. At an altitude of 200 meters, the pilot removed the gas, starting planning with a reduction in speed to 275 km / h. The landing took place at a lower angle of attack and at a higher speed than was prescribed by the test program. 4 seconds after touching Betonki released brake parachute. During the run at speed 186 km / h the duralumin sole of the ski caught fire, but after a full stop the flame disappeared. Because of the greater landing speed, the length of the run was not 740 m (calculated) but 1100 m. At landing, the shock load ranged from 0,6 to 1,95 units. The duration of the first flight is 12 minutes.

Two more flights took place on 3 and 9 on June 1959 year. Total Amet-Khan on NM-1 performed 6 flights, and later 7 flights performed Radiy Zakharov. In total, between 1959 and 1960. on HM-1 flew 10 test pilots who made 32 flight duration 11-40 minutes at altitudes 1-4 km. It was not possible to reach speeds of more than 490 km / h, as the plane with a small extension wing, having thrust of two turbojet engines in 4000 kgf, flew with a large angle of attack - 10-12 degrees.

Flights have shown that an airplane with such a wing can fly! During research, some particularities were identified: the direction of take-off is steadily maintained by the aircraft, the effectiveness of the controls begins at a speed of 60 km / h. At speeds 110-120 km / h during the takeoff and mileage there is shaking. Takeoff is difficult with great effort on the handle. During the flight there is a swaying roll. NM-1 has a good "volatility" both in flight and on landing. The NM-1 is much easier to control at take-off, while building a landing calculation, as well as performing it, than the Su-7, Su-9 and MiG-19, MiG-21.

Employees of OKB-256 during flight tests and fine-tuning of NM-1 produced working drawings of "RSR" in full swing, hoping to receive from the Perm plant No.19 of D-21 dual-circuit engines. But neither in 1958, nor in 1959, this did not happen. The main reason for the non-delivery of engines for the "RSR" was a strong opposition to A.N. Tupolev. The D-20 engines (represented by the D-21 or D-20F engine) were designed for the OKB-156 engine for the Tu-124 passenger, the serial production of which in 1959 was established at the Kharkov aircraft plant No. 135. According to Tupolev, the parallel production of D-20 and D-21 would lead to interruptions in the supply of solid fuel engines for his aircraft. In the Kremlin, Tupolev's authority was very high, especially after the creation of the Tu-104 and the sensational non-stop flights Khrushchev N.S. and Kozlova F.R. (First Deputy Chairman of the Council of Ministers) to the United States on the Tu-114 (passenger version of the Tu-95). Tupolev A.N. demanded to increase the release of D-20 to the detriment of D-21 (and, therefore, "PCP"), and these requirements met. Tu-124 went to the middle and local lines of Aeroflot, and the "RSR" again remained non-engine, but now without a carrier, and without a power plant, designed for independent take-off ...

The issue of obtaining the range in 12000-13000 km, calculated for the 2RS and ZRS airplanes (using the carrier), gave the leaders no peace, and 20.03.1958’s task to create the Tu-95Н was confirmed by government decree again. However, Tupolev again gave a reasonable refusal. The final decision was postponed to the time of the meeting on experimental aircraft construction, held in the Kremlin 15.05.1958. Myasishchevu V.M. on the recommendation of Tupolev A.N. It was instructed to contact Tsybin P.V. and provide a carrier for the aircraft "PCR" as well as other products OKB-256. This was the first step in uniting two subjects, objectionable and inconvenient to Tupolev, to punish them in one fell swoop ...

For many, the intention was obvious. The beginning of the work of Tsybin and Myasishchev at the very least would mean braking of current affairs in OKB-23, as well as distracting OKB-256 from the completion of the work of the previously adopted version of "PCP" and having an independent start.

In a desperate attempt to save the case, Tsybin P.V. appealed to the Politburo of the Central Committee, the command of the Air Force and TsAGI. He was met, moving to the end of 1960, the timing of the readiness of the "RSR", with a corresponding increase in the estimate. To speed up the work, AI Mikoyan, chief designer of the OKB-155, was told to help with the development of the power plant, and S. Tumansky - put the engines R-11F.

The main and last version of the "PCR" was equipped with two engines R-11F, equipped with input devices like the MiG-21F. The design and forms of reconnaissance during the work on this model changed again (not counting the updated turbojet engine nacelles). New, more advanced systems, blocks of aeronautical equipment were installed, improved layout of photographic equipment. Instead of separate installation of cameras, they were installed on a common single platform, which was installed in the pressurized cabin before the flight. After completing the task, the platform with cameras was sent to the laboratory for processing. To ensure the normal functioning of photographic equipment, the middle part of the fuselage (5,3 meter) was converted into a half-hexagon with a lower horizontal platform, which was partially glazed in the sealing area. Inside this sealed compartment (3,5 meter) installed aerial cameras AFA-33, -34 and -40. Two cameras having a focal length of 1000 millimeters and two 200 millimeters could be replaced with a combination consisting of a single device with an 1800-mm focal length and a pair of cameras with 200-mm. Both options for picking photographic equipment "PCP" - interchangeable units that are installed on universal platforms with glazing in the pressurized cabin. Also, a special reconnaissance equipment included a radio intelligence station and a radar sight with a photo attachment installed in the nosecap (the main purpose was to reconnoiter the industrial centers with 250 kilometers removal and radar detection at distances that make 125-130 percent of their range), and optical sight to control the operation of photographic equipment, radar exposure warning station of the aircraft, equipment for setting passive and active omeh enemy radar.

The main photographic equipment of the aircraft was intended for planned, planned-prospective and prospective aerial photography. The cameras were mounted in series, and before being included in the work on the goal, the glazing was opened using a guided shutter. The compartment was sealed around the embedment on the perimeter of the 7500 mm through an inflatable hose installed in the fuselage opening. This event was introduced on the last modification of "PCP" to avoid deterioration of the transparency of lenses from icing up of the common glazing and condensation of moisture. The presence of this very complex element of the fuselage filling increased its length to 28 meters, but not without taking into account the conical tail section to increase the shoulders of tail assembly units in order to preserve the controllability and stability of the aircraft in the track and longitudinal channels.

Due to the large length of the aircraft, his bicycle chassis was reassembled while simultaneously replacing the 2-wheeled cart with the 4-wheeled cart with reduced pneumatics. The preservation of the specific load on the wing with the greater mass of the fuselage was achieved by the universal relief of the structure. For example, the five-spar power circuit, which has been developed for three years, was replaced with an 16-wall openwork circuit using roller welding of cladding panel joints. For the use of just such a design from the beginning of the work, the head of the brigade of the wing, Belko YI, spoke. All elements of the internal structure of the aircraft and airframe units were given increased attention to reduce weight. The design in almost all parts, assemblies and links has become thin-walled with minimal use of bolted joints. Many so-called "locomotive" units and parts were replaced and revised. Even riveted joints in many cases gave way to welding. The main reason for such a total relief (possibly to the detriment of longevity) was the specifics of using "PC" and "PCP". The aircraft was calculated on just 3 flight with a total flight time of 200-250 hours before the appearance of 0,2 percent deformations. Scales, even standard products of foreign origin were audited. Elements of communications and wiring were ordered to subcontractors in the facilitated and reduced execution. For example, plug-in connectors were made in half the size and weight. This provided the laying of pipelines, harnesses and cables without unnecessary complications in terms of labor costs for installation and unnecessary reinforcement of the structure in the area of the mounting holes and openings.

As a result, the design of the airframe, and the aircraft as a whole, turned out so light that the weight culture (a new characteristic for that time) sometimes exceeded world standards.

The most effective means of reducing the mass of the RSR was the rejection of the use of supersonic overhead tanks. This idea was not immediately visited by the creators' minds, but afterwards. If you do not drag heavy and huge tanks up to the speed of 1540 kilometers per hour (at which you wanted to drop them), but hang tanks of much smaller capacity and dispose of them at a speed of about 850 km / h in order to overcome the number M = 1 only to a “clean” aircraft . They counted, after which they made a conclusion: do not create and hang up old outboard tanks (each with a capacity of 2200 kg), and apply new tanks (each with a capacity of 1300 kg)! And so they did. The weight of the fuel decreased without reducing the range, while the take-off weight fell more than 1 tonne.

Innovations in this area for the conservatives of the old guard from the Soviet aircraft industry seemed completely unsuitable because of their own retrograde. Innovations that were proposed by OKB-256 employees and embodied in RSR products within the ministry framework were categorically rejected. And the standards that existed at that time, the same for bombers and fighters, are still in effect. The official standards of strength are in themselves, but the actual strength of the structural elements, which is provided with considerable reinsurance, and today contributes to the "improvement" LTH and "saves" the fuel ...

The main material of the aircraft was duralumin. Attempts to use beryllium turned out to be premature due to unworked technology, insufficient purity of beryllium alloys and considerable toxicity of work (open contact during the application of anti-corrosion coatings caused workers' skin diseases). Aprons and protective gloves quickly broke down. The use of steel parts was limited: only in particularly critical areas with concentrated loads (chassis assemblies, spar termination, wing mechanization, hinge assemblies of all-turning controls, fixing of overhead tanks, bombs, etc.). Frames of the fuselage, mainly in its middle part, were made of frame (precise punching with further machining), open to the bottom for installing a platform with lower glazing and cameras. A particularly difficult task was the design of the wing, which was associated with its thin profile. The size of the building heights at the main termination points to the counter nodes of the fuselage was 230 millimeters (I-beam with shelves 25-250 millimeters). It was difficult to install engines with wing heights, where the construction heights were 86 millimeters.

In this form, the construction of a PCP prototype was finally launched at plant No. XXUMX. But it was not possible to fully assemble him at this enterprise, since the production areas and rooms of the OKB were transferred to the deputy. Chief Designer Mikoyan A.I. on unmanned rocket-related topics A.Ya. Bereznyaku

01.10.1959, the entire squad of OKB-256 was transferred to the OKB-23 by Chief Designer Myasishchev V.M., who was instructed to sort out the documentation on the RSP aircraft and report back to 28.05. 1960 to the State Committee for Aviation Engineering (formerly MAP). All design documentation, as well as production and technological papers at the new location were checked. The drawings of the units and parts were inspected, reissued with the sight of the heads of similar units OKB-23. Almost no changes were made to the documentation, and the work began again. Engaged in his own theme - strategic bombers M-4 -6, Myasishchev B.M. did not interfere in the work of the staff of Tsybin VP, who continued to improve and bring the "RSR", preparing it for flight tests. 29.09.1960 first prototype of the "PCP" brought in Zhukovsky to the test airfield. At the same time in Ulan-Ude, at the former repair plant No. 99, an experimental installation batch "PCP" was created, which was held under the designation P-020. Myasishcheva V.M. in October, 1960 was removed from the post of chief designer of the OKB-23, translating from the head of TsAGI. The staff of manufacturers and designers who worked with him was completely reassigned to V.N. Chelomey, chief designer of the OKB-52. OKB-23 became actually a branch of OKB-52, the production and laboratory base of which was located in Reutov. Plant number XXUMX redeveloped for mass production of Proton launch vehicles as well as other rocket and space technology. The work of the team Tsybina P.V. by this time they stopped by violent order. Wage subsidies were reduced, and the new neighbor was given the authority to completely head the plant’s services. The entire composition of OKB-23 by the summer of 256, together with the management, came under the authority of the Ministry of Medium Machine Building. Tsybin later engaged in the development of the Soyuz spacecraft.

On the territory of Plant No. 99, three P-020 aircraft were built, equipped with P-11 engines, and 10 sets of units, parts and assembly units were in preparation for assembly. Previously worked out the possibility of assembling the "RSR" at the plant number 23 was overlooked, and the finished aircraft and the reserve were sent to scrap according to the annual plan for the 1961 year.

Flight tests of the NM-1 aircraft were stopped, and the experienced RSR was not conducted at all. Both devices in a semi-assembled state were brought to Moscow and transferred to the department of aircraft construction at the MAI as a textbook. Some fragments of "PCP" are there until now ...

Before the final reorientation of plant No. 23 to missiles from airplanes, from TsAGI to OKB-23 addressed to Tsybin P.V. business letter arrived. The envelope had a recommendation from the specialists of this institute in supersonic aerodynamics. The chief designer of the "PCR" received a general view of this unit, reassembled into the most acceptable form for flying at subsonic, transonic and supersonic speeds. The wing sections with a large sweep along the leading edge, which would allow to overcome the sound barrier with minimal changes in the longitudinal balancing, were clearly marked. This is probably Myasishchev V.M. I found a stale document (maybe not intentionally sent to 1958 for the year) and forwarded it to my good old memory to my former File neighbor. Of course, by the end, more precisely, the cessation of work on the "RSR" this dispatch was useless, and resembled "herring served for tea drinking."

As already mentioned, competitors who had the sole purpose of interfering, probably out of envy, often interfered in the work on the PC, 2PC, HM-1 and PCP. An important role in slowing down the work of the OKB-256 was played by the most powerful and oldest of the aviation moguls three times Hero of Socialist Labor, academician, General Designer Tupolev A.N. The patriarch of the domestic aircraft building did everything to ensure that the successes achieved by the Tsybin Design Bureau were multiplied by zero. According to information received from Tsybin himself, Golyaev, Shavrov and other employees of the design bureau, Tupolev went to the shops, halls and offices and shouted: "You won't get a shit! You won't succeed!". Then he took and abandoned the aircraft carrier for the "2PC". But Tsybin and his specialists turned out! And even without Tu-95H and D-21! NM-1 flew off well, and serial production of PCP (P-020) was started in Ulan-Ude.

Closing a promising topic on "RSR", as well as the liquidation of the Tsybin Design Bureau, are more dramatic, since another influential person in the aviation industry - Mikoyan Artem Ivanovich - had a hand in these "events". According to one of Mikoyan’s assistants, subsequently First Deputy Minister of Aviation Industry, AV Minaev, there were 3 reasons for this. Firstly, the RSR aircraft did not receive the promised engines, since "R-11F were necessary for the MiG-21". Secondly, he took the plant number 256 for his own unmanned subject matter, planting A.Ya. Bereznyak, his deputy there. and loading the enterprise with parallel production of units for MiG. Thirdly, Mikoyan A.I. He promised the government to create a three-machined reconnaissance aircraft called "ed. 155". For this topic, the team of the MiG experimental design bureau had all the initial prerequisites: the R-15B TRD and photographic equipment that was created for PCP, mounted and tested on it.

Mikoyan A.I. led his OKB along a rather difficult path. Flight speeds that correspond to M = 3, could not be achieved. In the second half of the 1960's. it turned out only that Tsybin proposed back in 1956, that is, the speed corresponding to the number M = 2,85. The Mikoyan's flight range, planned for the RSR, did not work, and the MiG-25P turned into a tactical reconnaissance aircraft.

Aircraft performance characteristics:

Modification - NM-1;

Wingspan - 10,80 m;

Length - 26,60 m;

Wing area - 64,00 m2;

Normal take-off weight - 7850 kg;

Maximum take-off weight - 9200 kg;

Engine type - X-NUMX turbojet engine AL-2;

Thrust - 2x2000 kgf;

Maximum speed - 500 km / h;

Practical ceiling - 4000 m;

Crew - 1 man.

Information