Nuclear top

This ugly gray cylinder is the key element of the Russian nuclear industry. It looks, of course, not very presentable, but you should understand its purpose and take a look at the technical specifications, as you begin to realize why the state protects the secret of its creation and device like the apple of an eye.

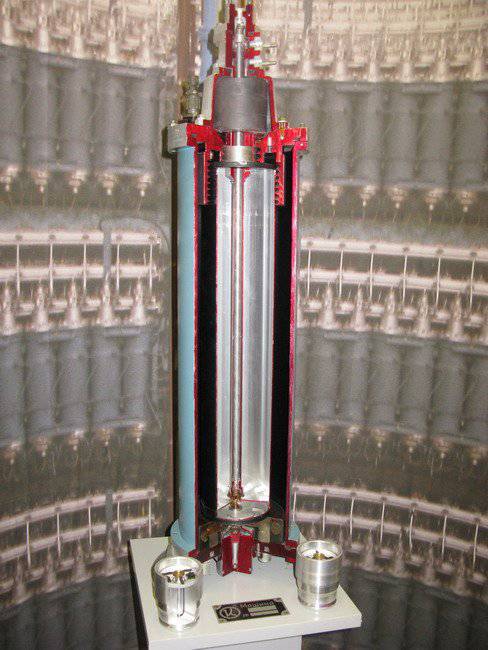

Yes, I forgot to imagine: in front of you is a gas centrifuge for the separation of uranium isotopes VT-3F (n-th generation). The principle of operation is elementary, as in a milk separator, heavy under the influence of centrifugal force is separated from the light. So what is its significance and uniqueness?

To begin with, let's answer another question - but in general, why divide uranium?

Natural uranium, which lies directly in the ground, is a cocktail of two isotopes: uranium-xnumx и uranium-xnumx (and 0,0054% U-234).

Uranium-xnumx - it's just a heavy, gray metal. From it you can make an artillery shell, well, or ... key ring. But what can be done from uranium-xnumx? Well, firstly, the atomic bomb, secondly, the fuel for nuclear power plants. And here we come to the key question - how to separate these two, almost identical atoms, from each other? No really AS?!

By the way: Radius of uranium atom nucleus -1.5 10-8

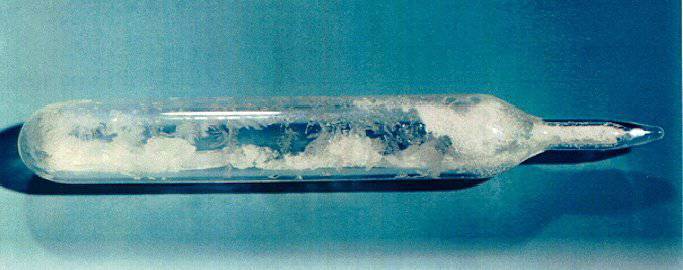

In order for uranium atoms to be driven into a technological chain, it (uranium) must be turned into a gaseous state. It makes no sense to boil, it is enough to combine uranium with fluorine and get uranium hexafluoride HFC. The technology of its production is not very complicated and expensive, and therefore HFC get right where this uranium is mined. UF6 is the only volatile compound of uranium (when heated to 53 ° C, hexafluoride (in the photo) directly changes from a solid to a gaseous state). Then it is pumped into special containers and sent for enrichment.

Немного stories

At the very beginning of the nuclear race, the greatest scientific minds, both of the USSR and the USA, mastered the idea of diffusion separation - passing uranium through a sieve. Little 235-th the isotope will slip, and "thick" 238-th stuck. And to make a sieve with nano-holes for the Soviet industry in 1946-th year was not the most difficult task.

From the report of Isaac Konstantinovich Kikoin at the Scientific and Technical Council of the Council of People's Commissars (given in the collection of declassified materials on the USSR nuclear project (Ed. Ryabev)): Currently we have learned how to make meshes with holes around 5 / 1 000 mm, i.e. 50 times longer than the mean free path of molecules at atmospheric pressure. Consequently, the gas pressure at which the separation of isotopes on such grids will occur should be less than atmospheric pressure 1 / 50. Practically, we propose to operate at a pressure around the 0,01 atmosphere, i.e. under good vacuum conditions. The calculation shows that to obtain a product enriched to a concentration in 90% with a light isotope (this concentration is sufficient to produce an explosive), you need to cascade around 2 000 such steps. In the designed and partially manufactured by us machine is calculated to get 75-100 of uranium-235 per day. The installation will consist of approximately 80-100 "columns", in each of which 20-25 steps will be mounted. "

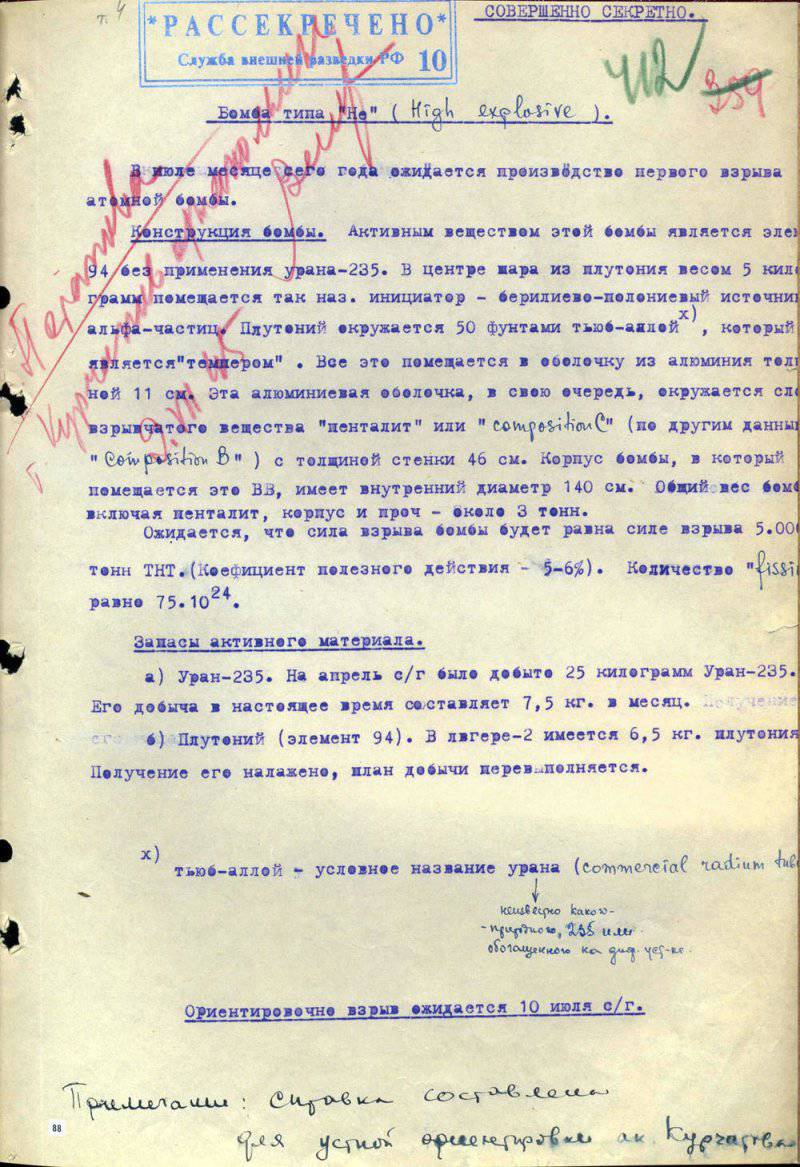

Below is the document - Beria Stalin's report on the preparation of the first atomic explosion. Below is a small certificate of accumulated nuclear materials by the beginning of the summer of 1949.

And now imagine for yourself - 2000 hefty installations, for the sake of some 100 grams! Well, where to go, because the bombs are needed. And they began to build factories, and not just factories, but entire cities. And it’s just that only the cities, these diffusion plants demanded so much electricity that they had to build separate power stations nearby.

In the photo: the world's first uranium gas diffusion enrichment plant K-25 in Oak Ridge (USA). Construction cost $ 500 million. The length of the U-shaped building is about half a mile.

In the USSR, the first stage of the D-1 plant No. 813 was designed for a total release of 140 grams of 92-93% uranium-235 per day for 2 cascades of 3100 separation stages, identical in power. Under construction unfinished aviation plant in the village of Verkh-Neyvinsk, which is 60 km from Sverdlovsk. Later it turned into Sverdlovsk-44, and the 813th plant (pictured) into the Ural Electrochemical Plant - the largest separation plant in the world.

And although the technology of diffusion separation, albeit with great technological difficulties, was debugged, the idea of mastering a more economical centrifuge process did not leave the agenda. After all, if you manage to create a centrifuge, the power consumption will be reduced from 20 to 50 times!

How does the centrifuge work?

It is arranged more than simply and looks like an old washing machine operating in the "spin / dry" mode. In a hermetic casing there is a rotating rotor. Gas is fed into this rotor. (UF6). Due to the centrifugal force, hundreds of thousands of times greater than the field of the Earth, the gas begins to be divided into "heavy" and "light" fractions. Light and heavy molecules begin to cluster in different zones of the rotor, but not in the center and around the perimeter, but above and below. This is due to convection currents - the rotor cover is heated and there is a backflow of gas. At the top and bottom of the cylinder there are two small tubes - intake. A lean mixture enters the bottom tube, a mixture with a higher concentration of atoms goes to the top tube. 235U. This mixture enters the next centrifuge, and so on, until the concentration 235-th uranium does not reach the desired value. A chain of centrifuges is called a cascade.

Technical features.

Well, firstly, the rotational speed of the modern generation of centrifuges reaches 2000 rev / sec (I don’t even know what to compare with ... in 10 times faster than a turbine in an aircraft engine)! And it works without stopping THREE TEN years! Those. now in cascades centrifuges rotate, turned on under Brezhnev! The USSR is no longer there, but they are all spinning and spinning. It is not difficult to calculate that during its work cycle the rotor makes 2 000 000 000 000 (two trillion) turns. And which bearing will withstand it? Yes, no! There are no bearings there. The rotor itself is an ordinary top, it has a strong needle at the bottom, resting on a corundum thrust bearing, and the upper end is hanging in a vacuum, being held by an electromagnetic field. The needle is also not an easy one, made of ordinary wire for piano strings, it is hardened in a very tricky way (in some way - GT). It is easy to imagine that with such a mad rotational speed, the centrifuge itself should be not just strong, but very durable.

Academician Joseph Friedlander recalls: “They could shoot three times completely. Once, when we had already received the Lenin Prize, a major accident happened, the lid flew off the centrifuge. Pieces scattered, destroyed other centrifuges. A radioactive cloud has risen. I had to stop the whole line - kilometer installations! In Sredmash, centrifuges were commanded by General Zverev, before the atomic project he worked in the Beria department. The general at the meeting said: "The situation is critical. The defense of the country is under threat. If we do not quickly rectify the situation, 37 year will repeat for you." And the meeting immediately closed. We then invented a completely new technology with a completely isotropic uniform structure of the covers, but very complex installations were required. Since then, it is these caps that are made. There was no more trouble. In Russia, 3 concentrators, centrifuges - many hundreds of thousands. "

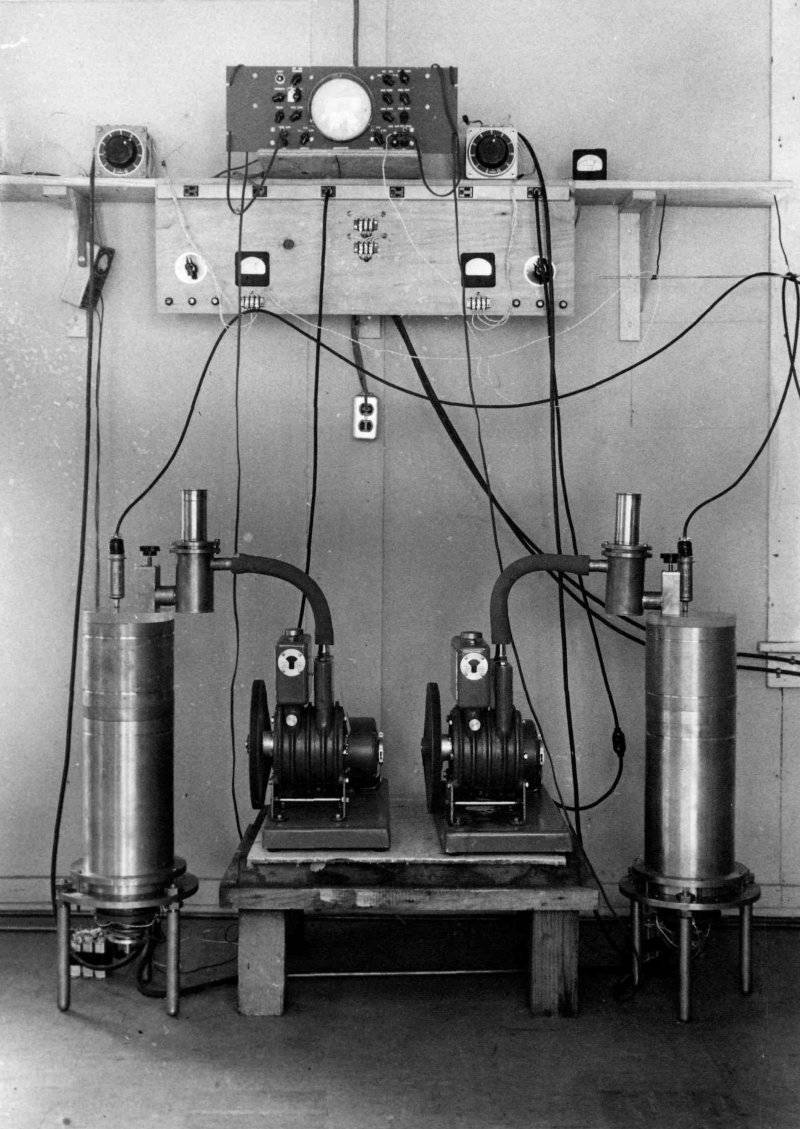

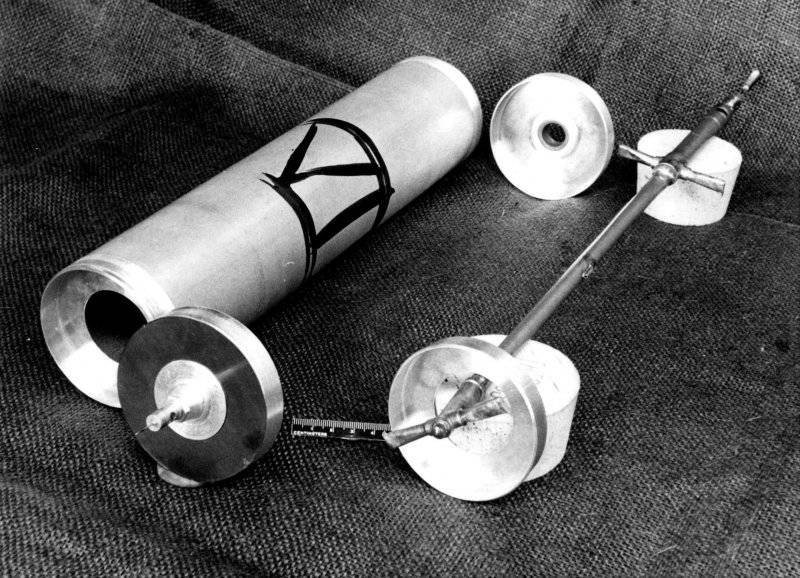

In the photo: first generation centrifuge tests

At first, the rotor bodies were also metal, until they were replaced by ... carbon fiber. Easy and extra strong on a gap, it is ideal material for the rotating cylinder.

Alexander Kurkin, Director General of UEHK (2009-2012), recalls: “It is ridiculous. When a new, more "revving" generation of centrifuges was tested and tested, one of the employees did not wait for the rotor to stop completely, disconnected it from the cascade and decided to move it to the stand. But instead of moving forward, he didn’t stand up, he embraced with this cylinder, began to move backwards. So we saw for ourselves that the earth rotates, and the gyroscope is a great force. ”

Who invented?

Oh, this is a mystery, steeped in mystery and wrapped up in uncertainty. Then you and the German captive physicists, the CIA, officers SMERSH and even downed spy pilot Powers. In general, the principle of a gas centrifuge is described at the end of the 19 of the 20th century.

At the dawn of the Atomic Project, Viktor Sergeev, engineer at the Kirovsky Plant Design Office, proposed a centrifugal separation method, but at first his idea was not approved by his colleagues. At the same time, scientists from defeated Germany fought to create a separation centrifuge in a special scientific research institute-5 in Sukhumi: Dr. Max Steenbeck, who worked with Hitler as a leading engineer of Siemens, and a former Luftwaffe mechanic, a graduate of the University of Vienna Gernot Zipppe. In total, the group included about 300 "exported" physicists.

The General Director of Centrotech-SPb, Rosatom Group, Alexey Kaliteevsky, recalls: “Our specialists came to the conclusion that the German centrifuge is absolutely unsuitable for industrial production. There was no partially enriched product transfer system to the next stage in the Shteenbek apparatus. It was suggested to cool the ends of the lid and freeze the gas, and then defrost it, collect and put into the next centrifuge. That is, the circuit is inoperative. However, the project had some very interesting and unusual technical solutions. These "interesting and unusual solutions" were combined with the results obtained by Soviet scientists, in particular with the proposals of Viktor Sergeev. Relatively speaking, our compact centrifuge is one third the fruit of German thought, and two thirds is Soviet. ” By the way, when Sergeyev came to Abkhazia and, with the same Steenbek and Tsippe, expressed their thoughts on the selection of uranium, Steenbek and Tsippe dismissed them as unrealizable.

So, what did Sergeev come up with?

And Sergeyev's proposal was to create gas samplers in the form of Pitot tubes. But Dr. Shtenbek, who ate teeth, he believed, on this topic, showed categorically: “They will slow down the flow, cause turbulence, and there will be no separation!” Years later, working on his memoirs, he would regret it: “An idea worthy to come from us! But it never occurred to me ... ".

Later, once outside the USSR, Steenbek was no longer engaged in centrifuges. Before leaving for Germany, Geront Zippe had the opportunity to familiarize himself with Sergeyev’s prototype centrifuge and its ingeniously simple principle of operation. Once in the West, the “cunning Zippe”, as he was often called, patented the design of a centrifuge under his own name (patent # 1071597 from 1957 of the year, announced in 13 countries). In the 1957 year, having moved to the USA, Zippe built a working installation there, reproducing Sergeyev’s prototype from memory. And I called it, we give it its due, the “Russian centrifuge” (in the photo).

By the way, Russian engineering thought manifested itself in many other cases. An example is an elementary emergency shut-off valve. There are no sensors, detectors and electronic circuits. There is only a samovar tap, which with its petal touches the cascade bed. If something goes wrong, and the centrifuge changes its position in space, it simply turns and closes the input line. It's like a joke about an American pen and a Russian pencil in space.

Our days

This week, the author of these lines was present at a significant event - the closure of the Russian office of observers of the US Department of Energy under the contract HEU-LEU. This transaction (highly enriched uranium - low-enriched uranium) was, and remains, the largest agreement in the field of nuclear energy between Russia and America. Under the terms of the contract, the Russian nuclear power engineers converted 500 tons of our weapons-grade (90%) uranium into fuel (4%) HFCs for US nuclear power plants. Revenues for 1993-2009 years amounted to 8,8 billion US dollars. This was the logical outcome of the technological breakthrough of our nuclear scientists in the field of isotope separation, made in the post-war years.

In the photo: cascades of gas centrifuges in one of the shops UECC. Here they are about 100 000 pcs.

Thanks to centrifuges, we received thousands of tons of relatively cheap, both military and commercial products. The nuclear industry, one of the few remaining (military aviation, space), where Russia holds indisputable primacy. Foreign orders alone for ten years ahead (from 2013 of the year to 2022 of the year), Rosatom's portfolio without the HEU-LEU contract amounts to 69,3 billion dollars. In 2011, he passed over 50 billions ...

In the photo warehouse containers with HFC UECC.

That's what I mean: September 28 1942 was adopted by the State Defense Committee Decree No. 2352ss "On the organization of work on uranium." This date is considered the official starting point of the history of the nuclear industry in Russia. So, on a holiday, atomic lobbyists!

Information