"Maksim". Relatives of the famous machine gun

"Pom-pom". Big Brother

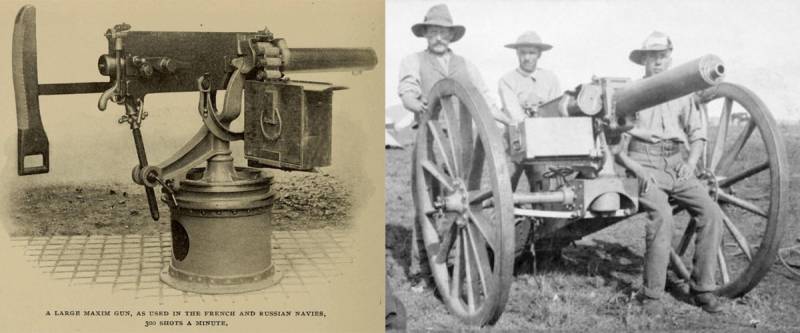

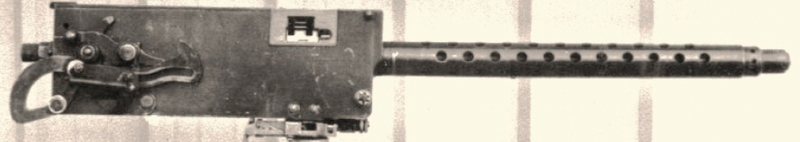

The world's first automatic cannon, in which recoil energy was used for reloading, was invented by the same H.C. Maksim. In 1883 he patented the 37mm cannon. The principle of operation of the machine gun and automatic cannon was the same, and outwardly they differed mainly in size. Maxim delivered a 37 mm cannon to Russia in 1888. First, it was tested by the War Department, and then transferred to the Naval Department. According to the test results, the Naval Department in 1889 ordered Maxim two 37-mm cannons.

In 1891, a decision was made to purchase six Maxim guns, and then twenty more. But no money was allocated for this.

The report of JSC MTK for 1894 indicated:

The cannon became famous thanks to the first Boer War.

The British refused to purchase automatic weapons, while the Boers who fought against them acquired a batch of guns through intermediaries. The Boers effectively used Maxim's cannons as an infantry weapons, and it was they who gave the nickname to this weapon "pom-pom" (because of the sound of firing), which was assigned to the 37-mm Maxim gun.

Having tasted the big machine guns, the British also began to buy them, followed by the rest of the Europeans.

In 1901, the Obukhov plant manufactured a prototype of the 37-mm Maxim cannon for the Naval Department.

The 37 mm automatic cannon worked on the same principle as the Maxim machine gun, being, in fact, its enlarged version. Added a device that absorbs excessive recoil - a hydraulic buffer, reduced the rate of fire to 250 rounds per minute.

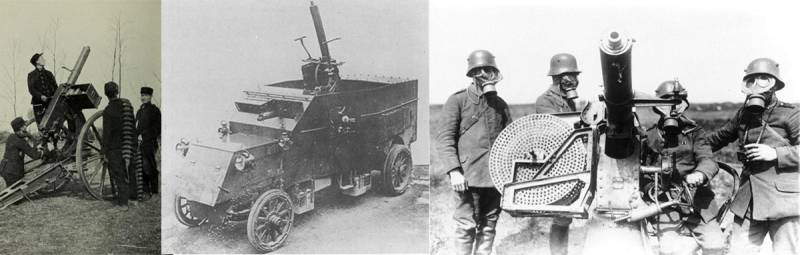

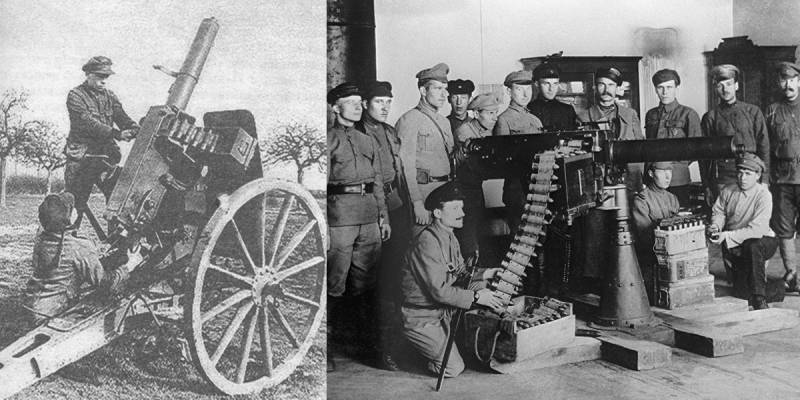

With the outbreak of the First World War, automatic cannons were urgently needed to fight both the infantry and the enemy in the air. Against the planes of those years, made of sticks and rags, the hit of a pom-pom shell was fatal. The use of automatic cannons was on both sides of the front, both in the anti-aircraft version and on the ground.

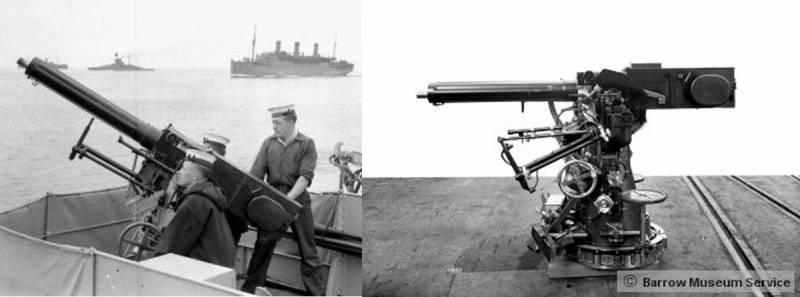

For the Vickers machine, and then Maxim in 1914, Lieutenant Sherspobaev designed an automatic tube installer (AUT) in the cartridge belt. It was the first domestic and probably the first in the world of AUT. Soon he appeared on all marine anti-aircraft guns.

The naval department urgently ordered 120 37-mm Maxim guns from the Obukhov plant, of which 80 were supposed to be delivered in 1917 and 40 in 1918. However, until the end of 1917, the Obukhov plant did not issue a single machine gun. This is due, firstly, to the extreme constructive (of course, for that time) complexity, individual fitting of parts (many of which were not even interchangeable), and secondly, to the heavy workload of the plant that produced sea and land guns with a caliber of 37 up to 406 mm.

The delivery, or rather the issue, of machine guns in the unit began only at the end of 1918, that is, they did not take part in the First World War, but were used during the Civil War in Russia.

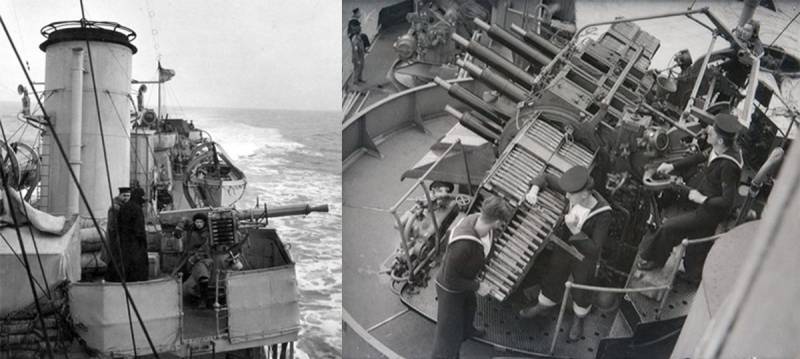

In Great Britain itself, with the beginning of the war, it was decided that the automatic anti-aircraft gun should shoot further, faster and be at least a little, but simpler. Therefore, in 1914, by order of the Royal fleet the Vickers company has developed a simplified and more technologically advanced version of the Maxim-Nordenfeldt cannon with a more powerful projectile - the automatic 40-mm Vickers QF Mark II cannon. The blueprints for the gun were transferred (for money, of course) to the allies, including Russia.

Both the Naval and the Russian Military departments immediately ordered 40-mm Vickers assault rifles in England. Moreover, the first required machine guns on pedestal beds, and the second - 16 anti-aircraft machine guns installed on armored vehicles, and 4 machine guns on field wheeled carriages of the Depor system.

By the end of 1916, twenty 40-mm Vickers assault rifles (from a naval order) were in service with the Black Sea Fleet.

And in the same year, the Maritime Department issued an order to the Obukhov plant for the manufacture of 60 swinging parts of 40-mm Vickers assault rifles. Until the end of May 1917, 12 swinging units were sent to Revel. The cabinet units for them were made by the workshops of the Peter the Great Fortress.

After the Civil War, efforts were made at the Bolshevik plant (formerly the Obukhov plant) to restore production. We remembered the technology for the release of the actual guns. We have developed a new machine. But the production remained practically handicraft, with individual fit of parts and the corresponding quality.

We also decided on the basis of the simplest 40-mm Vickers assault rifle to develop an automatic cannon suitable for serial production on existing equipment, moreover, with higher characteristics. And in order to improve ballistics without making the artillery system heavier as a whole, we switched from 40 mm to the 37 mm caliber, which is more familiar to us. This is how it appeared 37-mm automatic cannon mod. 1928 g.

On the first tests, it turned out that the accuracy of the shooting fell due to the unsuccessful geometry of the projectile and further development was required. In addition, the automation itself did not work perfectly ...

And, hiding behind a heavy workload on the development of large-caliber guns, as well as the release of tractors and tanks, the plant "Bolshevik" achieved the transfer of the finalization and production of automatic weapons to another plant, which had never before been engaged in automatic weapons. This plant was named after Comrade Kalinin and was located in Podlipki.

The assault rifle was assigned the index 11-K. At the beginning of 1930 for the gun arr. In 1928, the engineer of the Bolshevik plant, Upornikov, designed a wheeled carriage, which received the factory index B-5. By the way, in some documents the whole system was also called that.

In the stowed position, the carriage had a two-wheeled drive, and in the combat position, the move was separated and three three-meter frames moved apart, on the openers of which the carriage rested.

In 1929, plant number 8 was given an order for 50 automatic machines for the fleet. Only in 1932, 5 submachine guns were presented for testing, but the submachine guns did not want to fire normally. So it was not possible either in 1932 or in 1933 to hand over a single 11-K machine gun.

So the automatic machine arr. In 1928 he was safely buried, and in the Artillery Directorate, in order not to get a hat, they immediately caught fire with a super idea - to order everything from the Germans. True, it did not work out better with the Germans either.

In Great Britain, after the First World War, the Vickers automatic cannon continued to be produced in series and was used in the navy, in the army, and was exported. The gun received new shells and a metal tape instead of a cloth one. Finally, "pom-poms" disappeared as a working weapon only after the end of the Second World War.

Russian Maxim's stepchildren

In November 1918, a new old state appeared in Europe - II Rzeczpospolita, also known as the Republic of Poland. One of the main types of machine guns originally used by the new Polish army was the Maxim machine gun arr. 1910 under Russian patronage or, as the Poles called it - Karabin maszynowy Maxim wz. 1910.

After the adoption in 1922 of the 7,92x57 mm Mauser caliber as the standard ammunition for a rifle in Poland, attempts were made to adapt the wz. 1910 machine gun for firing with this cartridge. The result of this work was the Maxim wz. 1910/28 with 7,92 mm ammunition. Parts of MG08 machine guns were used for modernization.

However, not all machine guns were reworked - 400 pieces were sold to brotherly (brothers in hatred of the young country of the Soviets) Finland. The remaining 2 machine guns, after alteration under the German cartridge, were sent to secondary parts and warehouses, and in 000 they were sold to Spain.

After the proclamation of Finland's independence in 1918, up to 600 7,62-mm Maxim machine guns of the 1910 model entered service with the emerging units of the Finnish army and received the name Maxim m / 1910.

This type of machine gun became the main machine gun of the Finnish army. In the future, Finland bought these machine guns, where she could - in Poland, Germany, Italy. The production of Maxim machine guns was also organized at the Tikkakoski plant.

The machine gun underwent a slight modernization - the sights were replaced, and the Finns also abandoned the shield. Some of the machine guns received a self-developed tripod machine M / 21 instead of Sokolov's machine. It was developed on the basis of a German export pre-war machine (the same Swiss model).

Unlike the German model, the Finnish design had handles (metal loops) on the front legs of the tripod, and its longer third leg had a telescopic design, which made it possible to adjust its length. This tripod could also be equipped with an anti-aircraft adapter, which made it possible to use the machine gun as an anti-aircraft gun.

By the beginning of the 30s, the Finnish military ceased to be satisfied with the used canvas tape for the machine gun. The original 250-round ammunition fabric belts limited both the maximum rate of fire and proved to be problematic in some cases - in wet, humid and cold weather. In frosty weather, the fabric tape could first get wet and then freeze.

Therefore, in April 1931, the already well-known gunsmith Aimo Lahti was given the task to develop a modification of the Maxim machine gun for a metal non-scattering belt. Aimo Lahti designed a metal band based on individual links like Prideaux, but not crumbling due to the constant connection between the sockets. This non-loose metal tape was patented in the UK on October 12, 1933.

The machine gun itself under the new belt was named Maxim M / 32. In addition to the new tape receiver, the machine gun received a wide casing neck, allowing the casing to be filled not only with water, but also with snow, and an accelerating mechanism (in the rear of the receiver), and a new muzzle, which made it possible to increase the rate of fire to 850 rds / min.

Probably, the Finnish Maxim М / 32 is one of the best modifications of the Maxim machine gun.

Air brother

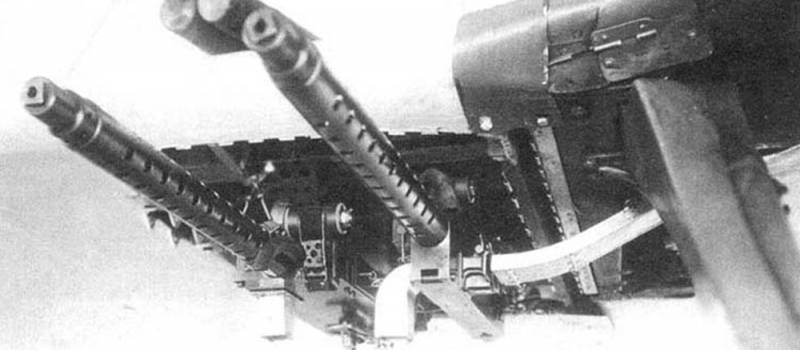

In 1923, the development of the first Soviet fighters began in the USSR. A batch of air-cooled Vickers machine guns was purchased to arm the aircraft, but these machine guns used British cartridges, and it was immediately decided that a separate air-cooled and belt-fed machine gun was required.

In the same year, work on the alteration of the machine gun "Maxim" in aviation began the pilot and aircraft designer of the Moscow Aviation Plant A.V. Nadashkevich. Initially, this work was carried out at the Aviarabotnik plant, and since 1924 - at the Tula Arms Plant. The designer was greatly assisted in this work by the engineers P.P. Tretyakov and I.A. Pastukhov, who were directly involved in the modernization of the original "Maxim" in 1910, as well as S.A. Yartsev.

In the design of Nadashkevich, the “Maxim” automatics were retained (recoil energy was used with a short barrel stroke). The aircraft machine gun differed from the easel in its lower weight, achieved by turning and shortening the barrel, by introducing an air one. The trigger was adapted for synchronized firing. To increase the rate of fire of the machine gun, the diameter of the muzzle sleeve was reduced and a buffer spring was introduced, which imparted an additional speed to the mobile system when it moves forward and took a blow when it retreated.

As a result of the design changes introduced to the machine gun, the rate of fire increased from 600 to 750 rounds per minute.

Initially, it was supposed to use loose metal tape, like the English one, but some of the machine guns of the first releases went under a standard canvas tape. And only since 1930, loose metal began to be fully used.

Field tests of the Nadashkevich PV-1 machine gun (first air machine gun) were started on May 19, 1926. Six months later, on November 15, 1926, the Artillery Committee, having considered the test results, accepted the submitted sample for supplying the Red Army Air Force.

Machine guns PV-1 were installed on aircraft for firing through the propeller from fixed installations, and outside the plane of rotation of the propeller - from fixed or limitedly mobile installations.

The first serial PV-1 machine guns had barrels with a shortened muzzle to reduce weight, but on August 24, 1930, the head of the Red Army Artillery Directorate G.I. Bondar turned to the chief of armaments of the Red Army with a proposal to standardize machine-gun barrels. Deputy Chairman of the Revolutionary Military Council of the USSR I.P. Uborevich approved the transition to the manufacture (since 1931) of PV-1 machine guns with Maxim machine gun barrels.

The development of the I-4 fighter with two firing points for ease of placement on the aircraft required the creation of a machine gun with a belt feed from left to right. The first batch of such machine guns in the amount of ten pieces was manufactured in 1929. In December 1929, after testing, machine guns with a left-hand feed of the belt were put into service. Their production began in 1930.

At the same time, an even lighter modification of the machine gun was developed under the designation A-2. The machine gun box became a mixed design - some of the steel parts were replaced with duralumin. The barrel cover also became duralumin.

All design changes led to a decrease in the mass of the machine gun by almost 2 kg while maintaining the rest of the characteristics. The machine gun was produced for some time, but later it was removed from service, since it was recognized that the complication and rise in the cost of the structure with these characteristics does not justify itself.

In total, in 1927-1939, almost 18 thousand units of PV-1 were produced. In 1940, in connection with the transition to more modern models of larger calibers and the removal from service of aircraft models on which the PV-1 was installed, the production of the machine gun was discontinued.

During the Great Patriotic War, in addition to the armament of the U-2 aircraft, the built PV-1s were used in the anti-aircraft machine-gun installations manufactured in Tambov designed by N.F. Tokarev, including for the air defense of Soviet armored trains.

In 1942, the arms factory in Zlatoust began to install the PV-1 remaining in storage warehouses on wheeled machines of the 1910 model, designed by A.A. Sokolov (there were no others). At the same time, the machine gun changed the tape receiver to a standard Maksim one, under the canvas tape, and the buffer spring was removed to prevent failures due to the fault of the tape at an increased rate of fire. The infantry units of the Red Army were supplied with 3 heavy machine guns.

Almost tame

The question of a light machine gun was one of the main issues posed by the First World War to the Russian army, and in the early 20s it became a priority in the Red Army's armament system.

During the war, Russia bought light machine guns abroad, but also Danish Madsen submachine guns (for which the plant in Podolsk was built, but the plant in Podolsk was never built), and French Shosha submachine guns, and more successful American Lewis by the middle The 20s were worn out, did not have spare parts and the proper amount of ammunition, which, in the conditions of the isolation of the Soviet country, could not be replenished.

The planned production of the Danish Madsen, which was planned for 1918, was actually disrupted. The development and fine-tuning of our own model of a light machine gun took time. According to the Deputy People's Commissariat for Military Affairs M.V. Frunze:

Moreover, there was the experience of the German army, which completed its manual MG.08 / 15 and MG.08 / 18 on the basis of the easel MG.08.

In 1923, the GAU Artkom issued the Shot training range with a task to convert the Maxim machine gun into a manual version. The designer of the landfill, I.N. Kolesnikov, then F.V. Tokarev, who worked for TOZ.

Kolesninov's sample was ready already in 1923, Tokarev's - in November 1924.

Technical requirements for future light machine guns were developed by the commission of the Revolutionary Military Council of the USSR formed on September 8, 1924, chaired by S.M. Budyonny:

the barrel must be shortened and made replaceable,

the casing is removable,

the machine gun should have an adjustable front sight on the casing and a simplified sight,

folding bipods to be made with the possibility of turning in a horizontal plane,

rifle-type butt,

the sleeve tube must be excluded.

It is easy to see that the German MG.08 / 18 was taken as the basis for the requirements (German weapons were available for study at that time, thanks to cooperation with Weimar Germany). At the forefront were the requirements to facilitate the system without changing the main parts and assemblies.

F.V. Tokarev, the converted light machine gun turned out better than the Kolesnikov one, which was confirmed by the tests on April 10, 1925, in which, in addition to the "Budyonnovsk" commission, representatives of the command and staff of the Red Army, the ground forces, the Air Force and even the fleet took part. All were unanimous in favor of the Maksim-Tokarev (MT) model.

Reducing the mass of weapons, Tula gunsmiths reworked the design of the receiver. Instead of the former box of rectangular shape, a construction with several notches was used. Saving weight was achieved through three notches in the front and rear of the receiver. In addition, the new design of the trigger with a trigger has reduced the length of the receiver.

The MT machine gun received a barrel with a length of 655 mm and a mass of 1,7 kg (for the easel "Maxim" - 2,1 kg) with fasteners for quick replacement. For the safety of the shooter, the barrel was covered with a casing with oval holes. Like the barrel, the casing could be replaced if necessary. Fulfilling the requirements of the military, Tokarev provided for the possibility of replacing the barrel without removing the casing.

On the front of the casing, lightweight tubular folding bipods were attached. The place of the butt plate was taken by a wooden rifle-type butt, to which a trigger mechanism with a safety catch was attached.

Not wanting to complicate the production, the authors of the MT project completely borrowed the automation from the base Maxim. The new light machine gun used the recoil of the barrel with a short stroke. The barrel was locked by a bolt connected to two levers. Used tape ammunition. The canvas tape was shortened to 100 rounds and was contained in a drum, again, following the example of a German machine gun. The ejection of spent cartridges was carried out through a window in the lower part of the receiver.

Military tests confirmed the possibility of using MT in the troops, despite the inherent drawbacks of rework systems. The MT was adopted on May 26, 1925, even before the final test results were obtained. The Armament Commission of the Red Army under the Revolutionary Military Council of the USSR even assigned him the place of a new light machine gun.

The MT machine gun also auditioned for the role of a tank machine gun and a light company commander with a tripod like Lewis.

On July 1, 1925, TOZ began setting up production of MT light machine guns, which began in November. The finalization of the structure took time, and by July 1, 1926, TOZ had produced only 50 MT. For 1926-1927. 2 copies were produced, after which production was discontinued.

The main reason is the adoption of a more advanced light machine gun of the Degtyarev system mod. 1927 (DP).

As they received DP, the MT machine guns were withdrawn from the troops and sent to warehouses, but they did not have to lie there for long. In 1937, the Maxim-Tokarev machine gun, among other weapons, began to be sent to the Spanish Republic. A certain amount of MT in the late 30s also went to China within the framework of the "Soviet Lend-Lease" - either the Communists, or the Kuomintang.

This is such a short fate happened to the reworked "Maxim".

Looking at the zenith

Since the appearance of combat airplanes, machine guns have become one of the most effective means of dealing with them.

At first, these were standard infantry models used from standard machines or handicraft devices for anti-aircraft fire. And at first, indeed, there were enough machine guns, and the planes did not fly very well. But as the altitude and flight speed of combat aircraft grew, it was necessary to come up with specially designed machines for machine guns, and in the future, multi-barreled anti-aircraft machine gun mounts, which could hit the aircraft many, many times with the correct sight. And they also had to be invented.

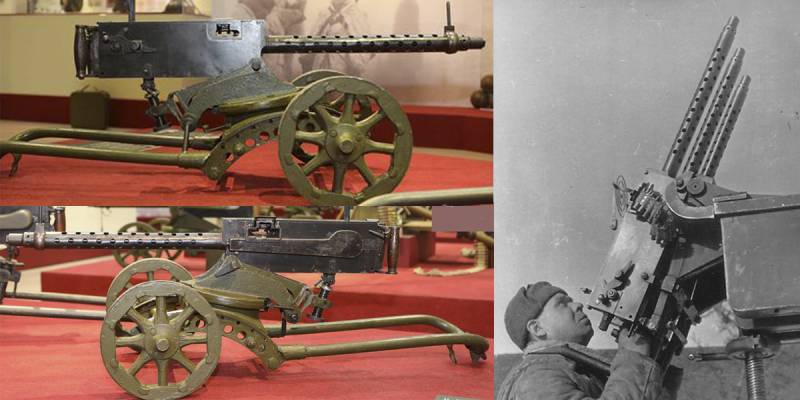

In the Russian army, the first anti-aircraft machine-gun machine was a tripod designed by I.N. Kolesnikov, created by him in 1915. The tripod had an original guidance unit (a little later used by Kolesnikov for his infantry machine) and telescopic legs. But they released very few of them. Either there were few planes on the German front, or, as always, the industry was “not good enough”, or the snob generals from GAU did not like it.

The first Soviet anti-aircraft gun was designed by M.N. Kondakov under the Maxim machine gun arr. 1910 g.

It was made in the form of a tripod and connected to a machine gun using a swivel. Possessing simplicity and reliability, the installation of arr. 1928 provided all-round fire and high elevation angles. Anti-aircraft machine-tripod sample 1928 with a swivel M.N. Kondakova had a mass of 16 kg. The tripod was a folding mechanism of three support tubes and one telescopic tube. Due to the telescopic tube with an arm (swivel) for the machine gun, height adjustment is possible. A ring sight was adopted for it, intended for firing at aircraft moving at speeds up to 320 km / h at a distance of up to 1 m.

Later, with an increase in flight speed, the sight was repeatedly modernized. The anti-aircraft machine was an addition to the Sokolov machine-gun machine. The tripod turned out to be easy to use due to its good stability, the ability to adjust the height of the machine gun, and the ability to conduct all-round fire with large elevation angles. A tripod with a machine gun was often installed on trucks, military trains, torpedo boats and patrol boats.

The production of anti-aircraft tripods was established at the "Kiev Arsenal" and the plant. Stalin NKTM in Voronezh (Voronezh Diesel Plant). In 1941, in connection with the sharply increased need for anti-aircraft machine gun installations, Degtyarev DA and DA-2 machine guns began to be massively installed on tripods.

In 1931, under the then fashionable motto of "versatility", S.V. Vladimirov, model 1931, weighing 39 kg. For firing at aircraft, the machine-gun machine with a swivel was removed from the wheel drive, telescopic pipes were extended from the openers, thus turning the wheeled machine into an anti-aircraft tripod.

In the early 30s, a special anti-aircraft machine was produced for the cavalry units, mounted on a machine-gun cart. The disadvantage of such a machine was the limitation of the possible anti-aircraft fire sector. Therefore, he was quickly withdrawn from the troops, although he was shown at parades.

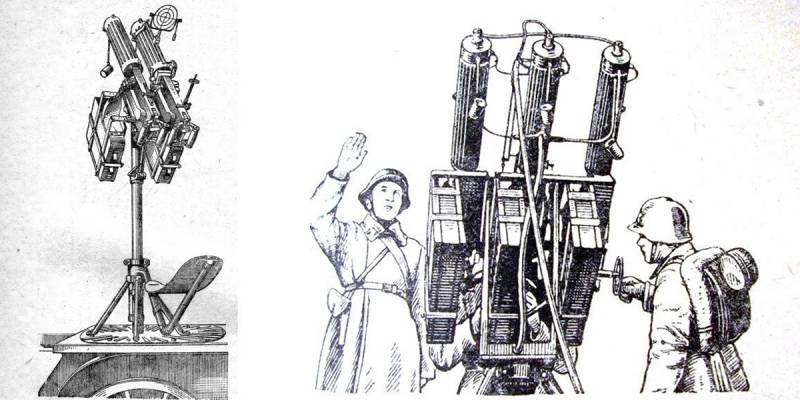

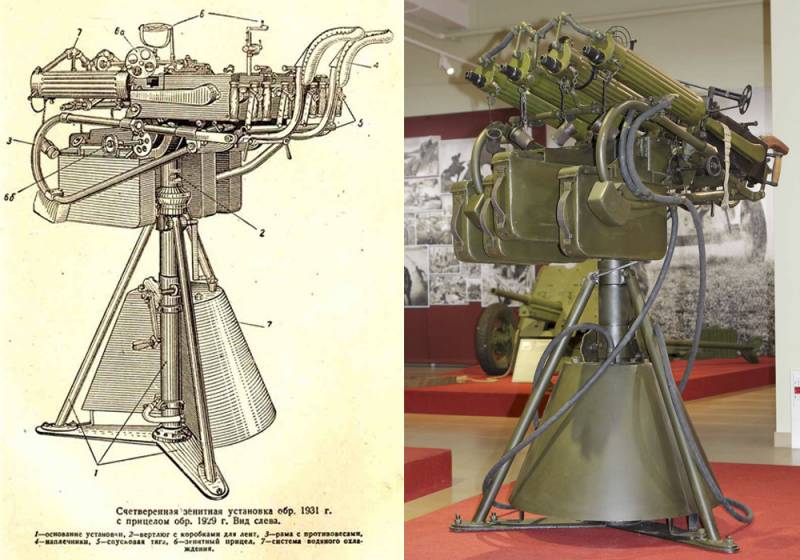

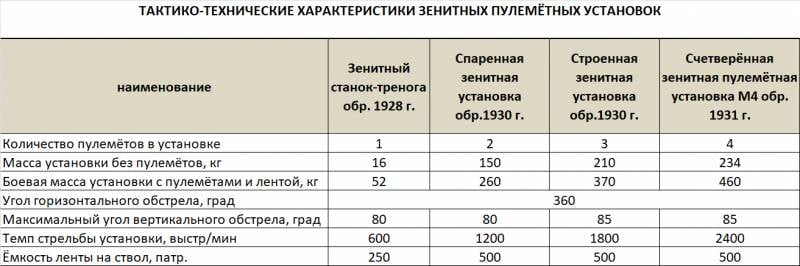

But since one Maxim machine gun had a low fire density to effectively shoot down planes, then in 1928 by the decision of the GAU Art Committee, adopted in July 1928, the design bureau of the Tula Arms Plant was instructed to design and build a twin, built and quadruple machine-gun mounts "Maxima" for firing at air targets.

By 1930, the designers N.F. Tokarev, G.G. Kurenkov, S.A. Prilutsky and A.I. Panov completed the task.

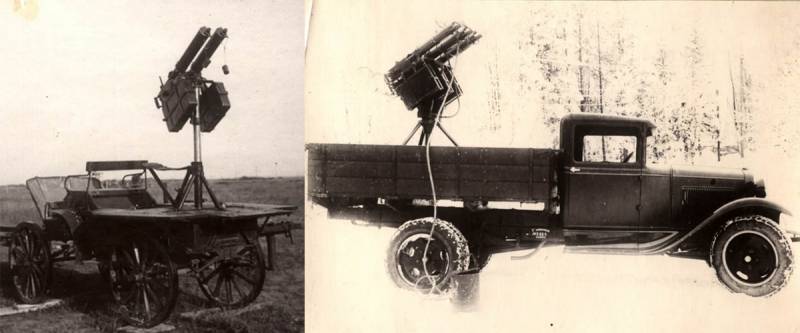

These installations at that time were usually designated by the general name - "complex". Their design made it possible to install them permanently: on the ground or on special sites, and movably: in the back of a car, on a wagon, on a railway platform or carriage, and on ships of the sea and river fleet.

According to the test results, all the installations developed under the leadership of Nikolai Fedorovich Tokarev (the son of the famous gunsmith) were adopted for the Red Army. The twin and triple units were put into service in 1930, and the quad unit in 1931.

The twin unit was used mainly on armored wagons and was produced in small quantities.

Data on the actual production of the built-in unit in 1931-1941. there is none.

Complex anti-aircraft mounts of Maxim machine guns were produced until 1941.

The manufacturers were: plant number 393 NKV, Kiev ("Arsenal") and "Plant of agricultural machines named after K.E. Voroshilov ", Kolomna.

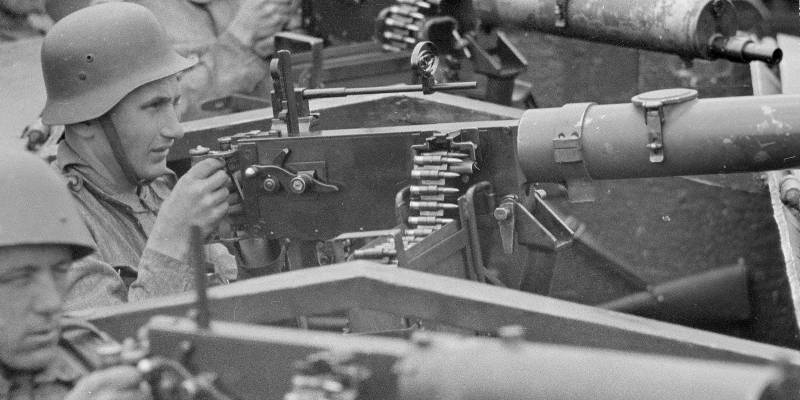

The most powerful of the created complex installations, quadruple, received the name quad anti-aircraft machine gun M4 model 1931... It was also the most widespread in the Red Army.

The power of the quad "Maxims" was first confirmed by their actions against Japanese aircraft during the armed conflict near Lake Khasan in 1938. Equally successful ZPU arr. 1931 acted on Khalkhin Gol in 1939, in the battles of the Soviet-Finnish war of 1939-1940, in the Great Patriotic War.

The installation consisted of a base, a swivel, an oscillating frame with counterweights, shoulder pads and a trigger rod, a sight and a forced cooling system. The base was a metal pedestal with a telescopic vertical tube, balancing springs and rack and pinion lifting mechanism. On the platform, the base was fastened with three paws (arrows).

The tubular swivel rotated on the tube on bearings. A frame was laid on the swivel sector, on which four maxims were attached in a row, united by one cooling system, single sighting devices and a trigger. The swivel housed boxes with high-capacity cartridge belts (500 rounds). To prevent the ribbons from curling, grooves were introduced into the design of the ZPU for them.

Aiming at the target of a block of machine guns (weighing up to 80 kg) was carried out by the gunner using shoulder arcs. In the vertical plane, machine guns can be aimed in the range of angles from –10 ° to + 82 °, in the horizontal plane, 360-degree circular fire is provided. The cooling system was designed to increase the intensity of cooling the barrels and prevent vaporization, which interferes with the work of the gunner.

Initially, the ZPU was used with an anti-aircraft ring sight arr. 1929; to change its settings in terms of range, there was a shaft with a handwheel on the frame. Then they put the sights o6r. 1936 and arr. 1938, for firing at ground targets they used the usual sight of the second from the left (main) machine gun.

The complex anti-aircraft machine gun mount with four "Maxims", possessing a high combat rate of fire, convenient and quick aiming at the target and flexible fire maneuver, has largely surpassed similar foreign weapons that appeared later. To determine the settings of the ZPU sight, the ZD stereo range finder with a meter base was used.

The staff of the rifle regiment introduced 4 quad mounts - the "Maxim" installation laid the foundation for regimental anti-aircraft weapons. At the beginning of the war, the rifle regiment had an anti-aircraft company of three 12,7-mm machine guns and six 7,62-mm installations, six more installations were included in the artillery of the division, the cavalry regiment was supposed to have three installations. In reality, by the beginning of the war, these states were not provided, which had an extremely negative effect on the anti-aircraft cover of troops and facilities.

Due to the shortage of air defense systems, at the beginning of the war, on the basis of PV-1 N.F. Tokarev, in August 1941, created a triple anti-aircraft installation, consisting of a base and a swivel with a head for the PV-1 machine guns in arsenal storage. The base consisted of a pipe with three struts and three legs for mounting on a platform. Three PV-1s were installed on the swinging head.

This weapon, despite its unsightly appearance, significantly strengthened the military air defense of the Red Army. The aircraft machine gun differed from the Maxim machine gun by the absence of water cooling, which made it possible to reduce the mass of the weapon. The weight of all three PV-1s without a cartridge strip was 43,5 kg. The total rate of fire of the built-in anti-aircraft gun was over 2 rds / min. At the same time, for a much more complex and heavy quad M200, this figure was 4 rds / min.

Tokarev's surrogate anti-aircraft gun, created in a short time, with a lower weight and cost, was practically not inferior in efficiency to a specially designed quad mount.

The mass production of built-in anti-aircraft machine gun installations using PV-1 began at the end of 1941 in Tambov. In 1941, the military accepted 626 such installations, they were produced in 1942. ZPU were used in the defense of Leningrad and Stalingrad.

But in the middle of the war it became finally clear that the growth of speeds, as well as the growth of security and survivability of aviation did not allow the ZPU, created on the basis of rifle-caliber Maxim machine guns, to effectively deal with enemy combat aircraft.

Actually, the inadequacy of the 7,62 mm caliber for anti-aircraft installations was clear even on the eve of the war, due to the increased survivability of combat aircraft. And since February 1943, Tokarev's 7,62-mm quadruple ZPU designs were withdrawn, as obsolete, from the anti-aircraft regiments of the RGK anti-aircraft divisions.

However, the installations that were in the active army in secondary sectors fought until the very end of the war.

Information