Dying Hope - I-52 minelayer

Today, most of those who are interested in history military equipment, they know that the Kryukov Carriage Works (Ukraine, Poltava region) in Soviet times, in addition to purely peaceful products, also produced military equipment. The company specialized in the development and production of engineering vehicles designed to overcome water obstacles and ensure crossings. The most famous examples: self-propelled tracked ferry GSP, floating conveyor PTS-1 (2), ferry bridge machine PMM-2 "Volna". However, with the collapse of the Soviet Union, the share of military orders declined sharply.

In the spring of 1992, the management of the Kryukov Carriage Works received a letter from the Ministry of Defense of Ukraine. It said that Ukraine had chosen a defensive doctrine for itself and, as a result, an offensive weapon, which also included the landing gear that the plant produced, she does not need.

Thus, the production of military equipment at the plant was suspended, although it did not exclude the possibility of returning to the orders of the Ministry of Defense of the already independent Ukraine.

New task

And such an opportunity presented itself in the same 1992. The plant was tasked with developing a new engineering vehicle - a minelayer. Although this task went beyond the scope of specialization, since the enterprise produced floating equipment, the special department of the chief designer enthusiastically began to develop a new minelayer commissioned by the Ministry of Defense of Ukraine. Viktor Shchepetov, deputy chief designer for serial production, was appointed as the project manager, and Ivan Plyutin was the chief designer of the machine.

The minelayer was designed to remotely deploy anti-personnel and anti-tank minefields, as well as mixed minefields.

The minelayer patent said: “The prototype of the invention is a universal minelayer UMP, developed on the basis of the ZIL-131 vehicle". Here, the negative aspects of this minelayer were also noted: the lack of protection for the crew, vehicle systems, mining systems, and the like.

Therefore, the purpose of developing a new minelayer was: to provide protection against weapons damage to the crew, minelayer systems, mining installations, to ensure overcoming water obstacles, high cross-country ability.

The new vehicle was based on the floating chassis of the Kharkov-made MT-LBu armored personnel carrier. A gas turbine supercharged diesel engine with a capacity of 300 hp was used as a power plant. with. A caterpillar propeller provided a good maneuverability to the car, and the design of the armored personnel carrier itself allowed the car to float.

Machine design

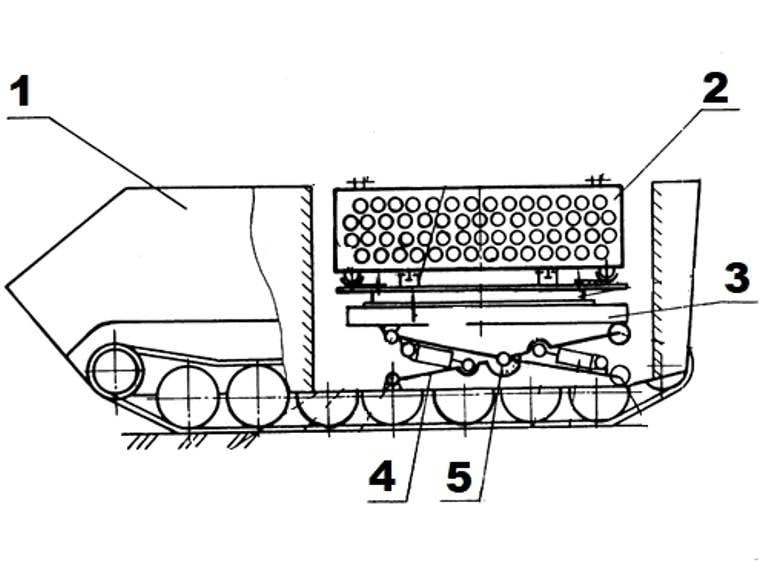

Structurally, the vehicle consists of an armored chassis and a lift with a mining installation.

The machine body is divided into three sections. In front of the vehicle, in the first compartment, there is a cockpit with a mining control panel. The middle compartment is a power compartment with an engine. The third is a mining installation and power mechanisms.

1 - armored vehicle body,

2 - containers for mines,

3 - turntable,

4, 5 - power elements of the lift

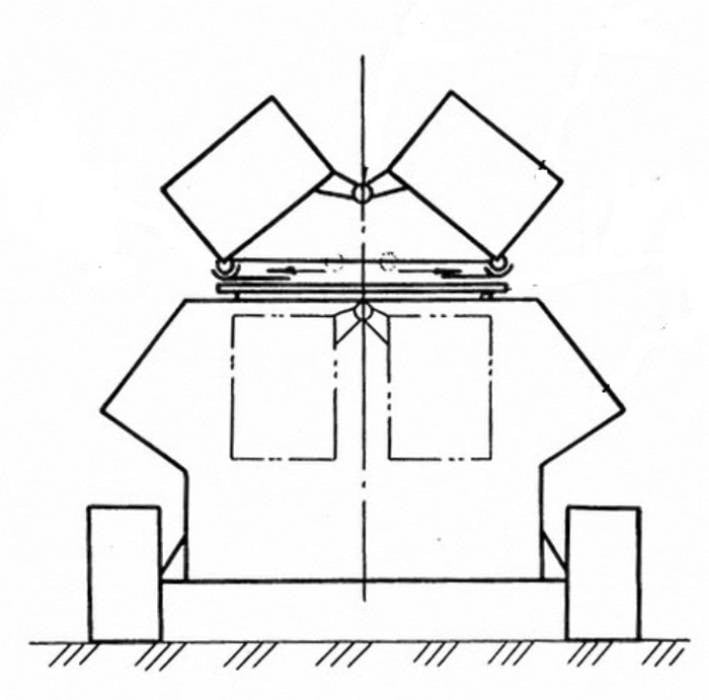

The mining installation is equipped with a turntable with two containers with mine cartridges. Placing the unit on a lift ensures its movement from the working position above the body to the transport one - inside the body, with the lowest position of the center of mass.

Preparation for work includes: lifting the mining installation over the hull, setting the angle of lifting of containers, setting the direction of throwing mines by rotating the platform in a horizontal plane. After that, you can shoot mines, both from the spot and on the move. At the same time, the minelayer can shoot mines, including on terrain with slopes up to 15 degrees (ascents, descents, slopes).

Testing and adoption

In 1994, the minelayer, named "Flint", entered preliminary and factory tests. The first demonstration of the car to the military happened by accident. During the factory tests, as A. Kudiyarova notes in her book "The Birth of Amphibians", the general director V. Prikhodko received a call from the KrAZ plant with a request to help. An inspection arrived at KrAZ with a general, and the factory workers had nothing to show through the Ministry of Defense.

At this time, work was underway on the minelayer to regulate the operability of containers for mines and load ammunition into containers. The containers themselves were half filled with mine cartridges. For the demonstration, they decided not to fill the containers to the end, because they did not plan to shoot. For the military authorities who arrived at the plant, the lifting and lowering of containers, their opening, turning and fixing the installation in various positions were shown. The general who headed the inspection even climbed into the control department, got acquainted with the principle of operation of the equipment issuing the command to shoot mines. In short, the car worked well and everyone liked it.

Then there were tests at the airfield in Kakhovka for shooting mines, determining the shooting range at various angles of lifting containers. The main mine that was used in the tests was the PFM-1 high-explosive anti-personnel mine (PFM-1S).

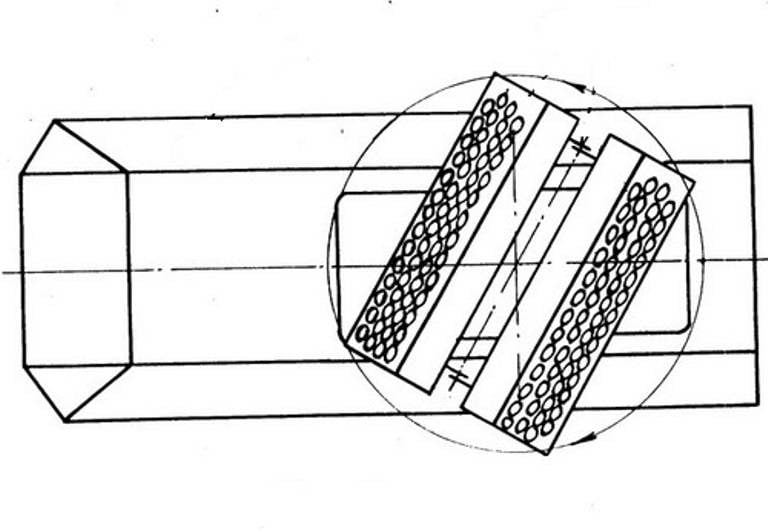

The PFM-1S mine differs from the PFM-1 in the presence of a self-destruction mechanism that detonates the mine after a certain time has elapsed after it has been transferred to a combat position. Each container of the minelayer contains 90 KSF-1S cassettes with 64 PFM-1S mines in each cassette.

As A. Kudiyarova writes in her book, while checking the operability of the smoke grenade system, an unpleasant incident occurred. The smoke screen was blown off by the wind on the Kremenchug-Poltava highway, adjacent to the airfield, stopping traffic for 15 minutes.

In 1995, State tests of two experienced minelayers took place at the Military Engineering Institute in the city of Kamenets-Podolsk. Here, the car was shooting mines, including during overcoming a water barrier, its driving performance was checked at the machine track.

The machine passed the tests, but one significant drawback was highlighted: with the maximum lifting of containers with mines, the height of the machine was almost 3,5 m. This problem had to be solved during mass production.

Another curious incident occurred in Kamyanets-Podolsk.

During the demonstration of the shooting of mines, it was decided to shoot all the ammunition at once. And when, after the completion of the shooting, the testers got out of the car, they were surprised - the tribune, where the members of the state commission were, was completely empty.

And this is what happened.

While driving past the stand, one of the mine containers turned out to be directed towards the stand, and the mines began to fly away towards the observers, which is almost 5 minutes. Although everyone knew that the mines were training mines, they decided: God protects those who are saved! In addition, no one wanted to get a mine, albeit such a small one, "on the hat".

After the completion of state tests, the minelayer under the designation I-52 was put into service. But it was never mass-produced.

In the same 1995, the layout of the minelayer was shown at the international arms exhibition in Abu Dhabi. Everyone liked the car, they were interested in its capabilities and characteristics, but no orders were received for the car.

They again remembered the I-52 in 2003 in the "Program for the Development of Engineering Weapons until 2010", where it is written that by 2005 the first I-52 minelayers should be purchased for the rapid reaction forces.

But the cars were not purchased again.

The reason is trivial: the state did not have the money to buy new equipment.

Baptism of fire, one of the two released I-52 minelayers passed as part of the 12th separate engineering regiment during the hostilities in the East of Ukraine near Mariupol. There are no exact data on the use of the minelayer, so it is too early to talk about the effectiveness of its use.

Today it is known that only one minelayer remained in service, but he no longer takes part in hostilities. There is no information about the fate of the second minelayer.

Thus, in the mid-90s, Ukrainian designers managed to create an original amphibious minelayer, which in terms of its technical and combat characteristics surpassed all existing machines of this class at that time, especially in terms of crew protection and mining equipment.

Unfortunately, today the fate of this project is vague. Most likely, the I-52 minelayer will not find further development, since Ukraine has signed the Convention on the Prohibition of the Use, Production and Storage of Antipersonnel Mines.

Since 2016, the destruction of the PFM-1 PFM-1S mines, the main weapon for the I-52 minelayer, began.

The main weapon of the I-52

The minelayer can use different types of anti-personnel and anti-tank mines, designed specifically for remote mining.

Mines are placed in a drop only on the surface of the ground. The main ones are:

- antipersonnel mines PFM-1 and PFM-1S;

- anti-tank mines PTM-1 and PTM-3.

Mine PFM-1S, in contrast to PFM-1, has a self-liquidator, which works in the interval from 1 to 40 hours (depending on weather conditions). Main characteristics of mines: weight - 80 g, mass of liquid explosive - 40 g, width - 60 mm, length - 119 mm, height - 20 mm, actuation force - from 5 kg.

Mines PTM-1 and PTM-3 are anti-vehicle (anti-tank) mines. Mine PTM-1 is triggered under a wheel or track. The PTM-3 mine is triggered both under the wheel (track) and from the magnetic field of the armored vehicle (that is, it is not necessary to run over it), and strikes the bottom of the armored vehicle with a cumulative jet. The body of both mines has the shape of a parallelepiped. So, the more modern mine PTM-3 has a body 33 cm long, width and height - 8,8 cm, weight - 4,9 kg, mass of explosives of the TGA type, TNT - 1,8 kg, the time of transfer to a combat state - 60– 100 s, self-liquidation time - from 8 to 24 hours.

Mines are fired from a minelayer in special cassettes. There are several types of them, and the design of the cassette practically does not differ from one another.

For mines of the PFM-1 (1C) family, KSF-1 cassettes have been developed. Each cassette carries up to 72 PFM-1 anti-personnel mines or 64 PFM-1S mines. The release of mines is provided at a distance of up to 30–35 m from the minelayer in any direction.

For mines PTM-1 (3) are KPTM cassettes. The KPTM-1 cassette is for PTM-1 mines and carries three mines, and the KPTM-3 cassette contains one PTM-3 mine. The maximum mining range using such cassettes is from 30 to 100 m.

The ammunition load of the minelayer, depending on the selected type of mines, can be (options):

- 180 anti-tank mines PTM-3;

- 540 anti-tank mines PTM-1;

- 12960-11520 antipersonnel mines of the PFM-1 type (depending on the type of mine).

At the same time, mixed charging of launching devices is also allowed to create combined explosive barriers.

So, one minelayer in one pass (15-30 minutes) can expose from the PFM-1 mines a single-lane antipersonnel minefield 20-30 meters wide and 3-5 km long. The consumption of mines in this case will be from 2 to 304 units per running kilometer. The probability of hitting the target will be 3 (that is, out of 840 attacking enemy soldiers, three will be blown up, which will disrupt the attack).

Specifications I-52

Base chassis: MT-LBu

Weight with a full set of cargo, kg: 16 000

Overall dimensions in transport position, mm:

length - 7 210

width - 2 850

height - 2 200

Overall dimensions in working position, mm:

length - 7 210

width - 3 450

height - 3 300

Crew, person: 2

Maximum transport speed

with a full set of cargo, km / h: 61,5

Cruising in store for fuel, km: 500

Type of minefields to be set:

anti-personnel

anti-tank

mixed

The number of strips (rows) of the minefield,

installed in one pass pcs: 1–2

Travel speed during mining, km / h: from 10 to 40

Types of mines installed: PFM-1, PMF-1S, PTM-1, PTM-3

Method of setting mines: ejection, by shooting from cassettes

Number of containers for mines, pcs .: 2

Number of cassettes in one container, pcs: 90

Rotation angle of containers

in the horizontal plane, city .: 360

Container installation angle

in the vertical plane (elevation angle), city .: up to 50

Information