Henri Pieper's pistols

Bernard Clare's pistol "Bayard" М1908, caliber 7,65 mm. Right view. (Photo courtesy of Alain Daubresse / littlegun.be)

Acts of the Apostles 19: 24

History firearms weapons. Last time we told you about the Bergman-Bayard pistol. But Bayard is a trademark of Henri Piper's firm. And what kind of pistols did he make and did he make at all? Or was he just fulfilling orders for the production of someone else's weapons? It turns out that he did a lot of things. And today we will continue our story about his pistols.

This was Henri Pieper. And for sure, like Hercule Poirot, he not only wore a well-made mustache, but also loved to eat deliciously!

To begin with, Henri Pieper (1841-1898) was a Belgian of German descent. He was born in the small town of Zöst in Westphalia, and immediately after leaving school he went to work. Right at work, and he worked at a metallurgical plant, he studied metallurgical production, the basics of designing steam engines, technological equipment and tools. And already at the age of 19, he left for neighboring Belgium on business and ... stayed here forever.

In Belgium, Pieper entered the engineering factory of K. Martin, and immediately as a senior foreman. In 1866 he moved to Liege and there he founded his own arms production. Like this: I did not graduate from universities, I did not have an engineering degree, but I wanted to start production - I just started it! For 15 years, his factory produced bolt boxes for Snyder, Mauser, and Albini rifles. Rifle barrels were also made at his enterprise - a job that required high skill. Moreover, they were sent for export to dozens of countries around the world.

On October 22, 1877, Henri Pieper carried out a unique test of smooth rifle barrels made from various grades of Damascus steel, as well as from iron and cast (crucible) steel. The advantage of cast steel over other materials was found. In fact, the foremost gunsmiths of that time knew this before. But only Pieper was the first to put the production of steel barrels on stream.

Compared to the best grades of Damascus of that time, Piper's steel had a higher strength, ductility, and, most importantly, had a homogeneous structure, which other industrialists could not boast of. Then he managed to improve the technology for producing steel, its quality improved even more, and the cost price decreased. Piper steel was marketed under the name Acier Bayard.

Why did Henri Piepert take the image of a rider galloping on a horse and with the inscription BAYARD as the trademark of his enterprise? The symbol is successful, which once again suggests that there are no trifles in business, and a well-chosen symbol immediately attracted attention to its products. And the appearance of this emblem is connected with the novel that appeared in Paris in 1872 about the adventures of the brave French knight Bayard. The novel was a huge success and was read throughout Europe. Moreover, Pierre du Terail Bayard was not an invention. He was born near Grenoble in 1476 and entered the service as a page for the king of France Charles VIII. At his court, he became famous for his indomitable courage and skill as a warrior.

In 1503 (already under King Louis XII), Bayard became famous for the fact that, defending the bridge, he fought alone against 200 Spanish horsemen. Twelve years later, he made a daring crossing of the Alps of the army of Francis I and fought with such courage that Francis wished to be knighted by Bayard. "A knight without fear and reproach" - so his contemporaries called him. And then the Bayard steel appeared, and they immediately began to say the same thing about it!

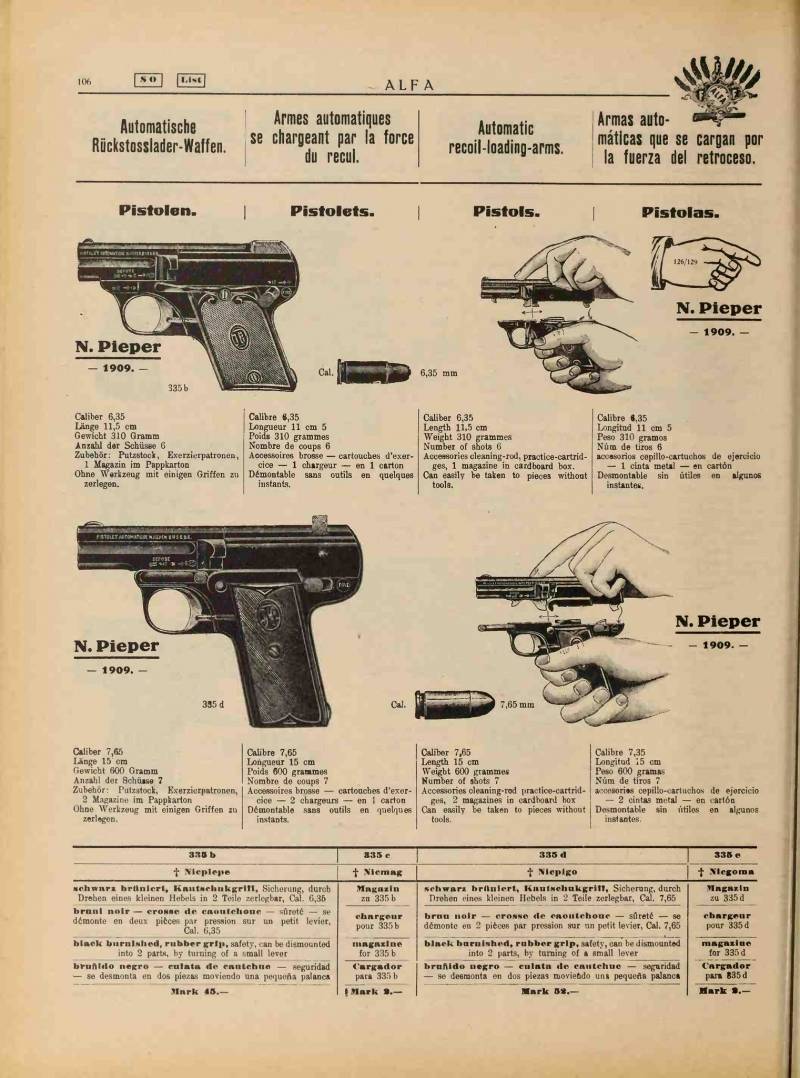

After the death of Henri Pieper, the company passed to his son Nicolas and became known as "Nicolas Pieper", but in August 1905 it received the status of a joint stock company and, accordingly, a new name: Anciens Etablissements Pieper Liege ("Old Pieper's establishments in Liege"). Well, the inscription now accompanied the image of a knight riding a horse.

The company began to specialize in the production of excellent hunting rifles "Diana" and "Bayard", as well as simple and cheap double-barreled shotguns with the inscription: "Nicole Pieper". The main production was in Liege. However, not only military and hunting weapons were made here, but also cars and even bicycles were assembled, and rifle barrels were made at a subsidiary in the town of Nesonvo. The main plant of the company in Liege had 500 machines, many of which were bought in the USA, that is, the production was carried out on a grand scale and using the most advanced technologies. At the same time, a number of operations were performed manually. And such a reasonable combination of manual labor with machine labor gave an excellent result. Hardening, polishing, bluing, engraving and other "delicate" operations were carried out exclusively by hand, and in the workshops of handicraftsmen-homeworkers, and not in the factory itself, where production was almost entirely by machine.

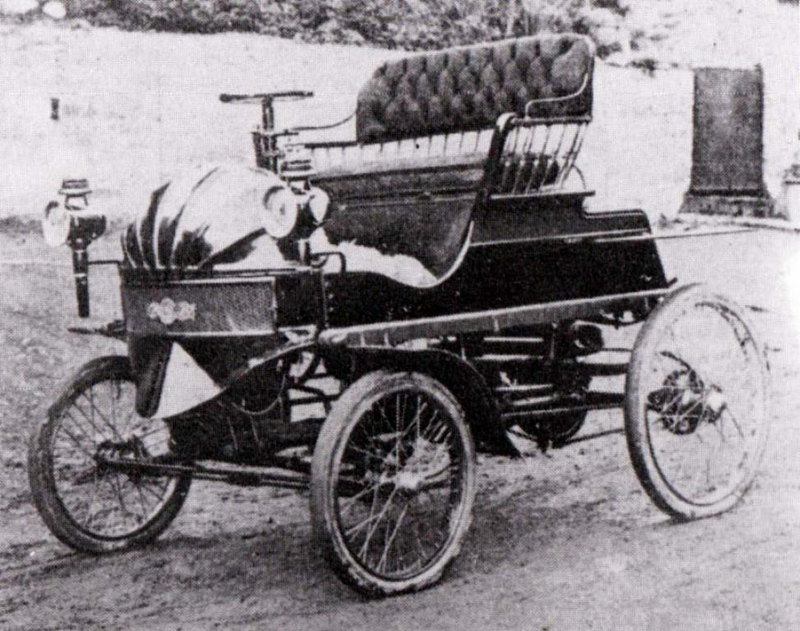

AER car with a petrol-electric (!) Drive, 1900!

At that time, almost 700 people worked at the Piper enterprise. Well, the scale of production can be judged at least by this figure: only in Tsarist Russia, his enterprise supplied 500 rifle barrels. In 000, the construction of the third factory was completed, already in Herstal. The company has once again completely renewed its machine park and put into production several new hunting rifles.

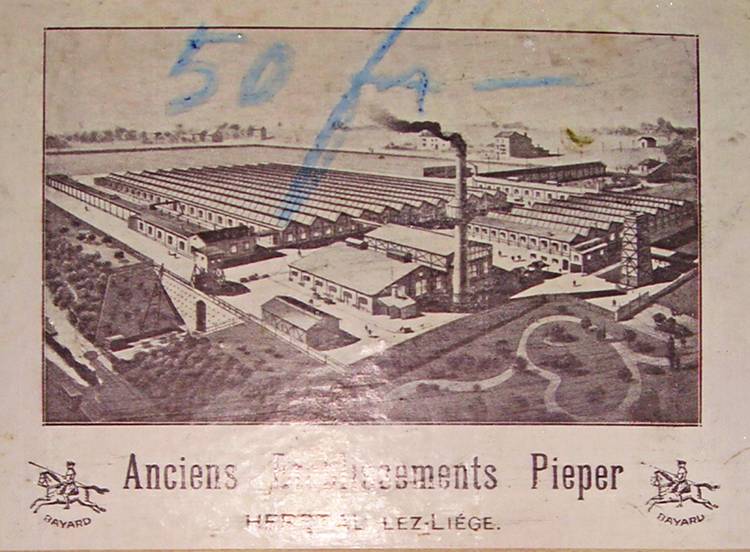

Plants AEP - Anciens Etablissements Рieperа Liege ("Old Pieper's establishments in Liege") in 1909-1912.

To connect the barrels in the breech, a method invented by Henri Pieper was used, and had no analogues. The ends of the barrels were pressed in a heated state into a unitary sleeve, which was milled together with the locking hooks and the continuation of the aiming bar from a single piece of steel. Then the barrels along their entire length were soldered to this strip with tin. This method guaranteed perfect straightness of paired barrels, which was not always found in other manufacturers.

Advertising of Piper hunting rifles

At the new factory in Herstal, the first model of a hammerless shotgun was also released with a simple but effective barrel locking system: a lightly tapering bar, which was a continuation of the aiming bar, was fixed in the breech with a transverse pin. This shutter by Nicolas Pieper was very successful.

Such guns cost about 70 rubles in Russia and were considered the best of foreign machine-made guns.

Advertising of the Bayard pistol, manufactured in 1911

As a result, the Piper-Bayard company survived two world wars and ceased to exist only at the end of the 70s of the twentieth century. And during all this time, she produced pistols, revolvers, sporting rifles and hunting rifles.

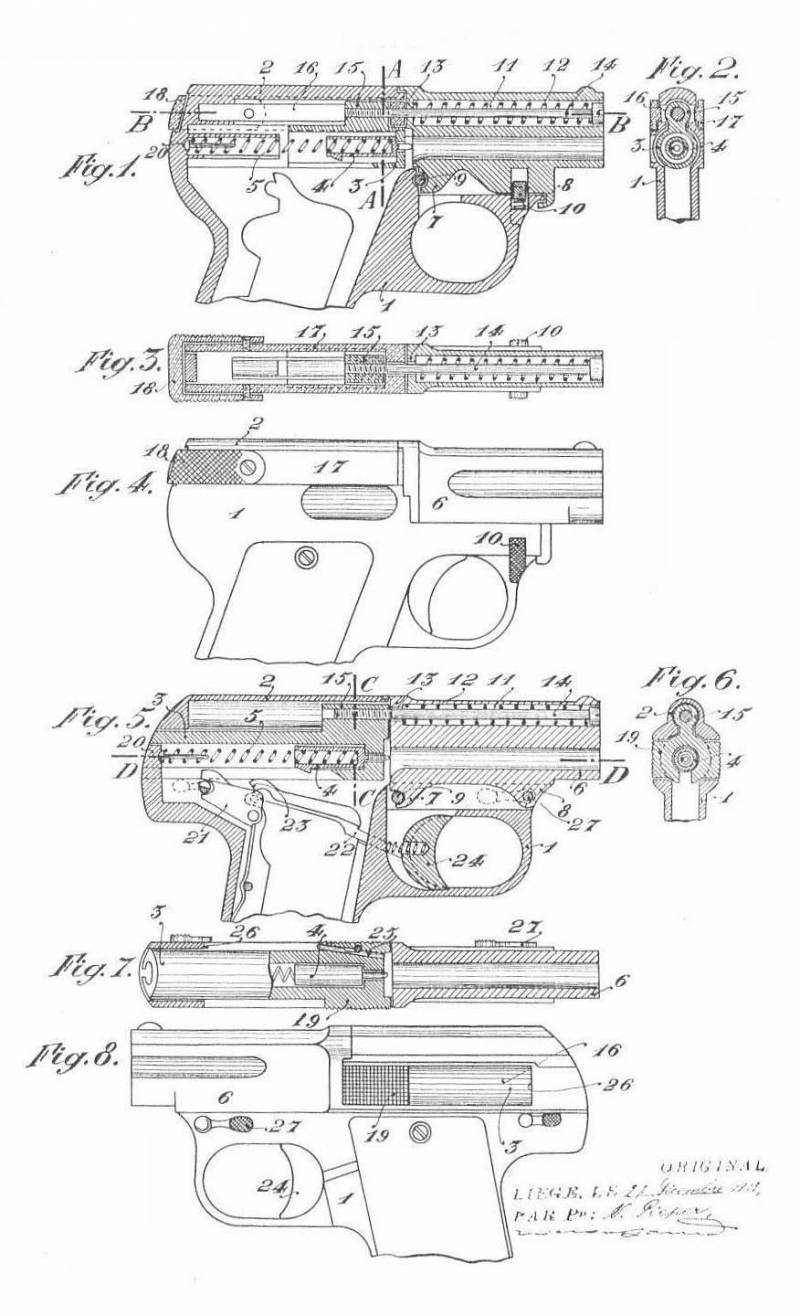

As it was already written about this in the last material, in 1908 the company entered into an agreement with the Bergman firm for the supply of automatic pistols to the Spanish and then the Danish government. The production of pistols turned out to be profitable, and soon she began production of her own pocket pistols under the Bayard brand, patented by the new director of the enterprise, Bernard Claru. In addition, the company also opened a factory for the production of cartridges for its pistol, guaranteeing the traditionally high quality of Pieper's products.

Bernard Clare's pistol "Bayard" М1908. Left view. (Photo courtesy of Alain Daubresse / littlegun.be)

In August 1914, the firm was forced to work for the German invaders, for whom Bayard pistols, Mauser bayonets and spare parts for Parabellum P08 pistols were produced.

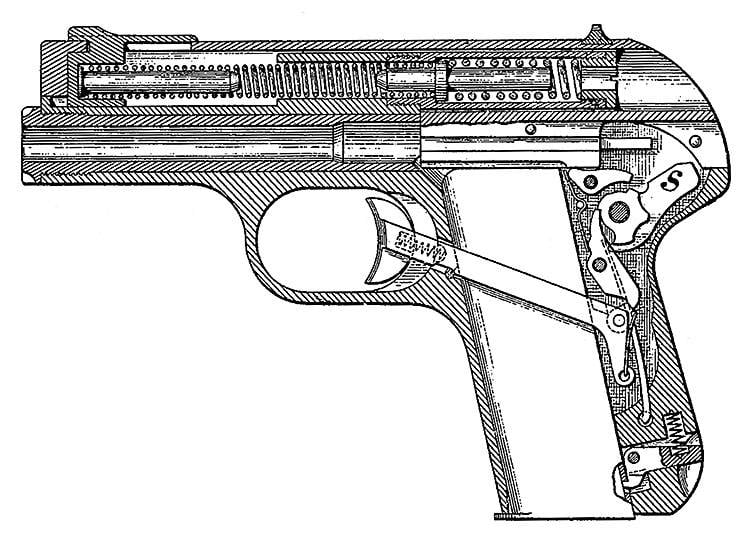

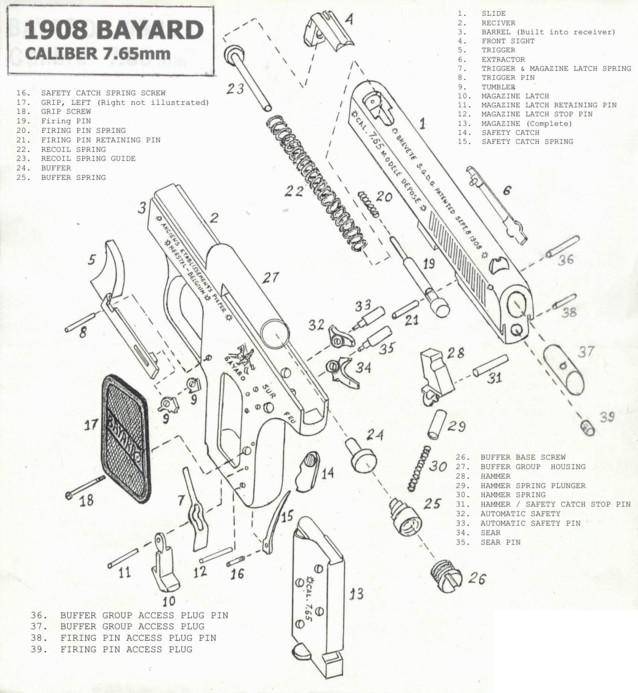

Diagram of the device of the pistol "Bayard" in 1908. Note that the barrel of this pistol is at the bottom and the bolt spring is at the top, which mirrors the mechanism of the 1900 Browning pistol.

At the end of the war, despite the crisis of overproduction of weapons, it was at the AEP firm that several new types of small arms were developed at once. Moreover, when in 1934 the Belgian army adopted an improved version of the Schmeisser-Bergman submachine gun, it was AEP who received an order for its production under the designation Mitraillette 34, as well as an order to convert the old M1889 Mauser into the M89 model. / 36. In 1940, the plant was again requisitioned by German troops, and ... the new German leadership organized the production of heavy machine guns for the Luftwaffe.

Diagram of disassembly of the Bayard pistol in 1908. Note that it was very, very difficult to disassemble this pistol for a person unfamiliar with its design. To do this, it was necessary to move back the bar with the front sight. Only after that it was removed and the pistol was disassembled!

Only in September 1944, after the liberation of the country, AEP with great difficulty was able to continue the production of hunting rifles and air rifles, and also put on the stream a new automatic pistol "Browning" 6,35-mm, and established the production of submachine guns "Sten" for British army. However, after the war, most Europeans were not up to the hunt, and the company declared itself bankrupt in 1953. Most of the buildings she owned were sold in 1956 and destroyed in 1957.

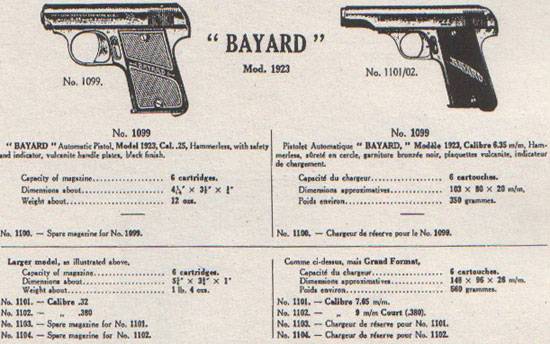

Advertising of Bayard pistols, model 1923

Pistol "Bayard" М1923. Right view

Pistol "Bayard" М1923. Left view. "Bayard" 1908 was sold on the civilian market under Browning cartridges of 6,35, 7,65 and 9-mm calibers. The manufacturer's emblem was a jumping knight above the word "BAYARD", and was carried out on the frame, above the left cheek of the handle

Over the long years of its history, the Piper company produced bicycle dog revolvers and hunting shotguns; pistols "Bergmann-Bayard" 1908, 1910/21; Bayard pocket pistols of 1908, 1911 and 1912 (patents of Bernard Clareu); Berthier submachine gun; 22 caliber semi-automatic rifles and pistol (1912 models) (patents Varnan and A. Pieper); bolt-action rifles of the 1921 and 1927 models; automatic magazine carabiner No. 7 (patents Joseph Declay); revolver "Bayard" model 1926 No. 10, 11 and 12; Belgian submachine gun M34; Mauser rifle model 89/36; air rifles "Bayard"; 6,35mm Browning pistol; Sten submachine guns.

Note that Bayard pistols were very popular and were produced in large quantities. The automatic pistol operated due to the recoil force of the free bolt, which was then returned back by a return spring. To minimize the size of the pistol, it was placed above the barrel. The striker with the ejector was located in the middle of the bolt casing. The trigger and other details of the firing mechanism were attached to the frame. The base of the front sight was long and wide, and its front end rested against the recoil spring guide rod. Therefore, the front sight moved back and it could be removed from the shutter-casing together with the return spring and the guide rod, after which the shutter-casing was removed from the frame by moving back and up. The trigger mechanism was of the trigger type and single action, with a hidden trigger. The cartridges were fed from a single-row six magazine. According to the tradition of those years, the store latch was located in the lower part of the handle. The flag-type fuse was located on the frame on the left. The handle covers are made of ebonite. Interestingly, the 6,35-mm Bayard pistol was featured in the Weiner brothers' novel Era of Mercy, and also in the film The Meeting Place Cannot Be Changed. However, the Walther Model 1908 pistol was used there instead of the Bayard M7.

Pieper-Steyr model C. Another pistol with a folding barrel. (Photo courtesy of Alain Daubresse / littlegun.be)

In 1909, the Steyr company wished to purchase a 7,65 mm Browning pistol and a small 6,35 mm Browning pistol with the same barrel locking system. Nicholas Pieper proposed his own design, and the result was the Steyr-Pieper pistol. The production of the 7,65 mm model (about 60 units) and the 000 mm caliber model continued until 6,35 and until 1928, respectively, and a total of about 1931 units were produced. The pistols had a drummer, a magazine for six rounds, and a weight of 130 g without ammunition.

To flip the barrel forward, it was necessary to squeeze the flag lever down on the left. The shutter consisted of two parts: the lower one was fixed, and the upper one was movable. (Photo courtesy of Alain Daubresse / littlegun.be)

Information