United Shipbuilding Corporation: the history of creation and development prospects

Five years is a sufficient period for summing up the interim results of the corporation’s activities, the main vocation of which was the revival of domestic shipbuilding.

BACKGROUND OF USC CREATION

The establishment of a single state corporation in the field of shipbuilding was provided for by the “Strategy for the development of the shipbuilding industry for the period up to 2020 of the year and for the future”, which was approved by an order of the Ministry of Industry in September 2007. In this document, the key problems of domestic shipbuilding were formulated. as well as the goals and objectives of the state and industry.

By the end of the “zero” years, due to a number of objective factors of external and internal nature, a paradoxical situation developed in the shipbuilding industry of Russia. On the one hand, Russian shipbuilding has a significant potential. Russia remained among the few states capable of building ships of almost all classes and types, including nuclear submarines (nuclear submarines) and icebreakers. At that time, the Russian Federation held a significant share of the world market for naval equipment (TDC). In 2007, it was estimated at 20% (more than $ 1 billion per year) with the prospect of growth of one and a half to two times. Russia has become the largest supplier of military equipment for the rapidly developing its naval forces of India and China. According to Mikhail Barabanov, Russia has become the largest (in terms of the number of units sold) exporter of non-nuclear submarines (NNSL) in the world: 1986 31 was sold to 877 in the world. Russia was one of the few countries exporting large surface warships. For example, in 1998-2006. a contract was concluded with China for the supply of four destroyers of the project 956E and 956EM for the sum of about $ 2,3 billion.

On the other hand, the Russian shipbuilding industry was in a state of deep crisis, which particularly clearly revealed the emerging trend of increasing domestic demand for the construction of modern ships, ships and marine equipment.

The Russian Navy, which received practically no new ships after the collapse of the Soviet Union, was in dire need of new warships and auxiliary ships of all classes to restore an adequate number of naval personnel. In addition, in 1980-2000. appearance fleet has undergone radical changes. The revolution in military affairs led to the transition to new technologies in shipbuilding: high-precision arms, low visibility ("stealth"), new communication systems, management, collection and processing of information. Under these conditions, the Russian Navy required not just the construction of new combat units, but the earliest creation of modern multifunctional ships in limited resource conditions capable of performing the whole range of tasks to ensure national security in peacetime and wartime.

Domestic shipowners, first of all - oil and gas producing and transport companies, sea and river shipping companies, needed the construction of a significant number of transport vessels and marine equipment for the development of the shelf. It was assumed that by 2015 the turnover of Russian ports would increase one and a half times (to the level of 2005) to 650 mln. Tons, which would require the construction of more 100 vessels with a total deadweight of about 3,8 mln. Tons. Hydrocarbon production on the shelf by 2030 will reach 110 million tons of oil and up to 160 billion cubic meters. meters of gas per year, which requires the construction of 2030 at least 90 specialized ice-class transport vessels, 140 auxiliary vessels and 10-12 icebreakers.

The river, fishing and research fleets were in a deplorable state. The average age of the river fleet vessels reached 25 years with a competitive age in 12-15 years, more than half of the fishing fleet also operated more than the standard service life, and the wear and tear of research ships reached 75%. The need for building new vessels was estimated at 100 units for the river fleet with a total capacity of about 400 thousand tons, 60 large and 280 small fishing vessels, several dozen research vessels.

Russia remained the absolute leader in the area of the icebreaking fleet, including the nuclear one, but even here the need for renewal of the ship crews has ripened. From the moment of the collapse of the USSR until 2008, not a single new icebreaker was built. The shipbuilding strategy has estimated the total demand for icebreakers in more than 40 units.

The shipbuilding industry in its state at that time was unable to meet the current and even more promising needs of the military, commercial, commercial, river, research and icebreaking fleets. Russia was uncompetitive in the global civilian shipbuilding market. Moreover, signs of declining competitiveness, attractiveness, and demand for domestic TDC on the world market have multiplied.

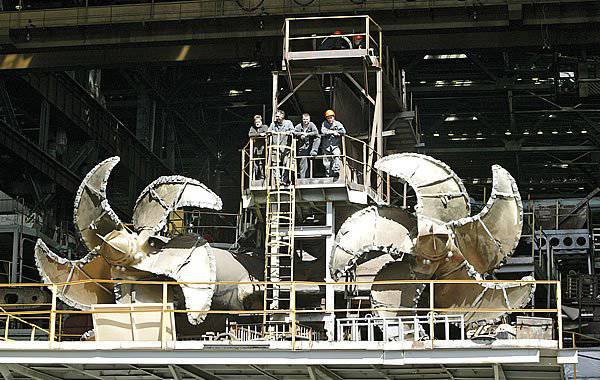

After the collapse of the Soviet Union, the domestic industry lost a number of important enterprises of the former branch system, many of which were focused on civil shipbuilding. One of the key problems of the Russian shipbuilding industry was the absence of large-capacity shipyards capable of building ships with a displacement of more than 100 thousand tons, and heavy-duty cranes (more than 600 tons).

Depreciation of fixed assets by 2007 has reached 70%, and the age of 65% of industrial equipment in the industry has exceeded 20 years. The complexity of production in the Russian shipbuilding industry was 3-5 times higher than the world average, and the duration of the construction of ships - 2-2,5 times higher than abroad. Labor productivity in domestic shipbuilding is about 3-4 times lower than the leading European ones, and 7 times lower than the best Korean manufacturers. According to the vice-president of USC, Dmitry Mironenkov, from the 1970-s. Russia missed three technological revolutions in shipbuilding: the transition to large-block shipbuilding with blocks weighing 500-800 tons, the transition to 3D modeling, and the start of building ships with "superblocks" weighing up to 3000 tons.

Shipbuilding is one of the most labor-intensive, low-profitable and technologically complex engineering sectors. The real development of the shipbuilding industry without the active participation of the state is not possible. One of the most important conditions for the successful development and competitiveness of the shipbuilding industry is the creation of favorable financial and economic conditions. Due to their high capital intensity and long production cycles, shipbuilders need long-term, cheap money.

Overseas construction of civil courts on 80% is carried out on credit. For the development of shipbuilding, it is necessary to create conditions for shipyards to receive large long-term (10-15 years) loans at low interest rates (around 3-6%). In Russia, shipbuilders at that time could receive a loan of up to 60% of the value of the vessel for 5 years under 12-14%. Moreover, shipbuilders were forced to seek funds to secure the loan, and the import of components and equipment was subject to significant taxes and duties. All this made civilian products of Russian shipbuilding even less competitive. The construction of military courts also required the formation of favorable credit conditions, the provision of state guarantees and timely and full funding from the state customer.

By the middle of the 2000-s, the share of Russia in the world civil shipbuilding industry was about 0,4-0,5%, and in the domestic market - 4%. Paradoxically, but from 2003 to 2005. The shipbuilding volume in Russia, according to the European Association of Shipbuilding Associations, increased 2,4 times and amounted to 106 vessels with a total tonnage of 910 thousand tons, which put Russia in tenth place in the world ranking of shipbuilders. At the same time, the volume of military production in the period mentioned was significantly reduced.

It is worth noting that many of the problems faced by domestic shipbuilding were explained not only by the internal crisis, but also by objective disproportions and negative trends in global shipbuilding.

Global shipbuilding in the mid 2000's experienced a period of rapid growth, which relied on the rush demand for ships of the transport fleet. The international economic crisis has clearly demonstrated the problem of overproduction in world shipbuilding. According to the Association of Shipbuilding Companies of Japan, about 2005 ships with a total tonnage of 2700 million tons were ordered in 60. This indicator increased to 2007 vessels by 5400 (total tonnage - 170 mln. Tons), and by 2009, it fell to 1400 vessels (about 34 mln. Tons).

The economic crisis had a negative impact on all participants in the shipbuilding market, but large Asian companies were able to partially offset the negative consequences due to the presence of a sufficient package of orders, diversification of production and active government support. Small and medium shipbuilding enterprises, concentrated mainly in Europe, did not have comparable resources and capabilities. New orders of European companies in 2009 amounted to only 9% of the level of 2005. In particular, in Germany, the turnover of shipyards decreased by 10 times, in one and a half year six German shipyards declared bankruptcy.

In military shipbuilding, the situation was somewhat different. The leaders of civil shipbuilding, which together accounted for 90% of the world market - Korea, Japan and China - have demonstrated their ability to successfully build warships of almost all major classes. At the same time, the leading positions in the construction of warships, as well as on the world market for BMT, remained with the states that occupy minor shares in the market of civil shipbuilding - the United States, Russia, France, Spain, and Germany.

In the second half of the 2000's. some negative trends that hinder the development of export-oriented military shipbuilding were more clearly manifested, while most of them represented a particular threat to Russian industry.

First of all, the largest importing countries began to decline their interest in high-tech foreign-made naval structures in favor of developing national shipbuilding. China by the end of 2000's. almost completely refused to purchase warships on the foreign market. Moreover, prerequisites have emerged for turning China into an BMT exporter, offering low-cost and relatively high-quality products that can compete with products of Russian shipyards.

Secondly, the reduction of military spending by many Western states and the processes of updating the fleet composition of their fleets created a large market of used combat ships, on which Russia's share was insignificant. The development of the market for used warships limited the growth opportunities for the new-built ships market.

The totality of the above factors showed the need for immediate government intervention in the shipbuilding industry of Russia in order to overcome the current crisis situation.

The main target indicator of the implementation of the shipbuilding strategy was the growth in the volume of production of domestic shipbuilding in comparison with the level of 2007. By 2010, the growth of the volume of shipbuilding in 50% was planned, by 2015 - 120%, and by 2020 - 210% and to 2030 g. - 330%. It was assumed that by 2015 Russia would occupy about 1% of the global volume of civil shipbuilding, and after 2020 g. - 2%. By 2020, it was planned to increase the export of high-tension vehicles to $ 3-4 billion, and also to fully satisfy the demand for new ships and vessels of the Russian military, sea, transport, river and fishing fleets.

In order to implement the shipbuilding strategy in the field of civil shipbuilding 21 in February 2008, the Government of the Russian Federation Decree No. 103 approved the Federal Target Program “Development of Civilian Marine Equipment” for 2009-2016, which meant the allocation of the federal budget 136 billion (66% ) and extrabudgetary (33%) funds. In total, according to the Federal Treasury, 2009-2011 was allocated 20,8 billion rubles of federal budget funds, which amounted to 91% of the federal budget program funding planned for this period.

FORMING USC

The primary task of XCUM’s% federal USC property was the consolidation of core assets with state participation. The shipbuilding industry in Russia was represented by a significant number of small and medium-sized enterprises, mainly focused on the construction of military products. The number of large enterprises was small. Also outside the shipyard structure there was a significant number of research and development bureaus (PCBs).

The basis of the consolidation of shipbuilding was laid historical-geographical principle. Within the framework of USC, three subsidiary territorial sub-holdings were created - OJSC Northern Center for Shipbuilding and Ship Repair (SCSN), OJSC Far Eastern Shipbuilding and Ship Repair Center (DCSS) and OJSC Western Ship Repair Center (SCS).

Sevmash and the Zvezdochka Ship Repair Center were the largest assets of the NCS, the Far East Center Zvezda and the Amur Shipbuilding Plant, the ZTSS the Baltic Shipyard Yantar and the Admiralty Shipyards. PKB were not included in the territorial subholdings and transferred to the direct possession of USC. The key design institutions in the USC were the designers of submarines - TsBB MT "Rubin" and SPMBM "Malachite"; surface ships - Zelenodolsk PKB, Northern PKB, Nevskoe PKB, Almaz Central Securities and Design Bureau; icebreakers - Iceberg Central Design Bureau, which at that time was part of a private United Industrial Corporation.

It is worth noting that the consolidation of shipbuilding assets coincided in time with similar processes in other areas of the military-industrial complex, including helicopter engineering and aircraft manufacturing. Often the policy of consolidation with state participation 2000-ies. It is seriously criticized, but it should be noted that, at least with respect to shipbuilding, this was the only correct decision in the current situation. As already mentioned in the case of European companies, specialized small and medium-sized shipbuilding enterprises, even being competitive in the civilian market, are threatened with closure during the economic crisis. The same is true for enterprises operating in the military sector.

It should be noted that USC consolidated only about 60% of shipbuilding and 70% of design enterprises in Russia. Private owners controlled such large enterprises as the Krasnoye Sormovo plant, the Vyborg Shipbuilding Plant, the Zelenodolsk Plant named after A.M. Gorky, as well as the "Northern Shipyard" and "Baltiysky Zavod", which were part of Sergei Pugachev's notorious United Industrial Corporation (DIC).

To revive the shipbuilding industry, consisting of disparate enterprises, it was possible only by methods of centralized management. In fact, Sevmash remained the only state-owned enterprise with sufficient weight for independent activities, but due to the collapse of the state defense order (GOZ), it also faced enormous difficulties and was literally saved by an order for repair and deep modernization for the Indian Navy of a heavy aircraft carrier cruiser. "Admiral Gorshkov".

One of the most important positive results of creating the USC was the emergence of a single center capable of lobbying the interests of shipbuilders in their dialogue with government agencies and foreign partners, and pursuing a centralized marketing and investment policy. There was an opportunity to formulate a common ideology and economic strategy of domestic shipbuilding, move to generally accepted business standards on the world market. So, in particular, in 2012, the transition of all enterprises that are part of USC to international financial reporting standards began.

Officially, the USC legalization process was completed approximately two years after the establishment of the corporation - 1 on April 2009. However, not all state-owned shipbuilding assets were transferred to the USC by that date. Thus, the federal state unitary enterprises subordinate to the Ministry of Defense: 10, 30 and 83 shipyards, as well as the Kronstadt Marine Plant (KMZ) were not incorporated into corporations and were transferred in time due to the need for preliminary financial rehabilitation of the enterprises. Three "license plates" shipyards were transferred to USC in 2010-2011. A particularly difficult situation has developed around the actually ravaged KMZ, the revival of which as an independent shipbuilding enterprise was not possible.

The critical situation that has developed around a number of shipbuilding assets dictated the need for the corporation to make difficult but necessary decisions. Enterprises whose survival in market conditions is impossible or unreasonable were suggested to be closed or merged with viable plants. The main condition was the preservation of promising competencies and human resources of the liquidated enterprises.

It is the lack of qualified personnel that has become one of the most pressing problems of USC. On the one hand, this leads to the fact that the salary of, for example, a welder of the 6 class with the necessary licenses can reach 200-250 thousand rubles. On the other hand, the financial capabilities of enterprises often do not allow for the provision of adequate interest among experienced workers.

The demand of USC enterprises for qualified personnel for 2020 is estimated at approximately 17 thousand people. It should be noted that the problem of staffing, like many others, is peculiar not only to domestic shipbuilding: shipyards in Europe and the USA directly face it, where shipbuilding is also in a tough competition for specialists with other industries.

New stage in stories USC began with the arrival of Roman Trotsenko in October of 2009 in the position of president of the corporation. At that time, the choice of a young entrepreneur (Trotsenko headed the USC at the age of 39 years) as president of the state corporation surprised many. Time has shown that this choice was a success. The new head of the industry was familiar with shipbuilding and shipping, managed a number of shipping companies, worked as assistant minister of transport, successfully implemented a number of large industrial and infrastructure anti-crisis projects and, not least, in his own words, “loved the sea business”. After becoming president of USC, Roman Trotsenko withdrew from direct management of his own business (in 2012, Forbes estimated his fortune at $ 950 million) and focused on the development of the corporation.

In 2010, it was decided to additionally transfer to the property of USC the blocks of shares of ten shipbuilding and ship repair enterprises owned by the state, including Novorossiysk and Tuapse shipyards. These enterprises are mainly located in the Southern and Volga Federal Districts and specialize in building ships for the river fleet. The state share in most of these companies was less than 30%. In addition, in 2011, USC acquired from private owners a controlling stake in the Caspian Energy group, specializing in the construction of offshore oil and gas facilities, and increased its stake in the Krasnoye Sormovo refinery, which holds leading positions in the domestic market of “river- Sea "and preserving the potential of creating military products.

The corporation’s consolidation of these assets raised the question of creating a fourth territorial subholding, the Southern Shipbuilding and Ship Repair Center (SSSC), which would focus on the production of civilian products for the domestic market. But the creation of the SJSC was postponed for a long time due to the fact that the Astrakhan region, which was to receive 25% of the shares of the new subholding, could not find the means to pay for them. Presumably, the UCSS will be formed by the end of 2012 - the beginning of 2013.

The creation and launch of the SSSC should coincide in time with the stage of fundamental transformations in the structure of the USC. It is assumed that SSRS and ZSS, which almost completely fulfilled their function of consolidation, restructuring and initial rehabilitation of disparate assets in the jurisdictional territory, will be eliminated by approximately 2015. DCCS will exist somewhat longer due to the need to implement projects for the construction of two large shipyards. After the consolidation of assets in the southern direction is over, SJSC will be abolished. Territorial subholdings will be replaced by “shipbuilding zones”.

7 November 2011, after several years of stormy discussions and approvals, was finally signed Federal Law No. 305 “On Amendments to Certain Legislative Acts of the Russian Federation in connection with the implementation of state support measures for shipbuilding and shipping”. This law, which introduces a number of important changes in the maritime, tax, customs and social legislation, was developed with the active participation of the USC. It aims to achieve a synergistic effect from the coordinated development of the domestic shipbuilding industry and shipping.

One of the key innovations of the law was to provide shipbuilding companies with the opportunity to become residents of industrial-production special economic zones (SEZs), which are commonly known as shipbuilding zones. Shipbuilding zones are designed to complement the port SEZs (in 2009, the port SEZ "Sovetskaya Gavan" was established in the Khabarovsk Territory, and in 2010 - the Murmansk SEZ in the Murmansk region. Residents of shipbuilding zones will receive a number of long-term tax, customs and other benefits from the state, which will allow, according to Deputy Transport Minister Viktor Olersky, to reduce the payback period of the vessel from 20 to 12 years and compare with the basic factors affecting the cost of production, with most competitors . The implementation of the main provisions of the law on support of shipbuilding and shipping is just beginning; it is planned to form about nine shipbuilding zones in total.

To date, the process of consolidation of shipbuilding is close to its completion. In February, 2012 of USC completed the acquisition of about 60% of Vyborg Shipyard for $ 80 million. The transition ends under the control of the Northern Shipyards and Baltiysky Plant USC. Both of these plants belong to the largest centers of surface shipbuilding and shipbuilding in Russia. Being owned by the MIC, the plants developed extremely unevenly. The former owners consciously made the “Northern Shipyard” loaded with the GOZ, a profit center, and the Baltiysky Zavod the center of losses. In the autumn of 2011, the Baltzavod, which was in deep crisis, was transferred to the USC “crisis management”. In December, 2011, in the conditions of a massive withdrawal of assets by the previous owner and almost $ 500 million of accumulated debts, at a meeting with the participation of Vladimir Putin, it was decided to introduce a bankruptcy procedure at the plant. In May, 2012 was finally controlled by Severnaya Verf.

Initially, the USC leadership ideology implied the formation of a vertically integrated holding. Thus, the previous president of USC, Vladimir Pakhomov, said in an interview with 2009, Mr .. “It is very important that allied and component suppliers be part of the corporation. Then they can be influenced in the construction of ships, both through the state defense order, and for external and internal customers. ”

After the change of management of the corporation and the arrival of Roman Trotsenko in October of 2009 to the presidency of USC, approaches to vertical integration were revised. In the “USC Mission” published later, it was noted that “USC does not seek to include subcontractors in its membership, that is, to try to build a vertically integrated holding. USC is enough to be able to buy a service or part in a competitive market. ”

For a long time, subcontractors to the shipbuilders within the framework of the state defense order were actually imposed by the Ministry of Defense. It was only at the end of 2011 that USC achieved the right to independently choose subcontractors. Recently, at USC, there is a growing need to use a number of key principles for the operation of a vertically integrated holding. This is due to the need for full control of financial flows, pricing processes and logistics, as well as the need to develop a unified corporate culture in the shipbuilding sector.

(End - in the next issue)

Information