Knives: the evolution of steel

The knife is one of the most ancient tools of mankind. If we ignore the Stone and Bronze Ages, then in the simplest case a knife is a sharpened piece of iron (steel) with a handle that is comfortable to hold.

The main part of the knife, which determines its functionality, is a blade with a cutting edge. Its capabilities are largely determined by the structural material - steel and its heat treatment.

Composition and structure

The properties of steel are determined by its composition and structure. The presence of certain impurities (alloying elements) can increase the hardness or corrosion resistance of the blade. The problem often lies in the fact that by increasing the hardness, we can simultaneously increase the brittleness of the steel and reduce its corrosion resistance. On the other hand, by increasing the corrosion resistance, we worsen other parameters.

For example, carbon increases the hardness of steel, but decreases its toughness and ductility. Other alloying elements also add both positive and negative properties to the steel. Chromium increases wear and corrosion resistance, but increases brittleness. Vanadium and molybdenum increase toughness and strength, increase resistance to thermal effects, nickel - increases corrosion resistance, hardness and toughness of steel, vanadium improves strength and wear resistance of steel. Manganese and silicon increase the ductility of the steel. All these elements carry their positive qualities only in strictly defined quantities, as a result of which metallurgists have to be extremely careful and balanced in the selection of the steel composition.

In addition, alloying elements often tend to concentrate at certain points at which a stress source can arise, as a result of which the blade will break at this point under load.

Distribution of carbides in steels

For this reason, in the old days, Damascus and damask steels arose, in which, by multiple superposition of several types of steel and their forging, the most uniform distribution of alloying elements was achieved.

According to the author, in the newest knife stories three periods can be distinguished.

The first period was the use of "rusting" carbon steels and stainless steels with low hardness and edge retention characteristics (first half of the XNUMXth century).

The second period is the emergence of stainless steels with high characteristics of hardness and cutting edge retention (second half of the XNUMXth century).

The third period is the appearance of powder stainless steels (the beginning of the XXI century).

These periods can be considered rather arbitrary, since even now some companies produce knives from carbon steel. Nevertheless, it was at the beginning of the 420th century that the first stainless steels appeared, including the famous 420 steel, from which a huge number of knives are still produced all over the world. For example, if an inexpensive Chinese knife is purchased, costing several hundred rubles, then the blade will most likely contain XNUMX steel.

The appearance in the second half of the 440th century of steel grades 440A, 440B, 65C (close Russian counterparts 13x95, 18x110, 18xXNUMX), characterized by a high carbon content, made it possible to produce conditionally stainless knives with hardness and cutting properties comparable to knives and blades made of carbon steel.

Why "conditionally stainless"?

Because almost any steel can rust, the only question is in the environment and the degree of exposure. For example, most stainless steels corrode well at sea from salt water. By the way, the ancient 420 steel is one of the most stainless steel.

Nevertheless, it is much more convenient to use stainless steel knives in everyday life - during the same period, while the stainless steel is only covered with rust spots, the carbon steel will rust to holes. In addition, carbon steels often produce an unpleasant aftertaste when cut.

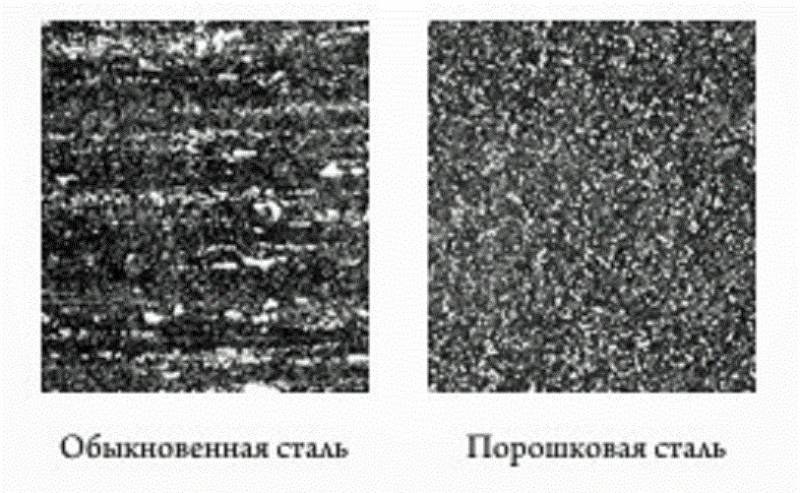

The appearance of powder steels helped to solve the problem of the uniformity of the distribution of alloying elements. One of the ways to obtain powder steel is spraying molten metal in an inert gas medium, after which a fine powder is formed with uniformly distributed alloying elements. After that, the powder is sintered into a monolithic bar by isostatic pressing.

Powder steel

One of the first and most common powder steels used for making knives was CPM S30V, developed in 2001 by Dick Barber, a specialist at the Swedish Crucible Materials Corporation, and Chris Reeve, a renowned knifemaker.

In addition to the usual process of making blades from strips and bars, powder steel allows for very interesting technological solutions.

The American company Kershaw released the Offset 1597 folding knife, with a blade made using MIM (Metal Injection Molding) technology - a technology for casting powder metals and alloys under pressure, also called MITE (Metal Injection Molding with an Edge). The MIM / MITE technology mixes the metal powder with the binder to make the mold size 20% larger than the final blade size. Then, with the help of sintering under pressure, the density of the finished product is increased to 99,7% of the density of the parent metal (the binder burns out during sintering). The result is a product with a complex 3D shape that cannot be obtained in any other way.

The possibility of uniform distribution of alloying elements in powder steels led to an increase in their percentage, which resulted in the emergence of so-called super steels, such as, for example, ZDP 189 or Cowry-X, however, the complexity of their sharpening and high cost limit their distribution.

More balanced steels such as M390 / M398, CPM-20CV, Elmax and others easier to manufacture and maintain - CPM S30V / CPM S35V, CTS-XHP, etc. have become more popular.

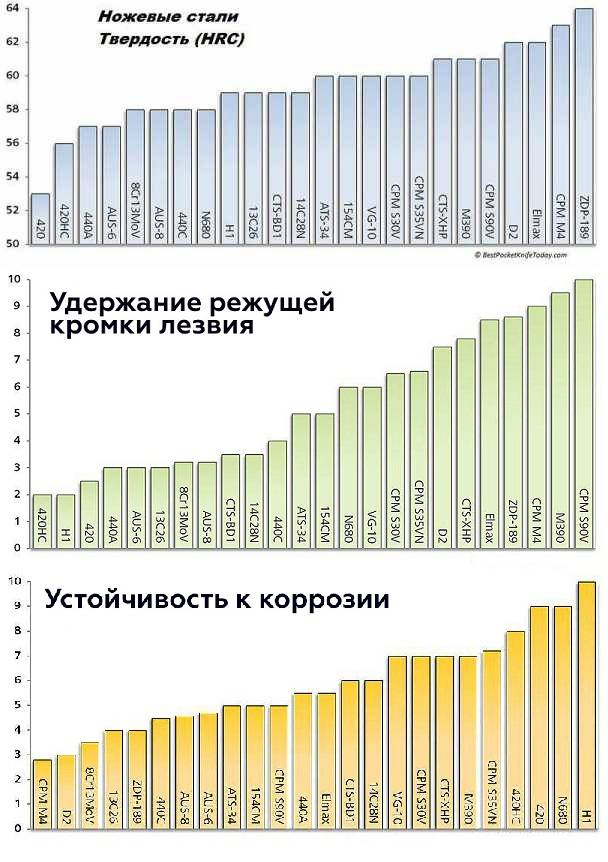

Relative characteristics of various modern knife steels

Ultimately, it all depends on the cost of the blade - neither super steels, nor even just high-quality powder steels have displaced cheaper non-powder steels from the market. The knife steel market can be thought of as a pyramid, with the well-deserved 420 steel at the base and the latest super steels at the top, descending as steels emerge that are even more “super”.

Moreover, the point here is not only in the cost of the starting material - the most important technological process that "reveals" the characteristics of steel is heat treatment. Each steel requires its own heat treatment, and when a new super steel comes along, it takes time for manufacturers to master it.

Термообработка

Heat treatment - hardening, tempering, normalizing, annealing and cryogenic treatment of the metal, allows you to bring the blade to those characteristics that are implied by the grade of the steel used. Correct high-quality heat treatment allows you to "squeeze" the maximum possible out of steel, while the wrong one can completely ruin the final product, no matter what expensive materials are used in it. It is safe to say that it is better to choose a blade made of simpler steel, but with good heat treatment, than a blade made of super steel, made by a specialist who does not know how to heat it.

The classic Buck Folding Hunter folding knife has long been made from "plain" 420HC steel, but the skills of Buck's thermists make it possible to get the most out of it.

A knife company is often renowned for its ability to work with a certain steel, and its products made of more modern steel may have inferior performance due to poor heat treatment processes.

Equipment for heat treatment plays an important role. Modern quenching furnaces allow for heat treatment in vacuum and in various media - argon, nitrogen, helium, hydrogen. Equipment for cryoprocessing at a temperature of -196 degrees provides an increase in wear resistance, cyclic strength, corrosion and erosion resistance. For example, the resource of products by cryoprocessing can be increased by 300%.

The need to use complex and expensive equipment does not allow artisanal workshops to perform all the necessary technological operations, therefore, the assertion that “our uncle Kolya makes the best knives in the world in the garage” are hardly justified.

Composite blades

Another way to make knife blades is to create composite blades.

In principle, the aforementioned blades made of Damascus and damask steels are also composite - in them materials with a lower carbon content are combined with materials with a higher carbon content. However, in modern composite blades, the process is implemented in a slightly different way.

Usually, the predominant part of the blade is made of a material that has more elasticity, but less hardness and brittleness, while the cutting edge is made of a harder material. Such a blade combines good mechanical properties and a high-quality cutting edge. However, on expensive models of knives, they still prefer to use super steels.

Another option is to use less expensive steel as a base, and more expensive but high quality steel on the cutting edge. For example, on the Kershaw JYD II knife, the base of the cutting edge is made of inexpensive Chinese 14C28N steel, and the cutting edge is made of the more durable American D2.

Kershaw JYD II knife

However, as in the case of more expensive knives, the reduction in the cost of the starting material is compensated by the complexity of manufacturing a composite blade, and therefore such models are the exception rather than the rule.

The most popular direction in which composite blades are used is designer knives produced in limited quantities. They combine materials to create a spectacular blade appearance.

Zero Tolerance 0777 knife with a composite blade including Vanax 35 steel on the cutting edge and Damascus steel butt

Past versus future

On the Internet, you can often see articles that say that the secret of real damask and damascus has long been lost, and now its pitiful counterparts are being released. Say, if that secret is revealed, then blades made of "real" damask or damascus will give a head start of 100 points ahead of modern steels.

In fact, this is highly unlikely. Technological progress, equipment and materials science are now at the highest level, unattainable for the masters of the past. Yes, good craftsmen could produce products from damask and damask with characteristics ahead of their time, but now their products are likely to yield to their modern counterparts made of super steels.

However, starting from the moment when modern stainless steels of the 440 line and their analogues appeared, there is no global need for improving knife steels - almost all high-quality knives with correct heat treatment cope with everyday tasks.

The appearance of super steels on knives is rather a tribute to the market and the desire of users, many of whom are fans and collectors of knives and want to get something new, more “cool”. And there is nothing wrong with that, since not only steel is being improved, but also the design of knives and design. Many of modern knives can be confidently attributed to art objects, whose artistic value is not inferior to the canvases of outstanding artists, and the value only increases over time.

In the next article, we will talk about the design solutions used in modern knives.

Information