From the construction site - into battle! Armored Cranes Liebherr

Autobahn cranes

Liebherr was originally a peaceful company. In 1949, its founder, Hans Liebherr, introduced the first development - the TK 10 quick-erecting tower crane. Such equipment was in high demand in the war-torn Germany and over time became one of the main revenue items of the company. Later excavators appeared in the product range, and in 1954 Liebherr unexpectedly organized the production of refrigerators. By 1977, when the first LTM 1025 wheeled crane appeared, the German company had already produced many construction equipment and aircraft equipment. But it was LTM 1025 that became the starting point for the military career of Liebherr equipment: the first military cranes were created on the basis of this machine. Since 1977, the company has collected for the military of different countries about 800 cranes with a lifting capacity of 10 to 500 tons. This, of course, is not much: in 2017, for example, Liebherr launched its fifty thousandth wheel loader.

1984 was marked by a major event for the company: the deployment of its own production of diesel engines for construction equipment. Now the experience of Liebherr in the field of engine building was useful to KamAZ. On the latest K5 tractor, which is assembled from various foreign components, is a KamAZ-910 six-cylinder engine - a copy of the engine from Germany. The Germans and domestic engineers remade the 12-liter D946 to meet the needs of the main tractors and localized production in Russia. By the way, without Liebherr engines, KamAZ factory teams would not have achieved such significant success in the Dakar rally. Now the competencies of the German company allow you to independently develop and produce diesel engines, the working volume of which reaches 100 liters, the number of cylinders is up to 20, and the power exceeds 6000 liters. from.

When applied to the military industry, wheeled cranes supplied to the armies of NATO countries are of most interest. So, since 2002, the French have been operating 50 Liebherr LTM 1055-3.1 machines with a 6x6x6 wheel arrangement - an all-wheel drive three-axle crane with all steered wheels. Five cars left for France with armored cabs. The crane's carrying capacity is 50 tons, despite the fact that its own curb weight does not exceed 36 tons. Since military production is not core for Liebherr, the machine for the French army turned out to be just a khaki-painted civilian crane with a telescopic boom. LTM 1055-3.1. This is road equipment unsuitable for rough terrain. The crane has a funny clearance and tires without developed lugs. A distinctive feature is a fully-controlled chassis: the rear wheels, depending on speed, turn either synchronously with the front or in antiphase. But this is only one of the steering modes, the rest will be discussed later. The rear wheel thrusters allowed the civilian wheeled crane to maneuver in narrow European streets no worse than delivery trucks, and the French military got this ability as a bonus.

Six years ago, Liebherr delivered 4 three-axle cranes LTM 1055-3.2 with a lifting capacity of 55 tons to the Swiss army. Together with the contract for the construction of cars, the Germans developed a set of equipment for cranes for the quick assembly of temporary bridges. By the way, it was in Switzerland in the city of Büle that the Liebherr headquarters have been based since 1983. Therefore, some mistakenly believe the company is originally Swiss.

71 bundeswehr crane

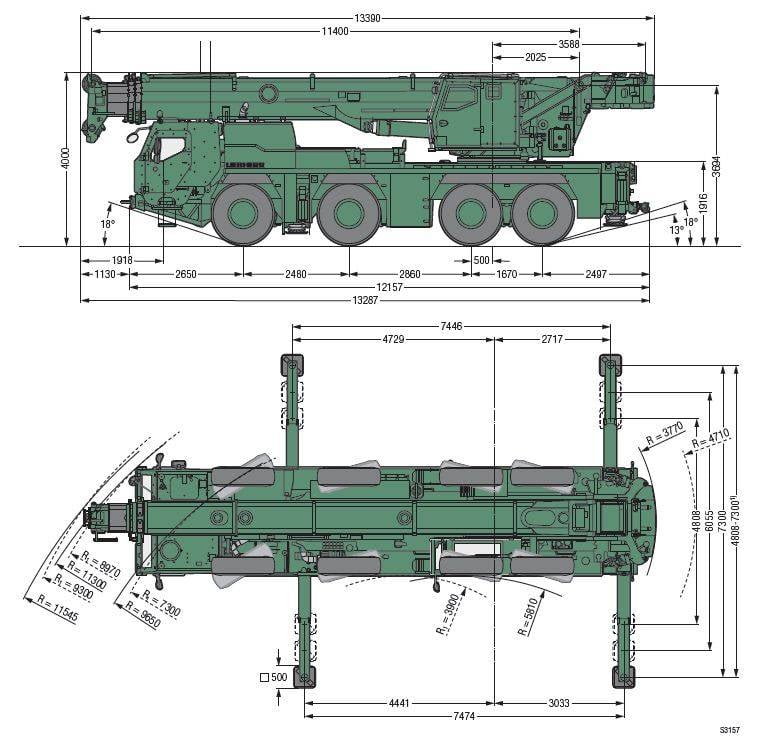

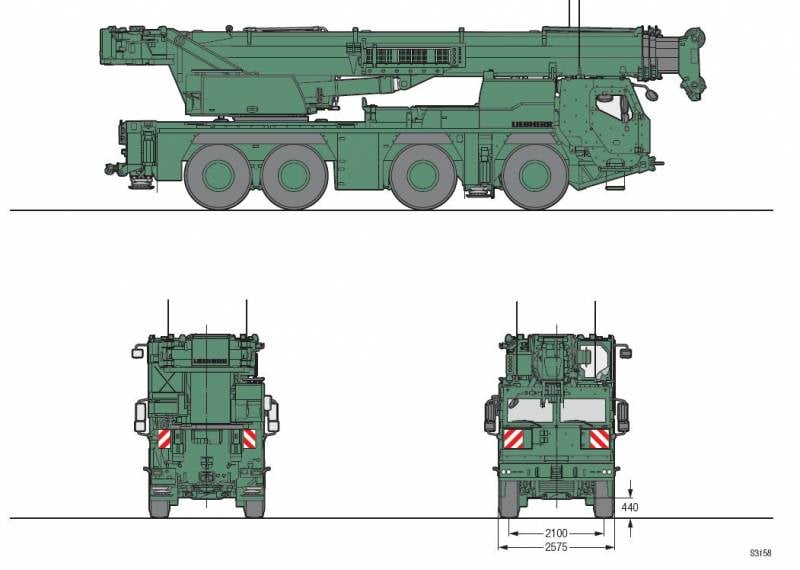

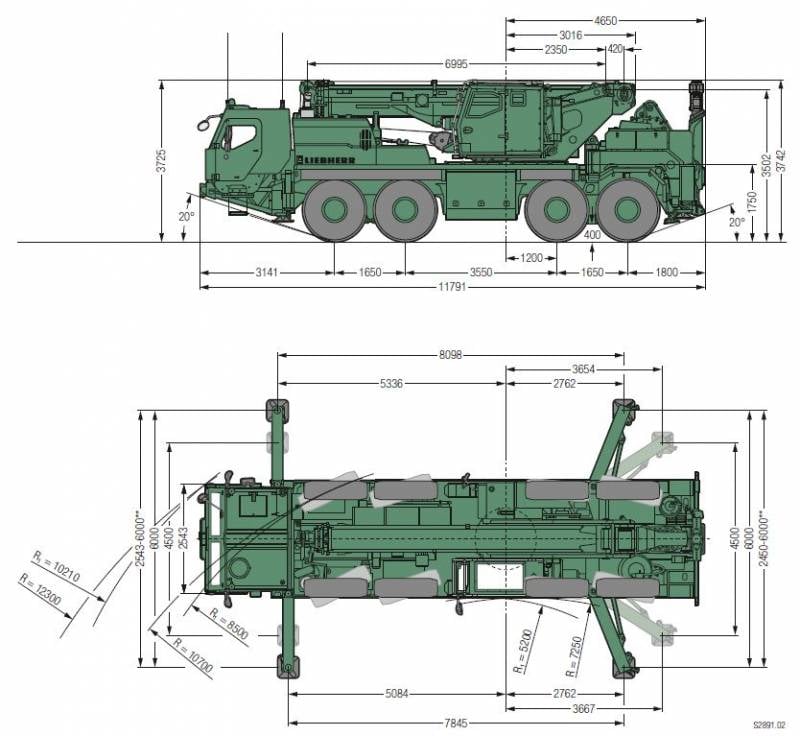

Since 2017, Liebherr has been fulfilling a large order for the Bundeswehr to supply 71 armored cranes with a total value of 150 million euros. It is easy to calculate that the cost of each machine on average exceeds 2 million euros - this is about three times cheaper than the main combat tank Leopard 2. The company plans to complete the supply of cranes to the army by December 2021. Of the total order, 38 cars are assembled in the performance of G-LTM 1090-4.2, which differs from the civil ancestor only in ceramic booking panels, a cabin and a painting increased by 250 mm. The armor protection of the driver’s cab and crane operator was developed by Rheinmetall (there are no open data in the press on what calibers this armor saves from).

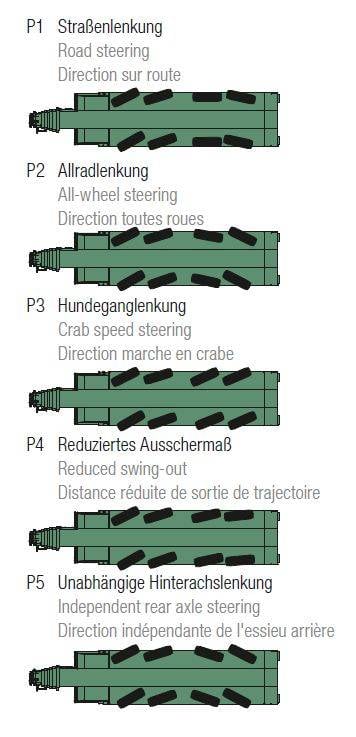

G-LTM has four axles (three of them leading) with all steered wheels. From the civilian version, the crane got a sophisticated steering system with five operating modes. On the front two axles, the wheels are controlled by the usual mechanical drive, and the third and fourth pair of wheels are equipped with electrohydraulics. At first glance, a similar system was implemented on the domestic ZIL-134, but our missile carrier managed only the first and fourth pair of wheels. And here at once everything, and even according to five algorithms. It is not clear why the military crane needs such difficulties, but the Bundeswehr did not refuse such a thing. In accordance with the algorithm of the first program, rear-wheel steering is carried out on public roads and depends on the speed of the crane. It's simple: the faster the car goes, the less taxiing. When you set a certain speed, the rear wheels become strictly straight during any maneuvers. The second program is necessary for a minimum turning radius of 10,2 meters, which is less than some passenger cars. The rear wheels rotate in antiphase front. The third program is “Sideway” - all wheels are turned in one direction and allow the crane to move diagonally. The fourth work program helps to avoid skidding: for this, the rear pairs of wheels rotate synchronously in antiphase with the front, but at smaller angles. Finally, the fifth algorithm allows independent control of the wheels of the rear axles with separate buttons.

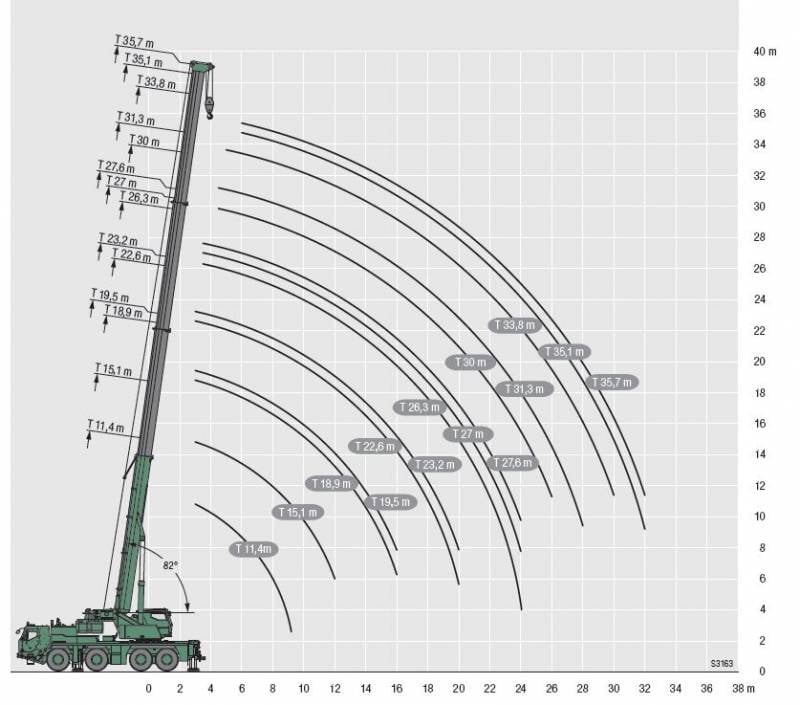

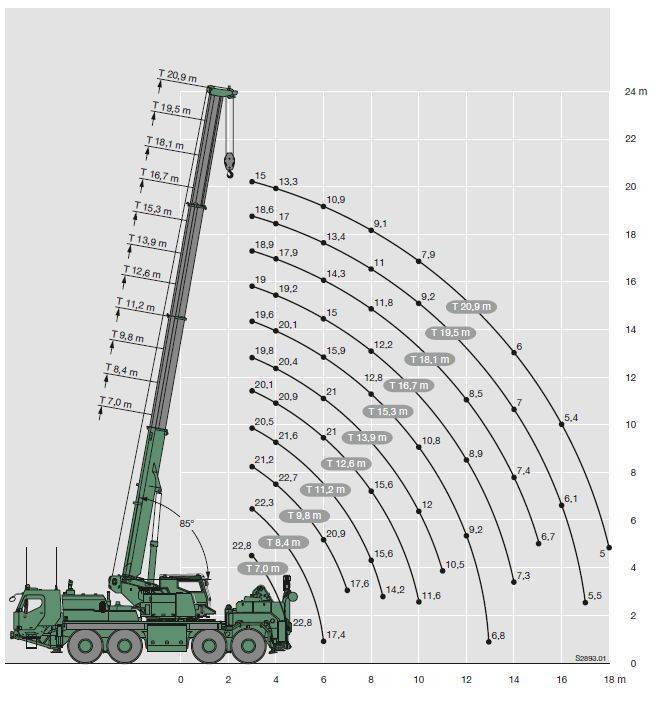

G-LTM is equipped with a 6-cylinder diesel engine with a capacity of 449 liters. from. and capable of lifting a telescopic boom of 36,6 tons. The military of the Bundeswehr got along with the crane two Liebherr proprietary technologies: VarioBase and VarioBallast, designed to work in cramped urban conditions. The first technology allows you to extend the outrigger supports at different distances independently of each other. VarioBallast is moving the ballast of a crane with the help of hydraulic cylinders: the further it moves, the greater the mass of a load a crane can lift. On the one hand, this allows the use of not so massive ballast, and on the other hand, it does not constrain traffic in cramped lanes.

The second part of the contract with the Bundeswehr consists of 33 armored towing cranes Liebherr G-BKF (Geschütztes Bergekranfahrzeug). This machine is already different from its civilian counterparts the ability to evacuate equipment weighing up to 16 tons in a semi-submerged state. For this, a special lodgement in the stern is used, on which the evacuated wheel equipment is fixed. Rigid towing is also possible. Two winches were mounted on the crane: Rotzler TR 200 (force - 200 kN, rope length - 75 m) and Rotzler TR 80 (80 kN and 49 m, respectively), which can be used simultaneously. The maximum mass of the load lifted by the telescopic boom of the crane is limited to 20 tons. G-BKF allows the operator to use both a crane and winches at the same time, which seriously expands the functionality of the machine. For example, a machine can rescue stuck equipment while lifting and pulling it. The crane operator can control the operation of the equipment remotely from a remote control unit that communicates with the machine via Bluetooth.

Despite the resemblance to the aforementioned G-LTM, the evacuation crane is built on an all-wheel drive MAN platform with a 544-horsepower D946T diesel engine. The machine control algorithms are built around five programs in complete analogy with the rest of the Liebherr technology. The suspension of each axis is dependent with the possibility of individual height changes: the machine can even roll forward / backward, left / right, and also lower to the belly like domestic BMD. The crane is also equipped with removable ceramic armor from Rheinmetall, which protects the driver’s cab, crane operator and part of the equipment.

Despite the fact that the manufacturer positions military cranes as cross-country vehicles, this is not entirely true. To do this, just look at the layout, considerable front and rear overhangs, as well as “toothless” road tires. Liebherr did not particularly bother designing a military crane from scratch, but simply adapted serial civilian equipment for the Bundeswehr, equipping it with local armor. On machines that must operate under bullets and withstand explosions of light IEDs, there is not even a centralized system for pumping wheels. Liebherr G-BKF and G-LTM are equipped with bulletproof inserts, which in case of breaking a tire out of the attack. And the problem of regulating the pressure in the tires was solved in an original way: the driver stops off-road, gets out of the car and bleeds air from each wheel, and individually pumps each wheel on a solid road with an on-board compressor. Despite the impressive technological level, Liebherr combat armored cranes are strictly contraindicated for off-road use - better, flat German autobahns.

Information