Failed record. Hughes XH-28 Helicopter Project

On October 23, 1952, the American company Hughes Aircraft first flew an experimental XH-17 Flying Crane helicopter. By this time, aircraft manufacturers managed to work out issues of further development of the project and even receive an order to create a new helicopter. On the basis of the experimental machine, it was proposed to create a full-fledged transport helicopter. This project received an XH-28 index.

From experiment to practice

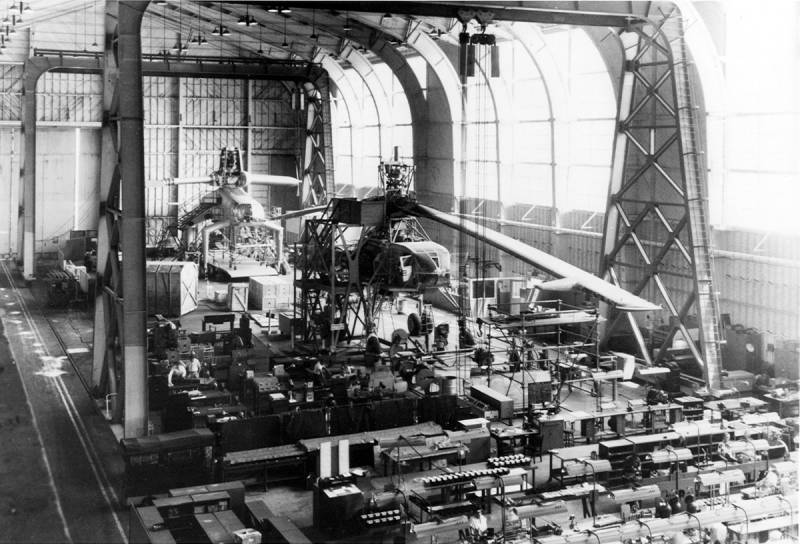

In 1951, the Hughes company was engaged in the analysis of the results of ground tests of the experimental XH-17 and was preparing for the first flight. In parallel, on the basis of the accumulated experience, the appearance of a future helicopter suitable for operation in the army was formed.

In October, materials on the project were submitted by the US Air Force. The military approved the proposal, and in early 1952 a contract appeared for the necessary work. The project of the helicopter for the army received the designation XH-28. In accordance with the terms of the contract, the prototype was supposed to go on flight tests no later than 1956 - the customer took into account that the experimental machine of the previous model still did not fly into the sky.

The technical specifications for the XH-28 were different from the requirements for the XH-17. The desired flight characteristics remained the same, but the required carrying capacity was raised to 18-20 tons. Preliminary calculations showed that such characteristics are real and can be obtained in practice - but the project will be very complicated.

Scientific work

Experiments with the XH-17 helicopter in the form of a ground test bench showed that the proposed architecture needs refinement and additional research. First of all, it was necessary to solve the problem of rotor strength. The helicopter was planned to be equipped with a large-diameter screw, capable of providing the desired traction. This required long blades of a special design that withstand the arising loads and vibrations.

Hughes, together with relevant research organizations, conducted research and found the best rotor design. It was proposed to keep the propeller with a jet drive blades. In this case, instead of two blades, four should be used. All-metal blades with a power set made of titanium could show the best strength characteristics.

Helicopter builders were going to order the development of a new engine with the required characteristics. Such a contract was offered by Allison, but it refused because of loading with other orders. Nevertheless, she promised to provide ready-made engines for the construction of an experimental helicopter.

In parallel with research, Hughes conducted design work and formed the technical appearance of the future XH-28. In mid-1952, construction began on a full-size prototype demonstrating the main features of a promising helicopter. Unfortunately for the developers, the project did not advance beyond the layout.

Record design

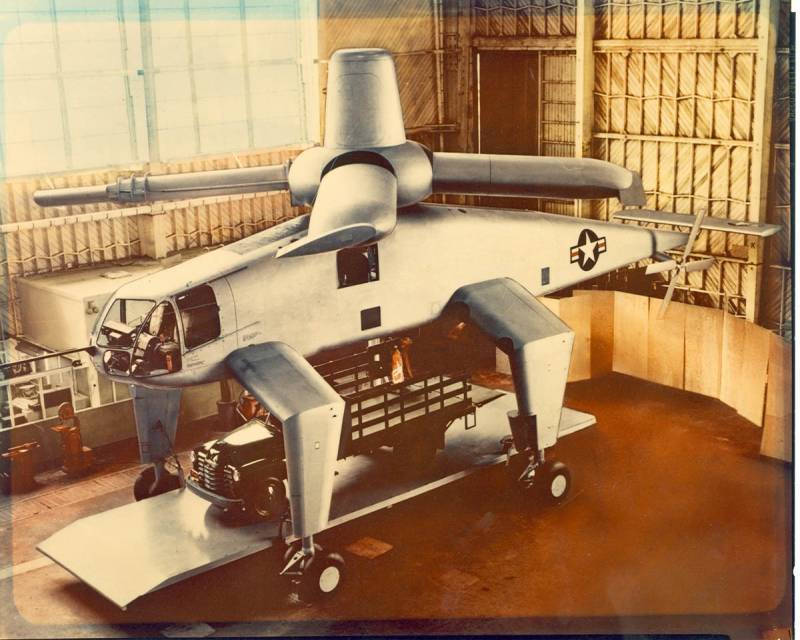

In terms of layout and overall architecture, the future XH-28 was similar to the existing XH-17. However, other requirements and accumulated experience led to a significant revision of the design and the replacement of a number of main units. In addition, unlike the prototype booth, the helicopter for the army had to have a full skin and unit covers.

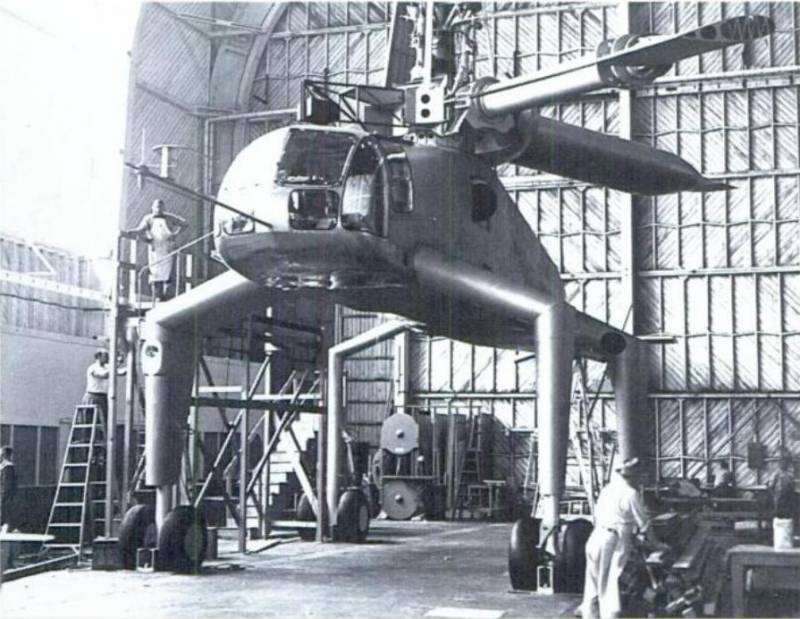

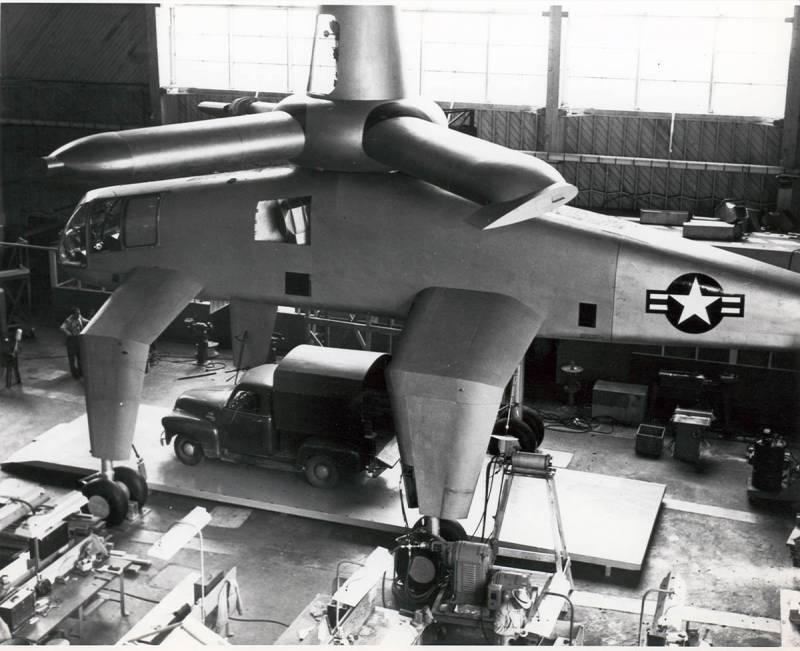

It was again proposed the construction of a “flying crane” - a helicopter on a characteristic high chassis with an open cargo area between the racks. The fuselage of the new machine had smooth contours and a variable cross section. The layout has changed slightly due to the advent of new units. A cabin was left in the nose, a large fuel tank and a pair of engines were placed behind it. A stabilizer and a tail rotor were placed on the tapering tail boom.

The XH-28 power plant included two Allison XT40-A-8 turboshaft engines with a power of 5300 hp each. This time the engines were placed inside the fuselage. The torque of the engines through the gearbox was transmitted to a separate compressor. He took atmospheric air and, under pressure, supplied it to the pipelines of the rotor hub. The gearbox also had a power tap for the tail rotor.

The principles of rotation of the screw are fully borrowed from the previous project. Compressed air from the compressor through the tubular spar of the blade came to the tip. There was a system of several combustion chambers where fuel was supplied through special pipelines. Jet engines at the ends of the blades created traction and had to untwist the screw to the required speed.

The main rotor with a jet drive of the blades received a standard swashplate with all the necessary capabilities. The presence of pipelines for air and kerosene affected the design of the sleeve. Like the XH-17, it was taller and larger than the classic design. To improve aerodynamics, the sleeve and root parts of the blades were covered with fairings.

In terms of size, the XH-28 did not differ much from the previous XH-17. Despite the change in the number of blades, the screw diameter remained the same. The estimated dry weight reached 23,6 tons. The maximum take-off weight was 47,6 tons. The estimated payload was brought up to 50 thousand pounds (22,7 tons) - almost half of the maximum weight. A helicopter could fly at a speed of up to 140-150 km / h for a range of up to 150-170 km.

To transport the payload, it was proposed to use a platform located between the landing gear racks. The absence of sides or barriers facilitated loading and unloading, and the equipment was planned to be driven on its own. Due to the unique carrying capacity, the helicopter could transport any samples of automobile and special equipment that were in service at that time. It was also possible to transport some samples of armored vehicles, artillery, etc.

Unexpected final

Work on the XM-28 project went according to schedule until the end of 1952. But in December, the Air Force made a fundamental decision on the further development of promising projects. Due to the ongoing war in Korea and due to limited financial resources, they had to choose which areas would continue and which ones would have to be abandoned.

Air Force decided to focus on promising tactical aircraft aviation. At the same time, it was proposed to substantially revise the helicopter development program. The result was new plans for the XH-28 from Hughes. This project was proposed to continue until the end of the next 1953 with the aim of completing the basic theoretical and design work, as well as to obtain the necessary experience. Further stages of the project, including the construction of the prototype, were canceled in advance.

However, until the end of 1953 the project did not survive. Already in the summer, August 17, the Air Force command ordered to stop supporting the Hughes XH-17 and XH-28 projects. The freed resources were redirected to the development of light and middle class helicopters - such equipment was considered more important for the army.

By this time, Hughes Aircraft managed to build only a full-size model of the promising XH-28. Soon this product was dismantled as unnecessary. Experienced XH-17 was more fortunate. He continued to be tested in the order of accumulating experience, but at his own expense. Flights continued until 1955, when the rotor exhausted its life. After this test was stopped, and later the car was scrapped.

For technical and other reasons, the XM-28 project could not even be brought to prototype testing. Other American projects of heavy or super-heavy helicopters were also not successful. As a result, the US Air Force still does not have helicopters with a payload capacity of 20 tons or more. However, available samples with less outstanding characteristics made it possible to build a workable and efficient army transportation system.

Information