Tank engine V-2: modernization and life after the war

Experiences and Evolution

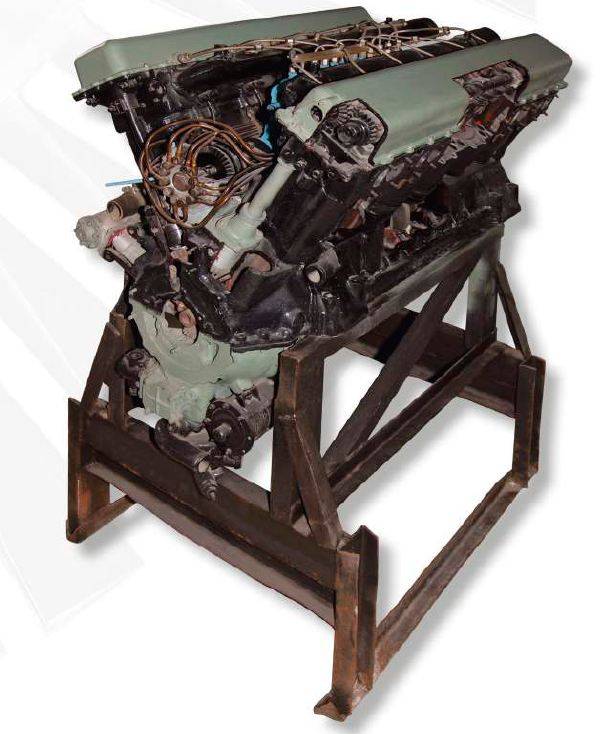

In world tank building, the use of high-speed diesel engines for tanks became the gold standard only in the late 50s. NATO countries realized that it was time to get rid of gasoline power plants much later than the Soviet Union, but quickly caught up. In the post-war era, domestic tank engine building was based on the proven B-2 concept, which had passed fire, water and copper pipes over the previous decade.

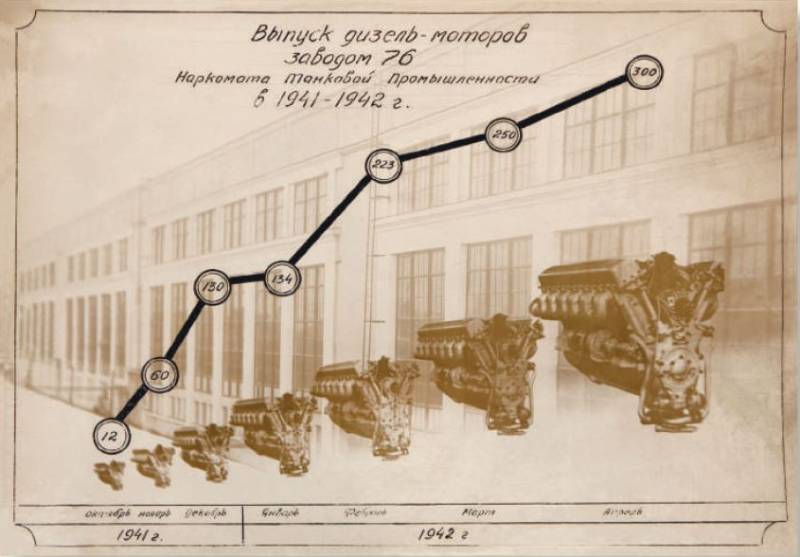

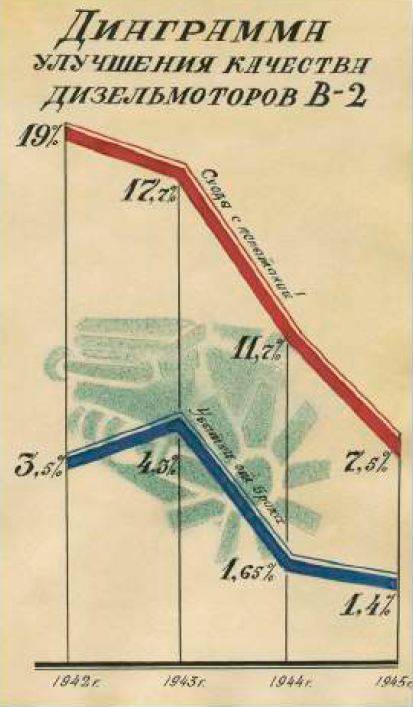

During the years of World War II, the leading design bureau No. 2 in Chelyabinsk played a leading role in the modernization of the V-75. Over the years of the war, a huge engine-building complex was formed at Tankograd, which was set up exclusively for the production of B-2 diesel engines. On the one hand, this made it possible to seriously save on large-scale production of motors, and on the other, it created difficulties in re-profiling the site. In the book “Tank Engines (from stories tank construction) ”E. A. Zubov in this regard even provides calculations on the costs of development work of small foreign manufacturing companies and industrial giants. On average, a small company receives a return on each dollar invested 24 times more than, for example, the giant Ford or General Motors. There were an overwhelming majority of large engine-building plants in the Soviet Union, which led to a certain conservatism in innovative developments.

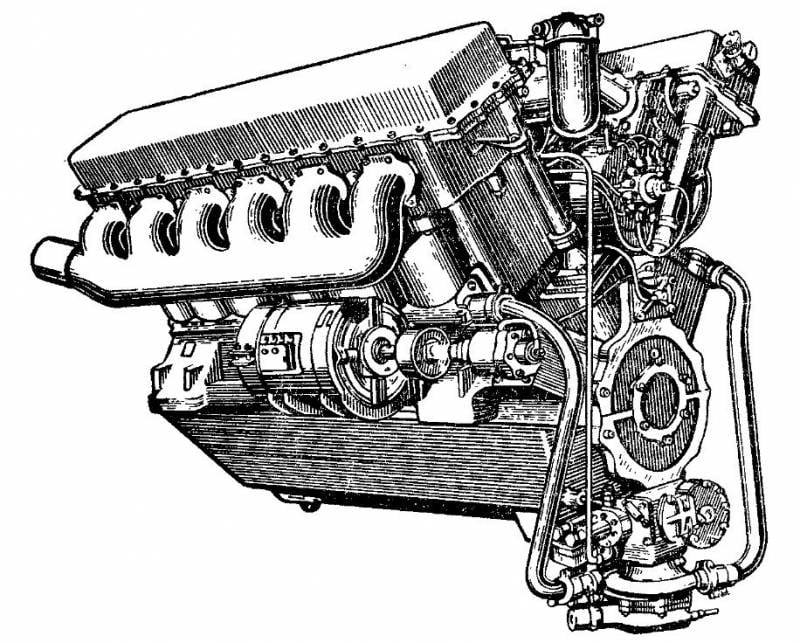

One of the first improvements to tank diesel in Chelyabinsk was the modernization of the V-2K, designed for heavy tanks. The diesel engine was increased torque, power was increased to 650 liters. sec., while the maximum engine speed was not touched - the crank mechanism of increased loads could not withstand. We achieved this by reconfiguring the high pressure fuel pump and increasing the fuel supply per cycle. Next was the V-2IS, which managed to reduce its height by 200 mm and carry out a number of minor improvements. One of the indisputable advantages of the IS tank equipped with such a diesel engine was the 220-kilometer mileage at one gas station, while the T-VI Tiger could only go 120 kilometers on the tank. However, such an increase in power did not allow to increase the engine resource - until the end of the 40s, it still did not exceed 300 moto-hours. Already during the war, it became clear that a further increase in B-2 power with a further increase in engine life was possible only by boosting. One of the first was the V-12 with a drive centrifugal supercharger AM-38F, which allowed the engine to develop 750 liters. from. and provided a torque of 3000 Nm. In November-December 1943, the motor successfully passed 100-hour tests, but after only six months it was no longer possible to repeat them. In early 1944, the V-2 for heavy tanks, it was decided to change to a new V-11 immediately for 700 liters. with., and in July of the same year, the Kirov plant was supposed to produce 75 motors per month. As a result, the first production engines appeared only at the end of April 1945 and were installed on the IS-3, which did not have time to fight. In 1947, the first production V-12s for the IS-4 appeared at ChTZ, which were produced in various modifications until the early 60s. Motors of the "heavy" series were installed on the T-10, T-10M and a pair of experimental vehicles.

Ural Turbine Plant. Source: Ural Turbine Plant. 80 Years Building Energy

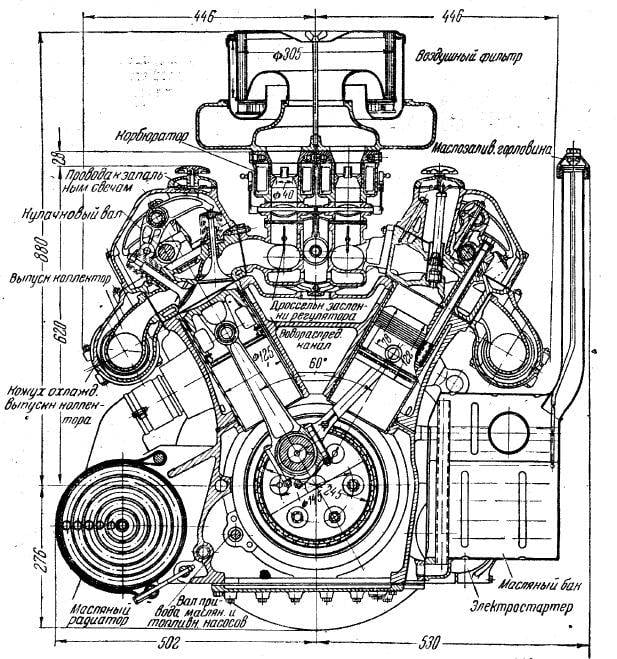

Sverdlovsk Plant No. 76 (Turbine Plant), also engaged in the production of tank engines, by the fall of 1944 was able to create its own version of the deep modernization of the legendary diesel engine, named V-14. It was a 700-horsepower engine with a cylinder diameter expanded to 160 mm, which increased the working volume to 44,3 liters. Bench tests of the supercharged V-14M were also carried out (the working volume was increased to 44,3 liters), which has a capacity of 800 liters. from. The long-awaited novelty appeared on both engines - the cylinder block shirt was now cast at the same time with the heads, which eliminated the notorious problem of a gas joint. This was a direct merit of the designer Timofey Chupakhin, who, since the late 30s, had nurtured a similar idea. Also on the B-14 there was a new, more rigid crankcase, which became the supporting structure - this increased the reliability of the crankshaft bearings and the piston group.

Supercharged and without

Noteworthy is the development work taking place at the testing range of the Armed Forces of the USSR Armed Forces of the USSR, the purpose of which was to increase the power of the V-2 naturally aspirated. Then it was once again confirmed that the arrangement of air purifiers in the engine compartment of a tank directly affects the filling of diesel cylinders with air. It turned out that the T-34 and IS-2 engines pretty much “swallowed” the air warmed up by their own heat (up to 60 degrees), which, coupled with clogged filters, reduced power immediately by 10%. The physics of the process is very simple - the cold air is denser, therefore, in one working cycle, the motor sucks it in more and the fuel burns more fully in the cylinders. The situation is the opposite with warm air.

In general, based on the results of work at the GBTU training ground, it was concluded that without a critical decrease in the motor resource, its power can only be raised to 600 liters. from. Further only with the turbine. In the naturally aspirated version, the base V-2 is accelerated with a whole range of measures - reducing the air resistance at the inlet, installing an annular intake manifold for uniformly filling the cylinders of both halves of the engine (this was spied on by the German tank diesel Mercedes-Benz 507) and the development of a new high-pressure fuel pump. The latter was also planned to be borrowed from Bosch, whose pumps were mounted on Mercedes-Benz 503A diesel engines. It was also recommended to reduce the tolerance of adjustment of serial fuel injection pumps for fuel supply from 6% to 3%. This work was part of a large project to modernize the V-2 at the site of the Chelyabinsk Tractor Plant, whose management did not want to make any fundamental changes in the production cycle.

As you know, you can increase the power of the motor by increasing the working volume (add cylinders or simply increase their dimension), and this, in turn, required serious changes in the design. Therefore, turbocharging has become the main post-war trend in the modernization of the V-2.

Engineers pointed out that the introduction of such a solution would increase the liter capacity immediately by 50-100%, while the drive centrifugal supercharger seemed to be the most optimal, giving higher economic indicators. The fact that all this will inevitably cause increased mechanical and thermal loads on the motor had to be put up with.

The next task for motor builders was to increase the engine’s warranty life up to 500-600 hours. Also, to realize the movement of the tank in underwater conditions, it was necessary to ensure the reliability of the motors at high resistances at the inlet and outlet.

In a kind of competition for the most successful modification of the V-2, several manufacturers of the Soviet Union took part at once. In addition to the head SKB No. 75 mentioned above from Chelyabinsk, they also worked on their program at Transmash Plant No. 77 in Barnaul.

The V-16 diesel engine, created by Siberian engineers, developed 600 liters without turbocharging. from. and was distinguished by the absence of fuel injection pump in the usual sense. It has always been a problematic B-2 unit, and in Barnaul it was decided to replace it with individual pump nozzles for each cylinder - a largely breakthrough solution that became widespread much later. Barnaul engineers developed the V-16 theme into a whole family - there was a 700-strong version for heavy tanks and an 800-strong supercharged V-16NF. They even developed a spark of two diesel engines, with which 1200 liters were removed from the stand. from. But all project work was curtailed either due to the closure of the development of the experimental tanks under which they were built, or because of the general cooling of the state to tank themes.

At the beginning of the 50s, the leadership had the impression that all military problems could be solved with the help of missiles, and that the rest of the armament had an associated role. Sobering came around 1954, when in the NATO countries they began, if not overtaking the USSR tank engine building program, then at least reducing the backlog. The Chelyabinsk multi-fuel V-27, equipped with a TKR-11F turbocompressor and developing a capacity of 700 liters, became a real symbol of rebirth. from. Subsequently, the design evolved into the well-known B-46-6 and B-84, which became the real crowns of the concept of B-2.

The next manufacturer, included in the race for the post-war improvement of the V-2, was the Ural Turbomotor Plant mentioned above, which developed a variant of the motor under the letter "M". It was a deep rethinking of the concept of diesel, most of the components in which were completely new. The V-2M received two TKR-14 turbocompressors, which in the future were supposed to be equipped with charge air cooling units - a revolutionary solution at that time. Now such nodes (intercoolers) can be found in the engines of main tractors. In addition to turbocharging, the engine received a new high-pressure fuel pump, improved cooling and lubrication systems, as well as many components reinforced in comparison with the ancestor. By 1968, the engine was ready, but the difficulties with its launch into production, as well as the large dimensions did not contribute to adoption. But many decisions of Sverdlovsk designers have found application in the next generations of tank diesel engines.

Germans, tanks and diesels

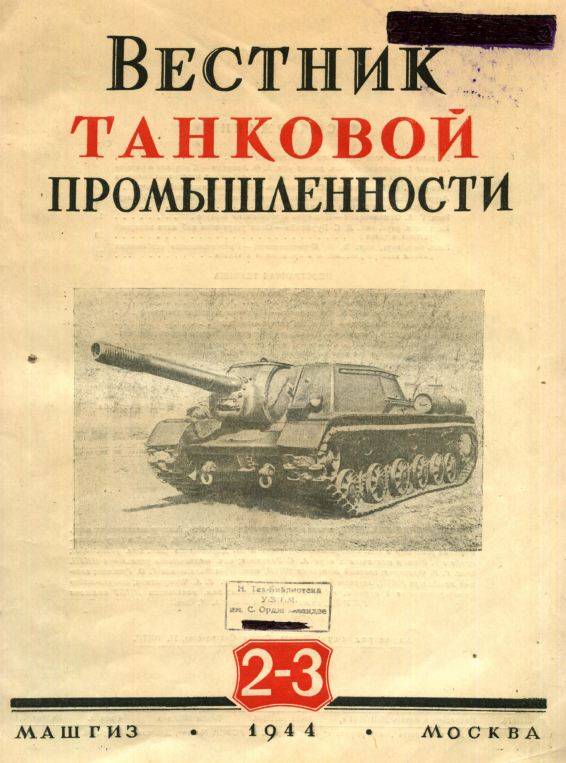

The dieselization of medium and heavy machines in the 40s in the Soviet Union was a unique event in world industrial history. Nobody in the world, except Japan, has used diesel engines on armored vehicles so massively. For comparison: the American "Sherman" of its thirteen modifications had only one M4A2 with a twin diesel power plant. Why, for example, in Germany during the war did not come to the idea of installing a diesel engine in a tank? There are many versions, starting with a shortage of aluminum and alloy steels and ending with the incompetence of German engineers in the field of the creation of land heavy diesel engines. In this connection, the opinion of Senior Lieutenant Technician S. B. Chistozvonov, which he outlined on the pages of the Bulletin of the Tank Industry for 1944 (No. 2-3), is interesting.

In the article “German tank engines”, the author analyzes in sufficient detail the enemy engines existing at that time, and in the end analyzes the reasons for the Germans abandoning tank diesel engines. Chistozvonov rightly points out that in Nazi Germany, even before the war, there were Junkers and Daimler-Benz aircraft diesels, which, after a little refinement, could well be installed in armored vehicles. However, German engineers considered this inappropriate. Why? In fact, the author among the advantages of a diesel engine notes only a relatively low fuel consumption (20-30% lower than that of a carburetor analog) and low fuel cost. Lieutenant Chistozvonov suggests in the article that the Germans did not get involved in diesel, since the gasoline engine is cheaper, simpler, more compact, more reliable in cold weather, does not require scarce alloy steels and highly skilled labor of collectors.

At the same time, the life of the tank in the battlefield is so small that it more than eliminates all the advantages of a diesel engine (read: V-2). The author considers far-fetched notions about the fire safety of compression ignition engines - getting a shell into a tank, engine compartment or a simple Molotov cocktail is guaranteed to cause a fire in the MTO of a tank with a diesel engine. In this case, the diesel tank had no advantage over the gas tank. The specific fuel balance of Germany also played a role in choosing the type of propulsion system for tanks. Synthetic gasolines, benzene and alcohol mixtures prevailed in the German balance, and were unsuitable as fuel for diesel engines. In general, a very bold article was for 1944.

At the end of the material there is a curious comment by the editors of the Bulletin of the Tank Industry:

Information