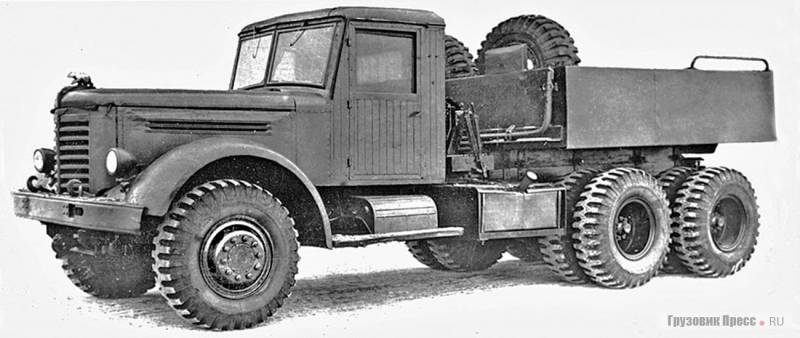

KrAZ-214. Ukrainian soldier originally from Yaroslavl

KrAZ-214 Photo: www.autowp.ru

Bear on the hood

The production line of heavy three-axle trucks was brought to Kremenchug from the Yaroslavl Automobile Plant, story which leaves in the pre-revolutionary 1916 year. Then the industrialist Vladimir Aleksandrovich Lebedev opened one of the first automobile plants in Russia, aimed at satisfying defense orders. They planned to produce one and a half trucks of the English brand “Crossley”, but the civil war mixed all the cards, after which the plant turned into a leading manufacturer of heavy trucks for the army and the national economy of the Soviet Union.

The most interesting for the "Kremenchug" theme is 1944, when the company received the name of the Yaroslavl Automobile Plant and began to develop a new family of trucks. It is important that for the first time a diesel engine was chosen as the power unit for production trucks, for the production of which machines and equipment were purchased in the USA. As a prototype, they took the basis of the overseas two-stroke diesel engine General Motors GMC 4-71 - it was a four-cylinder unit with water cooling and a working volume of 4654 cubic meters. see. Power he developed in 112 hp and in 1947 for the first time stood under the hood of a 7-ton YAZ-200 (a copy of the state GMC-803). This car subsequently “left” to Minsk, where it became the founder of a whole generation of MAZ trucks.

It must be said that American diesel engines mastered in 1946 were quite progressive engines for their time. They were compact, had good performance in terms of power density and efficiency, but they were demanding on the level of skill of both production workers and maintenance personnel. In addition, two-stroke diesel engines rustled mercilessly and weighed 800 kilograms. Over time, in Yaroslavl, they mastered the six-cylinder version of the American GMC 6-71 diesel engine, which received the name YAZ-206A and was already developing 165 liters. from. It was he who became the heart of the heavy triaxial Yaroslavl YAZ-210, the design of which for many years became the standard for future trucks from Kremenchug. In particular, the engineers equipped the truck with a heavy and durable frame, the spars of which were made of hot-rolled profiles (channels) using low-alloy chromium-containing steels. The frame was made durable, but the driver’s working conditions seemed to be the last thing they thought: the steering of these triaxial heroes did not have an amplifier. To understand what significance the Yaroslavl 12-ton trucks had for the Soviet and partially world industry, we can give an example of a Vietnamese banknote of 5 dongs, which shows the YaAZ-210E dump truck at work.

Ballast tractor YaAZ-210G. It was he who largely became the predecessor of the YAZ-214 (KrAZ-21) Photo: www.gruzovikpress.ru

Also in this line of particular interest is the ancestor of modern tankers - the YAZ-210G ballast tractor. This option received a shortened base and a metal platform copied from the American Diamond T-980 for 8 tons of ballast. The tractor dragged a trailer with a total weight of up to 30 tons and until a certain moment satisfied the military. However, the lack of all-wheel drive and the small angles of mutual skew of the rear axles required good quality roads for the movement of a military truck. Given the many requirements of the Ministry of Defense at the turn of the 50s, Yaroslavl began to develop a new truck with a 6x6 wheel arrangement.

They took the front drive axle from ZIL-164 as a basis, equipped it with a two-stage gearbox and hinges of equal angular speeds, and also made significant changes to the transfer case. The designers of YaAZ did not follow the path of colleagues from Moscow, who left a double busbar on the rear axles on the ZIS-151, but installed large-diameter single-wheel wheels. These were tires of the Trilex type, for their development they attracted the Yaroslavl tire factory located nearby. Trilex is a collapsible diskless rim, consisting of three sectors: one large and two small, connected by curly ends of the side flanges. The latter also acted as locking devices. When mounted with the tire, the dimensional wheel 15.00-20.00 has a rigid structure. There was no tire pressure control system on the machine, which somewhat reduced all-terrain qualities on soft soils. For a heavy and all-wheel drive truck, the old diesel engine with a capacity of 165 liters. from. was clearly weak, so a forced version of the YAZ-206B for 205 liters was developed. from. There was a more spacious cabin with heating, a power steering and even a device for blowing the windshield.

The chief designer of the new army YaAZ was Viktor Osepchugov, who chose the design of the transmission, which is largely a compromise, for the truck that received the "214" index. Naturally, since the car was built on the basis of American concepts, it received separate universal joints on all bridges - then there was no talk of any passing bridges. A similar transmission, by the way, was ZIL-157, also built on overseas patterns.

As mentioned above, the car retained a modernized transfer case from the YaAZ-210G, an interaxle differential and a trolley of two rear axles, and the new addition to the razdatka was with a razdatka with a removable drive to the front axle. When irregularities moved between the first and second driving axles, “parasitic” loads appeared that could not be leveled by the differential - it simply did not exist. In this case, I repeat, between the rear axles the differential was present. Viktor Osepchugov had to make this compromise because of the difficulties in mastering new equipment: at the Yaroslavl plant they held on to the complex “transfer case - center differential” assembly.

The car went into production in 1957. Such a primitive KrAZ drive scheme has been maintained for another 30 years. And a year earlier, in the vicinity of Yaroslavl, the YAZ-214 passed the last tests, organized for reasons of secrecy at night. Also at night, brand new trucks were transferred by rail under awnings to the Moscow arms exhibition, where the triaxial giant really liked the King of Afghanistan, Mohammed Zahir Shah. Nikita Khrushchev immediately ordered to collect 10 cars in a pilot plant at the factory’s experimental workshop and send them to Kabul as a gift.

Despite the fact that the diesel engine on the YAZ-214 had a very convincing power of 205 liters. With., a 7-ton truck was too heavy even for him. In running order on the scales, he showed 12,3 tons! The YAZ-214 was a huge, slow and slow-moving vehicle (maximum speed of not more than 55 km / h), which received the nickname "automobile tractor" in the army. The truck was able, depending on road conditions, to drag trailers from 15 to 50 tons. If we compare the dimensions of the truck with contemporaries, then only the quarry MAZ-525 was higher and wider than the Yaroslavl hero, but he also lost the all-terrain vehicle in length.

Nevertheless, the car turned out to be very popular both in the army and in the national economy, which caused a problem - the space and capacity of the YaAZ did not allow expanding the production of the entire line of trucks. In 1959, it was decided to transfer the entire production of heavy trucks from Yaroslavl to Kremenchug, where automotive equipment had never been assembled before. In total, before moving to Ukraine, YaAZ collected 1265 army all-wheel drive trucks, among which there were many special versions. One of these was the reinforced chassis of the YAZ-214Sh-7, assembled for the installation of promising missile weapons. The truck, already overloaded with various amplifiers, was additionally equipped with more durable units, a winch and power take-off shafts for driving equipment of special superstructures. Also, in Yaroslavl, by special order of the Ministry of Defense, they collected single copies of the 214th car with a fifth wheel coupling from MAZ-200V.

Kremenchug meets YaAZ

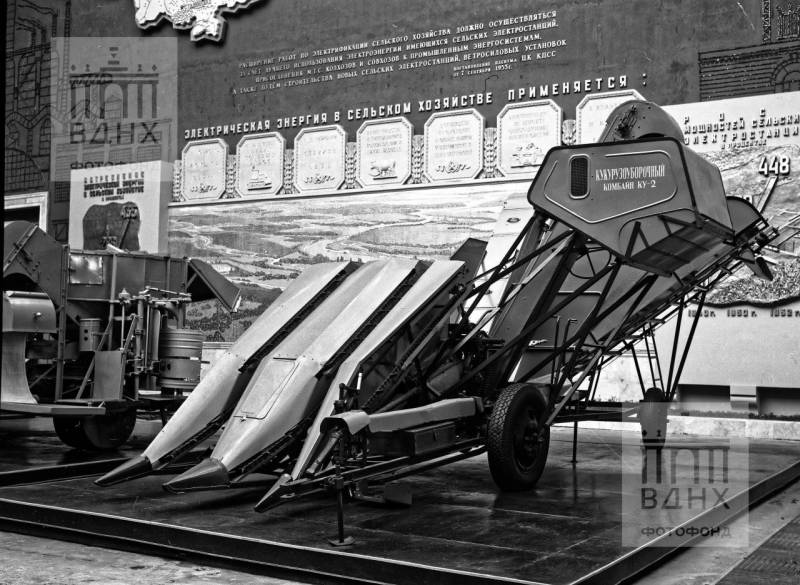

Until the end of the 50s, the city of Kremenchug in the Poltava region of the UkrSSR was never associated with cars and even more so with heavy trucks. Nevertheless, there were capacities and areas for industrial production in the city. In 1945, the People's Commissar of Railways of the USSR signed a decree on the construction of a bridge factory in Kremenchug. After the German invasion, the country urgently needed to build new bridges to replace the destroyed ones and organize ferry crossings. In 1948, the plant began to work and mastered advanced production methods for its period. For example, for the first time, it was in Kremenchug that submerged arc welding was introduced among bridge builders according to the legendary Paton method. By the way, the famous Paton welded bridge in Kiev was created not without the participation of craftsmen from Kremenchug - 600-ton railings were cast at the plant. The portfolio of bridge building production of the future KrAZ includes the Arbat bridge in Moscow, bridges across the Volga, Dnieper and Vistula, ferry crossings of the Kerch Strait and the White Sea-Baltic Canal. In total, the company assembled 607 bridges with a total length of 27 kilometers, which spent 104 thousand tons of metal. But by 1953, most of the bridges in the Soviet Union were restored, and the plant was sorely short of orders. After three years of stagnation, the enterprise came to the rescue ... Nikita Khrushchev, who announced corn as the main agricultural crop in the country. In 1956, the Kremenchug plant became a combine. The main production on the conveyor turned out to be a KU-2A corn combine, the production of which came to the plant from Rostselmash. Naturally, it was necessary to retrain the plant staff, to recruit new specialists (the staff was increased to 1958 thousand people by 4) and to expand production. For a short period of time, 14 thousand KU-2A units, about 5 thousand beet-harvesting machines, 874 road rollers, 4 thousand trolleys for breaking beets, 24 thousand tractor wheels and a few other items of small agricultural equipment were assembled at the combine production.

The first Soviet corn harvester KU-2. At one time it was the main products of the future KrAZ. Photo: media.vdnh.ru

On April 17, 1958, when the hysteria with corn began to subside, it was decided to create a huge enterprise on the basis of the Kremenchug plant to assemble huge Yaroslavl trucks intended primarily for the army. This was the largest transformation of the production cycle at the plant for all its existence. Firstly, it was necessary to allocate 20 thousand square meters for new workshops, and secondly, to place in them about 1500 pieces of equipment both from YaAZ and completely new. Since the plant in Yaroslavl was completely redesigned into motor production, many automotive engineers moved to the future KrAZ. They subsequently formed the backbone of the design headquarters of the Ukrainian plant. The head of the KrAZ test department, Leonid Vinogradov, wrote in this connection:

To be continued ...

Information