Cracks as features of production. New disputes around defective BTR-4

In 2013-14. made a lot of noise story with the delivery of Ukrainian armored personnel carriers BTR-4E to Iraq. The customer discovered a numerous marriage and refused to accept the products. The Ukrainian authorities, in turn, were going to deal with this problem and find the perpetrators. Years passed, but the situation as a whole did not change. The problem of cracks in the hulls has again come to the fore and causes new debate.

Not done, but cracking at the seams

The reason for the continuation of the “series” with cracks was a recent article from the Ukrainian information and consulting agency Defense Express. On January 23, it published the material “New BTR-4 for the army: don't be scattered, but even pull it all the way” (“New BTR-4 for the army: not yet made, but already cracking at the seams”). Agency head Sergei Zgurets criticized the production of armored vehicles.

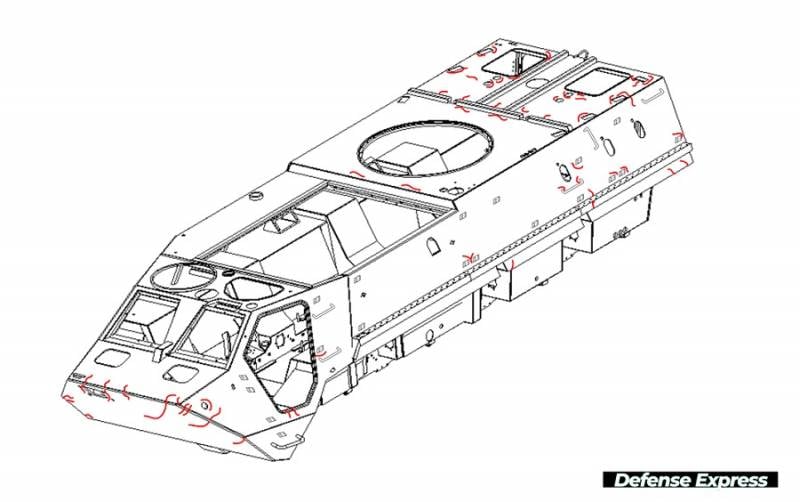

It is alleged that the Kharkov Engineering Design Bureau (KHMB) received three cases for the BTR-4 manufactured by the Lozovsky Forge-Mechanical Plant (LKMZ). The products bear the stamps of military acceptance of the Ministry of Defense, confirming the quality. Despite passing the acceptance, the enclosures are defective.

On the products there are low-quality welds with insufficient strength and requiring additional processing. There are also cracks hidden under the paint. All this requires, at a minimum, to spend time on processing and bringing buildings into an acceptable form. Defense Express accompanied its publication with interesting photographs and video filming.

In connection with the delivery of defective cases S. Zgurets asks three important questions. Why does the state HCMB pay to the private LKMZ defective products? Why is LKMZ a monopolist in the production of cases for armored personnel carriers? Why is “hands” more important than “mind” and KHKBM has turned from a design organization into an assembly organization?

Considering these issues and known problems, Defense Express comes to conclusions about production problems and the corruption component. In particular, charges are being brought against the 85th military acceptance office. Moreover, the whole acceptance system is referred to as the problem.

Meetings and reports

The state concern Ukroboronprom immediately reacted to the publication. The management of the concern called to account the enterprises involved in the production of BTR-4. They were given 24 hours to verify the information of S. Zgurts, study the delivered buildings and compile a report. If the marriage data is confirmed, Ukroboronprom plans to force the contractor to produce high-quality buildings at its expense.

The next day, the state concern published the results of an urgent audit. The presence of cracks in the joints was confirmed. However, the management of LKMZ claims that such damage occurs during the welding process and is part of the technological cycle. They are eliminated at subsequent stages of the production of equipment. Quality control of production is carried out by specialists of LKMZ and KHMBM.

In connection with the identification of the marriage, the Ministry of Defense already formed a working group on January 24, which checked the technique of combat units. On the army BTR-4, poor-quality seams were also identified. A search for the causes of such damage is ongoing.

According to the results of the audit, Ukroboronprom demanded that LKMZ fully and at its own expense correct defects and submit high-quality buildings for production. The Kharkov bureau was ordered to check the qualifications of their welders and to strengthen product quality control.

Unanswered Questions

On January 28, Defense Express again raised the topic of defective cases. Article “New BTR-4 and hulls: not cracks, but“ defects ”. Is that so? ”Began with a reminder of the agency’s activities and its feasible contribution to the improvement of Ukrainian production of armored vehicles. After that, its author, again S. Zgurets, turned to the topic of marriage on the BTR-4.

Defense Express reminds: now all Ukrainian production of light armored vehicles for its needs and for export depends on LKMZ, which produces corps. The armor for the BTR-3 and BTR-4 is made according to old technologies developed back in the Soviet era. Such a technological cycle is characterized by a long duration and a significant share of manual labor.

Since 2010, LKMZ has produced more than 250 cases for the BTR-4, mainly from “71” grade armored steel. Some of the delivered products had cracks and other shortcomings. All this was attributed to non-compliance with technological processes in production. The proportion of defective armored personnel carriers reached 30%.

In the past, KKBM allowed for use in the construction of the BTR-4 four types of armor - the Ukrainian "71" and several varieties of foreign production. From Finnish steel MiiLux Protection and the Belgian HB 500 MOD, several cases for equipment were made. The BTR-4 with Belgian armor passed tests that did not reveal problems with strength and other parameters.

Nevertheless, the Ministry of Defense took measures, and in the series there remained cases made of "71" steel, manufactured at LKMZ using old technology. There is a new order, which recently put the first case. It was these LKMZ products that became the occasion for the previous publication Defense Express.

In connection with this situation, pessimistic conclusions are being drawn. LKMZ maintains the status of a monopolist in the production of armored vehicles, despite the release of low-quality products and an actual lack of responsibility. In addition, there is no strategy for the development of HCBM production that could change the situation. To maintain current economic indicators, Kharkiv must hand in at least five BTR-4s per month. However, the supply of defective cases will not allow to maintain even such a pace, which virtually eliminates economic growth.

Looking from the outside

The Ukrainian military equipment specialist Andrey Tarasenko reacted in an interesting way to the new disputes over the armor from LKMZ. In his blog, he recalled that cracks are not only a problem with the BTR-4. Such defects were present on the APC, tanks and other equipment of almost all types - including those on Russian models. This question was regularly raised on the pages of specialized periodicals.

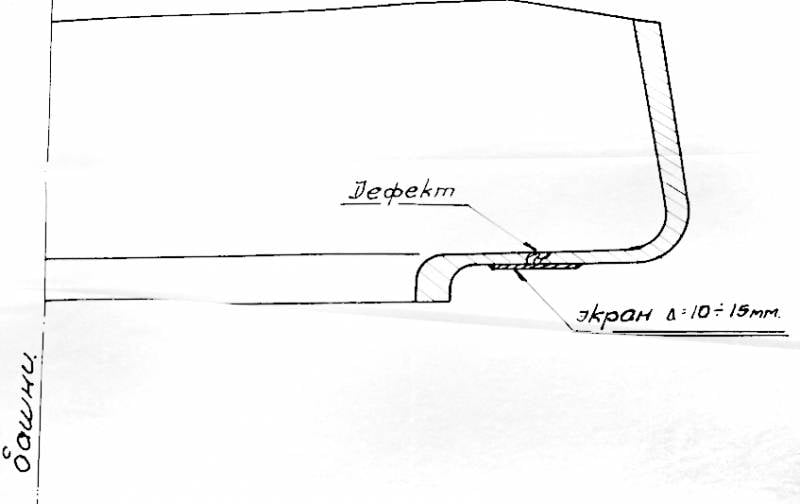

As an example, A. Tarasenko cited a drawing demonstrating the correction of a defect in a T-44 tank turret. In the drawing, an overlay 10-15 mm thick is provided on top of the armor defect. According to the Ukrainian expert, such damage does not affect the fighting qualities of equipment. He sees the roots of the current problems and disputes in another: the readiness to bite each other for the sake of receiving money.

Not yet the end

Thus, the temporarily forgotten story with defective armored vehicles for the BTR-4 is continued. The exclusive supplier handed over to the HCBM substandard products that needed to be finalized and corrected. At first, the public, and then Ukroboronprom, drew attention to this situation and now they are trying to find a way out of it.

Restoration of the tower of the T-44 tank upon detection of a defect, mentioned by A. Tarasenko. Figure Andrei-bt.livejournal.com

It seems that a compromise failed to resolve the issue. LKMZ does not consider cracks in welds to be defective and calls them a feature of production. Ukroboronprom does not agree with this and demands to correct the defects at the expense of the manufacturer. Such statements were made only a few days ago, and it is not yet clear what they will lead to.

However, the prerequisites for current phenomena and problems of past years are obvious. Enterprises strive to participate in the implementation of profitable orders on certain rights and receive appropriate payment. Problems of a production and technological nature do not stop them and do not interfere with earnings. In general, this is the case when the incomes of individual organizations and individuals receive a higher priority than issues of quality, cost or defense.

Obviously, this situation hinders the development of the armed forces of Ukraine, which is already facing a host of diverse problems. Measures to correct it have been announced, but their effectiveness will become known only in the future. Will it be possible to solve the long-standing problem with armored vehicles for the BTR-4? Time will tell. However, the events of recent years make us doubt the possibility of the normal production of high-quality equipment. Too many factors interfere with this outcome.

Information