Ural-375: the ideal of a war chariot

BORN IN US

The Ural Automobile Plant in Miass by the end of the 1950s was a sad sight: minor improvements to hopelessly outdated cars of the UralZIS series and the absence of a serious design bureau. They could not develop their car, all that was left was to hope for the assembly of other trucks created in third-party offices. Naturally, no one in the automotive industry was in a hurry to share defense contracts with a minor plant in Miass. So, it was necessary to find an enterprise that could develop machines, but it couldn’t produce. This was the Research Automotive Institute (NAMI, the last time we heard about it in connection with the development of the presidential Aurus limousine). Of course, the leaders of the Miass factory were unlikely to dictate their will to Moscow engineers and designers. This role was played by the Main Armored Directorate of the Ministry of Defense of the USSR, when it placed an order for a 5-ton army truck, distinguished by its original design, that is, not developed on the basis of an already existing model. Nikolai Ivanovich Korotonoshko, who oversaw the development on the basis of one concept of several all-terrain vehicles with wheel formulas 020x4, 4x6, 4x6, 6x8 and 4x8, became the chief designer of the machine, which was named NAMI-8.

In December 1956, the first metal-made machine was NAMI-020 with a three-axle all-wheel drive chassis, a direct ancestor of future Urals. We dealt with the task with US very quickly: less than three years have passed since the receipt of the task and the assembly of the first prototype. For the domestic industry of those years, this is simply an outstanding indicator, since most of the technology was developed two and three times longer. This is not to say that the truck was designed from the ground up by US, but part of the components and assemblies was borrowed. From MAZ-200 they took a gearbox, a transfer case from MAZ-502, Zilovites provided an experienced eight-cylinder engine with a capacity of 180 liters. s., and GAZ designed the cab. Even at first glance it can be seen that in Gorky they didn’t especially “bother” with the design and actually scaled the GAZ-51 cockpit.

Among the progressive developments in the future “Ural”, a passing middle bridge stood out. Compare with the ZIL-157 with its complex five-card transmission, borrowed from the Lendlizovskoy Studebaker. But Zakhar will go into production only in 1958, two years after the release of the prototype NAMI-020.

Among the purely “military” features of the future Ural, a centralized tire inflation system, airtight drum brakes and a cockpit roof hatch stood out. Tests showed a high cross-country ability of the car, as well as moderate fuel consumption even in comparison with the younger GAZ-63 and ZIS-151.

When they decided to launch the production of the NAMI-020 machine, the Ural Automobile Plant was not the only contender. At first they thought about the Moscow ZIL, then about the distant steam locomotive plant in Ulan-Ude. ZIL in the near future was to master the production of lighter trucks of the 130 and 157 series, so it was quickly rejected. Well, Ulan-Ude didn’t come for an obvious reason of excessive remoteness both from the consumer of the product and from the allies. And here the Miass enterprise turned out to be very useful in a crisis situation. We agreed with the plant manager A.K. Rukhadze and the chief designers S. A. Kurov on the preliminary reconstruction of the enterprise under such a complex truck model and sent NAMI-020 to Miass. And the staff of the institute in 1958 was awarded the second degree diploma of the All-Union Industrial Exhibition for the creation of a cross-country vehicle.

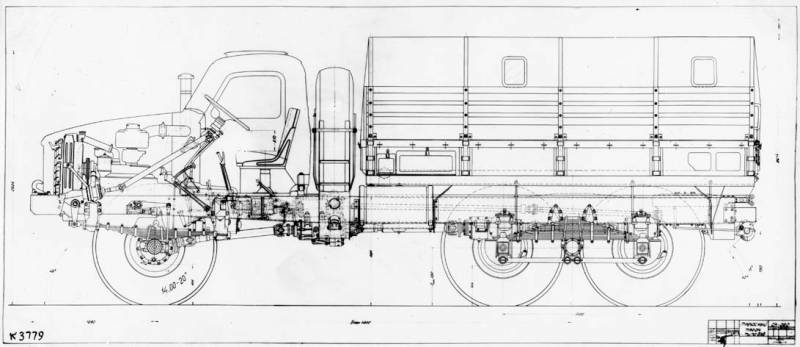

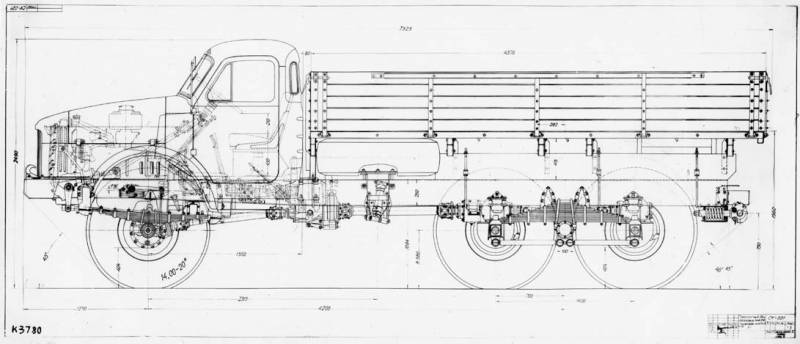

There was another modification of the NAMI all-wheel drive vehicle with the formula 6x6, it had the index 021. This truck was almost the same as the NAMI-020, but was distinguished by a long wooden cargo platform, adjacent to the cab. To do this, I had to place a spare wheel together with its hydraulic lift system under the floor of a body located above.

In Miass, a special design bureau was created for a promising machine, led by engineer Titkov Anatoly Ivanovich (now alive) in March 1957. To exchange experience and quickly put the machine on a conveyor, at least twenty development specialists of the future Ural moved from NAMI to Miass. It would seem that everything is ready for the development of production. But then the Ministry of Defense intervened in the GABTU - their plans for the car changed.

Gold medalist

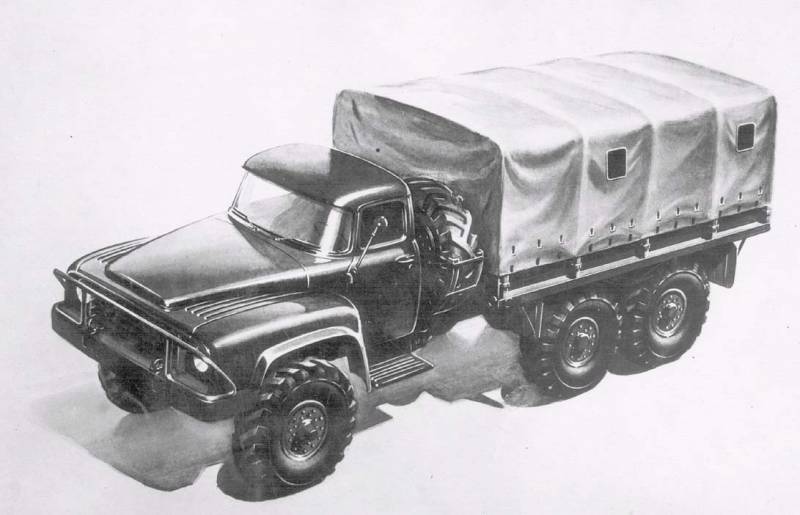

In Miass, the first joint development with NAMI specialists was the truck with the long name "UralZIS-NAMI-375", dated 1958. Here we already see the future index of the legendary truck and the old name of the Ural Automobile Plant. The car, by the way, was redesigned according to the requirements of the military.

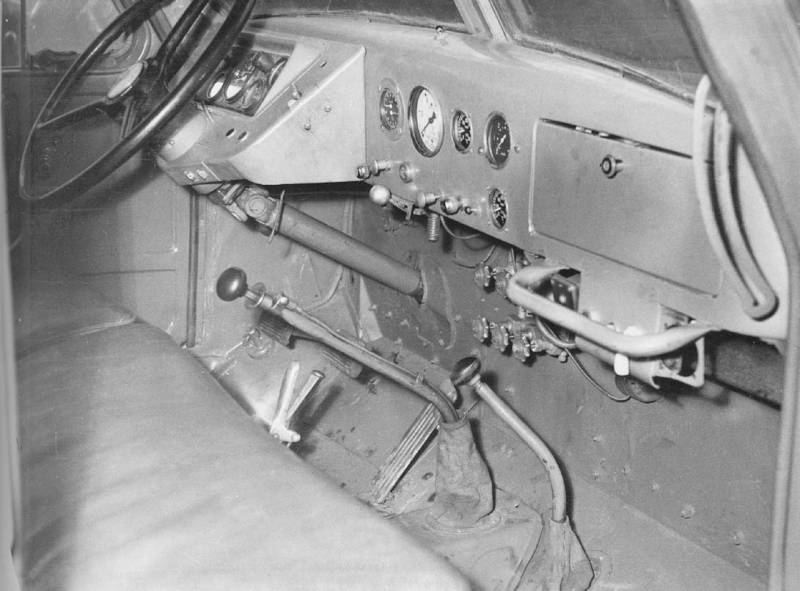

Firstly, the front and rear axles were unified, which forced the engine to be raised, and this led to a change in the front of the cab. Now all the crankcases of the main gears were located in one line, which had a positive effect on the patency of the truck. Secondly, the gas cabin was removed and a hybrid made of ZIL-131 with the famous panoramic glass (divided, however, into two parts) and the front end of its own design. The steering, front suspension, a reinforced frame and new wheels have also been changed compared to the NAMI-020.

After improvements, “UralZIS-NAMI-375” drove to the test, which showed that everything is bad and unreliable. In the book of Yevgeny Kochnev “Automobiles of the Soviet Army 1946-1991.” It is indicated that only a part of the transmission and tire inflation system remained alive after the test cycle. I had to modify the car, and at the same time bring it into line with the newly changed requirements of the main customer.

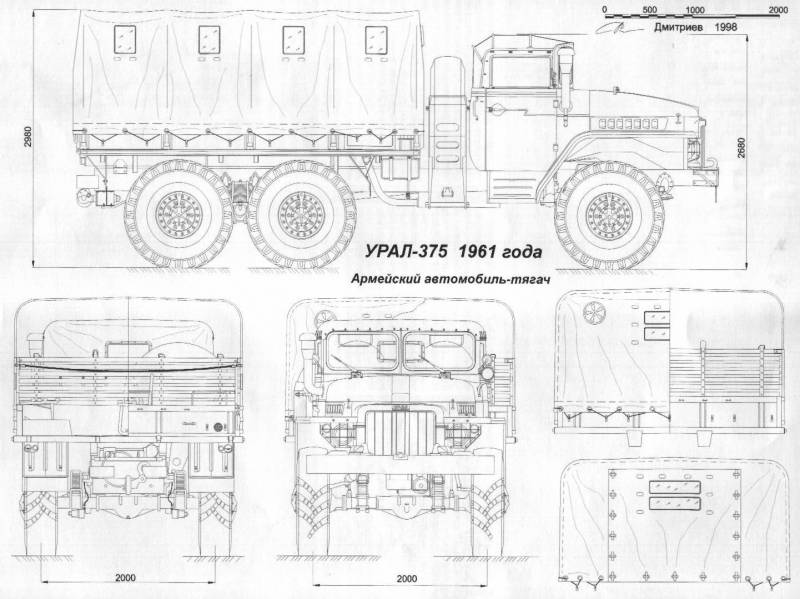

I must say that the first real Ural, which received the 375T index, was released quite quickly after large-scale alterations - already in 1959. It is interesting that the cabin was now with a cloth top and hinged windows, but this was not done for the airlift of the truck. The main goal of this innovation is to enhance the anti-atomic resistance of machines buried along the line of windows in the ground. In addition, all transmission and frame components were reinforced, and the engine was modernized.

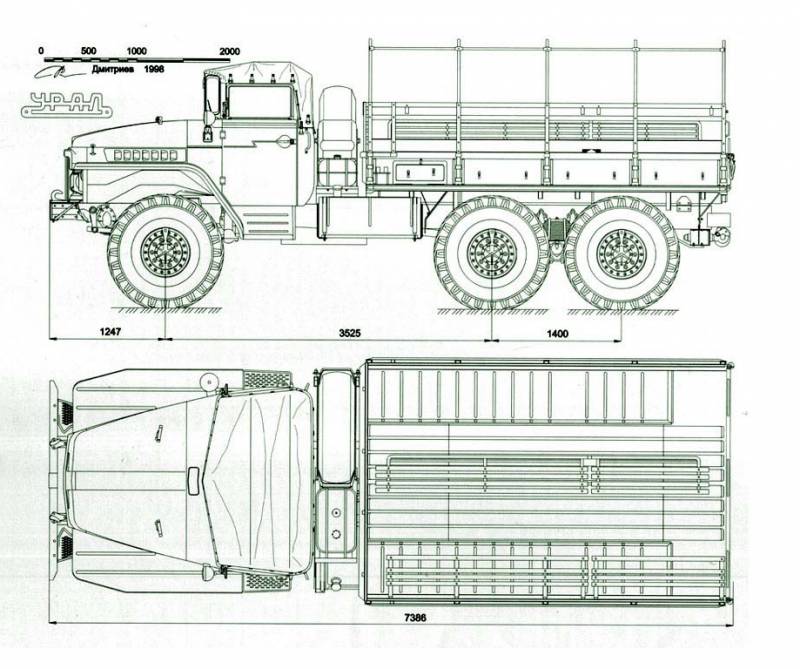

Strictly speaking, the Ural-375T was a pre-production vehicle in the “transport” version, that is, with an elongated wooden body, but the Ural-375 was an artillery tractor, which went into production on January 31, 1961. The tractor was designed to tow 5-ton trailers off-road and 10-ton on solid roads.

Among the borrowed serial trucks were units from the MAZ-200: single-plate clutch, gearbox, front suspension, towing unit, pneumatic equipment of the brake system, middle axle drive shafts, steering gear and intermediate cardan. Even the Moskvich-407 car shared with the giant the universal joint of the driveshaft, which the Urals used in the steering shaft. SHRUS also were in design "seamless" from the timber truck MAZ-501. Zilovtsy gave the Urals individual components of the tire inflation system, since they were almost the only ones in the world who knew how to make them. The motor was also a Moscow ZIL-375 with a capacity of 175 liters. from.

What was its Ural in “Ural”? In fact, only a transfer case, center differential and spring-balancer suspension. Having absorbed all the most progressive of the domestic auto industry, the Ural-375 hit the conveyor with a frankly crude machine. During the pre-series state tests, a paradoxical thing happened: the order to put the car in series was signed before the end of the research cycle. At the same time, the truck did not behave off-road in the Chelyabinsk region in the best way. The clutch broke down, radiators flowed, electrical equipment failed, springs and shock absorbers broke, and the main problem was the brakes that jammed and overheated ... One vehicle on the downhill in a mountainous area had brakes, then a hand brake, and when trying to brake the engine at speed under 90 km / h clutch disintegrated. Only by a miracle the driver was able to keep the car to a complete stop on the road.

With all the depressing results of state tests (tens of pages of comments were the result), the Miass plant received a plan for 1960 to produce 300 cars. The army's demand for an artillery tractor of this class was very high, and, obviously, the State Academic Technical University decided to correct the shortcomings already in the production process. This case dragged on for several years, but in 1969 it was crowned with international success: Ural-375D received a gold medal at an exhibition in Leipzig.

To be continued ...

- Evgeny Fedorov

- denisovets.ru, kargoteka.info, autowp.ru

Information