To replace M4 in the US Army: not HK416!

Many media are already discussing this news, we also have an opinion on this topic. Perhaps the main event today in the world of small arms. Agree, to rearm such a colossus as the US Army - this is not a dozen Armats for you to release for parades. These are such amounts that not only children can live on, but also grandchildren, great-grandchildren of gunsmiths.

Therefore, in fact, the movement began serious.

In general, the idea of replacing the tired and outdated M4 has haunted everyone in the Pentagon for a long time. There is nothing supernatural here, it is necessary to change. In the 21 century, M4 is generally not comparable to anything else.

In the process of finding a replacement, we decided at the same time to update the FN Herstal M249 machine gun, also known as SAW. By the way, SAW is an abbreviation for Squad Automatic Weapon, “saw” here is rather a successful game of letters. Also nothing of the kind, we change the rifle, it makes sense to look at the machine gun. There is a certain logic, especially if there is a choice of models and money.

With the money, as you know, in the USA there is no problem with the word “completely”, with models ...

As an alternative, such models as HN416 for M4 and FN417 for M249 in the hope of "weighting" a machine gun in caliber 7,62 were considered.

Both versions of the weapon have the ability to change the barrel length by replacement. It is worth noting that the guys from H&K are desperately trying to take over the US Army market, so they even offered such strange solutions as the XM-8, which was supposed to combine both a light machine gun and an assault rifle.

Yes, the German experience with the HK G36 can be traced completely.

However, none of the proposed samples did not suit the Pentagon. Large-scale rearmament did not happen.

Now it's worth talking about the days of today.

Today only affirmed the need to upgrade the weapons of a US Army soldier. The need was born and grew into an idea under the PEO (Program Executive Office) soldier program, which is the US government organization responsible for the rapid prototyping, procurement and deployment of equipment for its soldiers.

Its mission is to "develop, acquire, supply and maintain affordable, integrated, modern equipment to improve the dominance of soldiers in army operations today and in the future."

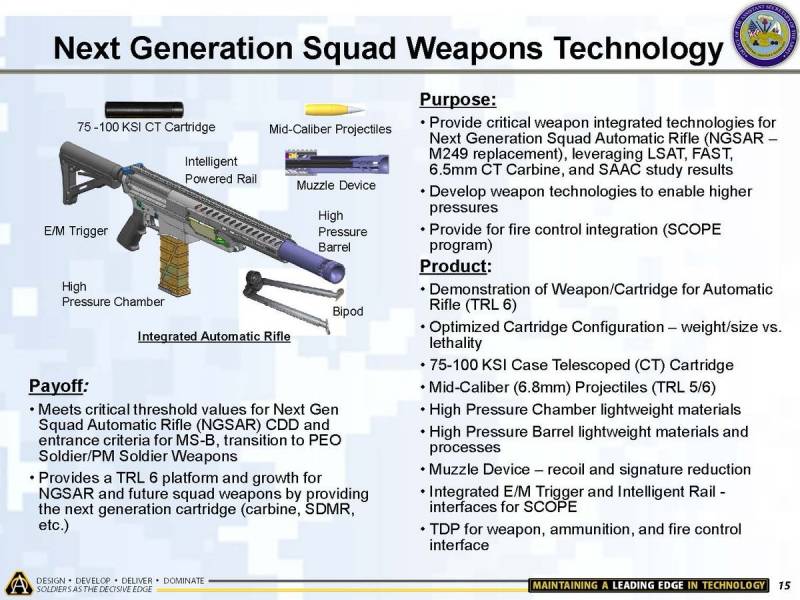

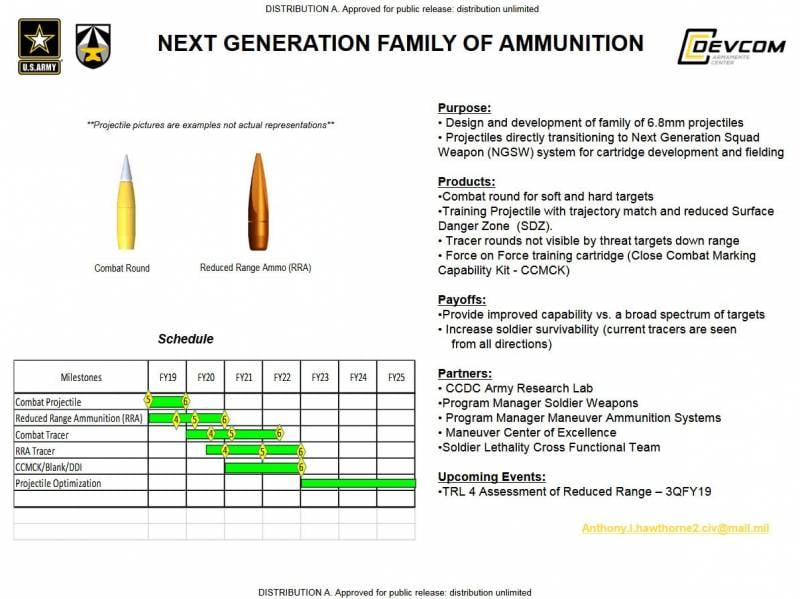

To begin with, let's consider what kind of a promising rifle complex the Americans ordered themselves. We will talk about NGSW-AR (Next Generation Squad Weapon Automatic Rifle) - a new generation automatic rifle and NGSW-R (Next Generation Squad Weapon Rifle) - a new generation rifle, respectively.

Consider in more detail the requirements for rifles.

It is worth paying attention to the decoding of the abbreviation FY, where the figure indicates the year for which "everything should be ready." Pretty fast program.

Excerpts from the terms of reference on the example of NGSW-AR

So, KPP (Key Performance Parameters) are key parameters that are mandatory for execution as part of the technical specifications.

1. Strength.

NGSW must be resistant to chemical, radiological, biological and electromagnetic effects.

2. Ease of learning.

The ability to train soldiers in fire training with minimal time and resources.

3. Accuracy.

The system should provide the accuracy requirements specified in closed annexes to the terms of reference.

4. Weight.

The maximum weight (taking into account tactical equipment) should not exceed 5,4 kg (preferably not exceed 3,6 kg) without ammunition and a magazine.

5. Ammunition Weight

The weight of the ammunition must be at least 20% less than the current ammunition.

KSAa (Key System Atributes) - key system attributes – requirements recommended for execution, but not critical enough to include them in the KPP list.

1. Reliability.

The system should function in all climatic conditions (cold, heat, normal conditions, with strong exposure to sand and dust)

The barrel resource in the accuracy-scatter ratio is not more than 10% on 10 000 shots.

2. Rate of fire.

Recommended rate of fire is 108 rounds per minute for 9 minutes 16 seconds and 300 rounds cyclically without changing the barrel. We translate - this is the so-called combat rate of fire. Why exactly 9 minutes and 16 seconds - so far no comment.

3. Shooting modes.

At least automatic and semi-automatic fire. It is recommended to provide a shooting mode with a cut-off on the 2 cartridge. Accuracy of shooting for automatic and semi-automatic fire is not more than 1 MOA.

The final result was the participation of companies: Textron Systems, General Dynamics Ordnance and Tactical Systems (GDOTS), VK Integrated Systems, Sig Sauer, Cobalt Kinetics.

Heckler & Koch, as you can see, didn't make it to the final. Alas and ah, but true. And here are the finalists.

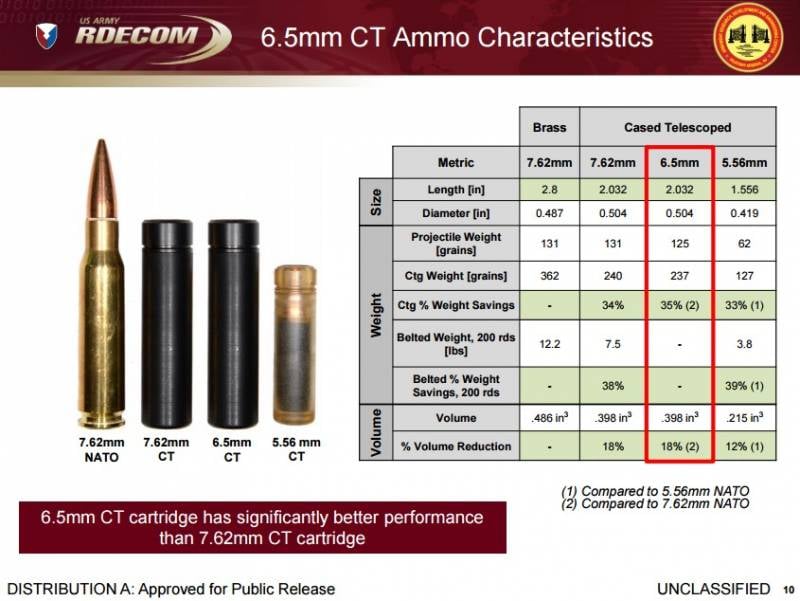

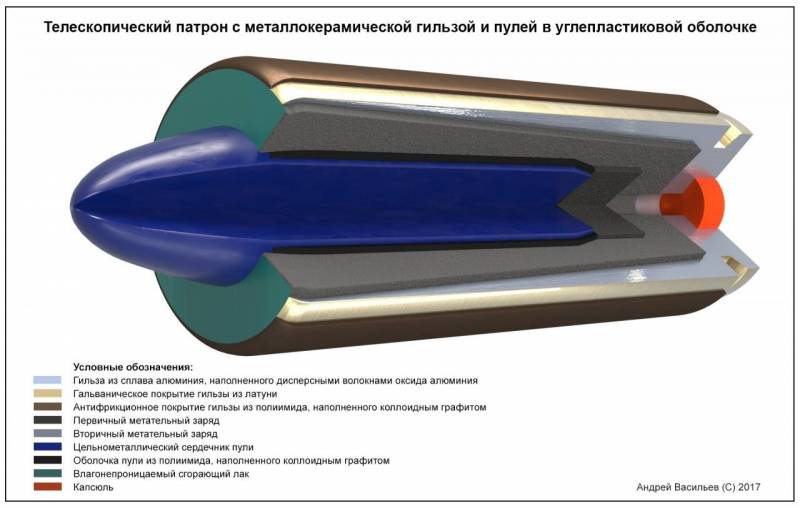

But with the ammunition, the guys at their Textron are more and more interesting. They used a multi-caliber telescopic cartridge system called Textron 6.8 CT and 7.62 CT. But we’ll talk about cartridges separately, there’s just not enough room.

Quite a bold decision. For all its external resemblance to a revolver, it has nothing in common. Its main feature is a double throwing charge: the primary one pushes the bullet out of the sleeve into the barrel channel, and the secondary one accelerates it.

An entertaining movie from Textron Systems with a demonstration of work:

Offer from General Dynamics Ordnance and Tactical Systems (GDOTS) with 6.8 True Velocity cartridge.

It is interesting because the complex uses an integrated silencer of its own design, which is made by laser welding of cermet alloys, which of course increases the cost.

As a result, Textron, General Dynamics and Sig Sauer reached the finals. The US Department of Defense has entered into contracts for the supply of pilot shipments of weapons and ammunition with all three firms.

Finally, the winner of the competition is Sig Sauer with the 6.8 Hybrid round hybrid cartridge.

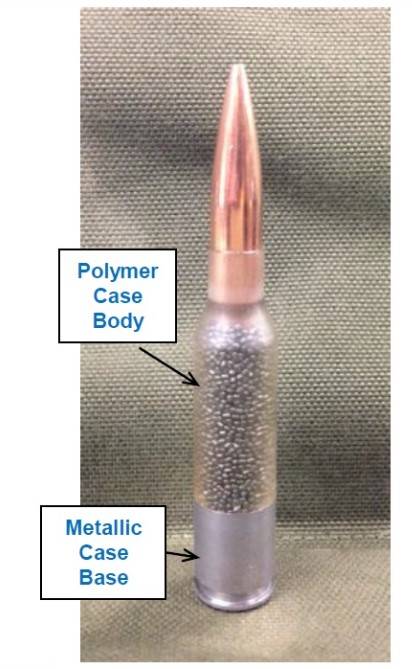

In this case, the hybrid cartridge is interesting in that it has a multi-component sleeve (a polymer body with a metal capsule).

As a result, we see something completely different from what we planned and predicted even last year. Heckler & Koch did not win, we can say today that the victory is celebrated by the German concern Sig Sauer. The Germans were not afraid to bet on real innovations and developments exactly at the level of the 21st century.

Where did we decide that innovation and latest developments? If such really interesting projects were lost to the Germans, it remains only to puzzle over what is hidden inside the development of Sig Sauer. But you have to wait, unfortunately.

You can argue and argue for a long time (which we will do in the near future) over how effective the German system is and how weapons from Sig Sauer can provide an advantage for the American army, but the fact remains: the first step has been taken by the Americans. And he will lead to the superiority of the American soldier over any enemy or not, time will tell.

Information