Military maintenance and repair: long-range or short-range prospects?

For the modern commander, one of the first tasks is to ensure the readiness of the weapons and equipment of his unit to work at any time. The lack of a sufficient (read: full-time) amount can mean a decrease in firepower or the ability to concentrate warheads of the correct size in the exact place and at the exact time. Maintaining high combat readiness is especially critical for troops participating in expeditionary operations. Here, the commander is very limited by the forces and means delivered by sea or by air, he must maintain all systems in good condition and be able not only to carry out operations, but also to maintain sufficient potential until reserves are replenished. During maintenance and repair, the expeditionary units face unique problems that the units do not encounter with the traditional rear workshops, since most of the work should be carried out on the principle of "self-sufficiency." Undoubtedly, the systems are becoming more complex, their repair and maintenance are becoming more complicated, but at the same time technologies appear that simplify this work and allow it to be done faster and at a lower organizational level.

Integrated Health Monitoring Systems

In the past, maintenance was carried out according to a schedule based on specific periods of time, for example, annually or after reaching a certain number of kilometers or hours. This routine maintenance often did not reflect actual depreciation or need. On the other hand, repairs were made only when a malfunction really happened and something broke. A malfunction could have occurred during the operation, depriving the commander of the failed component before the repair was completed. An integrated state monitoring system (ISMS) allows for predictive maintenance and repair due to the continuous collection, storage and cataloging of data on the use and condition of various components of a machine, aircraft or other subsystems.

This database is then analyzed either by the on-board computers or downloaded by technical specialists and compared with a large database of statistical data to determine the possible failure of the component.

The vice president of North Atlantic Industries, an IMSC manufacturer, said that “after identifying likely crashes and failures, appropriate corrective actions can be taken. The solutions we offer allow maintenance personnel to better predict service based on the actual characteristics and condition of the component itself or its parts, rather than waiting for the component to fail. ” IMSCs can be integrated into a wide variety of platforms, but their use in aircraft and vehicles is especially attractive. They allow you to get new opportunities, including increasing the efficiency of maintenance and repair and at the same time significantly reduce downtime.

The practical value of continuous monitoring of the parameters and status of subsystems was demonstrated by a representative of Bell and Boeing in describing the IMSC integrated in the next-generation V-280 Valor tiltrotor. The V-280 tiltrotor system not only detects a broken node, but can automatically report it to a service team on the ground even during its flight. With this information, staff on the ground can get everything they need and make repairs immediately upon returning the machine. With the advent of wireless digital data networks and integrated messaging, the same capabilities can be built into almost any system. Predictable repairs can prevent and correct the problem in advance.

Built-in on-board diagnostics

When combining ISMS and local data processing, you can get built-in on-board diagnostics. On-board diagnostics provide the crew with an initial indication of a possible malfunction or breakdown, and is also the basis of a more in-depth analysis by technical staff. These systems continuously monitor and in some cases record history the work of various key components of the main platform. As a result, they allow you to detect problems in advance and fix them before something more serious happens. Oshkosh Defense's Command Zone system includes on-board diagnostics as part of a wider, platform-integrated digital network. The Command Zone can not only carry out self-diagnostics, but also periodically or if necessary report its status to external monitoring devices. Thus, the availability of the system largely depends on the knowledge of technical personnel who can evaluate and plan preventative maintenance. The result is a pure “conditional service”, which can lead to preventative maintenance, increasing the level of readiness of the system for the proposed operations.

Quick change blocks

From the fact that maximizing the availability of systems is the main goal of maintenance and repair work, it directly follows that the time and effort necessary to return a system, especially a critical combat system, should ideally be minimal. A good solution here would be the concept of quick-change blocks. According to her, the components of the designed system should be easily accessible, easy to remove and replace. The quick-change component is repaired later, the attention of the technical staff at the forefront is aimed at the speedy return of the entire system. Originally adopted in aviation, this practice has been universally carried over to land and sea systems. A representative of Denel Vehicle Systems explained that “optimization for maximum operational availability is the main goal of our combat vehicle projects. For example, the RG35 armored car implemented a quick replacement of subsystems with a minimum number of operations. " The suspension can be replaced by loosening just four bolts, and even the dashboard can be removed and replaced in less than 15 minutes. The quick-change blocks method is equally useful in eliminating combat damage, since it allows you to make repairs on the front line, which otherwise would be impractical or would require evacuation of the machine to the rear.

3 Д print

It is very important to have the necessary part for repair. The deployed troops can take with them only a limited number of spare parts, so if the required component is not at hand, then it is impossible to make repairs. Over the past few years, 3D printing technology has been thoroughly studied. which allows you to make a specific part in place even in the field. The head of one of the projects at the US Marine Corps Systems Development Division explained that “ZD technology, also called adaptive, allows you to print one part if necessary. These technologies and processes essentially transform digital files into physical objects. A digital file can be created by scanning an existing object or by using an automated design system. The program sends instructions to the ZD printer, which prints the object, adding layers of material until a finished product is obtained. ”

In the 2014 year, the U.S. Navy began using ZD printing on board its ships to replicate the necessary parts. Since that time, the Marine Corps and the US Air Force have begun to integrate these capabilities into their service and logistics structures. The U.S. and Indian armies have also begun implementing programs to integrate direct digital production into their supply systems. The main advantage here is that it is possible to deliver parts to the user faster, which reduces downtime while waiting for repairs. In addition, it is possible to transfer digital data necessary for reproducing the part from remote production to the user's position, which also speeds up the repair process. This method is also suitable for the production of parts for obsolete equipment, which is no longer manufactured and for which spare parts are difficult to get.

The use of 3D printing is particularly attractive to expeditionary forces. Using on-site ZD printing can eliminate the need to transport spare parts stocks and reduce costs, and help increase the effectiveness and combat readiness of troops. Since some supplies can be invented in the field, this will make the armed forces more innovative. In addition, ZD printing requires cheaper raw materials, rather than finished products.

The U.S. ILC has already demonstrated the 3 X-FAB deployable printing system. It includes computers with CAD software; repository of digital drawings for 3D printing; manual 3D scanner; uninterrupted power supply unit; Widescreen 3D Cosine Printer; 3D printer LulzBot TAZ; and the Markforged desktop composite printer; all of them belong to the class of extruder machines. Although the complex is currently capable of manufacturing parts only from plastic, plans are being hatched to include printers that print parts from metal powder. Parts manufactured by the X-FAB complex become available in just a few hours, unlike receiving them through the spare parts ordering system, which can take days or weeks.

3D printing becomes even more attractive when combined with the IMSC and the real-time fault reporting system. The ability to have on-site production of parts reduces concerns that the necessary parts may not be available.

Consumables in place

The need for self-sufficiency is not limited to details. Many categories of military equipment, including vehicles, aviation and artillery, require various liquids or special gases for the operation of their subsystems, for example, suspension control, rollback mechanisms, fire extinguishing systems, day optics, night vision systems and even tires. They can be delivered to places of permanent deployment by the supplier, which is called directly “to the door”. During deployment or in field camps, technical personnel should have these substances available, many of which are harmful and dangerous during storage and transportation, especially in the combat zone. The possibility of obtaining these substances as necessary and as close to the consumer as possible allows for the most part to eliminate these dangers and at the same time guarantee the availability of the product at any time.

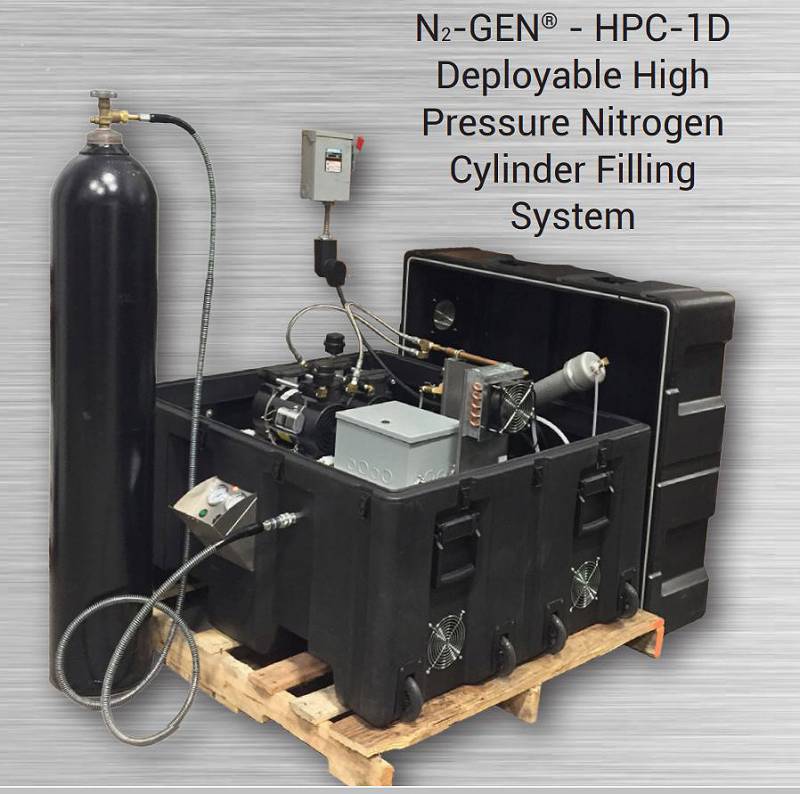

One such substance is compressed nitrogen. It is used in night vision systems, suspension systems, helicopter racks, various control systems, fuel tanks and tires. drones and aircraft. Heavy compressed nitrogen cylinders are difficult to handle and pose a hazard if damaged. “The Marine Corps was the first to deploy field-deployed nitrogen generators,” said Scott Bodman of South-Tek Systems. “It has integrated our compact stand-alone N2 Gen low-pressure nitrogen unit into its optoelectronic systems in Iraq and Afghanistan. These field workshops included everything needed to maintain and repair sights and night vision devices. The N2 Gen generates nitrogen from the air, runs on portable power, and provides consumers with nitrogen anywhere, eliminating the need for external suppliers. These systems allow infantrymen to quickly repair and return sights and night vision devices back to the soldiers. The increasing use of advanced active pods and the growing use of nitrogen in military applications has led South-Tek to also develop a fully deployable high pressure nitrogen system, designated the N2 Gen HPC-1D. Operating from a common power grid or generator, the system can operate both at military bases and in the field. The system produces nitrogen for combat vehicles such as the Stryker and AMV, the latest tactical trucks with advanced suspension such as the JLTV, artillery pieces including the M155 777mm howitzer, and aircraft and helicopters.

Often, due attention is not paid to loading fire extinguishing systems in the field. This includes, for example, fire extinguishing tanks of automatic fire extinguishing systems for military and tactical vehicles, airplanes and helicopters, as well as hand-held fire extinguishers. To obtain these capabilities in the field, the U.S. Army has developed the FSRS (Fire Suppression Refill System) refueling system. The entire system is located in a durable container that can be mounted on an airplane or ship and placed on a trailer for transportation by land. A spokesman for the US Army’s Armored and Motor Vehicle Dept. noted that “a malfunctioning fire extinguishing system on the platform means the platform cannot be operated. FSRS ensures that front-line technicians can repair the system without delay and put it back in service. The first FSRS systems will be deployed in the U.S. Army in 2019.

Maintenance and Repair Using Augmented Reality Tools

The increased complexity of military systems has increased the complexity of their maintenance and repair. This, combined with the need to carry out these actions at the lowest level and even more advanced to the forefront, where resources are more limited, creates great problems for technical staff. The main question is how to give these specialists the competencies to perform the basic tasks necessary in order to return the aircraft, vehicle, weapons system and other property to service. One of the proposed solutions is to use the capabilities of “virtual reality”. Increasingly using simulations for training, Krauss-Maffei Wegmann has expanded this technology to a dedicated technician. The head of the training and modeling department describes this system as follows: “It’s like a video game with elements of virtual reality, in which the owner of the display helmet sees not only the ZD image of the machine (or other system), but it is also carried out step-by-step through the repair process. It can be a purely virtual style for the learning or familiarization process, or it can be an overlay on a real platform. In the second case, the repairman will go through every necessary step in the process of repair or maintenance. ”

The use of augmented reality technology allows a specialist with greater confidence to tackle any number of tasks, even if he has never done them before. It additionally guarantees the correct execution of the process, which, as a result, eliminates errors that could put it at risk. This is more effective than using printed or even video tutorials, as users are actually immersed in the process. The system also allows the supervisor to remotely monitor the actions of a specialist in real time, indicate errors and give advice. The use of augmented reality technologies in training allows the personnel of repair units located at the forefront or deployed in expeditionary operations to perform a wider range of maintenance and repair tasks without the need for mandatory personnel training for this specific task. As a result, the likelihood of repairs being increased, otherwise, if such technologies are unavailable, it should be postponed due to lack of experience at the repair site. This, combined with the use of ISMS, on-board diagnostic tools and the concept of quick-change units, allows faster (thanks to a lower organizational level) to bring equipment and weapons back into operation.

The future of maintenance and repair

The advent of these technologies has every chance of revolutionizing the process of maintenance and repair, as well as operation. The new and unique additional features these technologies offer will have a big impact on how and at what level these actions are carried out. Involved in the integrated process of servicing, repairing, operating and supplying spare parts, these technologies will increase the independence and self-sufficiency of the advanced forces deployed in expeditionary operations. As a result, faster repair work and, accordingly, faster return of equipment or weapons to the system. In addition, this will increase the number of forces and means available to carry out operational tasks. This new approach to maintenance and repair becomes a factor in increasing combat capabilities and combat power, which can positively affect the ratio of victories and defeats.

Information