Combat aircraft. About aircraft engines, their own and not very

In general, in the 30-40-e years, our industry, of course, just made a huge leap. From direct photocopying, which, in general, is not shameful, but is an indicator of the level of development of the design school in the country, to the steady release of its technology in large quantities and in series.

And if we didn’t have tank building before the revolution, as such, it was bad and poor with aviation. It's bad - because the production of aircraft engines in Russia was not adjusted (let's not take the Gnome-Ron screwdriver assembly into statistics at all, it is not serious), and the most advanced designers like Sikorsky and Lebedev preferred not to get involved with the Bolsheviks.

Yes, Polikarpov, Gakkel, Grigorovich, Tupolev remained, the young ones were growing up, but ... There were no engines as before.

We refer to the memoirs of Alexander Yakovlev. In “The Purpose of Life” he repeatedly quoted his applications for foreign-made engines. And not because the young designer did not like something there, but simply because he didn’t have his own. The fact is, of course, not very comforting.

But, alas, it is hard to deny that in fact ALL Soviet aircraft engines were copies of imported designs.

The purpose of this article is absolutely not put some kind of humiliation of our industry or the labor of Soviet designers, rather, on the contrary. This is a demonstration in numbers and facts of how it came from nothing.

Technical progress is generally difficult. No need to go far for examples, not so long ago, in 1966, in the USSR a car factory was built, which produced outdated Italian cars. And in the 2016 year, however, already in the status of a subsidiary of the Renault Group, cars with disc rear brakes and similar to cars started to go off the assembly line.

Yes, we had previously decided to parade the best, that is, domestic, and to minimize the merits of foreign manufacturers in our technical development. Today, of course, easier.

Therefore, today I am completely normal and without reproaches of non-patriotism, I can say that the air shield and sword of the Land of the Soviets was forged around the world.

Let's start? By screws!

So, how to turn the screws of the Soviet aircraft. It is clear that the engines. And what?

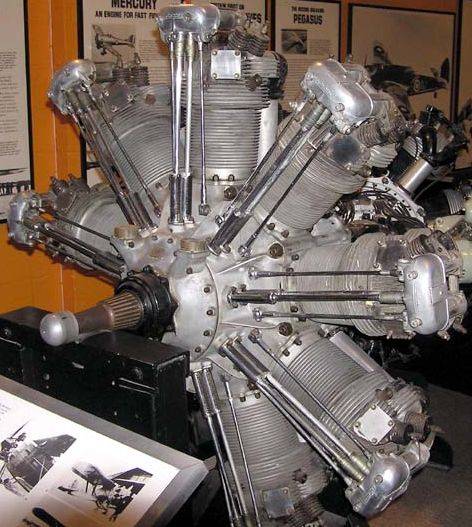

1. Bristol Jupiter. Great Britain.

Nine-cylinder single-row with star-shaped cylinders. Serially produced from 1918 to 1930 years.

Of course, the British just did not present us a motor. On the other hand, they opened production in France under the “Gnome-Ron” brand, and the French acquired the license from the Soviet Union quite normally. So "Jupiter" received an official residence permit in the USSR and was produced until 1935, having won the whole Great Patriotic War. Well, the first half for sure.

M-22 (aka "Jupiter") was installed on the I-16 and I-15.

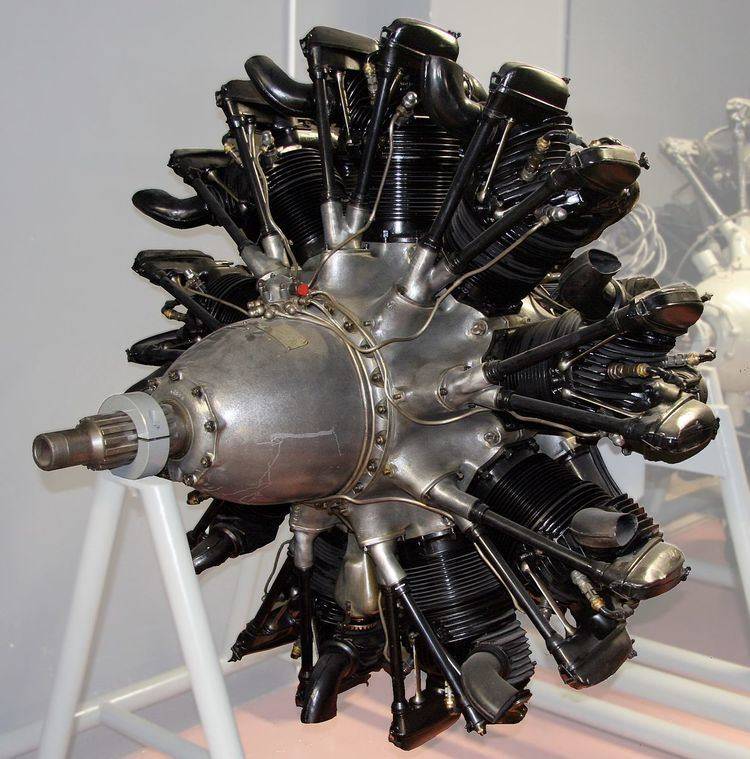

2. Wright R-1820 Cyclone. USA.

Nine-cylinder, single-row, star-shaped, air-cooled. Produced from 1931 to 1954 years.

Licensed produced in Spain and the Soviet Union under the brand M-25.

M-25 installed on I-15, I-15bis, I-153, I-16, COR-1 airplanes.

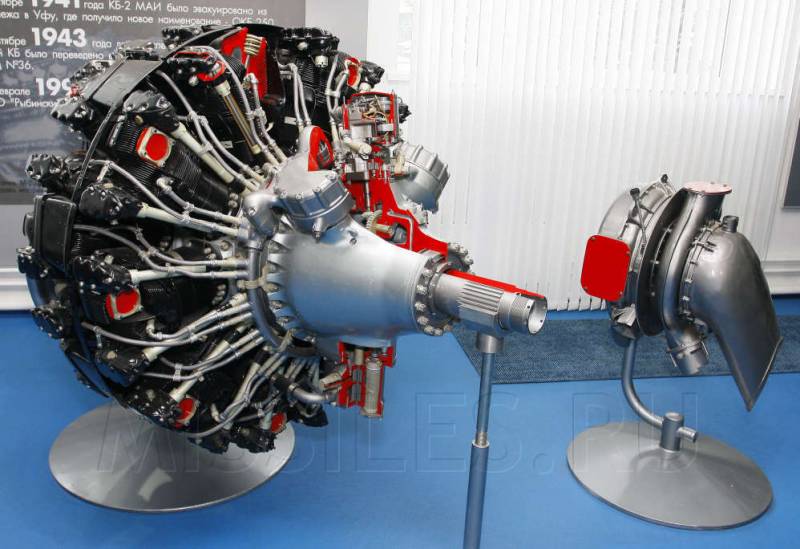

A further modification of the M-25 was the M-62 / ASH-62, which, in turn, came in handy when creating two-row star-shaped engines (ASH-82, for example).

M-62 installed on I-153, I-16 (18 and 27 series, in the basic version without gear), Li-2 and still under the brand name ASH-62IR used on the surviving An-2.

M-82 / ASH-82. Here are some of the difficulties. In principle, who says that this is the development of our engineers will be right. Who says that the engine from the same opera as its predecessors is also right.

The M-82 was double row, but the two rows of cylinders were nothing more than M-62, whose number of cylinders was reduced from 9 to 7. The piston stroke was also reduced, which resulted in a decrease in the diameter of the motor. Accordingly, the decrease in drag. Plus M-82 became the first injection engine of Soviet construction.

In total, more than 70 000 engines of this family were produced.

M-82 installed on:

- bombardment of TU-2, Su-2, Pe-8;

- fighters La-5, La-5FN, La-7, La-9, La-11;

- passenger IL-12, IL-14;

- Mi-4 helicopter.

There was a family of Shvetsov engines, which were “uncut” twin “Cyclones”, that is, 18-cylinder M-71, M-72 and M-73.

M-73 installed on the Tu-4 and Be-6, and, on a flying boat, proved to be just fine, since the Be-6 did not require the installation of a high-altitude compressor.

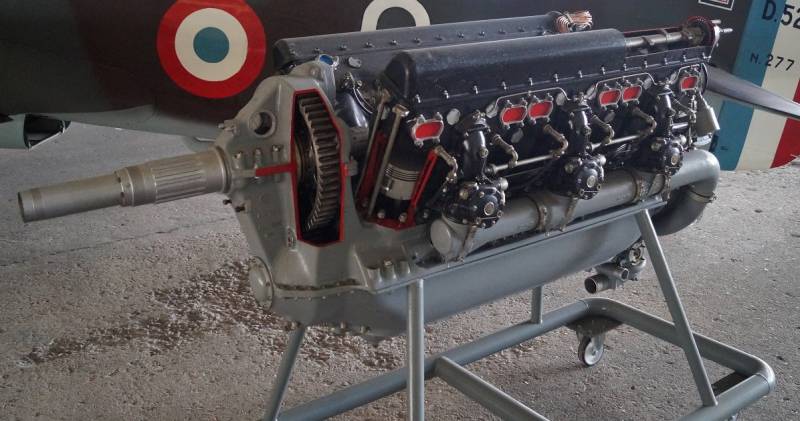

3. Hispano-Suiza 12Y. France.

12-cylinder V-engine liquid cooling.

I have already talked about this motor in the materials about the “Hispano-Suiza” and “Devuatin D-520”. It was also produced under license and refined here, and the HS 12Y became the ancestor of its equally well-known family of water-cooled engines V. Klimov.

M-100. Installed on the SB bombers. Next was a chain of upgrades through M-103 to M-105.

M-105. It was a really heavily modified M-103. The motor had a smaller working volume, an increased compression ratio, a two-speed centrifugal supercharger, two intake (and later two exhaust) valves per cylinder.

In total, more than 90 000 M-105 motors of all modifications were released.

M-105 / VK-105 installed on:

- LaGG-3, Yak-1, Yak-7, Yak-9, Yak-3, Pe-3 fighters;

- Yak-4, Ep-2, Pe-2, Ap-2 bombers.

The forced version of the M-105 engine, which became the M-107, was also released, albeit not by such a huge series, but only a little more than 7 000 pieces, however, it has every right to be on the list.

M-107 / VK-107 installed on the Yak-9U and Pe-2.

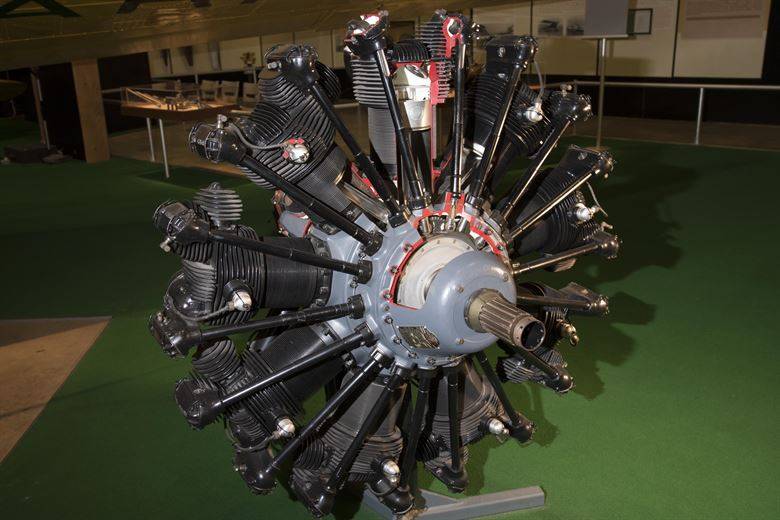

4. Gnome-Rhône Mistral Major. France.

Another star 14-cylinder engine. The licensed copy produced in the USSR was called M-85 and its further modification was M-87. The main designers of the motor were AS Nazarov (M-86) and S. K. Tumansky (M-87).

Motor was frankly weak, but very reliable. In general, it was licensed by everyone who wanted: Italy, Japan, Great Britain, Romania, Czechoslovakia, and Hungary. Even the Germans put the “Major” on their Hs-129 attack aircraft.

In our country, the M-85 - M-87 engines were installed on the DB-3 and Il-4 bombers.

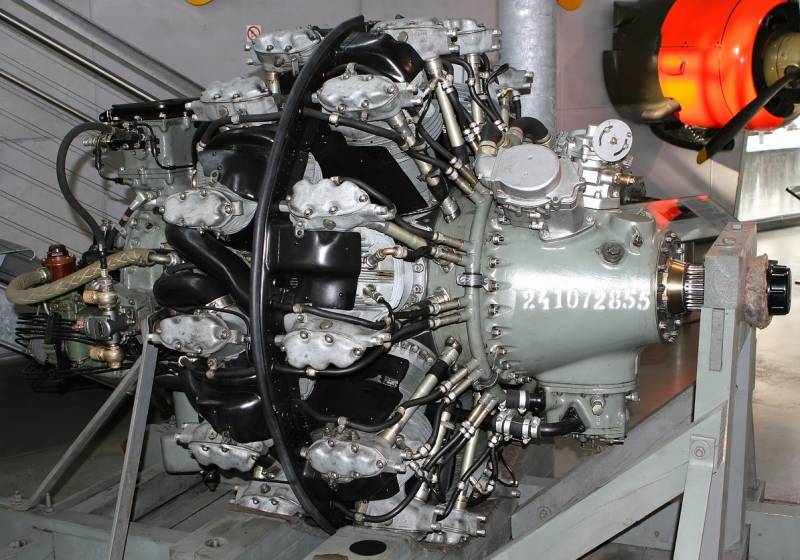

5. BMW VI. Germany.

Another line of engines. The German source, a V-shaped 12-cylinder engine with water cooling, was modified by Alexander Mikulin and went into the series as M-17. We must pay tribute to the Germans, who kindly granted us the right to produce an engine, engines in Bavaria were always able to build.

With this engine flew Non-111 and Do-17, it was released worldwide (Romania, Japan, etc.)

M-17 installed on TB-1, TB-3, P-5, MBR-2.

But the most interesting was ahead, in modifications.

AM-34 we just skip because it was put on all the same models, and flew to America on RD airplanes.

AM-35. Mounted on the MiG-1, MiG-3 and Pe-8. Was released in a series of almost 5 thousands of units.

AM-38. Mounted on the IL-2. In total, more than 40 thousands of engines were manufactured.

Still on many armory and aviation sites, people break lances, how should Mikulin's motors be viewed as independent works or as a copy of a German engine.

The truth, as always, somewhere in the middle will be. If, in fact, the Germans created a decent engine, and Mikulin was a strong designer who made a monster out of a “German” that dragged an Il-2 armored box into one screw.

So controversially here. But I personally do not feel anything unpleasant. Rather, it should be unpleasant for BMW engineers and designers.

Now surely some already wound up, I feel. Author, and what, our engines did not exist? Were

For example, here.

M-11, a miracle motor that literally brought several generations of Soviet pilots into the sky without exaggeration, and during the war they carried everything that was necessary: the wounded, mail, bombs.

The engine was developed by the design bureau of aircraft factory No. 4 as part of the competition for the best motor design for training aircraft with a rated power of 100 l. with., in 1923 year. The head of the design bureau at that time was A. D. Shvetsov. Shvetsov himself, although he was rewarded, never said that he was the author of the design.

The engine did not have outstanding performance, however, it was reliable, like a Mosin rifle, technologically advanced in production, like a bolt, not picky about used fuels and oils.

Someone will say that to put it mildly, it is difficult to compare, but that is what it is. Small and reliable on the one hand and borrowed on the other. Sorry, but there was such a time. No one, unfortunately, gave us either designers or engineers. About the plants even keep quiet.

The fact that, until recently, in our country we could not even think about such a problem as aircraft engines was an achievement. I hope no one will argue with that?

Information