Truck YAG-12. Eight tons on twelve wheels

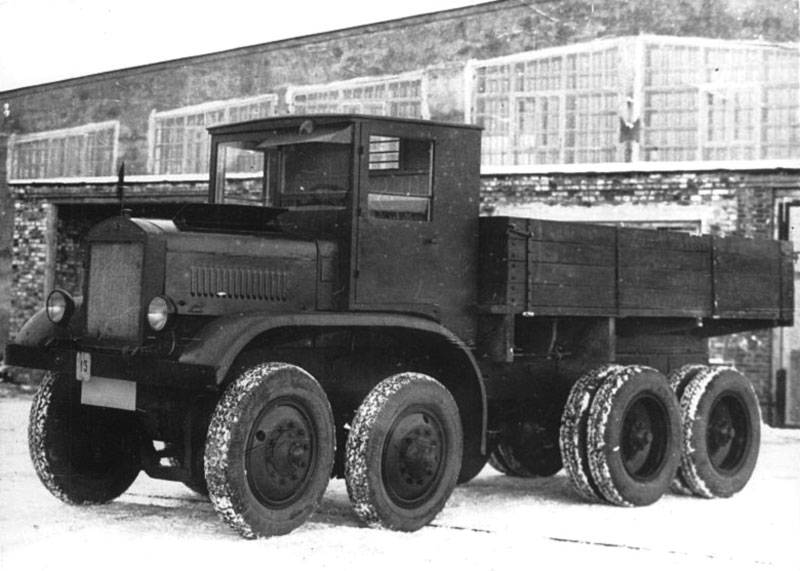

Experienced YG-12 on the factory site. Photo Bronetehnika.narod.ru

At that time, the Red Army command showed great interest in trucks with an increased number of axles. Thus, it was precisely at the initiative of the Red Army that new triaxials were developed, including the Yaroslavl YaG-10. In addition, the military in the 1931 year conducted tests of a four-wheel drive four-wheel drive vehicle of British design and became interested in similar technology. The consequence of this interest was a new order for YAGAZ.

New project

After the completion of development work on the YaG-10 machine, the load on the YAGAZ design bureau was sharply reduced. However, the engineers did not rest and began to implement the new army order. The military wanted to get a truck with an unusual wheel formula 8х8, due to which it was planned to get an increase in maneuverability on rough terrain and off-road.

At the beginning of the 1930s, similar trucks were developed in several leading countries, and the command of the Red Army considered this to be a cause for concern. Thus, YAGAZ should in the shortest possible time create a fundamentally new car and reduce the backlog of foreign industry leaders. The plant had an excellent opportunity not only to catch up, but also to outstrip foreign competitors.

The new project manager was A.S. Litvinov, who already had extensive experience in the development of trucks. A promising car from a certain time wore the designation YAG-12 - "Yaroslavl truck". The numbers indicate the calculated capacity of the machine.

The customer requested to submit the truck as soon as possible, and for this reason YAGAZ KB decided to build a new YaG-12 based on the existing YaG-10. It was planned to use the spent design solutions and borrow various units. At the same time, we had to use completely new components and introduce non-standard ideas.

For example, its own concept of a four-wheel truck with four-wheel drive was formed. The use of four pairs of wheels allowed to reduce the specific pressure on the ground, and all-wheel drive provided increased traction. Abroad, these opportunities were most often used separately: some projects offered middle-class cars with improved throughput, while others provided for an increase in carrying capacity. A.S. Litvinova decided to perform two tasks at once and get outstanding characteristics.

Four bridges

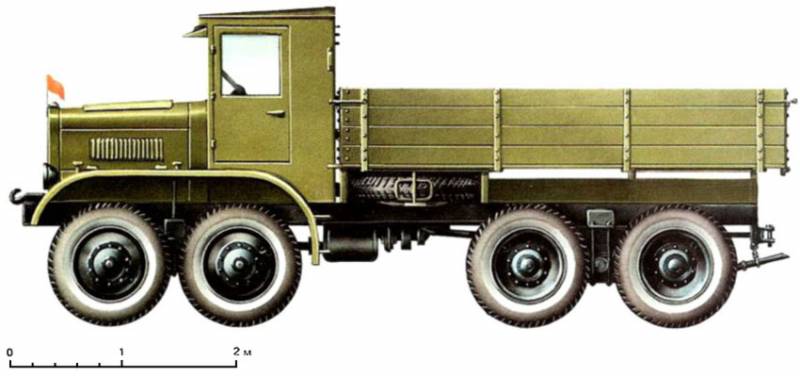

The new YG-12 truck should have to some extent resemble the YG-10 serial. It was proposed to use an elongated frame of channels, assembled on rivets. The back part of it was strengthened by additional profiles. In front of the frame was placed the power unit, behind which was the cabin. The rest of the frame was given for the installation of the cargo area. Under the engine and the cabin on the frame offered to place the front truck with a pair of axles. Two rear axle were under the body.

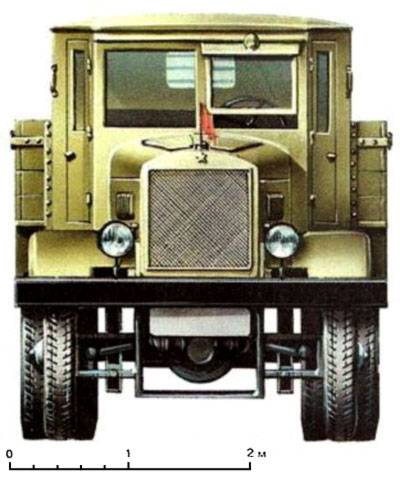

Front view. Well visible characteristic units of the front axles. Drawing "Technology - Youth"

The machine needed a more powerful power plant. For use on the YAG-12, they chose an American-made Continental 22R gasoline engine with an HP 120 power. The multi-plate dry clutch and Brown-Lipe 554 gearbox was taken from the serial YaG-10. The box had 8 forward gears and 2 rear. On the output shaft of the box there was a tape parking brake.

Behind the gearbox, under the rear wall of the cabin, there was a transfer box of the YAGAZ own design. The drive of the main gears of the four bridges was organized using a set of cardan shafts. The shafts from the transfer case went to the transfer of the second and third bridges. Two more shafts moved away from them to drive the extreme axles.

The rear trolley was borrowed from an existing three-axle truck. It consisted of two bridges with gears based on spur gears. The design of gearboxes and crankcases remained the same. The same was true of the suspension. The rear carriage retained the existing brake system with a vacuum booster. A mountain support was installed on the crankcase of the fourth bridge to fix the car on the slopes.

View of the starboard and aft, visible frame device and the location of the units. Figure Denisovets.ru

The design of the front carts developed from scratch. Two main gears with bevel gears were rigidly mounted on the frame of the car. Short transverse cardan shafts connected with open-type hinges of equal angular velocities departed from them. This made it possible to drive the front wheels, as well as to make both front axles manageable. Earlier calculations showed that a four-axle vehicle with the proposed layout needed several steered wheels, and this problem was solved. The front axles were controlled using a modified steering gear from I-5. He was connected to the wheels of the second axle, which through the longitudinal thrusts interacted with the first axle.

Despite the difference in the design of the drives, both trucks had a similar suspension. Under the frame were hung shoes with longitudinal semi-elliptical springs. The ends of the springs were connected to the crankcase CV joints (on the front axles) or with the bridge shells (on the rear axles). A characteristic feature of the running gear used was a slight reduction in the unsprung weight, which allowed an increase in the stock of carrying capacity.

It is worth noting that the designers of YAGAZ had to work on non-trivial tasks in the absence of proven solutions. This led to a serious complication of the transmission: 9 cardan shafts, 18 joints and more 40 bearings were immediately present. In this regard, along with other documentation, special schemes had to be transferred to production to control the directions of rotation of shafts and other components.

On wheels, the YG-12 truck was unified with existing equipment. The front carriage had single wheels, while the rear one was equipped with gable wheels. The wheels were borrowed from serial equipment. The rear wheels could be equipped with detachable Overall type track chains.

The layout of the power plant, transmission and chassis. Figure Bronetehnika.narod.ru

With the transfer case connected additional devices. Thus, under the front part of the body was placed a winch with the possibility of issuing the cable forward or backward. Also, the machine is equipped with its own compressor for pumping wheels. Permanent swapping, however, was not used.

The engine compartment of the new car was covered with an oversized hood, created on the basis of existing products. As before, there was a cellular radiator in front. Top cover was provided with rectangular hatches, on the side - lifting side with blinds. A ready-made serial cabin with three seats for the driver and passengers was used. Under the common seat was a fuel tank on the 164 l of gasoline. On the sides of the hood and cab, a new wing of increased length appeared. Its rear part served as a step.

Cargo platform was made in the form of an onboard body. She took the serial YAG-10, but slightly shortened. The front wall of the body was mounted rigidly, the rest could recline and were fixed with locks. Under the front of the body were transported spare tire and tool box.

YAG-12 on trial. Photo Bronetehnika.narod.ru

Fundamentally new chassis had a minimal impact on the size of the truck. YAG-12 length increased to 6,6 m, width did not exceed 2,4 m, height - less than 2,8 m. The curb weight of the car was 8 t. Estimated carrying capacity on the highway - 12 t, on rough terrain - 8 t. Thus, the total weight of the truck reached record 20 t. The engine of sufficient power allowed to reach speeds up to 45 km / h, as well as to overcome various obstacles. Fuel consumption - 52 liters per 100 km.

Car for the holiday

The development of the YAG-12 project was completed in the middle of the summer of the 1932 year. Soon after, the Yaroslavl State Automobile Plant No. XXUMX began the production of the necessary parts and the subsequent assembly of a prototype. The prototype assembly took about three months. Perhaps the construction of a complex machine could take more time, but automakers decided to present it to the next anniversary of the October Revolution. There was some lag behind the schedule, but in recent days the situation was corrected, and in the late evening of November 3, experienced YaG-5 wound up for the first time and drove off.

The first test for the car was a trip to Moscow to participate in the festivities. By the evening of the following day, the motorcade, consisting of a single YaG-12 and several YaG-10 serials, was in the capital. November 7 Yaroslavl-made cars passed through Red Square. Soon the equipment was shown to the military and political leadership of the country. The commanders highly appreciated the new development for the army and gave the go-ahead to continue the work.

After the holiday, the experienced YaG-12 went to the Scientific Automotive Institute for testing. Over the next few months, scientists and engineers tested the car and installed its real capabilities. Estimated running performance and carrying capacity have been confirmed. In addition, the capabilities of off-road technology were identified. A truck with a payload could climb the slope of the 30 ° steepness, cross the moats 1,5 m wide and the fords 0,6 m deep. The car moved through the snow 500 mm deep and could overcome obstacles of similar height. The use of caterpillars "Overall" significantly increased throughput.

Tests of the truck on a slope. Photo Bronetehnika.narod.ru

The YG-12 machine was also tested as an artillery tractor. With the help of a towing device and, in some situations, a winch, she could carry with her any domestic implements, including large calibers. In the back could carry ammunition and calculation.

Plans and reality

In general, the advanced heavy-duty four-axle YAG-12 truck arranged for the customer in the person of the Red Army command. Minor improvements and refinements were required to improve technical and operational characteristics. As part of the refinement, it was planned to build and test seven new prototypes. After completion of the improvement, the machine could find application in various fields - both in the army and in the national economy.

The main customer, as it was believed in 1932-33, was to be the Red Army. She needed cars in the configuration of on-board trucks, but did not rule out the possibility of creating other modifications with other equipment. A car with a lifting capacity of 12 t could become a vehicle for people, solid, bulk or liquid cargo, or a tractor for tools or other trailers.

Additional front axle simplified overcoming trenches. Photo Bronetehnika.narod.ru

In the interests of the national economy, it was also proposed to build various modifications of the YAG-12. Together with a truck in civilian structures could serve dump trucks, tank trucks, etc. A proposal to create a high-capacity double-decker bus was considered. Previous Yaroslavl trucks had become the basis for buses, and the new car also had a high potential of this kind.

However, all these plans did not reach implementation. The situation around the YAG-12 project and the whole direction of heavy trucks changed dramatically in the same year 1933. After passing the tests at NATI, the only four-axle truck built was transferred to one of the military units of the city of Saratov for further inspection in the army. On this his trail is lost. How long and how YG-12 was used in the new place is unknown. Information about his fate is also missing. Apparently, at some point an experienced truck was written off and dismantled.

Soon after the transfer of the prototype truck to the military tests, the command of the Red Army decided to abandon the further development of four-axle vehicles. This technique had great prospects and confirmed them in practice, but at that time did not look optimal. New machines of the YAG-12 type were more complicated and more expensive than the existing ones, which could hamper their massive construction. As a result, it was decided to abandon the eight-wheeled chassis in favor of existing and manufactured three-axle structures.

Past and Future

Work on the YG-12 advanced truck with an unusual wheel formula and unique technical characteristics did not last too long. The design of the new car started at the beginning of 1932, and the decision to stop work was made before the end of the next 1933. It should be noted that by this time only the Yaroslavl State Automobile Plant managed to develop and build its version of the four-axle truck. Other enterprises either did not deal with such topics at all, or could not advance further preliminary study.

The closure of the YG-12 project had a great impact on the further development of the Soviet automobile and special technology. To the subject of four-axle heavy-duty vehicles and high all-terrain returned only in the middle of the fifties. At the same time, the Yaroslavl Automobile Plant did not participate in the development of new designs - by that time he had been assigned to build trucks of a less daring appearance.

The project of the YG-12 truck took its place in stories domestic auto industry. He confirmed the ability of our enterprises to develop the most daring and promising projects of new technology. However, he also showed that not all such developments can find application in a specific period of time in characteristic conditions.

Based on:

http://denisovets.ru/

http://bronetehnika.narod.ru/

http://sovcarhistory.ru/

Shugurov L.M., Shirshov V.P. Cars Country of the Soviets. - M .: DOSAAF, 1983.

Dashko D. Soviet trucks 1919-1945. - M .: Automobile archival fund, 2014.

Kurikhin O. Premature Masterpiece // Technique for Youth, 1997. No.7.

Information