Truck YAG-10. The first Soviet triaxial

The history of domestic three-axle trucks began in the late twenties, when the command of the Red Army made demands to create a promising heavy-duty truck with the wheel formula 6х4. In 1929, the Scientific Automobile Institute and a number of automotive plants began to work out new topics and prepare for the creation of new types of equipment. Soon, several promising projects were created, and then experienced equipment came to the test. The Yaroslavl YG-10 truck was the first to go to the test site.

Updated five-ton

The engineers of YAGAZ, interacting with US, were quickly able to find the best way to create a promising truck. Serial car I-5 showed very high performance and therefore could become the basis for a three-axle machine. In the shortest possible time, the design bureau of the enterprise reworked the existing project and obtained the necessary appearance of the equipment with the required parameters. When developing a new car, it was decided to use the maximum number of ready-made units of existing cars, supplemented by new nodes. It is noteworthy that the main part of the new parts was borrowed from foreign cars.

The new truck, created on the basis of serial I-5, later received the official designation YAG-10. The development of the project was completed at the very beginning of the thirties, when YAGAZ switched to a new system of designations. As a result, in the name of the car appeared the letters YAG - "Yaroslavl truck". The number indicated the serial number of the project.

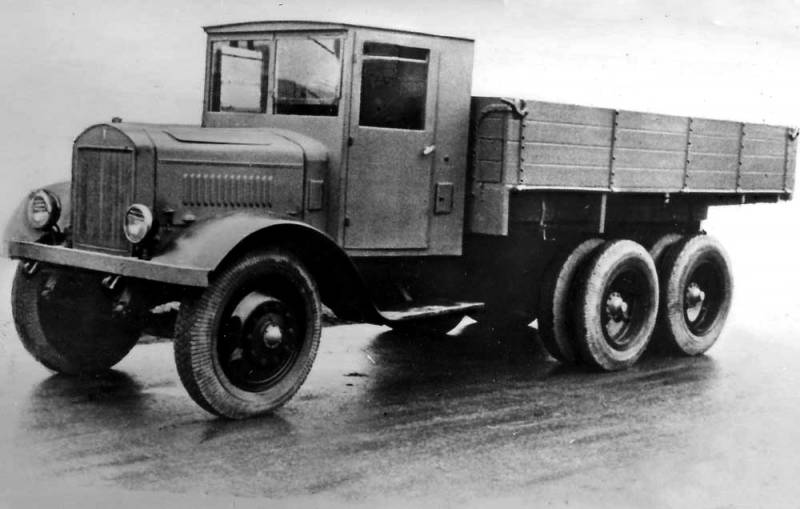

The main element of the YG-10 truck was the reinforced frame of channels. In connection with the growth of loads, its spars were reinforced. On their back from above, above the wheel carriage, additional channels were placed, placed with a shift back. This allowed to increase the length of the frame, but led to an increase in the height of installation of the loading platform. Also on the frame appeared new cross, providing the necessary rigidity. The overall layout of the units on the frame, with the exception of the new rear carriage, was borrowed from previous projects.

From the base I-5, the new YAG-10 was “inherited” by the American-made Hercules-YXC-B carburetor engine manufactured by the HP 93,5. The four-speed Brown-Lipe-554 manual gearbox remained in its place. Two drive shafts that drive the rear axle drive, it was proposed to borrow from the American truck brand Moreland. It is noteworthy that the experienced YAG-10 used these parts, taken directly from the imported machine. Later, the plant has mastered the production of copied units.

The front steering axle for YAG-10 was unchanged borrowed from an existing truck. It was not equipped with the most successful steering mechanism, as a result, it took a large-diameter steering wheel, which still had significant loads. Subsequently, this problem was solved with the help of new mechanisms.

The rear carriage with two leading axles was organized according to the WD scheme, which was then actively used by foreign automakers. Directly to the frame of the car was attached balancers, at the ends of which were placed the centers of leaf springs. The ends of the springs through the shoes with ball bearings were connected with stockings bridges. Also in such a suspension was attended by longitudinal elements that ensure the rigidity of the structure and the transfer of loads on the frame. Part of the parts for the rear truck YG-10 was developed on the basis of nodes "Moreland".

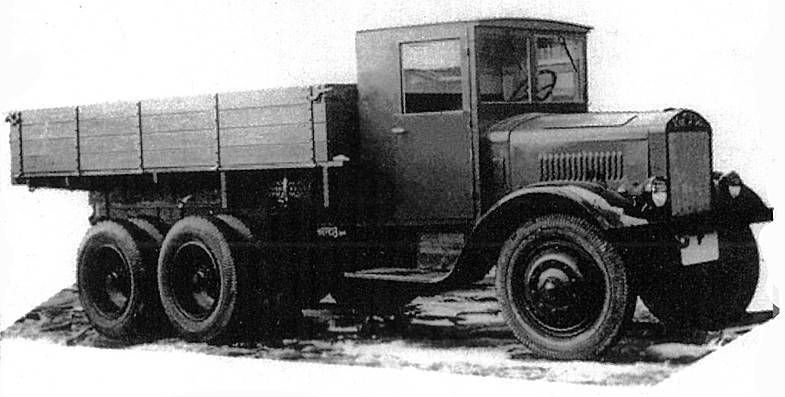

YAG-10, starboard view. Photo Bronetehnika.narod.ru

The rear axle of the YG-10 was the corresponding part of the I-5 machine. The second bridge was developed on its basis and included its own gear with gear. The engine torque from the gearbox arrived at the front axle of the carriage, from which the second shaft of small length departed. The shafts ensured large skew angles, which, in combination with the suspension design, should have provided high cross-country ability in difficult terrain.

Both rear axles had a double-aisle busbar. Unlike the I-5, the central brake associated with the transmission is now used. There was a foot brake with a vacuum booster taken from a previous project. In this case, the brake system reworked. In particular, the rear axles now used a system with two pads instead of the former four-block.

The presence of a two-axle rear carriage gave the car new opportunities. Thus, the designers have foreseen the use of the Overall type of track chains. If necessary, they could be installed on the rear wheels, increasing the area of contact with the ground, and with it the throughput.

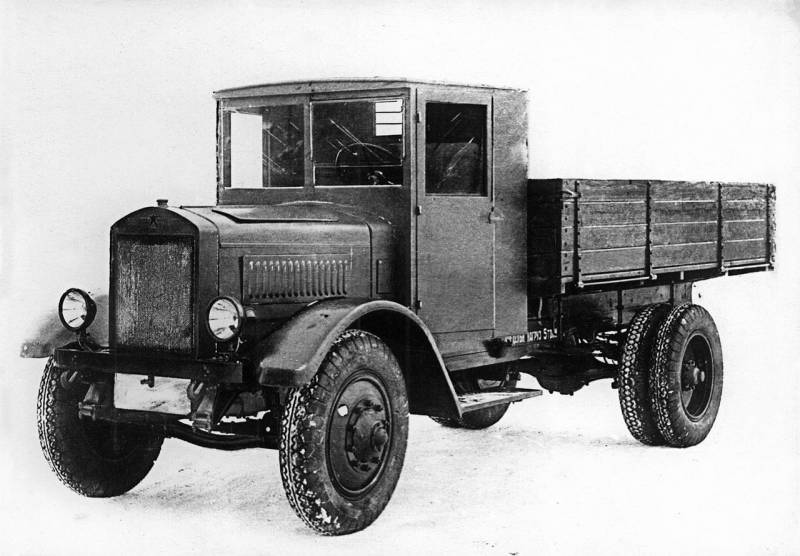

YAG-10 was equipped with the engine "Hercules" and therefore could save the existing hood. Instead of the front wall of the engine compartment, there was a cellular radiator of the existing model, and the side and rear of the power unit was covered with metal panels. For service intended folding side flaps with slits blinds. The fixed lid had a pair of rectangular hatches.

The car retained the old cabin of mixed design, which accommodates three people. The layout, ergonomics, equipment and design of the glazing have not changed. This, above all, contributed to the use of already mastered power unit. As in previous projects, under the driver's seat and passengers was the fuel tank on the 177 l.

The extension of the frame made it possible to slightly increase the size and volume of the cargo platform. Its design, however, generally remained the same. Flaps were hinged to the horizontal plate of the boards. An important feature of the YaG-10 was an increase in loading height. Due to the presence of a pair of additional channels on the frame, the body was raised, which could impede loading and unloading. Also, the modified frame could impede the construction of special equipment on the basis of the existing chassis.

The YAG-10 three-axle truck had a total length of 6,97 m - noticeably more than previous YAGAZ samples. The width was 2,47 m, the height was 2,55 m. The curb weight of the machine increased by almost 2 t and was 6800 kg. The increase and weighting of the truck paid off. The maximum carrying capacity (for work on highways) reached 8 t - it was a record among the Soviet cars of that time. When working on unpaved roads, the payload was limited to 5 t. The increase in weight characteristics led to a reduction in power density, and the maximum speed of the YaG-10 was only 42 km / h. Fuel consumption on the highway exceeded 60 liters per 100 km.

On highways and landfills

The first prototype of the YaG-10 was built by November 7 1931 of the year and went to Moscow in a few days. A few days later the car entered the test. To save time, several machines were checked at the same time. The Yaroslavl truck was to be compared with foreign triaxial samples. Already in the first test trips, some shortcomings were identified. There have also been minor breakdowns.

Bench check moves suspension. Photo Bronetehnika.narod.ru

Tests of three cars, including the first YaG-10, were carried out on the highway of the Moscow region on the streets of Moscow. Trucks loaded in different ways and carried on established routes of varying complexity and length. In addition, tests for permeability, stability, etc. were performed. In general, experts were able to conduct comparative tests and establish the ratio of all the main characteristics. However, in two weeks of testing it was not possible to determine only the real reliability of the equipment.

According to the results of the first stage of testing, NAMI / NATI determined the list of necessary improvements. The new eight-ton truck, in terms of basic indicators, was almost no different from foreign models that participated in the comparison. To improve the technical characteristics and reliability of NATI recommended to make changes to the design of the transmission and suspension of the rear bogie.

The requirements of the Scientific Institute were taken into account, but not all of its proposals came to realization. So, in parallel with the YAG-10 tests passed another truck developed by NATI. He had a main gear based on a worm, which according to test results was recommended for use on a Yaroslavl car. However, soon this unit almost failed the tests, and the YN-10 was abandoned. As a result, YAGAZ improved the system on the basis of gears and obtained the required characteristics.

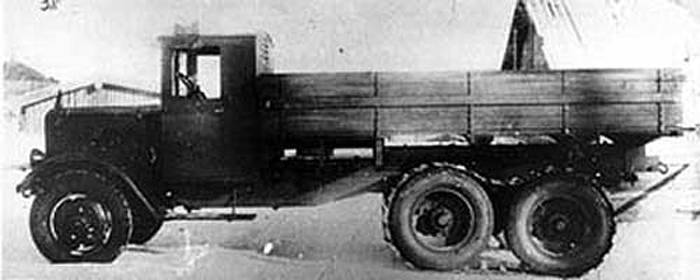

YAG-10 with chains "Overoll." Photo Denisovets.ru

Design improvements did not take much time, and already at the beginning of 1932, the first batch of serial trucks was assembled. 8 February five serial YG-10 drove to Moscow and demonstrated to the leadership of the country. People's Commissar for Military and Naval Affairs K.Ye. Voroshilov got acquainted with this technique and praised it warmly. In addition, he pointed out the importance of a three-axle truck for the army and the national economy. Voroshilov congratulated the YAGAZ designers with success and expressed the hope that the new machines would go into high-volume production as soon as possible and get into the troops.

After the first demonstration, the leadership of the country YAG-10 returned to fine tuning. Improvement of individual nodes was carried out, and minor shortcomings were eliminated. In addition, there have been major innovations. So, shortly before the launch of a full-fledged series, a multiplicator was introduced into the transmission, which allowed to increase the thrust by 40%, regardless of the gear. This gave a serious increase in mobility and terrain.

Machine in series

In the middle of 1932, the triaxial eight-sided YG-10 went into a full-scale series. According to estimates of that time, every year YAGAZ was supposed to produce at least a hundred of such machines. However, limited production capacity did not allow the implementation of these plans. In addition, the pace of construction was affected by the dependence on imported engines. By the time production was launched, full-scale deliveries of the Hercules engines had ceased, and this had become a threat to the new project.

Tests of the truck in a semi-tracked configuration. Photo Bronetehnika.narod.ru

The military wanted to continue to produce trucks and pressed on the leadership of the automotive industry. Almost all available Hercules-YXC-B engines and related equipment were reserved for the YaG-10 engines. This led to a halt in the production of two-axle I-5 machines and the subsequent appearance of the new YaG-3 truck. The stock of imported units allowed to continue the production of YG-10 until 1934-35. Using this stock, 1932 machines were assembled in 35, 1933 were assembled in 78, and in the following two years YAGAZ passed 50 and 15 machines, respectively.

However, having exhausted the stock of engines, production did not stop. Several dozen trucks were built each year up to the 1939 year. The new peak of release came in 1936 - 75 machines. The latest 4 instances were built already in the 1940 year. Engines for these machines were purchased under separate contracts in relatively small quantities. At the same time there were curious processes. Thus, the Azneft organization needed powerful trucks, but YAGAZ could not deliver them. To solve this problem, the oil companies independently purchased the necessary components from the USA and sent them to Yaroslavl.

In 1936, the project YAG-10M was developed. It provided for the use of a new ZIS-16 engine and a different transmission. In the near future, such a truck was supposed to enter the series and solve the problem of engines. However, only 10 prototypes were built. The reasons for this are trivial: Plant them. Stalin was able to satisfy only his needs and could not supply engines to other enterprises.

Taking into account the needs of customers, YaGAZ produced the YaG-10 cars in the configuration of an onboard truck and chassis for the installation of special equipment. Up to and including 1940, the company assembled 158 trucks and 165 units of equipment for re-equipment.

Operation and refinement

YG-10 trucks and chassis were shipped mainly to the Red Army. Onboard trucks were used as transport and artillery tractors. The car was praised for its high loading capacity and the ability to tow large trailers — first of all, large caliber implements. In some situations, the permeability was insufficient, but the carrying capacity fully compensated for these shortcomings.

A number of trucks and chassis were converted into original self-propelled anti-aircraft installations. A new metal platform with jacks, a machine tool and an 76-mm anti-aircraft cannon was mounted on the frame. 1931 3-K. This ZSU could in a minimum time to go to a given area and quickly deploy. Unlike the towed guns, the gun on the truck chassis could start firing almost immediately after arriving at the position. Anti-aircraft machines based on YAG-10 remained in service until 1941-42 and managed to take part in the Great Patriotic War, providing anti-aircraft defense of some objects.

Also in the army used cars with vans. Such equipment carried radio stations, performed the functions of command and staff vehicles, transported the wounded or solved other tasks.

YAG-10 found application in the national economy. Thus, tank trucks for various purposes were built on the basis of a truck chassis. Such machines transported fuel and water, and could also carry special equipment - fire pumps, etc. Among the fire engines based on the Yaroslavl chassis, the NATI-YAG-10 self-propelled autopump is of particular interest. In 1934, the Azneft organization ordered the development of a fire engine with a pump capable of extinguishing complex fires in the fields. It is for the construction of such equipment that the oilmen independently purchased the necessary engines abroad.

The fire option for Azneft received an open cabin, behind which there was a tank for 4,5 tons of water and two pumps. The drive of the first was carried out from the car’s own engine, and for the second it was provided for a separate Hercules-YXC-B type motor. The latter was in a characteristic feed hood. According to various sources, several such vehicles were sent to the Azerbaijan SSR.

Tank truck with a pump designed for Azneft. Rear view, in the foreground - an additional engine for the pump. Photo Autowp.ru

Despite the delivery of technology in the enterprise of the national economy, the major operator-vosmitonok car type PT-10 was the Red Army. Almost all of this technology remained in service at the start of World War II, and in the first months suffered serious losses. In the future, the active use of machines led to increased wear and known results. No later than mid-forties, all or almost all of the PT-10 were lost or written off by the development of the resource. Not one such car, unfortunately, has been preserved.

First of its kind

From the end of the twenties, the Red Army Command demanded the creation of its own three-axle trucks with high payload. This task was solved by a number of domestic automakers, but the Yaroslavl State Automobile Plant was the first to cope with it. His YaG-10 first came to the test and one of the first to enter the series.

Nevertheless, the Yaroslavl project depended on the supply of foreign components, which led to negative consequences. Manufacture of machinery PT-10 lasted for eight years, but was of an episodic nature, and even by the standards of that time was small-scale. For all the time managed to build a little more than 300 trucks and chassis for different needs. As a result, other domestic three-axle machines of the time were inferior to the YG-10 in terms of carrying capacity, but they were ahead in terms of numbers. The first domestic three-axle eight-ton trucks may not have been able to realize their full potential, but they still had a serious impact on the development of the automotive industry and took their place in its history.

Based on:

http://denisovets.ru/

http://bronetehnika.narod.ru/

http://opoccuu.com/

https://autowp.ru/

https://drive2.ru/

Shugurov L.M., Shirshov V.P. Cars Country of the Soviets. - M .: DOSAAF, 1983.

Dashko D. Soviet trucks 1919-1945. - M .: Automobile archival fund, 2014.

Information