Truck I-4. The first in the new family

Problems and solutions

The I-3 truck was developed by the 1 GARZ designers in 1924-25 on the basis of the White-AMO project previously proposed by Moscow auto builders. The original project was reworked in accordance with the limited technological capabilities of the plant, and in this form launched into the series. The Yaroslavl plant could independently assemble the bulk of the machine’s aggregates, but needed supplies from the side. Thus, the AMO plant supplied the engines and most of the transmission units.

The car I-3 turned out ambiguous. He combined a good payload with low running characteristics associated with the engine used. Gasoline engine AMO-F-15 power of all 36 HP was too weak for a car with a full weight of more than 7,3 t. The maximum speed of the truck on a good road and with partial load did not exceed 30 km / h. There were also claims to the reliability of individual components, to the uncomfortable driver's cab, etc.

The existing I-3 project had an important feature: it had a good modernization potential. The frame and other units of the truck allowed to increase the loading capacity and running characteristics, but this required a power plant of greater power. Unfortunately, the Soviet industry at that time could not offer an engine with the required parameters. However, the leadership of the automotive industry was able to find a way out. They were the German-made engines, purchased specifically for the promising technology YAGAZ No. XXUMX.

At the beginning of 1928, the Soviet Union and the Weimar Republic entered into an agreement for the supply of modern automobile engines. The subject of the contract was 137 Mercedes gasoline engines, as well as compatible clutches and gearboxes. Such power units were ordered specifically for the Yaroslavl Automobile Plant. With their help, it was planned to upgrade the existing I-3 truck, which would significantly improve its performance. For the selection of engines and the signing of contracts was responsible a special commission, which included V.V. Danilov - head of the Yaroslavl plant design bureau.

Soon after the signing of the agreement on engines, the designers of YAGAZ began to rework the existing project. The new power unit of the brand "Mercedes" was not only more powerful, but also increased in size, which imposed requirements for the design of the machine. In addition, some changes had to be made to the original design of the I-3 truck, the need for which became apparent from the results of testing and operation of equipment.

The new project involved not just replacing the engine, but a deep modernization of the existing car. In this regard, the truck with the German engine received its own designation - I-4. It is curious that such a name reflected not only the city of construction of the car, but also its carrying capacity in tons. The new car became the first Soviet four-tonne truck.

New design

The power unit from Mercedes was distinguished by its large size, which affected the design of the future truck. It was still based on a riveted frame assembled from rolled channels. The frame included a pair of longitudinal spars and several crossbars. Used standard hire. The spars were made of channel No. 16 160 mm in height with 65-mm shelves. There was a channel number 10 height 100 mm on the crossbar. The new engine and other devices forced to abandon the curved channel, which served as a bumper. Under the new bumper for the first time in domestic practice, a pair of towing hooks appeared.

As in the past project, on the basis of a rectangular frame, it was proposed to build a car bonnet layout, but the engine compartment was enlarged, and the cab moved back because of this. While maintaining the same onboard body, this led to an increase in the overall length of the car.

Unfortunately, story did not keep accurate information about the composition of the imported power unit. Different sources, including materials from that era, provide different data. According to some data, Germany handed over engines of the M26 model to the Soviet Union, according to others - L3. The power of the motors in different sources ranges from 54 to 70 HP. Moreover, the number of cylinders of these products is unknown - 4 or 6. A similar situation occurs with data on transmission devices of foreign production.

Anyway, Mercedes engines were more powerful and larger than domestic AMO-F-15, and were also supplemented with other units and aggregates. For this reason, for the I-4 truck I had to develop a new large hood with a rectified shape. The front wall of the hood was given under the radiator. Also, ventilation was provided by longitudinal hatches in the cover and side blinds. Engine maintenance was carried out with the raised side details of the hood.

According to some reports, a new type of engine was equipped with an electric starter, and also mated with a generator. Thus, unlike its predecessor, the new I-4 had an onboard electrical system. Among other things, it allowed the use of electric headlights. The latter were installed on U-shaped supports and could swing in a vertical plane.

The structure of the power unit included a dry clutch. Also, according to some sources, a manual gearbox with floor-mounted control lever was used. The box had four gears. Unfortunately, the type and design of the clutch and gearbox are unknown. From the box departed inclined drive shaft, transmitting torque to the main transmission of the leading rear axle. This gearbox was borrowed unchanged from the existing I-3 truck. The main gear with cylindrical and bevel gears and an increased gear ratio was designed to compensate for insufficient engine power from AMO, but could also be used with a Mercedes engine.

The truck retained the wheel formula 4х2, but the chassis was modified. On I-4, larger wheels were used - odnoskatnye on the front axle and gable on the rear. The dependent suspension on longitudinal elliptical springs was retained. At the same time, jet rods were removed from the rear axle, the functions of which were assigned to the cardan shaft. Its front hinge was fixed on the ball bearing, which transmitted the pushes to the frame cross member.

One of the reasons for criticism regarding the I-3 was a mechanically controlled brake. In the new project, a pneumatic system was used, supplemented by a German-made vacuum booster from Bosch-Devaunder. This device increased the effort on the pedals three times.

The cabin has been redesigned in comparison with the existing one. First of all, its width was increased, thanks to which two passengers were now placed in it together with the drivers. The cabin had a vertical front glazing, above which was a horizontal roof. Behind the driver closed the vertical wall with a window. Boards closed the cabin only partially. At the same time on both sides attended the door. The glazing above the doors was absent, and on the sides, on the sides, canvas curtains with transparent inserts were provided. They could be lifted to the roof or rolled out, fastening to the lower hooks.

The truck did not have power steering, which affected the size of the steering wheel. Under the steering wheel was the dashboard with a set of basic indicators. The driver also had a standard set of pedals and a gearbox control knob. From the point of view of the layout of controls and general ergonomics of the cab, I-4 was one of the first domestic trucks of the “modern” look.

In the base truck I-4 was equipped with a body with folding sides. This unit is unchanged borrowed from the previous I-3 and kept the same size. In the future, however, the dismantling of the standard body for installing other devices was not excluded.

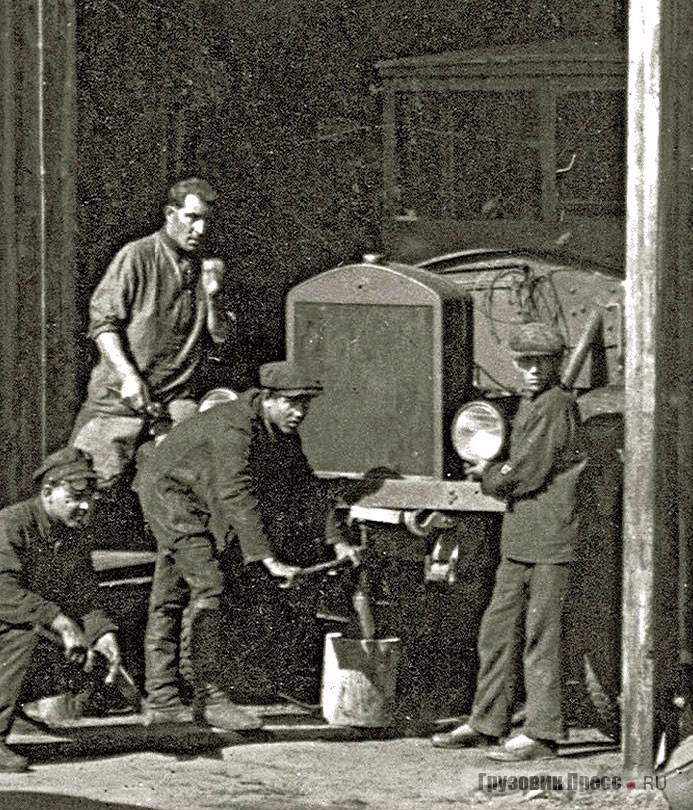

Machine maintenance I-4 in the workshop. Photo by Gruzovikpress.ru

Due to the installation of the new power unit and related design changes, the total length of the I-4 truck has increased to 6635 mm. The width and height remained at the level of the base machine - 2,46 and 2,55 m, respectively. The track and the chassis base also have not changed. Curb weight increased to 4,9 t. The increase in power allowed to bring the load capacity to 4 t. At the same time, the driving characteristics improved. The maximum speed increased to 45 km / h - in this regard, I-4 caught up with other trucks of its time, and with less capacity.

Small series

Ordered engines and other German-made products arrived in Yaroslavl in the second half of 1928. By this time KB VV Danilova managed to prepare the necessary documentation, and as soon as possible YAGAZ No. XXUMX produced the first cars of a new type. Powertrain brand "Mercedes" had time to pass the test abroad, and in the design of the car are widely used mastered and tested components. Thanks to this, the experienced I-3 tests did not take much time. Soon the leadership of the automotive industry ordered the launch of a full-scale production of such equipment.

Until the end of 1928, the Yaroslavl State Automobile Plant assembled a total of four-ton four-ton 28 trucks. In the next 1929, 109 machines were also manufactured and shipped to customers. On this serial production cars I-4 stopped. The reasons for this were simple and clear. Germany bought only 137 kits with engines and transmission elements. Using these products, YAGAZ could no longer build new trucks of the existing model.

However, the exhaustion of the stock of components did not lead to a halt in production. Yaroslavl car builders prepared for this in advance and took action. In the 1929 year, shortly before the I-4 truck production was discontinued, a new I-5 project was developed. He proposed the construction of a machine as unified as possible with the existing one, but using other engines and transmissions. This time the products of American industry were used. Thus, immediately after the last I-4, the first I-5 rolled off the conveyor. It should be noted that the use of new engines not only made it possible to continue production of equipment, but also led to an increase in the main characteristics.

Model tank truck based on I-4. Photo Denisovets.ru

In the army and national economy

One of the first customers of the new four-ton truck was the Workers 'and Peasants' Red Army. At least a few dozen I-4 went to serve in the artillery units. There cars were used as tractors for guns, as well as ammunition transporters and personnel. Without any problems, the truck pulled artillery systems with a caliber of up to 122-152 mm, while calculation and ammunition were placed in the back of the truck.

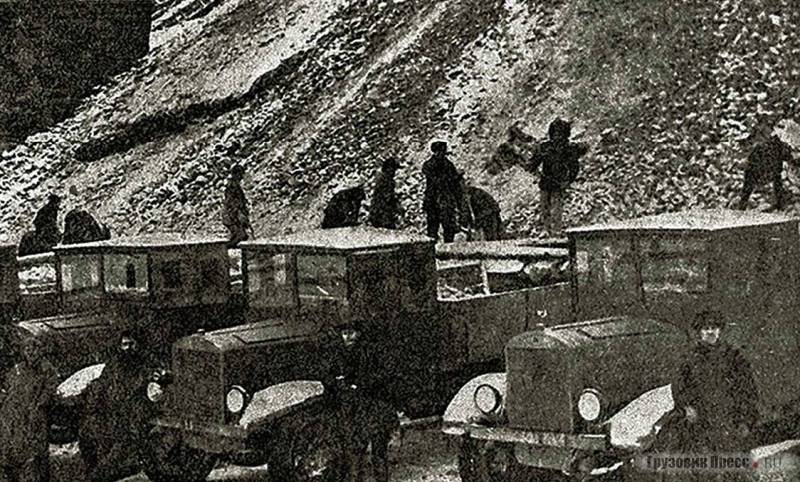

Another interesting customer was the organization “Sovmongtorg”, which provided trade between the USSR and Mongolia. The trucks of this organization were to carry various cargoes and goods along the roads of Altai to neighboring Mongolia and back. During this operation, Yaroslavl cars not only provided the transportation of the necessary goods, but also showed their potential when working in difficult conditions.

The remaining cars served in other organizations of the national economy and participated in a variety of jobs. Some trucks worked at construction sites, others were engaged in agriculture, and others in the mining industry. In all cases, the four-ton truck perfectly complemented the less powerful equipment and turned out to be the most convenient means of transportation. In some organizations of I-4, local auto repair shops lost their regular bodywork and received other equipment: tanks, vans, fire escapes, etc. However, due to the small number of trucks produced, this was not the most common practice.

During operation, the weaknesses of the new truck were identified. First of all, it turned out to be too heavy for some dirt roads, especially during the thaw. The total weight of the 8,9 t was divided into six tires of two axles, which imposed certain requirements on the quality of the road surface. For this reason, I-4 performed well in cities and could not work normally on the roads.

There was also a serious problem with import aggregates. For one reason or another, the delivery of spare parts produced in Germany was not arranged. As a result, serious damage to the engine or transmission simply took the truck out of service. In some cases, the I-4 was returned to work, replacing a broken engine with a workable motor of the available type. Transmission repair is often carried out in a similar way. As a result, by the mid-thirties, it was extremely difficult to find a truck in the basic configuration.

According to various data and estimates, not the most numerous I-4 trucks remained in operation until the end of the thirties. Perhaps these machines could work longer, but the lack of original German spare parts seriously affected their performance. However, the savvy drivers and mechanics ensured timely repair and return of equipment to work. I-4 in all "modifications" continued to contribute to the development of the country and the national economy. Having developed their resources, the cars were sent for disassembly. Unfortunately, not a single I-4 has been preserved.

Reserve for the future

The first own YAGAZ vehicle, the I-3, was a modified version of the White-AMO car, based on the outdated White TAD design. The new I-4 truck was developed on its basis, but modern components and technologies were used. The result of this approach was a very successful truck for its time with outstanding performance.

In terms of parameters and capabilities, I-4 surpassed all domestic trucks of its period, and was not inferior to many foreign models. Already in the late twenties, this machine was upgraded, which led to the appearance of the I-5 truck. In the future, on the basis of the existing machines and developments for these projects, the designers of YAGAZ developed a number of new trucks with high performance. All this makes it possible to consider I-4 as a landmark development, which seriously influenced the development of the whole direction of Soviet heavy trucks.

Unfortunately, the limited supply of German power units did not allow for the full-scale mass production of I-4 trucks. However, a way out was found from this situation, and soon Soviet drivers began to master I-5 cars. This machine can only be considered an improved version of the previous one, but in this case it is of great interest, and also worthy of separate consideration.

Based on:

http://denisovets.ru/

http://gruzovikpress.ru/

http://russianarms.ru/

https://kolesa.ru/

http://truck-auto.info/

http://dalniyboi.ru/

Shugurov L.M., Shirshov V.P. Cars Country of the Soviets. - M .: DOSAAF, 1983.

Dashko D. Soviet trucks 1919-1945. - M .: Automobile archival fund, 2014.

Information