Uniform Belgian machine gun FN MAG

In the breech there is a thread that serves to fasten it to the coupling. A closure fixing the coupling and preventing it from turning is mounted in the receiver on its left wall. The base of the carrying handle is attached to the flanges of the barrel coupling. Locking the barrel in the receiver by turning the handle. The handle is in this position, the aiming line does not close. Another important legacy of the Second World War is the use of spot welding, punching and riveting without compromising reliability. The receiver is assembled from parts made of steel sheet by stamping and fastened with rivets. However, some important parts are still made of steel billets by milling. The design turned out very heavy, but had high strength. In front of the design strengthened to install the barrel coupling, in the rear - to install the damper and the butt. Guides for bolt carrier and bolt serve the protrusions on the inner walls of the receiver. The receiver has several holes: a cutout for movement of the bolt carrier in the right wall, a window for throwing out the sleeves at the bottom.

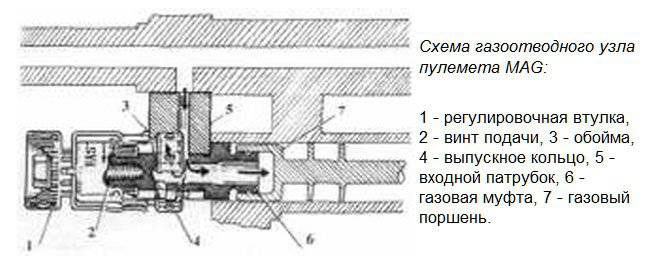

The barrel had chrome plating. Vapor unit includes a gas regulator and is located under the barrel. Powder gases enter the cylindrical clutch regulator. The gas piston moves inside it. The coupling has three outlets. During the shooting of the cold and polished weapons almost all of the powder gases escape through these openings, and only the minimum required amount of gases is used for the operation of automation. Heating automatics, sand ingress, carbonation and the like increase the friction force, causing the need to increase the pressure of powder gases. To do this, turn the gas regulator lever, after which the gas coupling moves along the gas chamber, sequentially closing the outlet openings. Powder gases in larger quantities begin to flow to the gas piston. Such a device makes it possible to adjust the rate of fire in the range from 600 to 1000 shots per minute. At the muzzle of the barrel are installed flame arrester with slots and front sight.

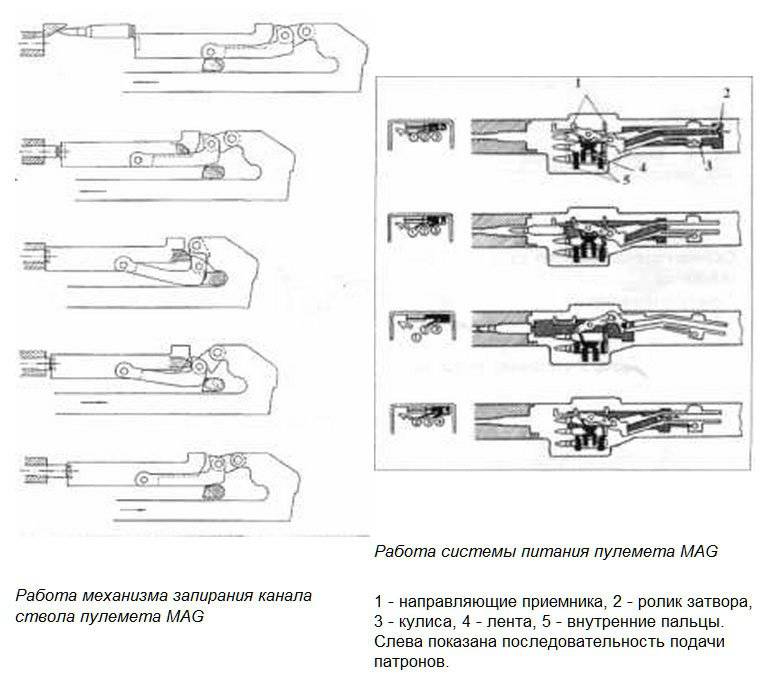

The layout of the locking unit and the vapor system is an “inverted” Browning scheme, since its machine gun had a box magazine inserted from the bottom, and the tape receiver at the MAG was on top. The gas piston is connected to the rod, which has a window for ejecting the liner. The slide frame (its rear part) is a massive strut that is connected to the locking lever arm, which is connected to the locking lever. Half of the locking lever is located in the notches on both sides of the gate frame. The drummer is mounted inside the bolt, the ejector is on the mirror. A reciprocating spring is installed inside the piston rod. To work properly, increase reliability and extend the life of the spring began to make multi-row. The recoil absorber consists of a hub of the bolt receiving shock, which, when moving backward, enters the damping cone. The cone, along with the sleeve, smoothly moves backwards and passes through eleven disk spacers, which accumulate the energy of the barrier frame. During the return movement, the gaskets forcefully push the sleeve and the cone forward.

As with most machine guns, the shot is made from the open bolt. The shutter at the cease-fire remains in the rear position, the cartridge - in the tape link. After the last shot, and in the chamber there can be no cartridge, the bolt from the front position does not go away. The basis of the trigger mechanism was also taken MG42. The trigger on the axle is fastened in such a way that its rear part, when pressed, rises, pushing the front shoulder whispered, its rear shoulder lowers, disengaging from the combat platoon. At the same time, the bolt is released and moves forward under the influence of a returnable spring. On the top of the trigger there is a disconnector that stands in the way of the piston and the gate. The disconnector lever is spring-loaded, its front side has a lip. The tail of the sear when the trigger is pressed rises, and the disconnector lever moves forward under the action of a spring blocking the sear. In case the trigger is not pressed, the disconnector lever rises, holding the sear in such a way that it cannot catch on the combat platoon. The protrusion of the disconnector lever at the same time again gets in the way of the bolt. The gas piston, moving away, presses the lever and squeezes its spring. The nose of the whisper goes up and the tail down. The piston rod, passing over the sear, comes into contact with the entire area of the upper surface of the sear, thereby eliminating the appearance of deformations and chipping. To prevent a spontaneous shot due to a disruption from the sear, the last series of machine guns install the sear with a pair of projections, respectively making the piston piston rod two-stage.

Button fuse is made in the form of a beveled rod. If the fuse is pushed to the right (the “SAFE” position) it is located under the spout tip, it does not let it go down, when the fuse is pushed to the left (the “FIRE” position) it turns with its notch to the sear, allowing it to drop.

A single NATO 7,62 millimeter cartridge mounted on an American M13 type link ribbon is used as ammunition. A metal tape with a capacity of 50 cartridges can also be used; however, these two types are not interchangeable, the replacement of the receiver is required.

Sector sight has a notch with a step 100 meters. When the bar is in the folded position, shooting is provided at a distance of 200-800 m, with the tilted (that is, in the version of rack mount) - 800-1800 meters. The diopter, which is used in the folded position, and the rear sight, having a triangular slot, are made on the movable tie. For vertical adjustment of the front sight, it rises behind the safety bracket and rotates. After that, put the brace in place. Horizontal adjustment is carried out by movement within the frame of the fly itself. For this adjustment, a special key is needed. In order to fire at night, the Trilux luminous nozzles were installed on the scope and front sight, but later they were replaced with special night sights.

Tape - metal link, with an open link. The loose cartridge belt was equipped only in factory conditions. Equipment cartridges non-folding 50-charging tape is possible even in field conditions. There is the possibility of connecting the tapes together, which ensures continuous firing. A box of 50 cartridges is attached to the left side of the machine gun, and the 250 cartridges are placed next to it.

For cocking the machine gun, the cocking handle is retracted all the way back with its subsequent return to the forward position. Only after that the fuse switches to the “SAFE” position, while the letter “S” becomes visible on the right side of the shutter. The machine gunner, pressing the two latches located in the rear part of the receiver's top cover, lifts it to the vertical position. After that, the tape is inserted across the receiver tray, the open part of the links down. The first cartridge is located on the right opposite the latch. The lid is lowered. The safety lever is set to the “fire” (“F”) position. When the trigger is pressed, the whisker's nose lowers, the bolt carrier together with the bolt begins to move forward under the action of the return-combat spring. The protrusion located at the top of the power system pushes the first cartridge out of the belt.

The locking lever moves down under the influence of the bolt. The cartridge is sent to the chamber, the ejector engages with the groove of the sleeve, while in the recess of the shutter mirror enters the bottom of the sleeve. The ejector, compressing the spring, is fed back and the shutter stops. In this case, the gas piston rod and bolt carrier continue to move. Before the combat stop, located at the bottom of the receiver, the locking lever is lowered. With further forward movement of the rod, the arm of the locking lever rotates and the bolt locks. At the last stage of the movement, the bolt projection strikes the firing pin and a shot takes place.

Part of the powder gases is fed into the gas regulator, after which the gas piston moves back. The arm of the locking lever begins to rotate again and, as the rod moves, disengages the lever and combat stop of the box. The locking lever moves the bolt, and the ejector removes the sleeve. The connection of the piston rod and the locking lever through the swinging arm at a high rate of fire softens the blows, making the locking system more reliable and smoother. The ejector moves the sleeve to the hole made in the piston rod. From there it is thrown out through a window in the bottom of the receiver. The slide frame, moving backward, compresses the reciprocating spring, after which, striking the shock absorber, moves forward. If the trigger is pressed, the cycle repeats.

The two-stage feeding system, whose scheme was borrowed from the German machine gun MG42, ensures uniform belt advancement during the movement of the bolt in both directions. On the frame of the shutter on top there is a spring-loaded roller, which is included in the figured groove of the receiver cover. In its rear part there is a hinge, and the front is connected to a short lever. This lever swings in such a way that when one shoulder moves to the axis of the trunk, the other leaves the groove. On one shoulder there is an internal finger of the feeder, two external on the other. Thus, during the forward movement of the bolt, the roller entered the straight section of the groove, after gripping the cartridge, passes into the curved part, moving to the right and tilting the lever to the left. At the same time, the internal thumb of the feeder captures the cartridge, while the outer ones push it relative to the longitudinal axis of the machine gun forward by half. While the shutter is moving backwards, the roller turns to the left along the slot. The lever goes to the right in such a way that the inner finger pushes the tape in half a step. In this case, the first cartridge stops at the lock, ready to be sent. The next cartridge is hooked by the outer fingers.

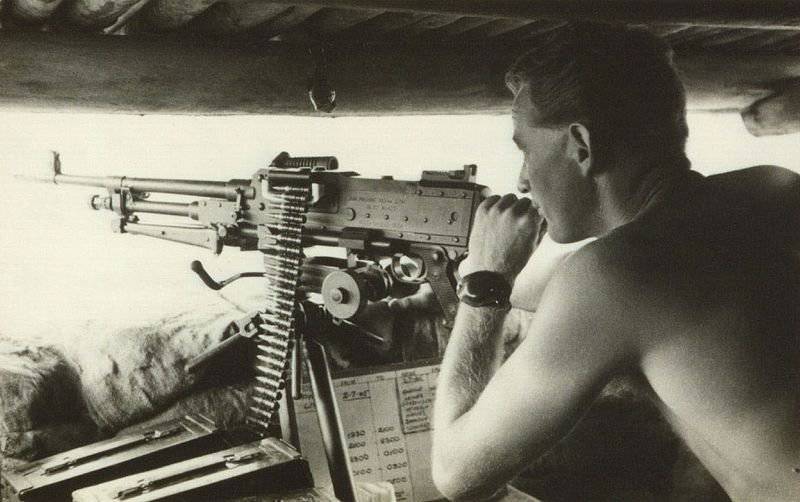

On the machine gun in the front of the gas cylinder are set bipod, turning in a transverse plane, and allowing to fire from the slope, without violating the line of sight.

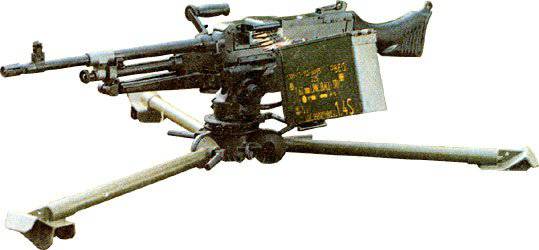

The machine is a folding tripod equipped with vertical and horizontal guidance mechanisms. To reduce mechanical loads and reduce recoil, FN has developed a so-called “soft” machine scheme, in which a shock-absorbing device is used to attach a machine gun in the machine's cradle. For the MAG machine gun in Denmark, we developed several models of the lightweight DISA tripod machines.

FN produced three main MAG series: 15 modifications of the Model 60-20 single machine gun, tank Models 60-40 and aviation Models 60-30. The latest models do not have bipods, butts, as well as their own sights. Tank modifications of MAG in some countries were introduced instead of other machine guns - for example, in the Dutch army on German tanks "Leopard-2" instead of anti-aircraft MG3. A Model 10-10 was also developed with a shortened butt and trunk (the so-called "model for the jungle"), but it did not find demand. A twin vehicle installation with separate or single descent was created for special purpose units.

To replace the barrel, you need to turn the safety lever to the right to the "SAFE" position, the shutter must be in the rear extreme position. If the weapon is discharged, it must be placed on a combat platoon. Discharging weapons is not necessary. The handle latch is inserted into the barrel coupling groove, the head of the barrel lock is located on the left side of the receiver, and the carrying handle is folded upright and removed to the front. After that, the trunk is separated forward. To install the barrel, hold the handle in an upright position, put the barrel on the protruding part of the gas chamber, then move it back. The gas regulator is included in the gas chamber, and the sector cutting of the barrel is in the sector slots of the coupling. After that, you need to turn the knob to the right, and bring the barrel into engagement with the clutch. The barrel is automatically locked by the closer.

Although MAG for using it as a handheld with its “body” mass equal to 11 a kilogram is obviously a bit heavy, it earned the popularity for its high accuracy of shooting and reliability of work. It is in service in many countries of the world, including: Argentina, Belgium, Canada, Cuba, Ecuador, India, Indonesia, Israel, Kuwait, Libya, Malaysia, the Netherlands, New Zealand, Peru, Qatar, Sierra Leone, Singapore, South Africa , Sweden, Tanzania, Uganda, UK, Ireland, USA, Venezuela, Zimbabwe and many others. In total, more than 75 countries acquired about 150 thousand machine guns. The 6,5 mm58 version was shipped to Sweden. Under the license, the MAG machine gun is produced in the UK (in service under the designations L7A1 and L7A2), India, Israel, Ireland, USA, Sweden, South Africa, Singapore (with a lightweight barrel under the designation "Type 74") and in Taiwan. Machine guns produced abroad have some differences - first of all, in the control bodies. The largest number of machine guns made in the United States, where it is under the designation M240 mounted on BMP (M240C), tanks (M240T), armored personnel carriers and helicopters (on pivot mounts, M240X1). The M240 device corresponds to the latest modifications of the Model 60-40 with power from the M13 type American tape.

With regard to the NATO 7,62x51 cartridge, it should be noted that it lacks energy as a munition for a single machine gun, and its approval as a NATO standard cartridge so far looks very strange. But over the years 50 cartridge in some countries well mastered in the production and continues to retain its value. Most often the cartridge has a brass sleeve, less often steel. NATO 7,62x51 is equipped with all permissible bullets - ordinary, tracer (mainly these two types are used in firing from MAG), armor-piercing and so on. The same FN created the SS123 bullet for this cartridge, which is similar in design to the SS109 bullet from the 56-mm cartridge. The mass of the SS123 is 9,6 grams, the initial velocity is 865 m / s. Due to the presence of a hardened steel core, armor penetration of bullets is 1,5 times that of a standard NATO cartridge.

The procedure for unloading a single machine gun FN MAG

Pressing the latch in front of the rack sight, flip the receiver cover up. If there is a tape to remove it, inspect the guide groove, close the lid. Pull back the cocking handle to remove the cartridge from the chamber, pull the trigger while holding the handle in the rear position, return it to the front position.

Technical characteristics of a single machine gun FN MAG:

Patron - NATO 7,62x51;

Mass machine gun - 10,85 kg (with a bipod and butt);

Machine gun weight - 21,35 kg (on a tripod machine);

Barrel weight - 3,0 kg;

Machine gun length - 1260 mm;

Barrel length - 545 mm;

Rifling - 4;

The length of the stroke rifling - 305 mm;

Sights - sector sight, front sight;

Initial bullet speed - 840 m / s;

The rate of fire - 600-1000 shots per minute;

Combat rate - 200 shots per minute;

Sighting range - 1800 m;

Range of effective fire - 1200 m;

Tape capacity - 50 or 250 cartridges.

Information