Giant Viper reactive mine clearance plant (UK)

In the early fifties, the British command again took up the study of the topic of engineering vehicles, suitable for the rapid demining of large areas. The analysis showed that the best ratio of characteristics should be shown by a system using a flexible elongated charge - a sleeve with an explosive. With the help of the simplest solid-fuel rocket, it could be laid on a minefield, and then blown up. This principle has already been used in the project "Conger", but then the sappers faced the most serious problems.

The reactive mine clearance installation during the war had two major flaws, which also complemented each other. Firstly, the used chassis of the armored personnel carrier had only bulletproof protection and did not provide high survivability. The second problem was the use of nitroglycerin-based liquid explosive mixtures, which can explode even from impacts. Thus, one of the installations of the Conger device was destroyed during refueling due to an unexpected detonation of the mixture. An unexpected explosion killed several dozen people and damaged a lot of equipment.

The reasons for using liquid explosives were fairly simple. During work on the minefield, the installation had to lay down a light and long fabric sleeve, which was then filled with an explosive mixture. This way of working reduced the requirements for the towing rocket. At the same time, it was necessary to use an unstable composition of the explosive, which led to serious risks for the calculation.

On the basis of experience, the command team has drawn up requirements for a new model of the engineering system. It required the development of a towed demining plant with the rocket principle of laying a completely new elongated charge. The latter should be performed on the basis of explosives resistant to detonation, which, however, should have led to an increase in its mass. To compensate for the large weight of the charge was proposed using a more powerful towing rocket.

The new project received a rather cumbersome official designation - Giant Viper Antitank Mine Clearing Line Charge - “Extended charge for the disposal of anti-tank mines“ Giant Viper ”. In addition, various system modifications had indices from L3A1 to L7A1. However, for more convenience, the installation of mine clearance is almost always called "by name", and the full designation is found only in documents.

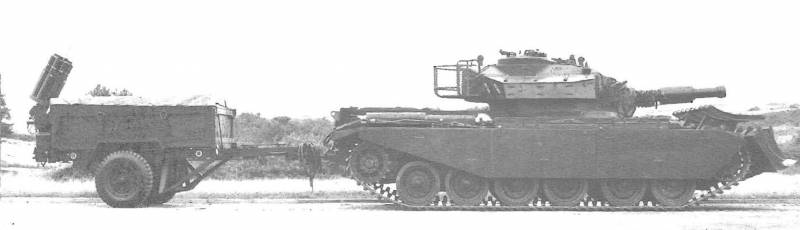

In accordance with the requirements of the customer, a simple technical appearance of the future installation was formed, which, however, made it possible to solve all the main problems. They decided to execute the “giant viper” in the form of a towed wheeled trailer with a set of necessary devices. It was assumed that this system will work together with tanks and other armored vehicles of the engineering troops. They had to bring the installation to the required position, and also be responsible for its evacuation after firing.

At the heart of the Giant Viper product was a regular single-axle car trailer. It was built on the basis of a rectangular platform of sufficient size, under which there was a single wheel axle with a dependent spring suspension. Also under the platform provided for the installation of a pair of additional supports, thanks to which she could stand smoothly and without a tractor.

During the development of the original design, various components were replaced, including the base trailer. So, in the L6A1 modification, the installation was based on a two-axle trailer. To improve the terrain on rough terrain directly on the wheels it was possible to install tracked belts. At the same time, regardless of the type and design of the trailer, the composition of other devices remained the same.

Special equipment trailer differed extreme simplicity. Most of it was occupied by a metal or wooden box for transporting ammunition in the form of an elongated charge. It is curious that instead of a special box for the "ammunition", which is part of the installation, a regular closure of an elongated charge was used. When preparing the complex, it was installed on the landing gear and removed the cover. This simplified both the design of the installation and its operation. After installation on the trailer, the capping was open at the top. When transporting and storing it should be closed with a canvas awning.

According to some data, experiments were carried out in which special boxes of armored steel were used, providing protection from bullets and fragments. However, if such products existed, they were not in large quantities and could hardly compete with unprotected closures in this regard.

Behind the box was a prop with a launcher for the towing rocket. The support was welded from several metal sheets of complex shapes, due to which the installation itself was located at the required distance from the box and at the required height, ensuring the free passage of the rocket.

The launcher for the Giant Viper differed in its original design, which was associated with the specific appearance of the rocket for it. On the support was placed the simplest rod guide. Due to simple mechanisms, it could move in a vertical plane: to transfer the unit to the stowed position or to change the firing range. At the junction of the support and the guide were placed control devices for launching the rocket engines.

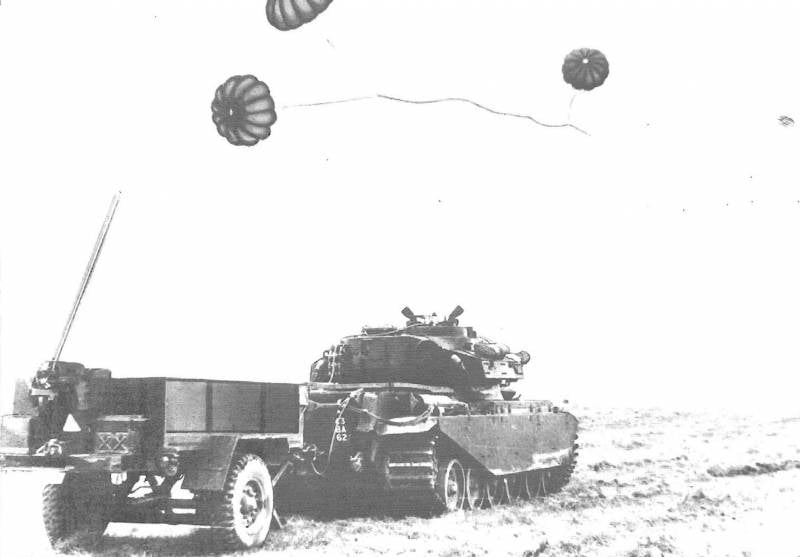

According to the experience of short-term operation of the previous installation of mine clearance, the new project proposed to use a flexible elongated charge, equipped in advance with an explosive. Regular "weapons"Giant Viper products have become an elongated charge in the form of a small-diameter fabric sleeve with a length of 250 m. Inside the sleeve were checkers of explosive type PE-6 / A1 with a total weight of about 1,5 t. at the same time. Also, the charge was completed with a fuse, providing undermining after a specified period of time. Several brake parachutes attached to an elongated charge were responsible for its proper installation.

It was proposed to lay the charge on the field with the help of a special design towing vehicle. It immediately included eight solid-fuel engines, similar to those used in the previous project. Cylindrical shells with a diameter of 5 inches (127 mm) were connected to each other using several transverse disk-clips with holes around the circumference. In the center of each disk there was a hole for interaction with the guide rod. The rocket was connected to an elongated charge using a cable. A second cable connected the other end of the charge and the launcher.

The Giant Viper reactive mine clearance system was not very large, which could affect its survivability. The total length of the product did not exceed 3 m with a width of about 2 m and a similar height (in transport position). The mass of the trailer with the launcher and "ammunition" - less than a ton. It should be noted that the dimensions and weight of the product in the working position depended, first of all, on the platform-trailer.

The principle of operation of the Giant Viper complex of all modifications was quite simple. Before entering the firing position near the minefield, it was necessary to raise the launcher guide and install a rocket-towing vehicle on it. A cable connected to an elongated charge joined the latter. The charge itself was lying in the box in the right way: he had to freely leave the installation without twisting and looping. A second cable of great length connected an elongated charge and launcher.

At the position of the installation was derived using any available armored vehicles. It should be placed in front of the minefield, sending in the right direction. At the command of the operator, the engines of the towing vehicle were ignited, after which he rose into the air. The thrust of eight engines was enough to accelerate and then extract the extended charge from the box. A flying rocket and a set of brake parachutes straightened the sleeve with explosives right in the air, after which it had to fall to the ground. The second cable associated with the launcher, limited the range of the charge. Further, an explosion occurred, designed to damage mines in the ground or to provoke their detonation.

During the tests, it was possible to determine the actual characteristics of the mine clearance unit. In general, they are as expected. The new towing vehicle could send an 250-meter elongated charge to a considerable distance from the installation. With the help of a cable, its flight range was limited to 200 meters (at the near end). Due to possible charge bends when falling onto the ground, the guaranteed length of the cleared passage was only 200 m. The width of the demining band reached 6 m. This was more than enough for easy access for people and equipment. The detonation capacity was sufficient for the effective destruction of anti-personnel and anti-tank mines.

However, there were problems. First of all, certain limitations were imposed by the use of a non-self-propelled chassis. Installation needed in the tractor. In addition, left much to be desired protection of the installation itself and explosives on it. Any hit of a projectile or even a bullet could provoke a powerful elongated charge exploding. This imposed certain restrictions on the operation of the Viper and the choice of firing position.

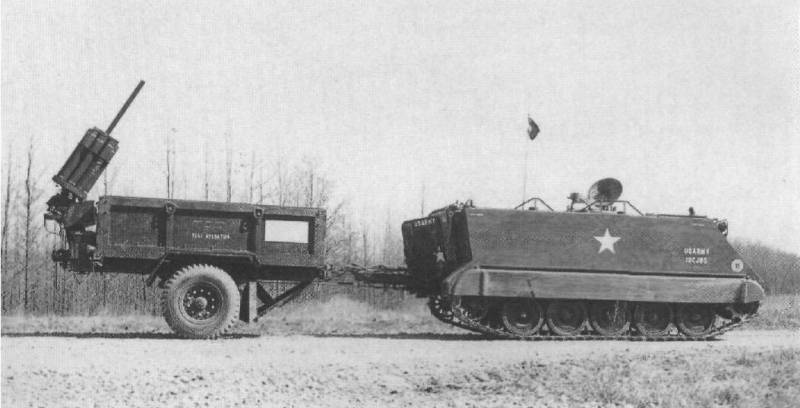

"Viper" on trials in the United States. The M113 armored personnel carrier is used as a tractor. Photo "Bradley: A History of American Fighting and Support Vehicles"

Nevertheless, the new sample was considered successful. In the mid-fifties, the L3A1 Giant Viper rocket demining unit was commissioned by the Royal Engineers Corps. The simplest design allowed in the shortest possible time to release the required number of installations and fully equip the engineering troops. Not later than the end of the decade, the Corps had a sufficient number of towed installations and had all the possibilities for clearing minefields.

In the future, "Giant Viper" repeatedly underwent modernization. First of all, the revision or even replacement of the base trailer, on which all other units were installed, was carried out. Also carried out the improvement of the extended charge and towing rocket. According to the results of such updates, the complex retained the basic combat qualities, but at the same time, its operational characteristics noticeably increased.

Most of the time, the Royal Engineers Corps equipment was located at the bases, occasionally going to training grounds to participate in training events. For several decades, the British army did not participate in major land conflicts, where demining facilities might have been needed, which determined the main features of the operation of the Giant Viper.

However, over time, this technique still had to be sent to the war. According to reports, in the 1991, during the Gulf War, the British Army used several demining facilities. There have been several applications of elongated charges on minefields organized by Iraqi forces. The following episodes of the use of such weapons relate to the next war in Iraq, which began in 2003. Also "Vipers" were used in Afghanistan.

At the beginning of the last decade, the British command came to the conclusion about the need for a deep modernization of existing demining systems or the creation of completely new models of this kind. A prospective demining plant should have been distinguished by a greater range of fire and increased efficiency of the extended charge. These tasks were successfully accomplished by the end of the decade, and in 2010, for the first time, a new Python installation was used in Afghanistan for the first time.

In this decade, the British Army acquired a certain number of new Piton demining installations, with which they succeeded in gradually replacing at least most of the existing Vipers. No later than in the near future, the latter should finally be out of service, giving up their place to modern systems.

As part of the Giant Viper project, the designers had to create an effective reactive demining plant, devoid of the characteristic shortcomings of the predecessor. This task was successfully solved, which led to very interesting results. "Giant Viper" remained in the ranks of more than half a century and occupied a special niche, not having competitors in it. Several successive upgrades allowed to increase the characteristics of this system, ensuring the preservation of the required capacity. As a result, the need to replace existing installations has matured only at the beginning of the last decade. All this can be considered as a sign of success.

Based on:

https://globalsecurity.org/

http://saper.isnet.ru/

https://thinkdefence.co.uk/

https://armyrecognition.com/

http://forces.net/

Avrami L. Kirshenbaum MS Giant Viper Antitank Mine Clearing Line Charge: Characterization of energetic materials. US Army R&D Command, Large caliber laboratory. New Jersey, Dover. Sept 1981.

Hunnicutt, RP Bradley: A History of American Fighting and Support Vehicles. Navato, CA: Presidio Press, 1999.

Information