The cruiser "Varyag". Fight Chemulpo 27 January 1904 of the Year. Part of 3. Boilers niklossa

As we said earlier, in this matter, the contracts for the construction of Varyag and Retvizan directly violated the requirements of the ITC, and usually sources blame it on the drafters. Official story, represented by such authors as R.M. Melnikov, claims that Nikloss's boilers turned out to be extremely unreliable, which is why their installation on the Varyag led to the fact that in daily operation the cruiser's power plant constantly broke down and failed - accordingly, the contract speed "in life" turned out to be unattainable. Subsequently, already in our "free from the heavy legacy of socialism", a different point of view took shape, according to which the MTK specialists were uniform retrogrades and only for this reason insisted on the installation of hopelessly outdated Belleville boilers, while all progressive mankind was switching to new types of steam boilers. According to this point of view, it is not the design of the boilers that is to blame for the constant problems and accidents of Nikloss's boilers, but the low qualifications of the Varyag machine commands. In other words, the fact that Nikloss's boilers required more skilled maintenance is usually not disputed, but it is argued that the qualifications of machine instructions in others fleets quite allowed to operate these boilers, but in ours it was not, and that we ourselves are to blame for all the problems of the Varyag power plant.

We will try to understand all this impartially.

Let's start with the outdated Belleville boilers. As you know, at the end of the 19 century, there was a transition from fire tube (or cylindrical) to water tube boilers, which had a number of significant operational advantages. At the same time, there were many water-tube boilers of various types, and Belleville boilers were just one of many such boilers.

And yes, indeed, for the first time in the domestic fleet, boilers of this type were installed on the Minin armored frigate during its modernization in 1887.

However, after this, the Marine Ministry took a “time out”, either by observing the operation of boilers of this type, or under the influence of the fact that the rest of the world was somehow in no hurry to refuse fire tube boilers. Especially paid attention to England - for example, when designing the armored cruiser "Rurik" (laid in 1892 g) preference was given to fire-tube boilers for the reason that the British do not use them. They even refused a mixed power plant, in which part of the boilers would be water-tube boilers, and some of them would be fire-tube boilers, as suggested by N. E. Kuteynikov.

Strangely enough, but the Russian fleet began to widely introduce Belleville boilers only 6 years after their installation on the "Minin". Large warships laid at the end of the 1880s and the beginning of the 1890s were still equipped with fire-tube boilers. They were received by the battleships Navarin, Sisoy the Great, Three Saints, Rostislav, as well as a series of battleships of the Poltava type - they became the last squadron armadillos with "cylindrical" (that is, fire-tube) boilers. The mass transfer to water-tube boilers occurred later: the first squadron armadillos that received these boilers in Russia were Peresvet-type ships (the main ship was laid in 1895), the armored cruiser Russia (laid in 1893), an armored cruiser Svetlana (1895). You can, of course, chide the Maritime Office for this, incomprehensible than the reasonable six-year pause in the introduction of water tube boilers, but let's see what happened in the fleets of other countries of the world.

England. The first major ships of the Royal Navy to receive Belleville boilers were the Powerfulll and Terribl, built in 1894. From then until the events we described (that is, before 1898), the British preferred to put Belleville boilers on their cruisers. The armored "Diadem" laid out in 1895-1897, the armored cruisers Cressi (1898-1899 g) and Drake (1899) - all of them received Belleville boilers, and only in the subsequent 10 series of armored cruisers of the type " Kent "some ships received boilers of other types:" Berwick "and" Suffolk "received boilers of Nikloss," Cornwall "- Babcock's boilers, but you need to take into account that these three ships of the British series were laid already in 1901 g! In other words, it was not that massively abandoning the Belleville boilers in favor of some other, but even the British only risked testing the boilers of other types on serial large ships only in the 20 century.

The same can be said of the British battleships - the famous Majestic series, which gave rise to the “classic” battleships of the end of 19, the beginning of 20, the whole world, and laid in 1894-1895, still carried fire-tube boilers. The transition to Belleville water-tube boilers in the Royal Navy took place only in the next series - six Canopus-type battleships laid out during the 1896-1898 period.

In other words, in 1898, England just made a massive transfer of the main force of its fleet to the “outdated” Belleville boilers. And what about other countries?

The first major French ship to receive Belleville boilers was the battleship Brennus, built in 1889. Since then, boilers of this type have been firmly “prescribed” on French warships. Armadillos of the types "Charles Martel", "Charlemagne", "Jena" (the latter was laid in 1897 g) - they all carried the Belleville boilers. And only “Sufféren”, laid in 1899 g, got the boilers of Nikloss. True, the French began to experiment earlier on “non-capital” ships, for example, in 1897 r the battleship of the 2 class (in fact, coastal defense) Henri IV was laid with Nikloss boilers, and in 1898-1899. three armored Montcalm cruisers were laid, one of which received the Belleville boilers, the second - Nikloss, and the third - the Norman-Sigodi. On the part of the armored cruisers, the French obviously did not decide on the type of power plant most suitable for them and experimented with might and main: for example, in Gnumx g they laid "D'Antrcasto" with fire-tube boilers, and almost right there, 1894 g, laid "Gishen" with boilers Lagrafel system D'Allae. But in the same 1895 r on the stocks, stood Šatereno with Norman-Sigodi boilers, and in 1895 r the French began to build the Jurin de la Graviere with the boilers of the Guyau du Tamplet! It is usually stated that for the first time the boilers of Nikloss were installed by the French on the Friant 1897 class armored cruiser, but the fact is that the series included three ships, one of which was built with Belleville boilers, the second - with Nikloss boilers, and the third - with boilers system Lagrafel D'Allae. Uniform katavasiya!

Germany? On April 1, 1895, the first German armored cruiser Furst Bismarck was laid, and there is no consensus in the sources about the installed boilers - either Schultz or Dürr. In the next 1896 g, the 5 armored cruisers of the “Maria Louise” type were laid, two of which were Belleville boilers, two had Dyurr, and one had Niklossa. In 1898 (in December, that is, later the Russian competition), the Germans began to build "Prince Henry" with Durr boilers. At the same time, on the battleships, the Germans did not even dare to move away from the fire tube boilers - three ships from the series of battleships of the Kaiser Frederick III type had 10 fire tube boilers, and only on the Kaiser Frederick III there were 8 fire tube boilers and 4 of the Thornicroft boiler, and on Kaiser Wilhelm II, 8 fire tube and 4 systems from Schulz. But these five ships were laid in 1895-1898., And at the time of the competition were considered the newest German battleships! However, the next series of ships of the Wittelsbach type (and this is already 1899-1900!) Was the same - their power plants were a mixture of fire-tube boilers and Schulz or Thornicroft boilers.

USA? They and in 1896 g laid their next battleships - "Kirsarge" and "Kentucky" - with purely fire-tube boilers. But the armored cruiser “Brooklyn”, which entered service the same year, had Belleville boilers.

Other large ships in this period, the United States did not build.

Based on the above, we can state the following - as at 1898 r, the Belleville boilers were absolutely modern and, by the way, the only type of water-tube boiler that confirmed its high qualities in practice. What kind of obsolescence of Belleville boilers in 1898 can we talk about if the two major sea powers (USA and Germany) have not yet made the transition to water tube boilers and continued to be satisfied with fire pipe boilers? If the second fleet of the world, French, did all of their battleships of the 1 class build with Belleville boilers? If the mistress of the seas herself - England just laid down its first series of battleships equipped with these boilers? And in the Russian fleet, by the way, except for the Minin of large ships in April 1898 r, only the armored cruiser “Russia” was in service (the Svetlana was handed over to 1898 in March)

We should also remember this when we read about the breakdowns of Belleville boilers on our ships - for example, those that happened on the battleship Victory. The fact is that in the Russian Imperial Navy there was a situation when “there was not a penny, but suddenly Altyn!”: At the very beginning of the 20 of the 20th century numerous ships with Belleville boilers poured into the fleet: here and “Peresvet”, and "Diana", and "Bayan", and "The Thunderer" ... Where was the trained machine teams to take on this magnificence? Where was their teach? On the battleships of the coastal defense of the "Senyavin" type, which consisted in the training detachment, there were fire-tube boilers, and where else? On the cruiser "Russia", almost immediately after the completion of the departed to the Far East? On the "Svetlana", used as a grand duke's yacht? In general, the combination of every possible economy, with the well-known contempt for "Beelzebubs" (as the fleet mechanical engineers were scornfully called here) did its dirty work - they did not make massive retraining of teams for Belleville boilers, apparently hoping that they would sort it out themselves - well , teams and understand ... how could. However, in fairness it should be noted that problems with the transition to a new type of boilers were observed in other countries, including in England.

However, let us return to the order of the MTC regarding the Varyag power plant. All of the above seems to convince us that the MTC has made the right decision regarding the cruiser’s boilers and its requirements to install Belleville boilers on the Varyag. And if not for the crafty Charles Crump, then ...

But this, alas, is the wrong conclusion, because, despite all its obvious and incontestable advantages, the Belleville boilers were absolutely not suitable for the 1-grade armored cruiser, conceived by our Navy department. After all, what happened? The Navy tried to create their own armored deck cruiser with Belleville boilers, the experts tried, worked, but what was the result? Ships over 6 600 t with a displacement, speed 20 knots (no one knew yet that Diana type cruisers would not even show this in 1898) and with only eight 152-mm guns. Now, just two years after the start of construction (despite the fact that the official bookmark "Dian" took place in 1897, construction began in 1896), the Navy wanted to get a ship in 6 000 t, speed 23 knots and a dozen 152-mm guns - and all the same Belleville boilers. Obviously, such requirements were exorbitant for any shipbuilding company in the world, and there is a persistent feeling that MTK was well aware of the impossibility of creating a ship given TTX. Therefore, they were ready to "bargain" in matters of displacement, and, in general, in other matters too.

As is known, the firm "Germany" won the competition 1898, presenting the draft cruiser, which later became the "Askold". But then another German company, Vulkan, proposed, albeit belatedly, the more advanced project Bogatyr. As a result, for the Russian Empire, according to one technical assignment, three different companies built three armored fighters of different projects. In general, they had the fact that none of them had installed Belleville boilers. On the “Akolde”, the boilers of the Thornicroft-Schulz system were installed (which is somewhat incomprehensible, since in the German fleet itself the Schultz boilers and Thornicroft boilers were distinguished separately). The "Warriors" were installed Norman boilers.

What gave the use of such boilers? Of course, weight savings. Thus, the power plant of the Bogatyr type cruisers had a rated power 19 500 hp, and its weight was 1 200 t. For the sake of fairness, we’ll clarify that the weight is given according to the weight list of Oleg, not Bogatyr itself, but they are unlikely to differ significantly. We will not recall the power plant "Dian" (almost 1 620 t with power only 11 610 hp), but let us turn to the Bayan, an armored cruiser built in France, which, in general, can be considered the same age as the Bogatyr. The Bayan was expected to reach 21-node speed, and therefore, although it was somewhat larger than the Bogatyr, its power plant had a nominal power in 16 500 hp. But "Bayan" was equipped with Belleville boilers, and the weight of its cars and boilers was as much as 1 390 t.

In other words, one ton of mass of the Bogatyr power plant accounted for 16,25 horsepower, and one ton of the Bayana power plant was only 11,87 hp. A direct recalculation is unlikely to be correct, but we will not make a big mistake by assuming that to ensure the power of the 19 500, hp (as in “The Bogatyr”) would require an energy plant with Belleville boilers weighing about 1 640 tons. In other words, in order to place Belleville boilers on the Bogatyr cruiser, it was necessary to find somewhere a weight saving in 440 tons. What simple sacrifices one would have to make are two simple figures: the weight of the Bogatyr’s entire artillery armament, together with the turret mechanisms (but apparently without armor of the turrets) was 550 t, and the total mass of the armor was 865 t.

Theoretically, probably with Belleville boilers, it would have been possible to get a high-speed cruiser with a displacement within 6 500 and speed in the 23 knot, but it would be so unintelligible and crystal something, and with such a minimum of armor and armament, that no military sense in building such there was no ship.

Consequently, the fact that Charles Crump immediately refused to use on Varyag (there is a separate talk about Retvisan here) Belleville boilers, if only he talks about something, so only about the professionalism of Mr. C. Crump, who immediately realized the impossibility construction of high-speed cruiser given parameters.

Such a statement may seem inconsistent to the reader - well, of course, as the author described the entire previous article of the cycle, which Charles Krump is a resourceful and roguish predator. But the fact is that neither now nor then did life consist of black and white — either the knight on a white horse, or the serpent struck by it. Of course, Charles Crump is a revolver and a crook, but this does not mean that he was a worthless shipwright.

But whether C. Crump was right in proposing precisely the boilers of Nikloss is another question.

I must say that about the boilers of Nikloss, the Internet battles do not subside even now. On the one hand, it seems completely understandable that their design is much more complicated than that of the Belleville boilers, there are numerous testimonies about the capriciousness of these boilers, the conclusions about their uselessness for domestic ships, and they did not take root, did not become the main one fleet of the world. But supporters of the point of view that these boilers were fully capable, only demanded a high level of training for the firemen, have a very strong argument in defense of their point of view. Yes, the Nikloss boilers did not really conquer the world, but nevertheless they were put on many ships of the USA, France, England, etc. And what is interesting is that if the sailors of some countries were dissatisfied with them and scolded Nikloss for something worthwhile, in other countries nothing is observed - it seems that boilers are like boilers, maybe not the best in the world, but some serious criticism of them there was no work. From this it is usually concluded that in those countries where the operation of the boilers of Nikloss did not cause any particular problems, the sailors were sufficiently prepared to handle them, and the sailors of other countries, where such problems did occur, should be criticized less and “ there was more combat and political training, then, you see, there was no reason to swear.

We will try to figure out who is right and start with the design features of steam boilers of that time, trying to describe them as accessible and simple as possible.

What was a fire tube boiler? Roughly speaking, it is a firebox on which the capacity with water is put. But the heat in this case would only heat the lower part of the tank, and it was too slow, so “smoke tubes” were inserted into the water tank, passing through the entire tank with water from the firebox to the top of the tank - the heat from the fire rose through these tubes, heated them and the water around them. Actually, from this boilers and received the name of the fire tube.

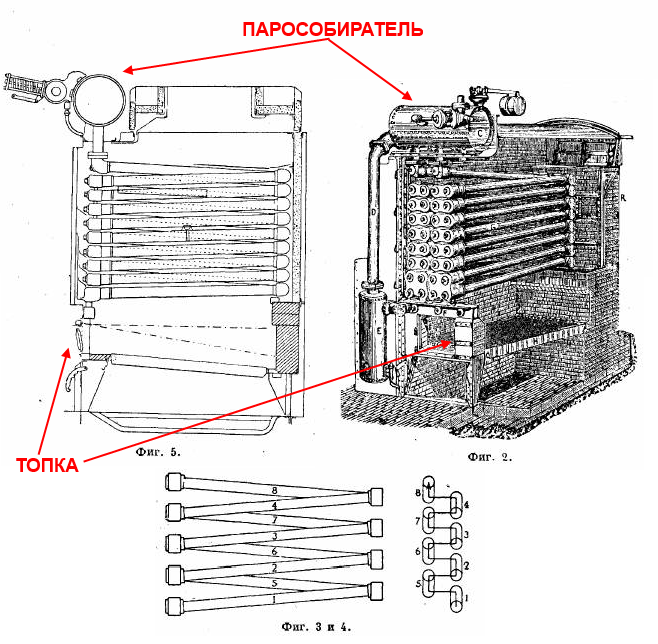

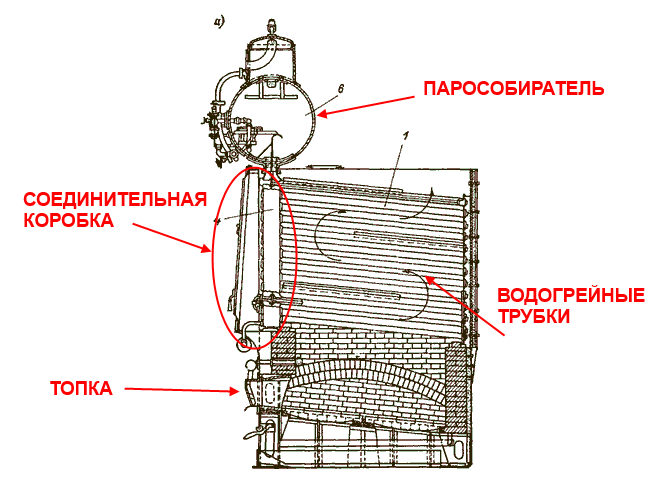

Water-tube boilers worked exactly the opposite - in the furnace were laid pipes through which water flowed, respectively, the flame heated these pipes and the water inside them. If we look at the Belleville boilers, we will see that these pipes were made up by a “ladder” inside the boiler — water was supplied to the lower one; it went to the upper ones in the form of steam, which left the steam tank.

It seems to be a simple and clear design, and what else can you think of? The company Niklossa came up with: instead of the usual tube, they used a “matryoshka”, one tube was inserted into another. The inner tube of small diameter was supplied with water, which (already in the form of a steam-water suspension) fell into the outer tube (the outer tube had a plug at the end, but the inner tube remained open). In order for this system to work, a unit such as a junction box, in which the water pipes were stuck, was provided in the Nikloss boiler.

At the same time, in one part of the junction box there was water supplied to the “inner” tubes, and to the other part, steam came from the “outer” tubes and from there it got into the steam collector. The special pride of the company Nikloss was the method of fixing the tubes and the junction box - these were special clamps, which were easily pulled out after removing the tube without disassembling the boiler itself (but this was not possible with Belleville). In this way, the excellent maintainability of the Nikloss boilers was achieved.

In general, the construction of the Nicloss boilers was more complex, but potentially much more efficient than that of the Belleville boilers. However, MTK experts almost immediately saw two weak points in it, which could lead to numerous breakdowns.

The first is the junction box, which was located dangerously close to the firebox and, of course, was heated from it. The junction box of the Nicloss boilers was made of ductile iron, and MTC quite rightly pointed out that such a complex and bore-rich structure, subjected to constant but uneven heating, will experience strong internal stresses that can lead to its deformation or even the formation of cracks.

The second is the formation of scale in the tubes. In Belleville boilers, the consequences of this unpleasant process (which could ultimately lead to the tube being burned out) were removed by some procedure called “blowing out” - unfortunately, the author of this article does not know exactly how and what the water pipes were blown through. Nevertheless, it worked in the Belleville boilers, but in Nicloss boilers it did not, and in order to clean the water-heating pipes from scale and so forth, they had to be removed from the boiler completely. However, the constant getting of the tubes “back and forth” naturally had to lead to the fact that the clamps, which ensure the tightness of the connection of the tubes and the junction box, loosened over time and did not provide the necessary tightness. In addition, it was necessary to understand that in any case the pipes covered the cinders from the firebox, they seemed to be “glued” to the junction box, which made it difficult to pull them out even with a perfectly working lock — often a sledgehammer and a blowtorch were needed for this. In such conditions, of course, to ensure the work of the clamp was even more difficult. Actually, a significant part of the accidents of the Nikloss boilers did just that - the lock holding the tube broke, and the tube “crawled out” during the boiler operation - and, of course, the pressurized steam broke out and did its dirty work.

So, the key question of the efficiency of the boilers of Nikloss was precisely that they demanded the highest quality manufacturing of the junction box, clamps and tubes. How difficult was it to achieve the desired quality?

Recall that the head of the Marine Ministry, P.P. Tyrtov raised the issue of the production of Nikloss boilers at the Baltic Shipyard. However, the plant manager, C.K. The warrior, although he confirmed the fundamental possibility of manufacturing basic parts, refused to guarantee the quality of the junction boxes. Probably, the Baltic plant was not the best ecumene plant, but certainly not the worst, and even if it did not provide the required quality, who then could guarantee it? Probably some of the best companies in the world.

And now let's ask ourselves a question - who, in fact, produced Nikloss's boilers? Alas, the answer "Nikloss's firm" will be too general and not entirely correct, because, as you can understand, boilers of this design were produced by different countries and at different factories. Perhaps the last major warships to receive the Nikloss boilers were the Courbet-class French dreadnoughts. But their construction began in 1910, that is, four years after J & A Niclausse stopped dealing with steam boilers for ships and reclassified to the production of cars with internal combustion engines.

But if so, then the logical question arises: is it possible to expect that all these boilers of the same design, but completely different manufacturing plants were of the same quality? Obviously not: and now is the time to recall the monograph by RM. Melnikov, in which, when describing the order of the boilers of Nikloss for Varyag, he indicates:

What was the quality of the products of this plant? As is known, a skilfully staked crack was found in the collector (junction box) of one of the boilers. That is, the plant did not cope even with the manufacture of the part, it was initially defective, and what quality can we talk about here?

Based on the above, the author of this article makes the following assumption (this is a hypothesis, not more). The efficiency of the boilers of Nikloss largely depended not only on the quality of service, but also on the quality of workmanship. In those countries that were able to ensure the highest quality standards in their production, these boilers did not cause any special complaints, and where this quality was not ensured, the sailors drank sorrow with them. The boilers of the cruiser Varyag, alas, were of poor quality, hence the problems of the crew of the cruiser Varyag.

True, the question then arises - is it possible to base such a conclusion on just a few words of one, even if a very respected author? Of course you can not, but let's see what happened with the boilers of Nikloss in the United States. We repeat once again - we are not interested in the experience of using them in England or France for the simple reason that boilers for ships of these countries were produced at other non-American factories, and, in accordance with our hypothesis, it does not make sense to compare them with US products.

So, as you know, the US admirals in 1898 g, comparing the results of operating their low-bordered "Indian", most likely a type of extremely powerful coastal defense battleship and the only high-breasted battleship Iowa built at that time, issued an unequivocal verdict on the preference of ocean-going ships . At that very moment, the Retvizan project turned out to be very useful, and the US Navy ordered the construction of three battleships of the “Men” type, which were laid down in the 1899-1900.

At the same time, the lead ship of the series - the Maine itself, which entered service at the end of 1902 g, received the Nicloss boilers, the other two - the Thornycroft boilers. What's next?

The next series of battleships in the United States — the five Virginia-style ships deployed in 1901-1902 — were a real triumph for the Nicloss boilers — they received the 4 battleship from 5 (Babcock-Wilcox boilers were installed on the Virginia boilers). But in the Connecticut series that followed in 1903-1905, the Nicloss boilers mysteriously disappeared, replaced by Babcock-Wilcox products.

And the same thing happened among armored cruisers. After having distinguished himself in the Spanish-American War "Brooklyn", in 1901-1902. on the stocks there was a series of armored cruisers of the type "Pennsylvania" consisting of six ships. As far as the author is aware, two ships from this series - the “Pennsylvania” and “Colorado” - received the boilers of Niklossa. But on the next "big cruisers" - four ships of the "Tennessee" type, the boilers of Nikloss were not installed - only Babcock-Wilcox.

We also know that the power plant of the battleship Maine caused numerous complaints from US sailors, which is why the ship was even called a coal eater. And it is of considerable interest that before the 1902 g, that is, while the battleship “Men” was still being built, the Americans widely used the Nikloss boilers for large ships under construction, but starting from 1903 g, after “Men” entered service, they completely stopped do. Of course, the logical rule can never be forgotten: “after this, it doesn’t mean as a result of this,” but ... In total, the Americans built seven large ships with the Nicloss boilers - five battleships and two armored cruisers. So, they later replaced the Nikloss boilers with different design boilers on five of them: the Maine itself, two battleships of the Virginia type, and both armored cruisers. And this is about something, yes it says.

Based on the foregoing, we can conclude: C. Crump was absolutely right in rejecting the Belleville boilers for the Varyag, but it was not worth allowing him to replace these boilers with the American version of the Nikloss boilers. The marine department should insist on using the Schulz-Tornikroft or Norman-Sigodi boilers, which were subsequently installed on the Askold and Bogatyr cruisers and with which the “Krivorukov” mechanical engineers of our fleet were well controlled. And after all, what is interesting is that the MTK specialists understood the potential problems of the Nicloss boilers, so why did they end up in the contract with Charles Crump?

Truly, in relation to our Maritime Ministry in this case the proverb would be best suited: "The left hand does not know what the right hand is doing." Apparently, the situation was as follows: V.P. Verkhovsky, who, as we know, was a supporter of the Nikloss boilers, bypassing the MTC, convinced the General-Admiral of the excellent quality of these boilers and the latter authorized them to be included in the agreement with Kramp. MTK specialists were a bit late: 14 on April 1898, just 3 days after signing contracts for the construction of Retvisan and Tsesarevich, MTK issued a decree categorically prohibiting the use of Nikloss boilers on warships of the Russian fleet. Alas…

Can we consider that “a scoundrel and a villain C. Crump slipped into the Russian sailors unfit boilers”? Oddly enough - no, nothing like that. The fact is that at the time of the conclusion of the contract, the advertisement of the Nikloss boilers was very strong and there were reports about their successful application, but information about the problems arising from their operation was not yet publicly available. Thus, C. Crump did not want the Russian Imperial Navy to be bad at all - he chose effective, and generally agreed, successful boilers for the Varyag and Retvizan, as they were produced directly in the United States and it would not be necessary to order them somewhere in Europe, to transport them to the USA, to incur extra expenses from this ... That is, the decision of C. Krump does not mean that he is some kind of pest, on the basis of the information that was in his order, he made quite a logical choice. Unfortunately, it turned out that this choice is wrong.

So who is to blame? Generally speaking, there is a great desire to blame everything on V.P. Verkhovsky - apparently, it was he who became the "conductor" of the ideas of Charles Crump. But here it is not so simple.

Recall the story of the boilers of the armored cruiser "Rurik". NOT. At that time, Kuteynikov advocated the installation of Belleville boilers, which, in his opinion, were much better than fire-tube boilers, but he was stopped by the caution of other officials who preferred the old, less efficient, but time-tested boilers. Nothing like? V.P. Verkhovsky, too, could see retrograds in the MTC, out of habit of not wanting to accept something new ... Today, in the case of Rurik, we curse the inactivity of the Navy department because we know that Belleville boilers turned out to be better. But what would have happened if N.E. Kuteynikov had the opportunity, bypassing the rest, to order Belleville boilers for Rurik and would he do that? We would see him as a hero. But N.E. Kuteynikov such a possibility was not. And V.P. Verkhovsky - was, and who knows, from what motives did the admiral actually proceed in the process of "promoting" the boilers of Nikloss? It is easy for us to judge today, because we know what happened afterwards, but V.P. Verkhovsky could not know this. In other words, the motives of V.P. Verkhovsky in this matter is completely unclear - from a banal bribe, to a sincere desire to arrange everything in the best way, if only bypassing the ITC.

Therefore, the only person whom we can rightly blame for what happened is the Grand Duke Alexey Alexandrovich, who, by permission of the Lord, turned out to be General-Admiral.

The very “7 pounds of the most august meat” that provided such “management” to the Marine Ministry entrusted to its care, with which today the specifications for the newest ships of the fleet with Nikloss boilers are signed, and tomorrow the very same boilers are anathema.

Продолжение следует ...

Information