Installation of mine clearance AAVP7A1 CATFAE (USA)

It should be recalled the events preceding the start of the CATFAE project and which caused it to appear. By the mid-seventies, the command of the American army had come to the conclusion that it was necessary to create a new engineering vehicle capable of making passages in minefields. It was proposed to destroy enemy ammunition using missiles with a detonating warhead. The project for such a demining plant is generically named SLUFAE. The engineering machine itself was called M130.

In 1976-78, the M130 prototype worked at the test site and showed its characteristics, while at the same time doing fine tuning. Uncontrollable rockets with a powerful charge coped with their tasks and made passes in various types of minefields. However, the firing range was limited, and the survivability of the machine and the protection of the crew left much to be desired. As a result, in its present form, the original installation of mine clearance could not enter into service and was abandoned.

However, the military did not stop work on all the subject of mine clearance. It was proposed to continue development work and create new ammunition with sufficient characteristics. After such processing promising weapon could enter service and find its place in the army, ensuring the safe passage of people and equipment through dangerous zones.

However, it was not possible to complete this work within a reasonable time. The SLUFAE project started on the initiative of the ground forces and naval forces, later joined by the Marine Corps. Over time, the army and navy lost interest in this subject, as a result of which the role of the main customer and supervisor of the work passed to the ILC. Since a certain time, the development of promising demining installations with ammunition of a volume explosion has been carried out only in the interests of the marines.

The conveyor has a volumetric troop compartment suitable for the installation of various equipment. USMC Photos

It is worth noting that at that time in service with the ILC there were already means of remote demining by an explosion. In operation were complexes M58 MICLIC with an extended charge. The launcher for two solid-fuel exhaust engines and a container for charging were mounted on different platforms, including amphibious transporters AAVP7A1. All this equipment was installed in the troop compartment of the hull.

After a series of preliminary studies aimed at finding the best ways to develop existing ideas, a new program was launched. It was designated as CATFAE - Catapult-Launched Fuel-Air Explosive (“Ammunition of a volume explosion with an ejection launch”).

Soon the technical shape of the future engineering vehicle was determined, which was to pave the way for the troops in the enemy’s minefields. As a basis for self-propelled mine clearance, it was proposed to use the KMP standard floating conveyor - AAVP7A1. He had to lose a number of devices related to the original transport role. In their place it was proposed to put a new launcher and fire controls. A completely new ammunition was also proposed, which had significant advantages over the XM130 product from the previous program.

The amphibious carrier of the CATFAE system should have retained all the main features and most of the units provided for in the basic configuration. At the same time, it was necessary to remove the landing places for the fighters and other equipment from the aft landing compartment, instead of which it was proposed to mount the launcher. As a result of this, a simple conveyor and installation of mine clearance should not have any external differences.

Both in the basic configuration and in the updated form, the AAVP7A1 amphibian had a body with anti-bullet and light anti-bullet armor. The displacing hull of recognizable shape was welded from aluminum armor plates no thicker than 40-45 mm. In front of the hull, with a shift to the starboard side, remained the engine compartment. To his left was a couple of places for the crew members, another one behind him. A large volume in the center and aft of the hull was initially given to accommodate the paratroopers, but in the CATFA project, its purpose changed.

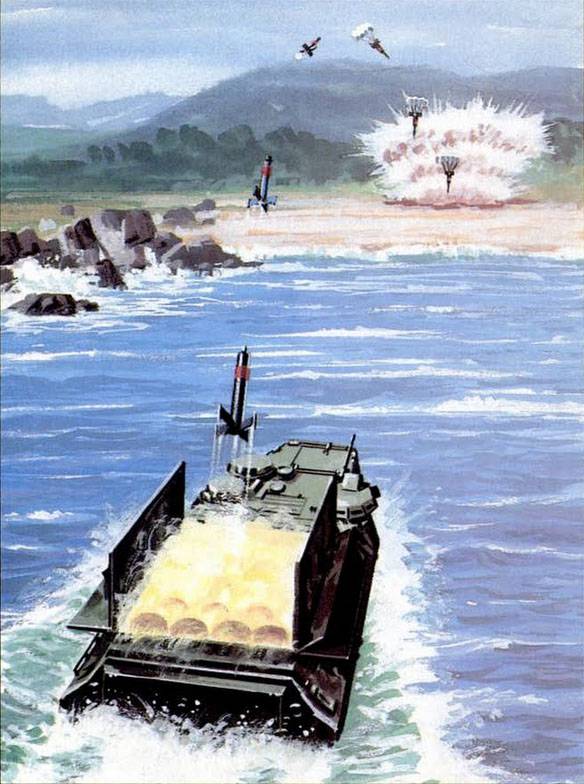

The work of the CATFAE system as an artist. Figure Popular Mechanics

The AAVP7A1 project used a power plant built on the basis of a General Motors 8V53T diesel engine with HP 400 power. With the help of the FMC HS-400-3A1 transmission, the torque was transmitted to the front-wheel drive wheels. In addition to the latter, the undercarriage received six road wheels with a torsion bar on each side. The guide wheels with the tension mechanism, respectively, were placed in the stern. Above the guide wheels on the sides were two jet propulsion.

Amphibian had its own cannon armament. In the revolving turret there was an installation with a large-caliber machine gun M2HB and a 40-mm automatic grenade launcher Mk 19. Install a set of smoke grenade launchers. Loopholes for shooting from the personal weapons of the crew and the landing were absent.

The new project CATFAE provided for the release of the existing amphibious unit with its transformation into a combat one. Now it placed the launcher for new missiles, not differing in complex design. Within the limits of the available volume, it was proposed to mount a small length 21 guide. These devices were to be placed in several rows of three or four in each. According to some data, a hinged installation was used with the possibility of some change in the angle of elevation. At the same time, due to the limited dimensions of the fighting compartment, the shooting could only be carried out “in mortar” mode - with large angles.

Prototype AAVP7A1 CATFAE on water. A shot from the newsreel

In the stowed position, the launcher was covered by the standard flaps of the upper hatch of the troop compartment. Having opened them, the crew could shoot and make a passage in a minefield. The stern swing door of the troop compartment remained in its place, but now it had to be used only for servicing the launcher.

Control over the shooting was carried out with a special device installed in the department of management. He was responsible for the operation of the electric propellant ignition system. According to known data, the control device allowed to shoot both single and a volley. The fire regime should have been chosen in accordance with the existing tasks: unguided rockets could be used both for mine clearance and as engineering ammunition for blasting various structures. On a full volley of 21 missiles should go about 90 seconds.

All the improvements of the project CATFAE literally remained inside the conveyor case AAVP7A1. As a result, the dimensions and weight of the car have not changed. The length still did not exceed 8 m, width - 3,3 m, height (on the tower, excluding open hatch doors) - less than 3,3 m. Combat weight remained at the level of 29 t. Mobility parameters remained at the same level. The maximum speed on the highway exceeded 70 km / h, the cruising range over land - 480 km. Water-jet propulsion allowed to accelerate to 11-13 km / h with a cruising range of the order of 20 nautical miles.

The moment of the shot, you can consider the flame of the rocket engine. A shot from the newsreel

The unguided XM130 rocket, developed under the SLUFAE program, showed unsatisfactory performance, and therefore a new ammunition was created for the CATFAE complex. Designing such a product was entrusted to Honeywell. Taking into account the experience of the previous project, the new look of the rocket was determined, which allowed to obtain the required fighting qualities with acceptable operational parameters.

The new rocket received a cylindrical body with a length of at least 1,5 m. In the tail section of such a body were installed folding stabilizers, disclosed during the flight. Inside the hull of such a product were placed a warhead, a solid fuel engine and a parachute. According to some reports, the new project again used a combat unit of the BLU-73 / B FAE type - a container with a flammable liquid, equipped with a remote fuse and a low-power spray charge of explosive. The CATFAE rocket assembly weighed just 63 kg, which, among other things, reduced engine power requirements.

As planned by the authors of the new project, the combat work of the engineering vehicle AAVP7A1 was not very complex. Having approached the minefield of the enemy for a given distance, the crew had to open the hatch of the crew compartment and fire missiles. With their own engine, they accelerated and entered the calculated ballistic trajectory. On a given part of the trajectory, a parachute was ejected. With it, the combat unit was to descend to its goal. Undermining the spray charge was supposed to occur at a small height above the ground. After the formation of an aerosol from a flammable liquid, an explosion was to occur.

The rocket descends by parachute. A shot from the newsreel

At the first undermining of the warhead, the flammable liquid was scattered for some distance, which increased the zone of destruction of the subsequent explosion. In addition, the soil area, which was directly affected by the shock wave, increased. According to calculations, a volley of 21 missiles with BLU-73 / B FAE charges allowed to hit mines in the zone with a width of 20 yards (18 m) along the front and 300 yards (274 m) in depth. It was previously shown that the warhead provides for the defeat of anti-tank and anti-personnel mines. The shock wave of a volumetric explosion caused the mines to detonate or collapse mechanically.

In the mid-eighties, the CATFAE program reached the stage of construction and testing of experimental equipment. In 1986-87, the Marine Corps research and development companies and contracting companies converted the AAVP7A1 production vehicle into a launch vehicle for special missiles. It is obvious that the restructuring of the amphibian did not take much time, and soon experts were able to begin testing new systems.

Exact information about the test has not been officially published. However, the CPM several times shared information about the project with the press and read out individual data. The public was told about the purpose and design characteristics of the demining plant. At the same time, photographs of the experimental equipment were not published until a certain time, and only its military work appeared in the press in the artists representation. Later, other materials appeared.

The explosion of the space-detonating charge. A shot from the newsreel

From the available information, it follows that in the framework of the first stages of testing, the authors of the AAVP7A1 CATFAE project managed to get the desired results and start new works. In 1990, a new contract for the continuation of development work appeared, this time with subsequent preparation for future mass production. The necessary volumes of production of new equipment and methods of combat use were also determined.

According to the 1989 plans of the year, the Marine Corps was to purchase a significant number of CATFAE systems and install them on part of the existing or newly built equipment. According to calculations, each battalion of the Marine Corps should have received 12 demining installations AAVP7A1 CATFAE. It was assumed that during landing the vehicles would move ahead of the main forces and attack the minefields or enemy fortifications. According to the passes they made, other vehicles and infantry were to move.

Thus, the command of the CMP remained a fairly new development and began to make plans for the construction and operation of such equipment. However, the new plans were not implemented. CATFAE serial production with subsequent deployment in the army was supposed to start in the early nineties, but this did not happen. There is reason to believe that the promising program has become another victim of changes in the geopolitical situation. In connection with the collapse of the Soviet Union and the disappearance of a potential enemy, the United States sharply reduced military spending. A number of promising programs had to be closed or frozen. Probably, among such “losers” was the CATFAE project.

It is curious that in the early nineties, work on the installation of mine clearance actually stopped, but the project was not officially closed. The official document of the Ministry of the Navy of July 2008 of the year is known, where the CATFAE project is on the list of active programs implemented in the interests of the Marine Corps. How to interpret this information is unknown. One thing is clear: even if the project has not been officially closed, its real results have not been obtained so far. The US Army has various demining facilities, but the systems based on the volume explosion ammunition have not been put into service.

Since 2008, the Catapult-Launched Fuel-Air Explosive project has not been featured in open sources. The self-propelled demining plant based on the amphibian AAVP7A did not go beyond the limits of the polygons. The original method of getting rid of mine-explosive obstacles could not be brought to practical use. Despite positive assessments and far-reaching plans, the second program for the development of engineering equipment did not lead to the desired results. As far as we know, in recent decades, the Pentagon has not attempted to "resurrect" the old idea and create a new model of engineering equipment of this kind.

Since the mid-seventies, various structures of the US armed forces have been trying to create a fundamentally new engineering machine with remote clearance facilities. The first project of this kind was developed in the interests of the army, fleet and marine corps, but the resulting model of equipment did not fully meet the requirements. Soon the army and navy abandoned new ideas, but the ILC continued to work. However, his attempt to get a self-propelled vehicle with unguided missiles for mine clearance did not reach the stages of serial production and operation of equipment.

Based on:

http://military-today.com/

https://globalsecurity.org/

https://fas.org/

https://army-technology.com/

http://militaryparitet.com/

http://russian-tanks.com/

Busting Beach Defenses // Popular Mechanics, 1988, #3

Information