Experienced all-terrain vehicle ZIL-134

It should be recalled that the projects of the ZIS-ЭНNUMX family were developed in accordance with the decree of the USSR Council of Ministers, which was aimed at creating a promising multi-purpose vehicle for the army. Fulfillment of the customer’s technical assignment was associated with certain difficulties, which led to the creation of several experienced all-terrain vehicles designed to test a number of ideas and concepts. Four prototypes showed the pros and cons of the solutions used, and SKB ZIL was able to proceed with the design of a full-fledged vehicle suitable for use in the armed forces.

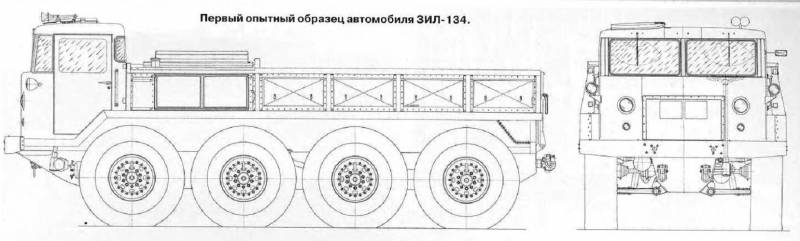

The first prototype ZIL-134

Development work on the new project started in the first months of 1956, shortly after receiving the first results of the ZIS E134 program. Design continued for several months and was completed by the end of the year. The Special Design Bureau of the plant, headed by V.A., played a leading role in these works. Grachev. In this case, as far as is known, specialists from other structures of the Plant named after him took part in the project. Likhachev.

The development of a new all-terrain vehicle was completed in the second half of 1956, after the new name was given to the plant. The consequence of this was the official designation of the project ZIL-134. It reflected the new name of the plant, but it clearly indicated a certain continuity with the previous experimental project. Also known about the existence of the army designation ATK-6 - "Artillery tractor, wheeled."

In accordance with the original terms of reference, the prospective all-terrain vehicle was supposed to be a four-wheel-drive all-wheel drive vehicle capable of carrying loads on its own site and pulling a trailer weighing several tons. There were special requirements for the patency of the car on complex landscapes. She had to move confidently over rough terrain and overcome engineering barriers.

Even at the stage of development of experimental prototypes, it became clear that completely new approaches and ideas should be used to solve the set tasks. You might also need to develop new components and assemblies that were not previously used in automotive technology. In the case of the ZIL-134 project, this meant maintaining a certain similarity with previous prototypes while at the same time obtaining a number of serious differences.

Special requirements led to the formation of the characteristic appearance of the machine. The project planned to use all the newest developments, both domestic and global automotive industry. At the same time, a number of technical solutions were used for the first time in domestic practice. All this threatened with certain risks, but the expected benefits completely compensated them. Taking into account the results of the previous experimental project, it was proposed to build a four-axle machine with a uniform distribution of the axes on the base. The project was planned to apply some original layout solutions.

Taking into account the necessity of crossing water obstacles, a new all-terrain vehicle ZIL-134 was decided to build on the basis of a supporting displacement hull. Its lower part, which served as the basis for the installation of the chassis, was made in the form of a unit with vertical sides, curved sheets in the front and aft parts? And also a horizontal bottom. In front of such a hull there was an overhang, which served as the basis for the cockpit. Under the cab, as well as behind it, there were volumes for the installation of power plant and transmission units. Behind the hull of the engine compartment located a large rectangular cargo area.

Especially for the ZIL-134 all-terrain vehicle, a new 12-cylinder petrol engine ZIL-E134 was created. This product was a pair of 6-cylinder experienced engines ZIL-E130, assembled in a common unit. According to calculations, it was possible to remove power from such an engine up to 240-250 hp. For the first time in domestic practice, the motor was equipped with a centrifugal fine oil filter, hydropushers and other devices. The engine was proposed to install the flywheel forward near the center of the housing. The engine compartment was covered with a light cover, which had several windows with louvers for access to atmospheric air.

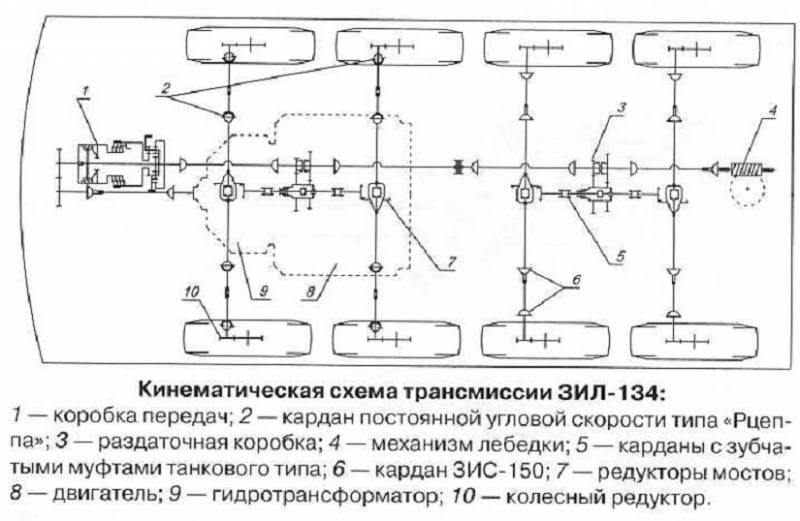

Directly in front of the engine was installed torque converter with a mode of operation as a clutch. The real benefits of such a device were previously confirmed during testing of mock-ups. The absence of a rigid connection between the transmission and the engine made it possible to save the latter from shock loads. In addition, smooth automatic gear shifting was provided in accordance with the speed and position of the engine throttle.

From the torque converter left the front drive shaft. Through an intermediate transmission of the “guitar” type, the torque was transmitted to the front input shaft of the gearbox, located under the cabin. The ZIL-134 project provided for the use of a hydromechanical three-stage planetary gearbox with automatic control, which provided for gear shifting without breaking the power flow. The output shaft of the box was displayed in the back.

ZIL-134, starboard view

In the first and third gaps between the bridges, two transfer cases connected by a gearbox were installed. Two-stage boxes had a parallel power diversion to each of the two bridges connected to them. Initially, it was proposed to equip the transfer cases with locking center differential, but they were later abandoned. The possibility of separate or joint inclusion of boxes was envisaged, but in practice it turned out that in all modes of their operation, the all-terrain vehicle shows similar characteristics.

The ZIL-134 project provided for the use of four main gears providing power output on the axis. They were built according to a single-stage scheme and were completed with spiral bevel gears. It was originally proposed to use differentials with manual locking, but later self-blocking devices were introduced into the project.

The side shafts of the chassis were equipped with off-center gearboxes on the basis of two gear wheels, which made it possible to increase ground clearance. Drive the front steering wheels performed using the so-called. Rcep's hinges. It is curious that such devices were used in some domestic projects in the early forties, but then they were virtually forgotten. ZIL-134 was the first car with similar hinges after a long break. Subsequently, they were repeatedly used in new projects.

All-terrain vehicle at the site

The eight-wheel chassis was built on the basis of an independent torsion bar suspension with telescopic shock absorbers, characterized by a long stroke - 220 mm. Suspension blocking tools were envisaged that were planned to be used with minimal tire pressure. The chassis has received pneumatic hydraulic brakes on all wheels. The axles were installed at regular intervals in 1450 mm. In this case, the track of the car was increased to 2150 mm.

ZIL-134 proposed to complete the wheels with new thin-walled tires size 16.00-20. The wheels were connected to a centralized tire pressure adjustment system. If necessary, the pressure could be dropped to 0,5 kg / sq. Cm, which led to an increase in the contact patch and a corresponding increase in patency. Unlike previous prototypes, the all-terrain vehicle of the new type had an internal air supply to the tires: all tubes and other devices were located inside the axle and the wheel hub.

During one of the modifications made according to the results of the next test phase, a winch was introduced into the ZIL-134 project. It was placed in the back of the case and removed the power from the propeller shaft associated with the transfer case. Part of the winch units was borrowed from the artillery tractor AT-C. The cable extended through the window in the aft hull. The winch drum was equipped with a treadmill. The mechanisms available provided traction up to 10 t.

Tests on snowy terrain

In front of the hull, above the gearbox, there was a triple crew cabin with advanced glazing, providing all-round visibility. Access to the cabin was through a pair of side doors and a sunroof. Three crew seats, if necessary, could be displayed in two beds. For the comfort of people in the cold season, a liquid heating system was provided, associated with the means of cooling the engine.

The driver’s workplace had a full set of controls. The steering wheel using the steering boosted front swivel wheels. The gearbox was controlled by a lever with four positions. There was also a five-way lever for downshifting and switching on carts.

Behind the engine cover was the cargo area. Experienced all-terrain vehicles ZIL-134 were completed with a simple flatbed, allowing to take on a standard test load. Provided for the installation of arcs for the tension of the awning. The car could tow a trailer using an existing drawbar. According to calculations, an ultra-high car could take on board up to 4-5 t of cargo and pull a trailer weighing up to 15 t. Depending on the route and terrain, the allowable load values could be reduced.

The length of the ZIL-134 was 7,16 m, width - 2,7 m, height - 2,65 m. Thanks to the processing of the transmission and chassis, the ground clearance has grown to 470 mm. The all-terrain vehicle’s curb weight was 10,6 tons. The total was 15 tons. The car had to reach speeds of up to 60 km / h on land and 1-2 km / h on water. It was expected that she would be able to overcome various engineering barriers.

Construction of the first experienced all-terrain vehicle ZIL-134 completed 22 January 1957 of the year. In early March, the plant them. Likhachev completed the assembly of the second prototype. It was also planned to build a third prototype, but its assembly was stopped. Subsequently, an unfinished all-terrain vehicle became a source of spare parts for two other machines.

Tests of the first car started the next day after the end of the assembly. Until February 13, the car drove along the highways of the Moscow Region and showed its capabilities. The all-terrain vehicle passed about 1500 km and showed a number of characteristic problems. So, the “raw” engine ZIL-E134 gave out power no more than 200 hp, which negatively affected the general characteristics of the car. An attempt to modify the engine in accordance with the results of bench tests ended with several breakdowns.

In March and April, the prototype was tested in the vicinity of Molotov (now Perm) on virgin snow with a snow cover thickness of about 1. In parallel, the GAZ-47 tracked tractor and ZIL-157 truck were tested in the same area. Unlike the two "competitors", the new all-terrain vehicle could confidently move across the snow cover with a thickness of 1-1,2 m and showed acceptable performance. At the same time, however, work as a tractor in such conditions was excluded. However, in other conditions, the ZIL-134 could lose to the GAZ-47 tracked vehicle. At the same time, there was an obvious superiority over the cargo ZIL-157.

In the summer and autumn, two prototypes were reworked and tested in less severe conditions. On the highways of the Moscow Region, their dynamic and economic characteristics were tested. It was found that when the engine is operated at partial power, the ZIL-134 is capable of developing speed on the highway to 58 km / h. Towing a 7,2 t trailer, the car accelerated to 50,6 km / h. Fuel consumption, depending on the mode of operation of the power plant and transmission, ranged from 90 to 160 liters per 100 km of track. This indicated a lack of efficiency in the operation of individual transmission units and noticeable power losses.

In the last months of 1957, all-terrain vehicles again had to face snow fields, and also show their capabilities in wetlands. An experienced ZIL-134 with a trailer weighing more than 9 r confidently moved along a snow-covered road designed to test tracked vehicles. He moved along the long climbs, and also overcame wades and ravines. In the same period, tests were conducted in the swamp. Such a “route” had a gentle entrance, after which a shallow, loamy bottom began with a peat mass above it. Above the peat there was an ice crust a few centimeters thick that could withstand the weight of a person. Despite the freezing of water and the thickening of the peat mass, ZIL-134 moved through the swamp and pulled the trailer. At the same time, there were problems during the ascent to the shore, since the trailer could rest against the front axles in the hummocks. On the most part of the route, the all-terrain vehicle did not skid. At the same time, an AT-C tractor and a ZIL-157 truck were tested in the swamp. Tests have shown that the tracked tractor and the eight-wheel all-terrain vehicle are approximately equal in terrain.

At the beginning of 1958, an experienced ZIL-134 went to the Vnukovo airfield for testing as a tractor. By this time, the operation of passenger aircraft Tu-104 with take-off weight of about 70 t began. Existing airfield towers could hardly cope with towing such equipment, and in the winter time its movement was completely impossible.

ZIL-134 received a ballast weight of about 6,5 tons, thanks to which it was possible to significantly improve the adhesion of wheels to the surface. After that, the all-terrain vehicle confidently pulled the plane along, including along the ice-covered concrete paths. Established tractors YAZ-210G and YAZ-214 with such a task could not cope. Also, a new car could roll the plane into the hangar or into the parking lot with its tail first. Tests have shown that the new ZIL-134 can be used not only with the Tu-104, but also with other types of aircraft that have a close take-off weight.

In March, 1958 was tested in a wooded area covered with snow. During such checks, the experienced ZIL-134 moved through the snow to a depth of 600 mm. The track was laid through a solid forest, and the car fell trees with a diameter of up to 250 mm. Also, the 1 m blockage covered with snow was overcome on the track. Spruce with a diameter of 350 mm was succeeded in dumping from the fourth bumper strike. Two more trees piled winch.

Experienced cars could overcome engineering barriers. So, the all-terrain vehicle without problems moved through a moat of width 1 and 1,5 m. When crossing the 2,5-m trench, the car rested its front bumper on the far wall and could not get out of such a trap. Without a trailer on solid ground, the car could climb the slope of the 40 °. With the C-60 in tow, we managed to climb the 30-degree slope. Both prototypes were tested in overcoming scarps. The second prototype was able to climb the wall height 1,1 m, but its upper edge was at the level of the bumper and was torn off by it. The first overcame only a meter escarpment.

During these tests two crashes occurred. The prototype №2, rising on the wall, at a certain moment appeared to be hung out in the air and relied on the ground only by the wheels of the third axle. Due to the increased load, the case of the rear transfer case has been destroyed. Under similar circumstances, on the prototype №1, the main gear and the differential of the third axis collapsed.

In the late spring of the same year, two ZIL-134 all-terrain vehicles were tested on the water. Machines with additional sealing of seams and joints were lowered into the water and moved with the help of wheel rotation. The possibility of mounting a boat motor was also considered, but this idea was not tested in practice. The car could reach speeds of no more than 1-2 km and cross a reservoir up to 70-80 meters wide. At the same time, there were problems with controllability that prevented the fight against the passage. In addition, during such a voyage through non-hermetic joints inside the hull, up to 3 cubic meters of water was drawn.

The tests clearly showed that in terms of mobility and maneuverability, the promising all-terrain vehicle ZIL-134, at least, is not inferior to the existing tracked vehicles, not to mention wheeled vehicles. It could be used as an ultra-high vehicle, artillery or airfield tractor, etc. However, the launch of mass production with the subsequent development of equipment by the army and the national economy was impossible.

Even by the middle of 1958, the specialists of the Plant them. Likhachev failed to complete the development of the new engine ZIL-E134. Experienced all-terrain vehicles had constant problems with ignition, which is why only 12 actually worked from 10 cylinders, pistons and valves constantly burned through, various breakdowns occurred. As a result, while maintaining performance until the next failure, the motor produced no more than 200 HP. of the required 240-250. This did not allow to obtain the desired dynamic and driving characteristics. We have to admit that the transmission of cars also sometimes broke down, but in her case the repair was not associated with major problems.

A good all-terrain vehicle with a “raw” engine did not interest potential customers. After examining the proposals, the army chose to take on the supply of multi-purpose chassis ZIL-135. In the near future, several new models of combat and auxiliary vehicles at its base were put into service. In addition, checks of new special cars from the Minsk Automobile Plant were completed. From ZIL-134, respectively, refused.

One of the no longer needed experienced all-terrain vehicles remained in the Museum of the Research and Testing Autotractor Test Site in Bronnitsy, where it had been previously tested. The second under its own power was driven to MVTU im. Bauman and transferred to the laboratory of the department "Wheeled machines." According to known data, in 1967, the museum at the autotractor range, which by this time became part of the 21 NIII, was liquidated. At the same time several unique models of equipment, including an experienced ZIL-134, were destroyed. The exact fate of the second prototype is not known for certain. Information about its existence is not available. Apparently, at some point he repeated the fate of the first car.

A special ultra-high-performance automobile ZIL-134 was the logical outcome of the work that began as part of the pilot project ZIS-E134. Using solid experience and collected data, the team of SKB ZIL, headed by V.A. Grachev could develop an interesting machine capable of solving a wide range of tasks in various fields. However, the all-terrain vehicle was faced with a serious problem in the form of an imperfect engine. The lack of progress with the motor in the end had a negative impact on the fate of the whole car. Not having received the required power plant, ZIL-134 could not show the calculated characteristics and therefore could not go into the series. However, the ZIL and MAZ brands adopted for the supply of chassis were not worse and were able to meet all expectations.

Based on:

http://denisovets.ru/

http://alternathistory.com/

http://russianarms.ru/

http://strangernn.livejournal.com/

Kochnev E.D. Secret cars of the Soviet Army. - M .: Yauza, Eksmo, 2011.

Prochko E.I. R. Danilov Off-road cars. Medium artillery tractor ZIL-134. // Technique and weapons, 2009. No.9.

Information