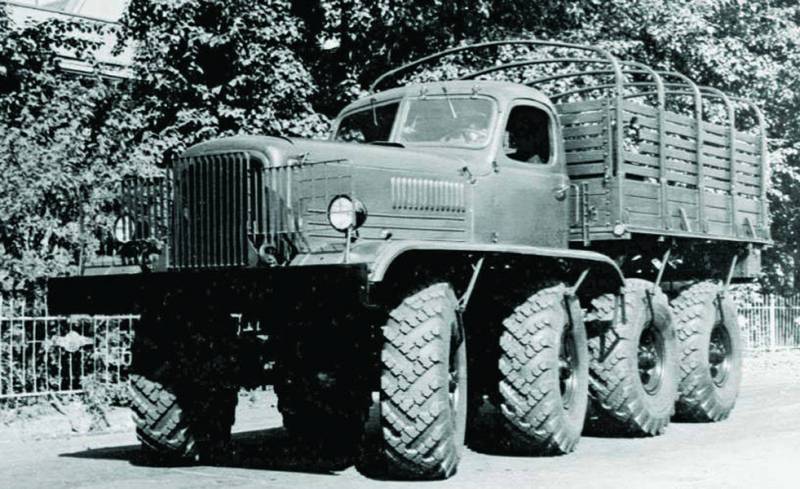

Experienced all-terrain vehicle ZIS-E134 "Layout No. 1"

In a hypothetical war, Soviet troops would have to move and carry cargo, not only along roads, but also over rough terrain. The existing wheeled vehicles with insufficient cross-country capacity could not always cope with such tasks. Tracked conveyors, in turn, coped with obstacles, but did not differ in ease of operation and high resource. In addition, the tracked chassis was inferior to the wheeled when working on good roads.

25 June 1954, the USSR Council of Ministers adopted a resolution on the formation of a number of new special design bureaus (CSC). Similar structures appeared in the composition of several leading automotive plants. The task of the special design bureau was to create special equipment on the order of the military department. Simultaneously with the decision on the formation of new bureaus, an order appeared to create several projects of special machines for the army.

The army wanted to get an eight-wheel ultra-high car capable of working effectively on roads and on rough terrain. The machine had to overcome various obstacles, including engineering barriers; ponds should cross ford. At the same time, the new vehicle had to transport up to 3 t of cargo in the body and tow a trailer weighing up to 6 t.

The technical task and the order for the design of a promising machine received Moscow Plant them. Stalin (ZIS) and the Minsk Automobile Plant (MAZ). Having a great experience in the field of off-road trucks, both enterprises were able to present ready experimental projects and experimental equipment of new types in a relatively short time. In the Special Design Bureau of the ZIS plant, design work was carried out under the supervision of Chief Designer V.A. Grachev.

Starboard view

The trial design of the special design bureau of the Moscow plant received the working designation ZIS-E134. For several years, three versions of experimental equipment were created with these or other features. According to the project, a prototype “Layout No. XXUMX” was built in its original form. According to some information, this machine appeared in the documentation of the Ministry of Defense as ZIS-1E134. Curiously, all the work on this project was completed and completed by the middle of 1. As a result, the car retained in its designation the letters "VMS" and was not renamed in accordance with the new name of the manufacturer.

It should be noted that according to the results of testing the ZIS-E134 “Layout No. 1” machine, an improved version of the original project was developed. He retained the old designation, but at the same time differed a number of major changes and innovations. The prototype of the updated ZIS-E134 was designated as “Layout No. 2” or ZIS-134-2. Soon the third mockup appeared. In fact, the three running layouts were completely different machines, but wore similar names. This can lead to some confusion.

All the basic requirements for a promising all-terrain vehicle related to driving performance on highly rugged terrain, including those equipped with engineering barriers. Such a technical task made V.A. Grachev and his colleagues use in the first ZIS-ЭNNXX project both well-known and fundamentally new technical solutions. As a result, the new machine had to have a non-standard technical look and an original appearance, which, however, allowed to solve all the tasks.

The project proposed the construction of a four-axle special machine with a chassis frame structure. On top of the frame should have been placed the engine and cockpit, covered with a common body. The latter occupied about half the length of the machine, ensuring optimal use of the available spaces. The back half of the frame served as the basis for the cargo platform on which one or another payload could be placed. The frame was based on the units of the car ZIS-151. In the framework of the new project, the existing serial frame was strengthened and slightly shortened. The same car "shared" and a closed cabin, which in this case had to be slightly rebuilt.

Under the hood of the ZIS-E134 all-terrain vehicle, there was a modified ZIS-120BK gasoline engine that differed from serial products with increased power. In the framework of the new project, it was forced by processing the cylinder head and the gas distribution mechanism. According to the results of such a change, an engine with a capacity of 5,66 l could deliver power up to 130 hp. The boost led to a certain reduction in the resource, but this was not considered a serious shortcoming.

The specific purpose of the car and the special design of the chassis led to the need to develop an original transmission, which included a large number of different units. A three-stage automatic hydraulic transmission / torque converter borrowed from an experienced ZIS-155A bus was connected directly to the engine. Its presence was due to the need to repeatedly increase the torque at the beginning of the movement: on weak soils required a fourfold increase in this parameter. While driving, the torque converter facilitates machine control by automatically shifting gears. Also, this device had the function of reverse, which simplified the “buildup” of the stuck car. Breaking the rigid connection between the power plant and other elements of the transmission, hydraulic transmission also prevented the engine from stopping during overloads.

At the level of the rear wall of the cab was placed five-speed gearbox, borrowed from the truck ZIS-150. Due to its location, it was necessary to use a relatively long and curved control lever. The gearbox was connected to a two-stage transfer case, which had reduction gears. She distributed the torque to a pair of power take-offs associated with the four-axle self-locking differentials. The transfer box and power take-offs were taken from the BTR-152В armored personnel carrier. All mechanical devices from the transmission were connected to each other using cardan shafts.

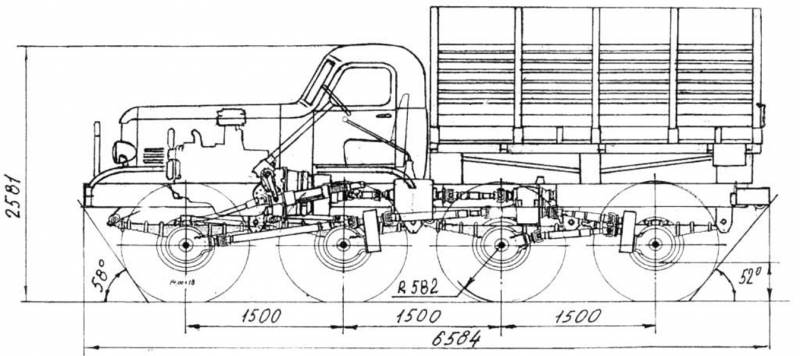

Ultra-high permeability should be provided, first of all, by the undercarriage of a special design. In the project ZIS-ЭНNUMXЕ, in accordance with the requirements of the customer, should use a four-wheeled chassis. To evenly distribute the weight of the car to the ground, it was decided to install axles with equal intervals in 134 m. At the same time, two wheels on each side were under the engine and cabin, and the other two were under the load platform. Continuous bridges from the BTR-1,5В with suspension on leaf springs reinforced with double-acting shock absorbers were used. The two front axles had steering controls controlled by power steering.

The all-terrain vehicle was proposed to be equipped with specially designed tires I-113. These products of the eight-layer design had the size of 14.00-18 with a total diameter of 1,2 m. The chassis received a centralized tire pressure adjustment system. The air pressure varied from 3,5 kg / sq. Cm to 0,5 kg / sq. Cm. When changing the pressure from the maximum to the minimum area of contact with the ground increased fivefold. All wheels were equipped with shoe brakes controlled by a centralized pneumatic system.

"1 layout" overcomes an obstacle

Despite the relatively large diameter wheels, the ground clearance of the machine was only 370 mm. In order to avoid possible problems when driving on difficult terrain, the bridges were covered with a special bottom pan, suspended under the frame. When traveling on snowy terrain, it was proposed to use a special wedge-shaped blade mounted under the bumper. With its help, much of the snow was set aside from the wheels.

Behind the engine compartment on the ZIS-ЭНNUMX car was located the crew cabin. The cab body and much of its internal equipment was borrowed from the ZIS-134 serial truck. At the same time it had to install a set of new equipment. The specific gear lever, torque converter controls and other new devices forced the designers to remove the middle seat from the cab, making it double. Indicators of temperature and oil pressure in the engine, power steering and hydraulic transmission were taken to a new instrument panel.

The back of the frame of an experienced all-terrain vehicle was given for the installation of a cargo platform. As the latter, the onboard body of the ZIS-121В serial car was used. It had a rectangular platform, surrounded on all sides by low sides. Also used metal arc to install the awning. In the future, after the launch of mass production, machines based on ZIS-E134 could receive other targeted equipment, both transport and special purpose.

All-terrain vehicle on snowy terrain

An experienced ultra-high-performance car had a total length of 6,584 m with a width of 2,284 m and a height (on the roof of the cabin) 2,581 mm. The curb weight of the car was set at 7 tons. With the 3 tons payload on the cargo area, the total weight reached 10 tons. When driving only along the highway, the car could tow a trailer weighing up to 6 tons. 1 T. According to calculations, an all-terrain vehicle on the highway could reach speeds of up to 65 km / h. On the ground, the maximum speed was limited to 35 km / h. There was also some potential in the context of overcoming various obstacles.

The development of the new project and the construction of “Layout No. XXUMX” lasted just over a year. The assembly of the prototype was completed in mid-August 1-th. At the same time, the new machine came to the testing grounds only after a couple of months - in the middle of October of the same year. All-terrain vehicle tests were conducted at several sites of the automotive industry and the Ministry of Defense. They lasted for several months, which made it possible to check the equipment in different areas, on different soils and in different weather conditions.

During the tests, the first prototype was able to show the maximum speed at the level of 58 km / h. The machine successfully moved on dirt roads, rough terrain and low load bearing soils. The all-terrain vehicle proved that it was possible to climb the slopes of the 35 ° steepness and roll off to 25 °. He could cross a trench up to 1,5 m wide and climb a wall 1 m high. Water obstacles up to 1 m in depth crossed the ford. Having two steered axles improved maneuverability. The turning radius (along the outer wheel track) was 10,5 m.

Snow blade

Particular attention during the tests was given to the work of the suspension and wheels with variable tire pressure. All undercarriage systems showed the desired performance and capabilities, but there were some unexpected results. As it turned out, soft tires with relatively low pressure can do without elastic suspension elements. Such tires perfectly absorbed all the shocks and compensated for uneven ground, literally leaving the springs out of work.

The prototype “Layout No.1”, built as part of the ZIS-ЭNNXX project, was primarily considered as a technology demonstrator, able to show the pros and cons of new solutions. According to the test results, this machine could be modified to improve certain characteristics and eliminate the identified deficiencies. In its current form, it was not considered as a possible sample for mass production and mass exploitation.

The tests of the first prototype continued until spring 1956 of the year and led to the desired results. An experienced all-terrain vehicle in practice showed the correctness of the ideas used, and also made it possible to identify the weak points of the proposed concepts. Without waiting for the completion of the tests of the “Model No. XXUMX”, the designers of the SKB VMS started the development of an updated project of an ultra-high maneuverable transport vehicle. It is curious that this project retained the existing designation - ZIS-E1.

Prototype ZIS-Э134 "Layout 2"

Almost immediately after the completion of the ground tests of “Layout No. XXNX”, a new ZIS-ЭNNXX “Layout No. XXNX” came out for testing. In connection with the preliminary results of the previous project, some noticeable changes were made to the design of this machine. Later, these ideas were developed and even were brought to the series in several subsequent projects. It is the second prototype ZIS-E1 that is considered to be the direct “ancestor” of a number of well-known ZIL brand amphibious all-terrain vehicles.

As part of the experimental project ZIS-E134, only one prototype prototype vehicle was built. After the completion of independent and joint tests, he was returned to the manufacturer, and his fate was unknown. According to some reports, the prototype was later disassembled as unnecessary. The development of special automotive technology now had to help other prototypes.

The first result of the pilot project ZIS-E134 was the mock-up sample №1, built on the basis of existing components and assemblies. His tests allowed to clarify the optimal appearance of a promising all-terrain vehicle and to begin the construction of a new prototype machine. Within a few years, three prototype all-terrain vehicles with the same name were built under the experimental program. “Layout No. 2” and “Layout No. 3”, as well as their predecessor, made a significant contribution to the study of subjects of ultra-high-traffic cars and are also worthy of separate consideration.

Based on:

http://русская-сила.рф/

http://denisovets.ru/

http://russoauto.ru/

http://strangernn.livejournal.com/

Kochnev E.D. Secret cars of the Soviet Army. - M .: Yauza, Eksmo, 2011.

- Ryabov Kirill

- Russoauto.ru, Denisovets.ru

Information