Newest industry

It followed (since not much had been done in the prewar period) from the very beginning of the war to take vigorous measures to organize the newest branch of the Russian industry - the chemical industry. Unfortunately, in the first months of the war nothing was done - it was believed that the war would be short and all the necessary things could be purchased either from the allies or in the USA. But the allies did little better than in Russia, and the Americans also needed to build new plants to service foreign orders, primarily to produce toluene and benzene.

The government had to take a number of urgent measures, establishing the production of explosives, as well as studying methods of manufacturing (aromatic hydrocarbons - as soon as possible). Donetsk pool became a lifesaver in this matter.

In the fall of 1915, the Chemical Committee at the GAU combined the activities of various institutions in charge of the production of chemical products needed for military purposes. A program of construction of chemical plants, enormous in size, was implemented - chemical plants appeared that did not exist in Russia before. It can be said without exaggeration that the needs of the army and fleet During World War I, they created a powerful new industry in Russian industry - the chemical industry - which was completely independent of foreign raw materials.

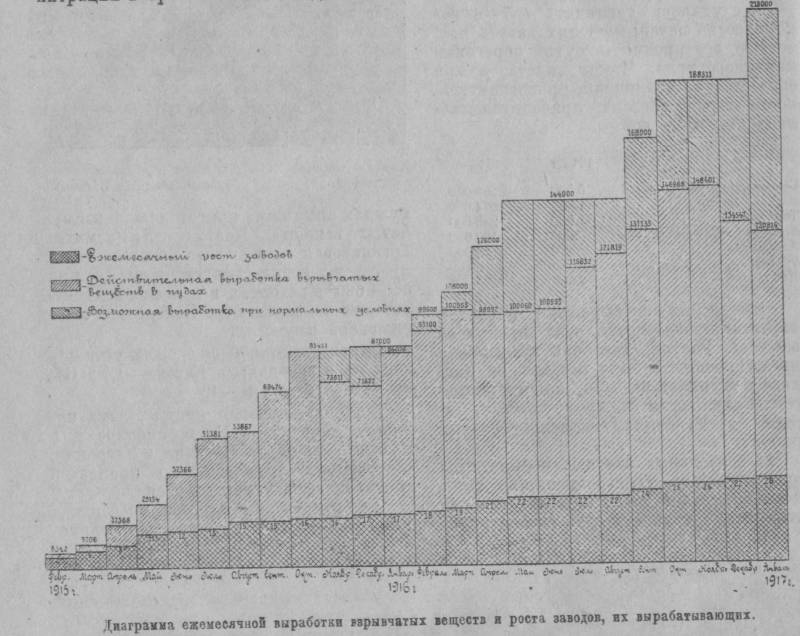

The chemical industry developed as the production of explosives increased, the required volumes of which constantly increased during the war. It is enough to cite only a few figures in order to see how the productivity of Russian plants has increased.

If in February 1915 in Russia produced only about 104 tons of explosives, about 256 tons of raw benzene and 11,5 thousand tons of sulfuric acid, then in March 1916 these figures exceeded 1,7 thousand tons, 903 tons and 21,3 thousand. tons, respectively - that is, for the year production increased by more than 15, 3,5 and almost 2 times.

It should be noted that at the beginning of the war explosives were made only at one private and two state-owned factories. For a specified period of time, explosives were manufactured at two state-owned and ten private factories.

By the beginning of the First World War and Naval Offices, forming stocks of military equipment in the event of an impending war, ignored the problem of their replenishment during hostilities - not taking into account what expenditure would be present during the modern battlefield. France was in the same position, and after the first battle on Marne was left without shells - and for a certain period of time waged a defensive war.

In Germany, the entire private industry was adapted to the transition to a war footing even in peacetime.

In France and Russia, no one even thought about it - as a result, in the course of the armed confrontation it was necessary to create new industries and hastily adapt existing industrial enterprises for military purposes. Of course, in Russia, for well-known reasons, it was much more difficult to do than in France — and the higher the score in solving this difficult task. Russia with honor got out of a predicament and achieved such a productivity of plants, which previously could not even dream of. Unfortunately, it should be noted that during the war proper attention was not paid to the adequate production of essential necessities for the rear — without the normal functioning of which it is impossible to be confident and in the proper supply of the army.

Due to the revealed inability to receive toluene (necessary for the manufacture of the most important explosive) from abroad, a special commission was sent to the Donbass - it had to study the possibility of extracting aromatic hydrocarbons, so necessary for the needs of the army.

A special commission examined the Donetsk coal basin and found it possible to establish the production of toluene - and in a relatively short time. She also found out that, in addition to toluene, other organic compounds in the same crude benzene can also be a source for the production of explosives. It was decided to immediately start developing ways to nitrate xylene, replacing TNT with trinitroxylene, which should not be inferior in its qualities to TNT. Similar events in Russia have not yet been held.

Since the process of pyrogenetic decomposition of coal in large quantities was carried out in the coke ovens of the Donets Basin, attention was drawn to the issue of trapping benzene and other products from coke oven gases. The extraction of coking coal products became a completely new sector of the chemical industry - before the war, products in this area were ammonium sulphate, ammonia, coal tar and pitch (more valuable products - benzene, toluene, naphthalene and anthracene - were produced in very small quantities). By the beginning of the war, gas washing in the Donetsk basin was carried out only at three plants that had a gross output of about 2,5 thousand tons of crude benzene per year. A plan for the construction of benzene plants appeared - and with existing coke ovens (benzene capture was not yet established), and a plan was developed for the construction of new coke ovens with complete capture of dry distillation products with a total capacity of over 41 thousand tons of crude benzene annually.

A very difficult task was to interest the owners of the coke ovens and convince them to take orders for the supply of the much needed toluene and benzene to the military department. An important task was the construction of benzene plants. As a result, a wonderful state-owned benzene plant was born near Almaznaya station - which gave impetus to private initiative in this area.

Benzene plants - a powerful base for the production in the country of basic materials necessary for the manufacture of explosives. These plants are also needed for other branches of the military economy, as well as for supplying the civilian market with products previously imported from abroad. Factories producing dyes, pharmaceutical and medical preparations scooped raw materials at the expense of coking products - and the dependence of these products on Germany had not previously allowed the development of these major industries. Therefore, the Chemical Committee, after Russia’s withdrawal from World War II, when considering the issue of demobilizing the military chemical industry, took care to preserve the existing benzene plants - insisting on the completion of construction of unfinished enterprises.

It was possible to increase the number of furnaces in 7 - 8, which gave the whole complex of products of dry distillation of coal.

The increase in productivity of the Russian chemical industry was as follows: if 1913 produced: raw benzene - 91 ton, pure benzene - 30 tons, toluene - 16 tons, xylene - 8 tons, naphthalene - 115 tons, then in 1918 - 25550 tons, 10000 tons, 5000 tons, 1700 tons, 4500 tons, respectively. Anthracene and phenol were not produced in 1913, and in 1918, their production reached 213 and 105 tons, respectively. And for 1918, the numbers do not take into account production in a number of regions.

26 of benzene plants producing aromatic hydrocarbons from coke oven gas was not enough to meet the needs of the army in explosives in time. Therefore, the Chemical Committee organized the production of benzene and toluene from oil by decomposing the latter at 660 - 680 ° in retorts or in special generators at the Nobel Brothers plant (the method of the Krussel engineer).

Oil pyrogenation was carried out at 6 plants: 1 in Kazan, 4 in Baku and 1 in Fergana.

Toluene was produced at two more state-owned plants (in Ekaterinodar and in Grozny) - from grades of gasoline and naphtha containing a few percent of aromatic hydrocarbons.

To extract toluene from gasoline, large rectification units had to be built. The fractions enriched in toluene were subjected to nitration to obtain toluene mononitre. The last product was sent to the state-owned Sergievsky Explosives Plant - for further nitration into TNT. These factories could produce from 65,5 to 100 tons of mononitra-toluene per month, fully justifying their existence. By correctly installed rectification, it became possible to obtain varieties aviation gasoline.

Benzene plants with coke ovens, as a rule, gave crude or purified benzene, which is a mixture of aromatic hydrocarbons, not divided into its constituent parts - whereas pure benzene, toluene, and xylene are necessary for the fabrication of explosives.

The experiments conducted at the Gutuyev alcohol cleaning plant in Petrograd demonstrated the ability to produce chemically pure benzene, toluene, and xylene. And this plant was equipped for the distillation of aromatic hydrocarbons in large quantities - both for products imported from abroad and for benzene coming from the south of Russia (until Donetsk plants were built for the rectification of raw benzene).

For fractionation of raw benzene, a private alcohol cleaning plant near Mukhanov was adapted near Belgorod. Then a state-owned distillation plant was built in Kadievka - with a capacity of over 8000 tons of crude benzene per year. A number of owners of benzene plants also agreed to supplement the equipment of their plants with the installation of distillation apparatuses - for the production of pure toluene and benzene.

Since, in addition to TNT, the army needed other explosives, the starting materials for which were various aromatic compounds, it was necessary (first of all) to make synthetic phenol - which was absent before the war.

Synthetic phenol was needed for the manufacture of picric acid - as there was almost no natural phenol extracted from coal tar in Russia. The first was the Moscow plant of synthetic phenol at Farbwerk - starting production in May of 1915, in December, it already delivered up to 100 tons per month. Then a plant of synthetic phenol was built at the station Rubezhnoy and, finally, at the station Shakhtnoy. A small amount of phenol was produced in Revel - at the R. Mavera plant. The capacity of the last company allowed to increase production to 250 tons per month.

Production of another important product, which was of great importance for the manufacture of explosives, naphthalene, was also established. Of the benzene derivatives, mention should be made of the fabrication of dimethylaniline, which is the starting material for the production of the powerful explosive tetryl used as a detonator. In addition to dimethylaniline, diphenylamine was produced at chemical plants, which was necessary to give the powders a corresponding resistance. Aniline and its salts began to be produced in Russia before the war.

The increase in the volume of manufacture of explosives went in parallel with the increase in the raw material procurement (that is, aromatic hydrocarbons and acids). It was necessary to make a tremendous job of organizing the extraction of sulfuric acid to 33 thousand tons per month. In addition, the commission managed to build the first nitric acid plant in the Donbass Yuzovka. As a result, the Russian industry manufactured the following explosives: trotyl, trinitroxylene, picric acid, dinitronaphthalene, dinitrobenzene, tetryl, ammonium nitrate, explosives of the Favier type, etc.

For the manufacture of explosives served two state-owned plant and a number of private. And only one trotyl was made at 8-m private factories.

All explosives were made from domestic raw materials.

For the needs of chemical warfare, beginning in the summer of 1915, it was necessary to organize the production of a whole range of chemical products — many of which had not been manufactured in Russia before. The manufacture of suffocating agents was preceded by laboratory experiments — to obtain proper technical methods of production.

Asphyxiation substances were produced in two types: for release from gas cylinders, where they were in a compressed state, and for filling chemical projectiles. For the first purpose, mainly served as liquefied chlorine, which is in cylinders under pressure 30 - 35 atmospheres (phosgene was added to chlorine, in relatively small quantities). Various materials were used to equip himsnaryadov - mainly phosgene, chloropicrin, arsenic chloride and hydrocyanic acid.

Other chemical products were added to the above listed basic substances in order to achieve the best results.

From the very beginning of the war, 2 large plants that produced chlorine using electrolysis could be used to obtain liquid chlorine: the Lyubimov and Solvay companies at the station Perezdnaya, and the plant of the South-Russian Electron society in Slavyansk. The first from 2 in August 1915 to 1 in October 1916 delivered about 1500 tons of chlorine; the second gave for the same time only 377 tons. Through persistent efforts, daily production of liquid chlorine in the amount of 10 tons was achieved. The last figure referred only to the two mentioned chlorine plants, but, in addition, a number of companies and organizations were given an order to produce more 14000 tons of liquid chlorine.

Another essential product of chemical warfare is phosgene. Phosgene production in Russia before the war was absent. The first order for the manufacture of phosgene was issued on July 1 1915, to the Ivanovo-Voznesensky Mechanical Products Association. Despite the enormous difficulties, the production of phosgene was established, and only 16 July - 1 October 1916, the plant supplied 17 tons of this product.

Another plant, the Shustov partnership in Moscow under the guidance of Professor Shpitalsky, produced 1 by 1917 in July to 100 tons of phosgene.

Bromine production was established in Sakki, at the Balashov plant. It was the first plant in Russia to produce bromine, a product required for pharmaceutical and other purposes. From bromine and toluene, it was supposed to produce (as a suffocating substance) benzoyl bromide, but its production was not finally established.

Chemical products produced for the filling of shells or for the manufacture of the latter were the following: chloropicrin, sulfuryl chloride, chlorine tin, yellow salt (ferrous-synergistic potassium), potassium cyanide and sodium, chloroform, arsenic chloride, hydrocyanic acid, sulfuric anhydride. Russian enterprises in the period before 1 in October 1916 produced up to 344 tons of chloropicrin. Sulfuryl chloride and sulfur dioxide was also produced before October 1 1916 g.: The first - 230 tons, and the second about 295 tons. Chlorine tin until the end of 1916 was about 230 tons delivered. Potassium cyanide and sodium were produced in small quantities — just over 1,6 tons during 1916. Chloroform (technical) was manufactured by October 1916 in about 5 tons. Arsenic chloride to 1 October 1916 was produced in quantities of about 33 tons.

The Russian chemical industry not only made a tremendous quantitative and qualitative breakthrough during the First World War. New productions appeared, a lot of work was done to mobilize the chemical industry. And this newest industry, without exaggeration, born of a world war - has become a powerful industrial base for the subsequent development of the domestic military and civilian economy.

Information