Carbine Coenders-Röchling Volkssturmkarabiner (Germany)

All the leading German enterprises were involved in the creation of the most simple in production and cheap small arms for Volkssturm. In addition, on their own initiative, several other organizations proposed their own versions of such systems. In particular, without a corresponding order, Röchling'sche Eisen und Stahlwerke GmbH launched its project in the design bureau of which, at that time, was the engineer Augustus Koders. The designer and his colleagues already had a lot of experience in creating small arms, and now it should be used in the interests of the newly created militia.

The initiative project received a fairly simple name indicating the designer, developer company and weapon class. A promising product called Coenders-Röchling Volkssturmkarabiner - "The Coenders of the Volkssturm Coders-Rehling system." Looking ahead, it should be noted that this name has remained working. The original carbine was not put into service, and therefore did not receive an official army designation.

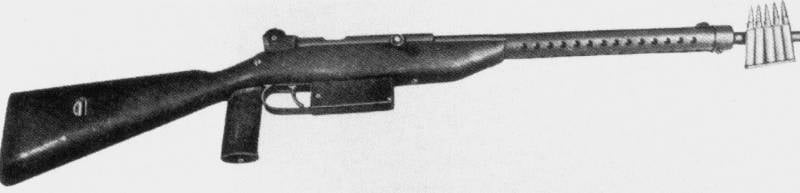

The main task of the new project was to maximize the simplification of the design of the weapon, allowing it to reduce the cost of its production, as well as simplify operation. In general, A. Koenders and his colleagues managed to get similar results. In the Coenders-Röchling Volkssturmkarabiner project, both already well-known and popular ideas were used, as well as original solutions aimed at simplifying the design. According to some information, in the course of the further development of the project, it was possible to create a fairly simple self-loading carbine.

The requirement to simplify the design eliminated the possibility of using any automation. As a result, the basic version of the Volkshturmcarabinera was supposed to have only manual recharging. The weapon should have been equipped with a regular magazine for several rounds and accessories, which ensure the proper convenience of the shooter. The carabiner was supposed to use the standard German rifle cartridge 7,62x57 mm, which made it possible to eliminate problems with the supply of the militia.

A characteristic feature of the carbine A. Koenders, also characteristic of other weapons for the Volkssturm, was the use of very simple technologies. Most of the parts had to be made by sheet metal punching. Screw, riveted and welded joints were used. At the same time, however, cast parts that were comparatively difficult to manufacture were also present.

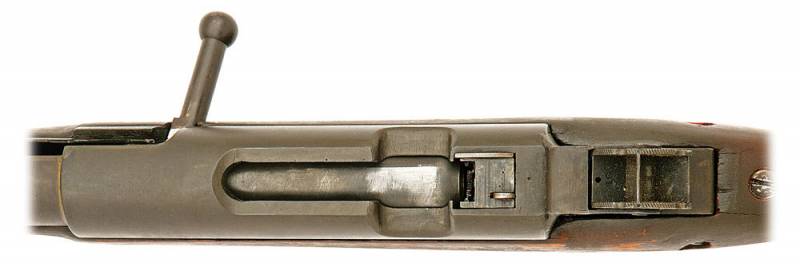

One of the main elements of the carbine was the receiver of a simplified design. Its upper part was formed by a semi-cylindrical one, which was abruptly transformed from behind into a rectangular block. The bottom box element inside the box had a rectangular cross section. In front of the receiver, on its right side, there was an L-shaped groove, necessary for controlling the recharge. In the center of the box, with a slight shift backwards, there was a hollow of a complex shape, in which the cartridge ejection window was located.

The front end of the box was designed to install the trunk housing. The latter was performed in the form of a long, open cylinder of small diameter. In the right upper part of such a cylinder there was a longitudinal groove necessary for assembling a weapon. About two-thirds of the casing, located in front of a wooden box, had a perforation. The front end of the casing was proposed to close the removable lid. It was made in the form of a small glass with a hole for the trunk in the bottom. In its place the lid was held by a screw.

Manual reloading rifles are traditionally equipped with a sliding bolt. A. Koenders decided to abandon this principle and use a moving barrel. His carbine was supposed to have a rifled barrel with a length of 609 mm (77 gauges) that did not attach to other units. The muzzle of the trunk was proposed to be carried out through the opening of the front cover of the casing. At some distance from the last on the trunk protrusions were located to interact with the return spring. The spring, respectively, was placed between the protrusions of the barrel and the front cover of the casing.

Near the breech breech on the right, at some distance from the chamber, the designer placed a straight control handle. With it, the shooter could move the barrel, reloading. To prepare the carbine for a new shot, it was necessary to turn the knob up and then move it forward. After this, it was proposed to return the barrel back and lock it by turning around its axis. At the same time, the base of the handle turned out to be an additional combat support. How other means of locking were arranged is unknown.

The use of a rolling barrel has greatly simplified the design of the internal units of the receiver. It is for this reason that the Coenders-Röchling Volkssturmkarabiner product was not equipped with a traditional shutter. Instead of a moving part, characteristic of other weapons, inside the receiver there was a rigidly fixed unit with holes for the drummer and extractor, as well as a set of guides. In preparation for the shot, the barrel pressed against this part and was fixed in place by the military stops.

The weapon received a maximally simple double-action firing mechanism that ensured consistent production of several shots. Cocking and descending sequentially carried out directly when you press the trigger. This design USM allowed to do without a separate fuse.

For Volkssturm, it was proposed to equip a carabiner with an integral box magazine on 5 with cartridges 7,92x57 mm. The store was located directly under the chamber, and a significant part of it stood outside the box. For this reason, before the trigger hook there was a relatively large metal casing. Equipping the store was offered using standard clips when the barrel was displaced. The holder itself was placed in the corresponding grooves of the plate-gate, after which the cartridges could be pushed into the magazine. Ammunition was fed to the dismounting line with a spring. The empty sleeve was removed and thrown through the upper window of the receiver.

A. Koenders proposed the original design of sights. At the rear of the receiver, on its rectangular unit, there should have been two small supports, between which was placed a drum with side discs. On the last plates were fixed-pillars with holes, designed for shooting at different distances. Turning the drum around the axis, the shooter could fire at distances up to 800 m. Immediately behind the front cover of the barrel casing, the annular base of the front sight was welded. The very fly in the form of a small pin was placed on the turntable. The latter was located inside the base, and it could be rotated around the vertical axis, changing the position of the front sight.

All accessories "Volkshsturmkarabinera" had to be made exclusively of wood. It was proposed to use a rifle box with a shortened front part protruding beyond the bounds of the receiver and supporting the rear element of the barrel casing. The neck of such a lodge had a hole for one of the mounting screws. Behind her was the butt of a traditional triangular shape with a metal back plate. For greater convenience of firing, the carbine received a wooden pistol grip mounted under the neck of the butt.

The Coenders-Röchling Volkssturmkarabiner product had a simple design and a simple working principle. However, an unusual method of recharging was used. For re-shot should turn the barrel around the longitudinal axis and feed it forward, compressing the return spring. When this was carried out removing the liner with its subsequent release. Returning to the place with the help of the muscular strength of the arrow and the energy of the spring, the barrel was put on the next cartridge and pressed against the bolt, after which it was locked by turning. After the shot, the shooter had to repeat this operation.

The cartridge is placed on the line of filing, the barrel is approaching it. Photo Amoskeagauction.com

According to reports, at the end of 1944 of the year or at the beginning of 1945, Röchling'sche Eisen und Stahlwerke manufactured at least one or two experienced carbines with manual reloading. In addition, some sources mention the existence of a self-loading modification of this weapon. The only picture of a simplified carbine, which had serious external and, probably, internal differences from the base product, is known. It could be captured second version of the weapon, which had the possibility of self-preparation for the shot.

Such a carbine as a whole repeated the design of the base Volkssturmkarabiner, but had some noticeable differences. The largest difference was the shorter barrel length, which also led to a reduction in the dimensions of the perforated casing. In addition, sights were reworked. The front sight was pushed back behind the perforation, and the mechanical sight changed its design. Finally, the casing of the barrel lost a longitudinal slot, and the trunk was equipped with a new handle. Now it was placed in the immediate vicinity of the chamber. General layout, means of ammunition, accessories, etc. did not change.

There is reason to believe that the barrel and the associated aggregates were altered in connection with the use of automation. Given the design features of the base carbine, it can be assumed that the self-loading modification should have used the principle of the bore roll. During the shot, the barrel interacting with the bullet had to unlock and move forward, compressing the return spring. Then the spring could brake the barrel and send it back, at the same time doing the ramming of a new cartridge. A new trigger pull would have led to the next shot.

At the turn of 1944 and 1945, Röchling'sche Eisen und Stahlwerke introduced experienced rifles to army specialists. Those conducted the necessary tests in the conditions of the landfill, and returned the product to the manufacturer. The carbine was considered unfit for use in the militia units. The exact reasons for this decision, however, have not been preserved. Apparently, the desire to simplify and reduce the price of weapons led to the emergence of certain design flaws or difficulties in its operation.

According to various sources, several prototypes of the new weapon were produced in two versions. The refusal of a potential customer led to a halt in production, and new carbines were no longer produced. Subsequently, several units of Volkssturmkarabiner, which were kept at the manufacturing company, fell into the hands of the experts of the winning countries. Most likely, they were studied, but, for obvious reasons, for all their originality, such weapons were of no interest to foreign gunsmiths.

Two samples of the Coenders-Rehling carbine have survived to our time. One of them is in the Springfield Armory Collection Museum. Unfortunately, this carbine over the past decades has managed to lose its trigger mechanism. The second prototype in the complete set, corresponding to the first version of the project, appeared several years ago at one of the American auctions. To get a unique sample, a foreign collector had to pay 28750 US dollars.

By the end of 1944, German enterprises had time to develop several projects of the most simple and cheap weapons for Volkssturm units. Some samples of this type were put into service and put into series, while others — such as the Augustus Coenders carbines — did not even cope with the tests. This result of the Coenders-Röchling Volkssturmkarabiner project once again confirmed the well-known truth: not all simple, interesting and unusual ideas can be put to practice.

On the materials of the sites:

http://amoskeagauction.com/

https://shotguncollector.com/

https://invaluable.com/

http://forum.guns.ru/

Information