The project of multi-purpose transporter MGT

Recall, the multipurpose armored conveyor MT-LB entered service in the mid-sixties of the last century, and remains in the army until now. Such a long-term use of this machine contributed to the successful design of the power plant and chassis, as well as the layout with the stern placement of the cargo or passenger compartment. Later, on the basis of the MT-LB machine, the MT-LBu project was created, which retained the main positive features of the basic design. The armored vehicles of the two models were used both independently, in the basic version of protected transport of one purpose or another, and as the basis for various special equipment.

For a number of reasons, the replacement of MT-LB machines is associated with certain design and technical difficulties. As a result, several projects of this kind were closed in the absence of real prospects, and the Russian industry continues to produce equipment created more than half a century ago. However, the failure of previous projects does not prevent the development of new machines designed to replace old equipment.

A new project of a multi-purpose tracked transporter is being developed by the Moscow enterprise Special Engineering Projects (SPM). This organization is engaged in various projects in the field of vehicles. Its specialists are developing both full-fledged new types of equipment and individual units suitable for use in such projects. According to available data, the project of a promising transport vehicle is based precisely on the SPM developments on the subject of power plants and transmissions.

The new project received a fairly simple designation, revealing its essence. The car was designated as MGT - “Multipurpose tracked carrier”. There are no other names in official sources. It is impossible to exclude such a scenario that the existing name will remain even after a hypothetical launch of mass production.

As the name suggests, the MGT project proposes the construction of a multi-purpose tracked vehicle capable of solving a variety of transport tasks. In addition, it can be the basis for special equipment of one kind or another. The developer calls MGT an innovative machine, because when it is created it is planned to use technologies that have not yet received wide distribution in the field of military technology. First of all, it is proposed to use a hybrid power plant and an electromechanical transmission.

In the basic transport version, the MGT machine should receive a relatively simple case, taking into account the basic requirements. Perhaps the machine in the army configuration can be equipped with an armored corps, but there is no information on this. It can be assumed that the armored hull for MGT will provide protection against small arms weapons and shell fragments.

As follows from the available data, the original power plant and transmission allowed to optimize the layout of the internal hull volumes. So, a number of large mechanical units can be replaced by compact cable routes. In this case, the power plant and various elements of the transmission should be located in the front and center parts of the hull, next to the control compartment. All feed should be given under the cargo compartment.

The frontal part of the body appearing on published MGT images is formed by several large panels. Provides for the use of an inclined upper front sheet, paired with a larger lower. On the sides of them are encouraged to mount small zygomatic parts. The lower part of the hull sides, having fastenings for running gear parts, should be placed vertically. The top is proposed to perform in the form of large nadgusenichnyh niches, increasing the available volumes. Behind the body should be covered with a vertical sheet. Provides for the use of a horizontal roof with small inclined side sections.

The MGT project proposes to use a hybrid power plant, which includes a diesel engine and a set of electrical units. In the central part of the hull, on the left side, the YMZ-536 diesel engine must be placed, coupled with the GWIT-210 alternating current generator with an XWUMX power of kW. The energy from the generator must come to the control system that controls the operation of all systems, as well as converts electrical impulses. A constant current must be supplied to the two traction motors DVIT-210 with a power of 110 kW. Traction motors are proposed to connect with drive wheels.

The generator, engines and control systems were developed by the designers of the “Special Engineering Projects”. The first copies of products GVIT-210, and DVIT-110 not so long ago were made by Sarapulsky generator plant. It is noted that the main units of the power plant and electromechanical transmission were developed and produced at Russian enterprises. Thus, the implementation of the project is not related to the procurement of imported components, which in the current situation can be considered a definite advantage.

A multi-purpose tracked carrier must be equipped with an intelligent on-board equipment complex, which includes a number of necessary systems, including controls. Control over the operation of the power plant should be carried out by controlling the power parameters of the traction motors. The absence of a traditional mechanical transmission, which has certain technical limitations, makes it possible to obtain new opportunities in the context of maneuverability. In particular, the car will be able to turn right on the spot.

The widespread use of electrical and electronic control systems in the future may provide new advantages. For example, remote controls can be integrated into the onboard control systems. In this case, the MGT machine, supplemented by a remote control panel, will be able to solve new tasks of one kind or another. A positive consequence of the use of remote control will be a sharp reduction in risks for the crew.

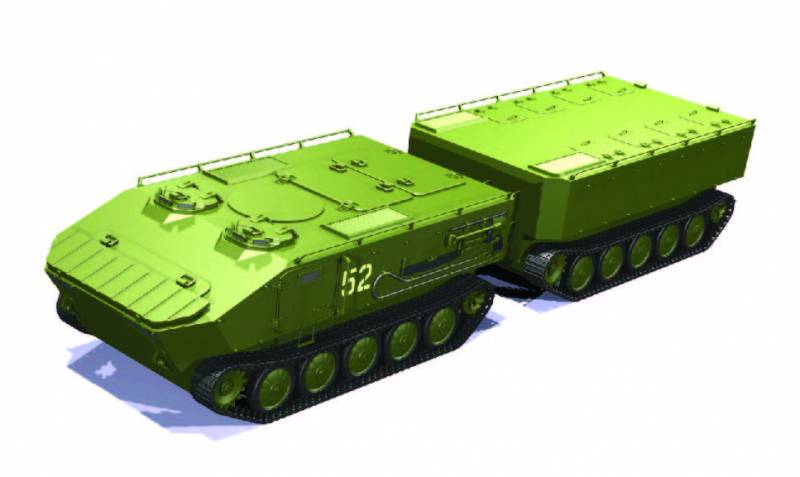

In its current form, the MGT project proposes to use the chassis, built on the basis of proven solutions and structures. On each board should be placed on five large-diameter support rollers. Also published images of the car with seven rollers on board. Regardless of the quantity, the road wheels must be equipped with an individual torsion bar suspension. Front and rear torsion bars are proposed to be supplemented with hydraulic shock absorbers. In front of the hull should drive wheels with zevochnym gear, in the stern - guides. Support rollers are not provided. A track with a rubber-metal joint should be used. Images of the conveyor suggest that its undercarriage should be built on the basis of details borrowed from MT-LB.

The optimized layout of the case allows you to get the maximum possible volume to accommodate the payload, including in the form of people. The front compartment of the hull must accommodate a double compartment of management, equipped with its own hatches in the roof. Directly behind the control compartment, on the side of the main engine, in the roof is the placement of a large hatch. It can be used for the installation of a particular equipment. The central and aft roofs can be used to place the hatches in one configuration or another. The machine can be equipped as one large doorway with several covers, and several small hatches. Side and stern doors for landing or loading should also be used.

The dimensions of the hull and the volume of habitable compartments allows you to place on board the MGT to 18 seats, including the driver. Available volume can also be used to place a load of equivalent dimensions and weight. To obtain new features, you can use the modified housing. For example, published an image of an ambulance, characterized by the presence of an additional superstructure in the aft hull. Such an add-on can be used in the construction of equipment for other purposes.

The shortened “pyatikatkovy” version of the MGT machine on official images is shown along with the tracked trailer. This product should have a large box body with its own chassis. The presence of characteristic drive wheels suggests that the trailer must have its own traction motors. The supply of energy to them, apparently, can be carried out by cables from the generator of the self-propelled machine. The design of the undercarriage of MGT and trailer for him is identical.

In its dimensions, a promising multi-purpose tracked carrier should not differ from the existing equipment of its class. The length of the car (probably in the "long" version) should be 7,21 m, width - 2,85 m, height - 2,235 m. The base of the chassis is 4445 mm, the track - 2,5 m. The chassis clearance is set at the level of 400 mm. The operating mass of MGT is defined in 12 t. The maximum carrying capacity of the machine itself is 4 t. It is able to tow a trailer weighing up to 6,5 t. Specific ground pressure is equal to 0,485 kgf / sq. Cm.

A hybrid power plant coupled with an electromechanical transmission should provide high mobility characteristics. With the help of two traction motors rated at 110 kW, the conveyor should accelerate onto the highway up to the speed of 65 km / h. It is possible to climb the slope of the 35 ° slope and move with a heel to 25 °.

A promising transporter, like its predecessors MT-LB and MT-LB, will be able to overcome water obstacles by swimming. A large enough sealed hull should have a good buoyancy margin. It is proposed to navigate through the water by rewinding the tracks. Separate propulsion for swimming is not offered. In order to prevent the frontal part of the body from burrowing into the water and flooding the roof, it is proposed to equip the car with a flip-up wave deflector. In the transport position, it must lie on the upper front plate.

At the moment, the project "Multi-purpose tracked carrier" from the company "SPM" is at the design stage. It is reported that experts have already completed the stage of calculations and mathematical modeling. Formed several options for the overall technical appearance of the future machine. According to the results of these works were published several three-dimensional computer images of the machine. In addition, published a demo video showing the features of the chassis in different landscapes.

According to the project developer, the new MGT transporter is fully adapted for operation in the difficult conditions of the Arctic. Perhaps the machine can be used in areas with other conditions, including in hot climates. In addition, it is noted that the promising project of MGT has no analogues of domestic development.

A promising multi-purpose machine MGT is proposed as a modern replacement for the old MT-LB and MT-LBu. As a result, it is designed to solve similar problems of all sorts. Depending on the configuration and configuration, this sample of equipment will be able to participate in a variety of operations and operations, ensuring the transport of personnel or cargo. In addition, it can be used as a self-propelled base for special equipment for one purpose or another.

Recall that in half a century of development and operation, the MT-LB transporter has managed to become the basis for several dozen types of equipment. Radio-electronic systems, artillery systems, special equipment of chemical troops or sanitary facilities, etc. were mounted on the existing crawler chassis. It was also created several versions of a light armored personnel carrier with cannon or machine gun weapons. Based on the basic military machine, some samples of civilian use were developed. The later multipurpose machine MT-LBu also became the basis for various samples. As before, on the basis of this chassis were built electronic complexes, artillery installations, transport and special machines.

The emergence of a new multi-purpose machine, built using modern components, but having maximum similarity to existing samples, can have the most noticeable impact on the further development of the fleet of equipment of the troops or paramilitary structures. In case of successful completion of the current MGT project, various customers will be able to get a good replacement for the existing MT-LB or MT-LBu. In this new machine, based on other ideas and solutions, will have certain advantages over existing ones.

However, we should not forget that at the moment the project "Multipurpose tracked conveyor" is in one of the early stages. The study of some basic questions has been completed and the overall look of the car has been formed. In addition, the first samples of basic electrical units have already been manufactured. Development of finished products and further development of the entire project should take some time. The complexity of such work, directly related to the use of new ideas and solutions, can lead to their noticeable delay.

Nevertheless, despite all the possible difficulties and difficulties, the project of MGT and the equipment built on it can be of great interest to domestic and foreign operators. Thus, the successful completion of the necessary work is quite capable of leading to the most interesting results. Whether the company will be able to bring its promising MGT project to the construction and testing of a prototype, and whether such technology will be able to interest potential buyers, time will tell. It is hoped that the “Special Engineering Projects” will continue to work and promptly notify the public about the successes achieved.

On the materials of the sites:

http://spmrussia.ru/

http://gurkhan.blogspot.fr/

http://bastion-karpenko.ru/

Information