“The first was bought by our patent Steve Jobs”

“A laser installation on ships will reduce transportation costs along the Northern Sea Route and when developing the Arctic shelf. For transportation in the Kara Sea instead of three nuclear-powered icebreakers of the Arktika type and two Taimyr types, three ice-breakers with a laser complex will be enough, ”one of the creators of the laser equipment for icebreakers Sergey Popov told THE VIEW newspaper.

“A laser installation on ships will reduce transportation costs along the Northern Sea Route and when developing the Arctic shelf. For transportation in the Kara Sea instead of three nuclear-powered icebreakers of the Arktika type and two Taimyr types, three ice-breakers with a laser complex will be enough, ”one of the creators of the laser equipment for icebreakers Sergey Popov told THE VIEW newspaper.In November of this year, sea trials will begin on the Dikson icebreaker, a unique laser facility for breaking ice, developed at the National Center for Laser Systems and Complexes (NCLSC) Astrophysics (part of the Shvabe holding of the Rostec State Corporation) together with scientists from the Arctic and Antarctic Research Institute of St. Petersburg.

What attitude does Steve Jobs and his “iPhone” have to do with laser technology developed in Russia, how the creators of this laser persuaded skeptics who do not believe in the possibility of laser prickling the ice, and how these technologies can save from floods and oil spills, told the VZGLYAD newspaper first Deputy Director General for R & D and Innovative Development of Shvabe Holding, Dr. Sc., Associate Professor Sergey Popov.

QUESTION: How did such an idea come about - to create a laser unit for cutting ice?

Sergey Popov: It all started in 2011, when a television report showed an operation in the Arctic to free a ship from ice captivity by two of the most powerful icebreakers. And together with scientists and laser engineers from Astrophysics NTsLSK, we thought how to make the development of the Arctic more efficient with a laser. How to help ensure uninterrupted transportation of minerals and supply of equipment for their extraction in the harsh climatic conditions of the Arctic Ocean?

The prototype of the idea of cutting ice with a laser can be called the technology previously developed by us, which almost everyone now uses. But few people know that this is a domestic technology. The first to notice this invention and bought our patent is Steve Jobs. Now

All screens on the "iPhone" and "Aipad" are cut using our method and equipment. We use this invention for industry, and Steve Jobs - for the mass consumer.

We are talking about the invention of the company "Sapphire" (now it is "Shvabe - Photosystem") in conjunction with the Institute of Thermal Engineering of the method of controlled laser thermal cracking of fragile materials. Prior to this, the screen for smartphones and telephones was cut out with the help of a diamond wheel, but this method produced a seam, the screen borders required grinding, and this is a rather laborious work.

We invented another technology: local points are heated by a laser, small lines are formed on the glass, and then a coolant (water-air mixture or nitrogen, for example) is superimposed on the heated surface. As a result of rapid heating and rapid cooling cracks of small dimensions occur. This method allows you to manage the process of cutting glass and get a seamless screen for your smartphone. In addition, it allows you to remove an edge of 0,5 mm or even less, which makes the cut glass more durable. And it can be not only the screen of a smartphone, but also sapphire or other fragile materials.

LOOK: And how does this technology work when cutting ice? Probably one of the drawbacks - the need for enormous power for the operation of a laser machine when cutting ice?

S. P.: Many people really think that it is impossible to cut ice with a laser because of the low thermal conductivity of ice, the conversion of water into steam, and other factors. Rather, it is possible, but in order to cut the ice the thickness of the entire 20 cm, it will be necessary to spend such power as two power plants produce. In fact, this is how to cut glass with a hacksaw: a lot of energy has been expended, but there is little confusion. How is glass cut at home? A diamond or a glass cutter disc, passing over the surface of the glass, leaves a scratch from which a crack is born. To cut glass with a thickness of 5 mm, a crack in 0,05 mm is sufficient. Ice splitting technology is similar to glass cutting technology.

S. P.: Many people really think that it is impossible to cut ice with a laser because of the low thermal conductivity of ice, the conversion of water into steam, and other factors. Rather, it is possible, but in order to cut the ice the thickness of the entire 20 cm, it will be necessary to spend such power as two power plants produce. In fact, this is how to cut glass with a hacksaw: a lot of energy has been expended, but there is little confusion. How is glass cut at home? A diamond or a glass cutter disc, passing over the surface of the glass, leaves a scratch from which a crack is born. To cut glass with a thickness of 5 mm, a crack in 0,05 mm is sufficient. Ice splitting technology is similar to glass cutting technology.In order, for example, to cut sapphire or glass for a smartphone screen using laser thermal splitting, the laser power must be just 20 – 200 Watts. This is an ordinary light bulb. Therefore, to cut the ice, not so much power is required.

Another important point for understanding technology. How is overcoming the ice obstacles now? Icebreaker picks up speed and its gravity with the wedge shape of the bow breaks through and pushes the ice.

The essence of the invention is that

ice is incised by a laser beam, like a glass cutter, in those places where stress concentration points occur, along which ice breaks.

To do this, we do not need to cut all the ice like a glass with a hacksaw; it only needs to be cut like a glass cutter into one tenth of the thickness of the ice. Therefore, the laser machine does not need much power. Optical design and laser head making is an art. Our know-how is to form the beam of rays that will cut the ice at a given distance from the icebreaker.

VIEW: What tests have already been carried out, what difficulties have you encountered, what do you expect from the first open-water test in Arctic conditions, which is planned to be held in November?

S. P.: At first we modeled this method mathematically. Then he conducted experiments with ice frozen in a refrigerator from ordinary water. He pricks without problems. But a number of scientists objected: salt water freezes in the northern seas, therefore there are splashes of water in the ice. This is the so-called pack (non-uniform) ice.

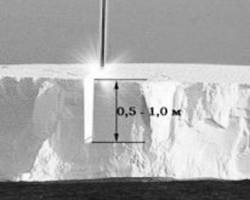

Therefore, to demonstrate the effects obtained, we invited scientists and practitioners from more than 20 organizations and conducted an experiment with a pack ice from salt water as a video. We have demonstrated to everyone that low-power laser radiation is capable of breaking ice of a meter thickness.

Six months later, we completed this technology at the St. Petersburg Central Research Institute. Academician A. N. Krylov. There is a large pool to determine the hydrodynamic characteristics of models of vessels up to 3 meters in length, where you can create ice conditions. And an experiment was conducted with a laser installation on a model of an icebreaker at a reduced scale. The result also turned out to be positive.

VIEW: At what depth did the ice break?

S. P.: At a distance of 10 meters from the vessel, pack ice is one meter thick. More have not tried.

VIEW: And where will be the laser installation on the ship?

PS: For some reason, everyone thinks that the laser system should be on the bow of the ship. In fact, it can be anywhere. It can be mounted on the upper deck or inside. And the laser radiation is transmitted over a fiber optic cable of large diameter.

VIEW: In November, you plan to conduct tests in the winter navigation on the Dixon icebreaker with a laser installation. What concerns are the real challenges?

S. P.: There are many of them, and for this we need a full-scale experiment. For example, from the icebreaker are vibrations. Ideally, the laser beam goes in a straight line, but in practice, if the source on which the laser is mounted vibrates, then we can get another picture. We tried to take into account the vibration mathematically, came up with a gyrostabilization of the laser head. Gyrostabilization is generally our strong point, we can do it. Not the fact that in practice everything will be one to one as in theory. Therefore, I can not say that tomorrow it will work. But in that it will work, I am sure. It is just necessary to test and modify in practice.

S. P.: There are many of them, and for this we need a full-scale experiment. For example, from the icebreaker are vibrations. Ideally, the laser beam goes in a straight line, but in practice, if the source on which the laser is mounted vibrates, then we can get another picture. We tried to take into account the vibration mathematically, came up with a gyrostabilization of the laser head. Gyrostabilization is generally our strong point, we can do it. Not the fact that in practice everything will be one to one as in theory. Therefore, I can not say that tomorrow it will work. But in that it will work, I am sure. It is just necessary to test and modify in practice. VIEW: What is the practical significance of such a laser installation? Is it announced that it will increase the ice passability and icebreaker class?

S. P.: The icebreaker "Arktika" can overcome the ice 3,5 depth meters, because it has a powerful power plant and a huge mass. And there are small vessels that can pass the ice with a depth of no more than 1 meter. But with the help of a laser system, they will be able to overcome the ice depth as far as 1,5 – 2 meters without special load. Formally, the ship's class rises. The icebreaker will not become harder and more powerful from this, but its ability to overcome the ice field will increase.

VIEW: The state in the framework of the State Program for the Development of the Arctic is investing huge sums in the construction of expensive powerful icebreakers. But if the laser system can increase the class of the icebreaker, then maybe such expensive ones are not needed anymore, there are enough small class icebreakers?

S. P.: An interesting question. I think that large vessels of the class "Arctic" will still be needed. Despite the high level of scientific forecasting, it is not always possible to calculate the depth and movement of the ice field until the end. Periodically, the ice still clamps the vessels. For example, on the way of an icebreaker with ice penetration depth up to 1,5 meters thicker ice appeared, to release him from the ice captivity it is necessary to organize an expensive rescue expedition. And the presence of such a laser system will help the icebreaker to maintain permeability in more severe weather conditions than meteorologists have calculated, which will reduce the number of rescue operations.

According to economic calculations, a laser installation on ships will reduce transportation costs along the Northern Sea Route and in the development of the Arctic shelf. For example, they considered that instead of three nuclear-powered icebreakers of the “Arctic” type and two nuclear-powered icebreakers of the Taimyr type, three icebreakers with a laser complex would be enough for transportation in the Kara Sea. That is, instead of huge icebreakers, there will be enough smaller class icebreakers. Our technology will help to quickly implement the tasks set by the state: to increase the season of ship transportation along the Northern Sea Route, make it year-round, and increase the freight turnover.

VIEW: Are there any other ways to apply this technology?

S. P.: We have directly “squeezed” another development out of the same laser. Based on the same laser, another idea emerged for new development. It helps to quickly deal with oil spills on water. Oil film now collect special equipment. In the Gulf of Mexico, spilled oil was attempted to be collected in various ways over a long period of time, due to which enormous damage was done to nature, many fish, marine animals and birds were killed. And using a laser system to solve this problem can be much faster.

We carried out pilot tests with small oil spills - you can remove several hundred square meters of oil pollution per hour.

The laser beam is directed to the spot and focuses just below the surface of the water, then the oil spot lights up and rises with the steam. Steam-water mixture burns with almost no residue. Combustion products are minimal. Environmentally it is safe: nothing happens under the surface of the water. This technology is developed and patented.

There are pessimists who believe that if a large area of spilled oil is scorched in this way, then an oil cloud will turn out. But you just need to find a middle ground so that the oil on the water burned manageably. And for this we need practical tests.

We showed this development to oilmen. They ask for the finished product. But the finished product requires investment, and this is only the development.

Another of our inventions can help flood control. There are many northern rivers in Russia, and each spring the ice thaws in their mouths later than in the southern latitudes, floods occur. To prevent them, the Ministry of Emergency Situations conducts ice blasting measures using aviation, as well as specialists in this field to crush the ice field and raise the water level. These are not the most environmentally friendly and safe methods of control for marine life.

VIEW: There are already potential customers of laser systems?

VIEW: There are already potential customers of laser systems?S. P.: At least two customers are available. This is the Northern Shipping Company (this organization will provide an icebreaker for full-scale tests in November), as well as the Ministry of Emergency Situations.

After the presentation of the laser machine at a conference on flood control, representatives of the Emergencies Ministry, as well as the government of the Yakutsk region, expressed interest in this development. At present, the stage of scientific research on all three inventions has been completed, but there is no mass production yet. It is necessary to complete the development phase.

VIEW: Is there an export potential?

S. P.: After carrying out experiments at the Institute named after academician A.P. Krylov project was nominated in 2013 year for the competition in Geneva, where he was awarded the gold medal of the International Innovation Salon Inventions Geneva. At the same event, representatives of the Canadian company became interested in the development. In Canada, ice conditions are very similar. However, after the introduction of sanctions, interaction ceased.

In 2017, representatives of the People’s Republic of China also became interested in the project.

VIEW: How many have already passed from the beginning of the idea?

S. P.: The idea originated in 2011 and was patented in 2012 by our company NTsLSK Astrophysics. Since then, we are gradually implementing this innovative project.

VIEW: Not enough funding? As part of the state program, funds were allocated ...

S. P.: The money allocated for scientific research is not enough. And since the success of this project was doubted by many, the funds allocated were only enough for modeling.

VIEW: Now believe?

S. P.: Believe. But now we are talking about the development work, practical tests, requiring new tools. While we are trying to find money from different sources. Due to the fact that funds are allocated from disparate channels, we can not do it all right away. Now we are trying to join the program of development of maritime transport to 2030 year and enter the program of development of the Arctic as a separate segment.

VIEW: How much money is needed to bring the project of a laser machine for icebreakers and two other laser projects to mass production?

S. P.: This is not a cheap pleasure, but the amounts are far from transcendental. We are talking about several hundred million rubles for an icebreaking project, and about the same amount is needed for two other projects - to remove oil stains on the water and to destroy ice in the mouths of northern rivers to reduce the risk of flooding. And then within one or two years we could bring all three projects to a commercial product.

VIEW: How much will the finished product cost?

S. P.: Not ready to say exactly. But it will most likely be tens of millions of rubles. A laser machine for an icebreaker, which will raise its ice class, will cost only about 5% of the icebreaker cost.

Information