Driving "Wave" on the shore of the enemy. Part one

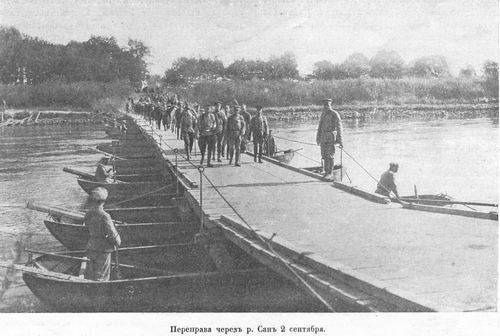

Crossing the troops through water barriers is one of the most difficult engineering challenges. Famous military engineer A.Z. In 1856, Telyakovsky wrote: "Crossings, made in the mind of the enemy, belong to the most courageous and difficult military operations."

A water barrier is one of the most common obstacles in the way of troops, and crossing over rivers is one of the most dangerous activities. In addition, the equipment and maintenance of the crossings is also a difficult engineering task in all types of modern combat, and especially in the offensive, because the enemy will seek to use water barriers to delay the attacking troops, disrupting the attack or reducing its pace.

In this case, there are two ways to overcome the water barrier - the actual crossing and forcing. A crossing is a section of a water obstacle with an adjacent area, provided with the necessary means and equipped for the transfer of troops in one of the possible ways, namely:

- landing on floating tanks, Armored personnel carriers and infantry fighting vehicles (landing crossings);

- assault force on ferry-landing craft and ferries (ferry crossings);

- on bridges (bridge crossings);

- in winter on ice;

- tanks for deep fords and under water;

- in the shallow water ford;

Crossings are equipped and provided with means of transport, depending on the nature of the units being transported and their armament. At the same time, it is necessary to strive to ensure that units (crews, crews) are transported in full force with their regular combat equipment. This determines the type of crossing, its carrying capacity and the necessary engineering equipment.

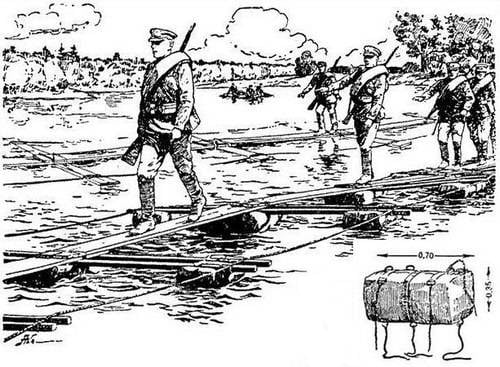

Forcing is the overcoming of water obstacles (rivers, canals, bays, reservoirs) by the advancing troops, the opposite bank of which is defended by the enemy. Forcing differs from the usual crossing over the river in that the advancing troops, under enemy fire, overcome a water obstacle, seize bridgeheads and develop a nonstop offensive on the opposite bank.

Forcing rivers is: - on the move; - with systematic preparation; - in a short time in the conditions of direct contact with the enemy on the water line, as well as after a failed crossing of the river on the move.

Thus, the success of combat operations when forcing water barriers largely depends on equipping troops with the means to overcome water barriers, as well as on their level of development. Therefore, at all stages of development of the Soviet Army, these issues were given special attention.

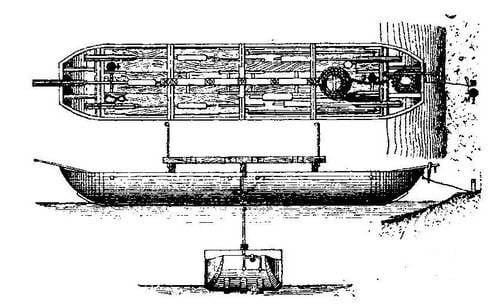

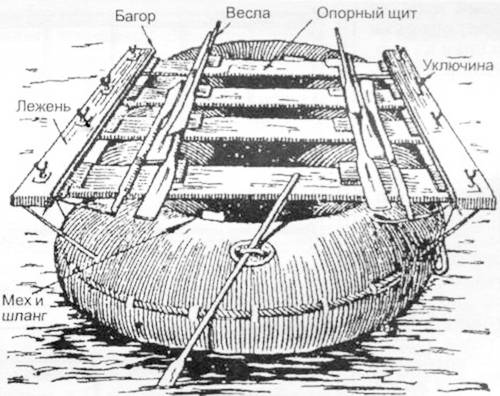

The Red Army inherited from the old Russian army overalls - a pontoon park built by Tomilovsky, light transport means in the form of canvas bags by Ioloshin and inflatable floats of Polyansky.

These funds were obsolete, were available in small quantities and did not correspond to the maneuverable nature of the hostilities of the Red Army. The first steps in the development of new crossing facilities were made in the direction of creating a park on inflatable boats, which was determined by the positive experience of the use of float property by the Red Army during the civil war, as well as the need to focus on the transport of the park by horseback transport.

In 1925, the A-2 inflatable boat park with a wooden superstructure (flooring) was designed and tested. The park allowed to assemble ferries and build bridges with a carrying capacity of 3, 7 and 9 tons. and 1931 t. In 3, after some modernization, which somewhat increased the load capacity, it received the designation MPA-3 (the designation MPA-3 occurs). The kit was transported on 7 special vehicles or on non-equipped 9 vehicles.

In connection with the increase in the level of mechanization and motorization of the Red Army, with the advent of tanks weighing up to 32, etc., in 1928 - 29. work was begun on finding new designs of pontoon - bridge facilities. The result of this work was the adoption of the Red Army in 1934 – 35. heavy pontoon park NHNUMXP and light NLP. For the first time, high-quality steels were used in these parks for the manufacture of the upper structure (girder), and for the motorization of the ferries - towboats.

However, the N2P and NLP parks did not allow equipping crossings across wide rivers in the presence of significant waves on the water, since they received a large rolling pit, during which the movement of equipment was difficult and sometimes impossible. In addition, open pontoons are often overwhelmed with water. With this in mind, a special pontoon fleet SP-1939 was adopted in 19. The park's pontoons were steel, closed and self-propelled.

The park included 122 self-propelled pontoon boats and 120 bulk trusses of the span structure. For the assembly of bridges and ferries served one railway crane, also included in the park. Due to the large size, the park elements were transported by rail. Farms of the span structure were installed on boats and served as a carriageway of bridges.

During the war years, work continued on new and modernization of pre-war means of transport. Thus, the TMP park (a heavy bridge park), which differed from the HNNUMP by the presence of closed semicontons, became the further modernization of the H2P park.

At the end of 1941, a simplified version of the H2P and TMP parks appeared - a wooden bridge park DMP. In 1942, the park developed a DMP - 42 with a carrying capacity of up to 50 t (for a DMP - up to 30 t). In 1943, a light wooden DLP park was adopted, which had open glide pontoons.

The experience of the use of pontoon parks during the Great Patriotic War showed that the work on the device of the crossings was poorly mechanized. All parks were distinguished by multiple elements, which increased the complexity of work. Therefore, immediately after the war, in 1946 - 1948, work began on the development of new pontoon parks, as well as work began on the creation of self-propelled transfer means.

In 1950, a K-61 tracked transporter and a large floating vehicle were used for assault landing of infantry and light artillery systems.

At the beginning of the 1960's they are replaced with more advanced and larger self-propelled GPS steam and a floating conveyor of an average TCP. GSP was intended for the crossing of tanks, the PTS transporter for the crossing of personnel and artillery systems with tractors (the tractor was transported directly on the conveyor, and the gun on a special floating trailer).

In 1973, the floating transporter PTS - 2 is put into service, and in 1974 - the self-propelled pontoon SPP fleet. The main element of the SPP park bridge was the ferry - bridge PMM, which is a special off-road vehicle with a hermetic hull and two pontoons. The PMM machine can also work autonomously, providing for the transfer of equipment weighing up to 42 t. In addition to the PMM in 1978, the crawler version of the PMM self-propelled ferry 2 is used.

The creation of self-propelled PMM ferries increased the rates of bridging of bridges and ferries, and also significantly reduced the time of transition from the bridge to the ferry and vice versa.

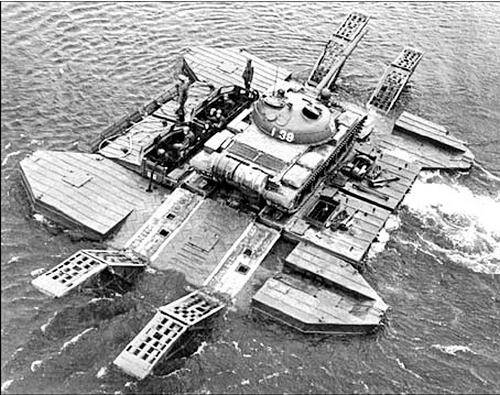

Self-propelled ferries are designed for ferry and bridge crossings of heavy military equipment, primarily tanks. They can consist of one car or two cars with half-steam trains. The required capacity and stability of self-propelled ferries is ensured by equipping the driving machine with additional tanks (pontoons). The pontoons themselves can be rigid or elastic (inflatable). For loading equipment on additional ferries, ramps are hung, usually of a rut type.

In the Soviet Army in service consisted, as mentioned above, self-propelled ferries GSP, PMM and PMM - 2. The head enterprise for the production, development, testing and modernization of the above ferries was the Kryukovsky Carriage Works, or rather the design department of the OKG - 2.

This is a brief storyand now about the main thing.

Once, Yevgeny Lentsius, the chief designer of the special equipment of the Kryukovsky car-building plant, was asked: "And what is your favorite car?" Evgeny Evgenievich replied to this: "Floating conveyor and ferry - bridge machine on tracks" Wave - 2 ". Regarding the ferry - bridge machines - this was a new milestone in the history of the development of floating machines in our country. It was a new generation of cars - with a large carrying capacity, with great potential. "

But before Wave, the 2 was a Wave machine, the 1. It all started with the fact that in the minds of designers has long flown the idea to create a machine capable of carrying a tank. However, experts understood that to hold such cargoes on the water, additional sliding or inflatable tanks are needed. But how to place them so that these containers can be used not only on the water, but also transported by rail, inscribed in its dimensions, taking into account the ground clearance of the railway platform? How to achieve such nasal bevels of the car, so that it was streamlined and easily moved by land and water? How to get the required volume to create a buoyancy margin when working on water with a load?

To address these and other issues, the Central Scientific Research Institute. Karbysheva designed and manufactured an experimental model of a machine with longitudinal loading of cargo and folding containers. It was a wheeled vehicle with the formula 8х8 based on a ZIL car, equipped with front and rear jet engines. During the tests, a number of flaws were identified: when driving on land, the visibility to the driver was unsatisfactory, the car hardly landed on the shore during the course, etc. These problems had to be solved. And they should have been solved in Kremenchug.

In 1972, the Kryukovsky car-building plant was assigned the task of developing a ferry-bridge machine under the code "Volna". The purpose of the vehicle is to provide ferry and bridge crossings over water obstacles of machinery and cargo weighing up to 40 t.

It should be said that 40 t is the load capacity of one machine. The technical assignment also provided for the possibility of docking individual PMM machines for the formation of ferries of greater capacity and solid bridge crossings over rivers with a current speed of up to 1,5 m / s.

The car was created on the basis of the car with the wheel formula 8х8 using the components and assemblies of the wheeled vehicle BAZ-5937. The car itself was commissioned to create the Bryansk Engineering Plant.

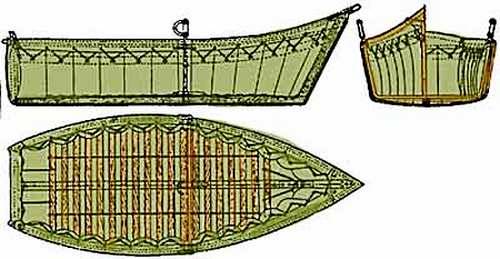

At the same time, it was decided to design the Volna car (product 80) with the transverse arrival of the load on the ferry. To obtain the required minimum buoyancy margin, we decided to reduce ground clearance by unloading torsions and placing the wheels on the stop, reducing the pressure in the wheels, making the car body and pontoons of aluminum alloy.

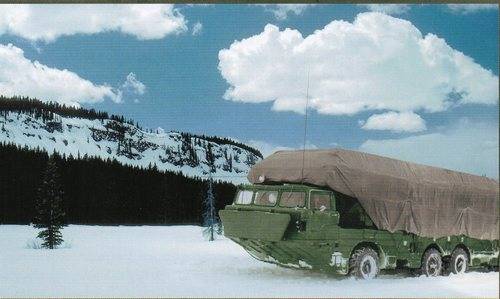

The “Wave” machine consisted of a leading machine (hermetic enclosure), above which two pontoons, laid one on top of another, stood in a stop-like manner. On land, the pontoons with hydraulics opened one to the right and the other to the left, forming a cargo platform of length 9,5 m. To load cargo onto the platform, each pontoon was equipped with two ramps that fit the shore, providing docking for the ferry with the shore. Each ferry has docking devices with which the machines can be interconnected. Thus, depending on the width of the water barrier, a floating bridge was formed, in which there were two, three or more cars.

In order to simplify the design and to meet the requirements for transporting the car by rail, aluminum alloys are used in the manufacture of hulls and ferries, and all the power elements of the hull structure are made of alloy steel. At the same time, the complexity caused the joining of steel and aluminum elements. Since it was impossible to weld such a connection, bolts and rivets were used.

To move the machine afloat, the Ministry of Shipbuilding Industry developed special folding columns, which, by means of a remote control, provided the movement of the machine on the water. However, during the tests it was found that these columns do not provide a given afloat speed and movement synchronism. The plant abandoned these speakers and developed its propulsion design. They were a round nozzle in which the screw was placed. The attachment was attached to the body and had the opportunity to change its position. When driving on land, the nozzle was removed into the body cavity at the stern of the car, and when working on water, it was lowered down.

The hull of the leading machine - a closed type of all-welded aluminum alloy construction - has a three-seater closed cab made of fiberglass and the roadway, on which the transported equipment is placed. The machine has intra-ferry and inter-ferry butt devices for connecting the boats and the hull of the leading machine and the formation of a ferry with a single carriageway, as well as for connecting several ferries to each other in order to form a ferry with an increased carrying capacity or floating bridge.

Movement on the water is provided by retractable propulsion-steering devices in the form of two propellers with a diameter of 600 mm in guide nozzles with water rudders.

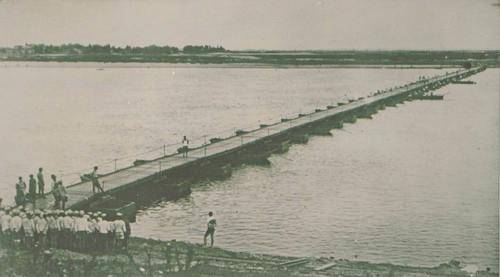

When a prototype was assembled in 1974, as E. Lenzius recalled “I understood with satisfaction that all the specified technical characteristics were fulfilled. The machine has successfully passed the factory tests. Several samples were made for field - military tests, which were conducted on the basis of the Kiev Military District in the area of the town of Rzhishchev. During these tests, experiments were carried out on joining only the ferry-bridge cars among themselves, but also the connection of our cars with the elements of the ferry-bridge park ”.

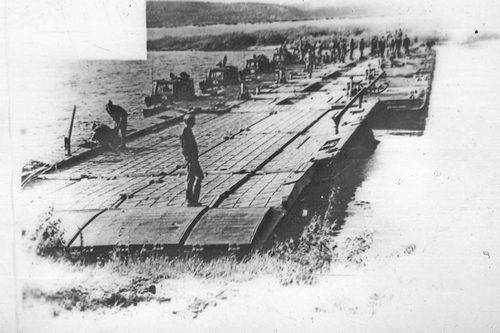

The park links docked to the machines with the help of specially made transition elements - special floats with power joints. One side they docked to the "Wave", and the other to the links of the park PMP. Depending on the number of machines and links, the PMP created bridges of different lengths and passed through them a column of tanks. Bridges tested passed.

It is appropriate to note here that at the development stage of the technical design of the machine by the Leningrad Institute. Krylova conducted studies of its behavior in the water. And at the Moscow Energy Institute studied the behavior of the machine in the line of the bridge. Now all this has been confirmed in practice.

The main load in the line of the bridge fell on the butt beams. Each such beam was tested for strength and laboratory tests with strain gauges before mounting into the body, i.e., when sensors were applied to all of the power elements, which showed voltage on a particular section of the beam under different loads.

The new car had characteristics unheard of at the time. The time of formation of the ferry, starting from the moment the machine approached the water's edge and up to taking over the load, was 3 - 5 min. Assembly time of the bridge is a long 100 m - 30 min. The speed of movement on the water of the ferry from one machine with a load of 40 tons - 10 km / h. The crew of the car consisted of three people - a driver, a pontoon and a car commander. Each machine was equipped with radio communication and intercom.

A pumping system was provided at the PMM: one motor pumped water from the hull, the other from the pontoon. In addition, the pontoons "Waves" filled with foam, which increased their unsinkability. For the first time, fiberglass was used for the cabin, it came out lighter and stronger. For the manufacture of the cab made a special blank, which pasted over several layers of fiberglass.

After all the necessary tests, the Volna PMM was put into service, and in 1978, production was established at the Stakhanov Railcar Building Plant.

On the basis of the PMM "Wave" machine, a pontoon - SPP bridge park was created, which included 24 amphibian PMM with coastal and transitional links, which, depending on the combat requirements, could be quickly transformed into separate ferries or used for the construction of temporary belt bridge crossings. When two or three ferries were connected, large self-propelled transport and amphibious vehicles with a carrying capacity of 84 and 126 were formed, and from the entire fleet of the fleet during 30 - 40 minutes it was planned to assemble an 50-ton bridge up to 260 meters long.

The SPP fleet was put into service, but in operation it turned out to be impractical and unsuitable for performing its basic functions. An important constructive error of the PMM machines was the uncovered drive wheels, which significantly increased the resistance afloat and reduced handling. However, the inclusion of all the wheels afloat could provide additional traction. Increased own weight of the ferries and low landing led to an increase in the specific pressure on the ground and reduction in maneuverability in the coastal zone (but this could be solved using the “liner”), and their huge dimensions did not allow to move on public roads and did not fit into the railway dimensions. In addition, the PMM amphibians proved to be the most difficult, large and expensive transport means, unable to compete with traditional pontoons transported. With the advent of heavier military equipment, the use of an SPP fleet and PMM vehicles in general has become impractical. Their release was carried out until the middle of the 1980-ies, and the total number of collected amphibians was calculated for the acquisition of one set of SPP. To date, the AMP amphibians remain in service.

Also, the lack of protective weapons can be attributed to the lack of PMM, which is a major and long-standing disadvantage of all engineering machines. This disadvantage is especially significant for machines that force water barriers, i.e. troops operating in combat formations. Moreover, PMM does not have at least any armor protection.

TTH ferry - bridge machine PMM "Wave - 1"

ferry weight, t 26

load capacity, t 40

land speed, km/h 59

speed on water with a load of 40 tons, km/h 10

speed on water without load, km / h 11,5

crew, people 3

Information