Mortar complexes: mobility first

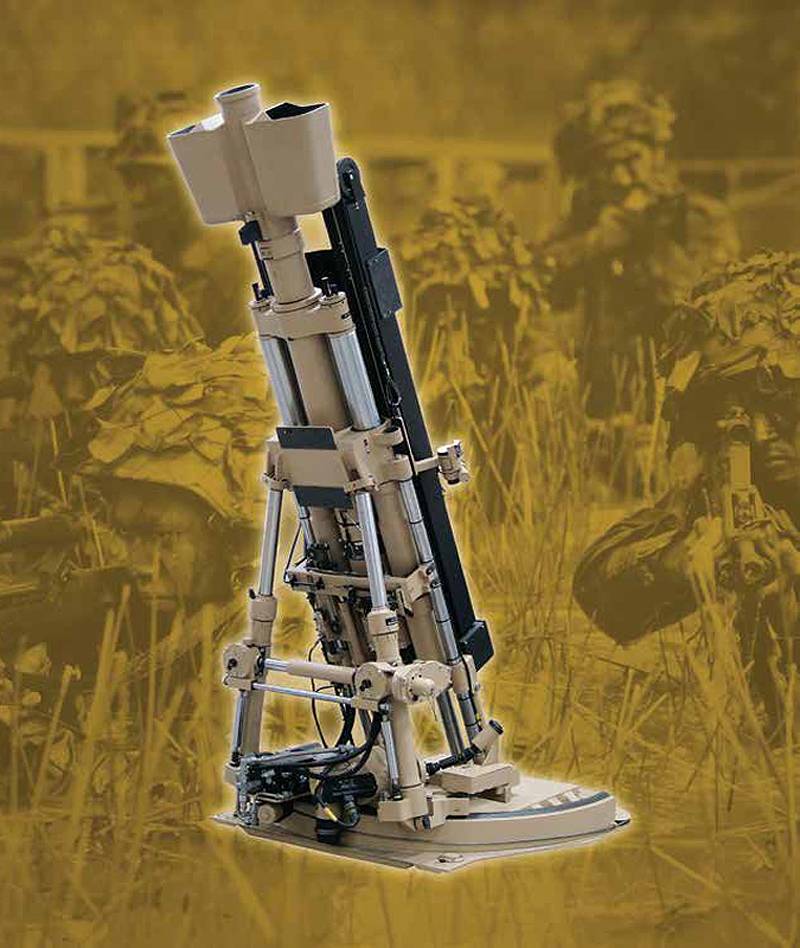

Mortar complex Cobra company RUAG, which is a further development of the mortar Bighorn, was shown at the exhibition IDEX 2015 with new electric drives and new control system

The improvement of ammunition for mortar systems, which for many years were considered to be the infantryer's own artillery, greatly enhances their effectiveness. Digitization added the ability to shoot several shells in a very short time with unprecedented accuracy, the control systems now completely take over the fire with all control over the firing cycle, in some cases with the exception of loading. Mainly considered previously a stationary weapon system, the mortar was subsequently installed on vehicles in order to obtain the mobility necessary for light infantry and motorized rifle units. Nowadays, infantry formations are increasingly operating from light armored vehicles, and mortars follow this trend. In this regard, it is necessary to develop new solutions with small forces of rollback, so that the chassis of vehicles of this class can withstand them. Mortars installed in the towers are not considered in this article.

In the world of 120 caliber mm, one of the newest systems is the Cobra mortar complex, developed by the Swiss company RUAG Defense, which used the experience gained from the previous Bighorn system. The barrel, recoil brake and recuperator are taken from the previous Bighorn project, among the main changes are electric drives that replaced all hydraulic systems, as well as a completely new ballistic computer. Cobra can be equipped with smooth-bore shafts of different lengths, 1600 and 2000 mm, while the range is respectively 7000 and 9000 meters. At the time of the shot within 30 milliseconds, the recoil forces do not exceed 30 tons, which allows the mortar to be installed on two-axle trucks, although most of the proposals are based on the 8xXNNXX chassis. The total mass of the Cobra mortar is 8 kg in the base case and 1200 kg when adding an automatic loading system. The starting customer is the Swiss Army, its 1350 armament program of the year provides for the purchase of 2016 systems for 32 million euros, which will be installed on Piranha 370 + (3x8) armored vehicles manufactured by GDELS. Since 8, when the 2009-120 64 / 91 mortar systems based on MPZ armored personnel carriers were decommissioned, the Swiss infantry had no mobile fire support system from closed short-range positions. The Swiss army chose a barrel with a length of 1600 mm and a new “12 cm / 16 mortar” was assigned to artillery units. Each of the four divisions of self-propelled artillery will receive a battery of 8 mortars, two platoons of the 4 system. In combat conditions, mortar batteries and a platoon can be subordinated to the formations of the level of an infantry battalion or left under artillery subordination and used as main firing units. Thus, the mortars are integrated into the system of command and control of artillery fire INTAFF. The contract includes 36 ammunition transport containers, as well as 12 protected supply trucks. Shipments are scheduled for 2018-2022 years.

The TDA's 2R2M mortar is the best seller among the systems installed on the machines. It is in service with four foreign customers in Italy, Oman, Malaysia and Saudi Arabia and is chosen by France for the MERAC program (Mortier Embarque Pour l'Appui au Contact). The 2R2M mortar has an 120-mm rifled barrel with a length of 2000 mm, which is also equipped with a towed version of the 120RT; the maximum range is 8,2 km when firing standard ammunition, 13 km when firing with active-reactive mines and 15 km when firing guided projectiles. Serves a mortar with a semi-automatic loading system calculation of three people. Mortar complex 2R2M is constantly being improved, the second modification has received some new elements, which will then be implemented on already deployed systems. Based on the specifications of the MERAS project, which is part of the Scorpion program of the French army, further refinements of the system will follow; The 2R2M will be installed on the new Griffon 6x6 armored personnel carrier. The safety level of working with the system will be increased, the functional responsibilities of the hand operator and the loader will be reduced while simultaneously expanding the control functions of the calculation commander. TDA, part of the Thales group, is also going to refine the recoil mechanism that will allow the installation of the 2R2M mortar on the 4x4 configuration machines. The possibility of finalizing the software for firing in different modes is being considered.

Mortar 2R2M installed on an Italian army Freccia armored vehicle during qualifying shooting

Middle plan mortar 2R2M; TBA is improving the base model and developing a version designed for installation on a new French mortar conveyor

At Eurosatory 2014, Elbit Systems unveiled its stand-alone Spear 120-mm mortar system equipped with a recoil system that reduces the recoil forces to less than 10 tons. With a mass less than one tonne, it can be installed on light vehicles, for example, the chassis of an HMMWV armored car, in this configuration the ammunition load is 36 shots. The calculation of the muzzle-loading mortar is two to three people, it is equipped with a fully digital computerized guidance and navigation system. This system is based on the second-generation Cardom mortar complex tested in combat conditions; its rate of fire reaches 15 rounds per minute. The mortar is ready to fire in less than 60 seconds, and its circular deviation is less than 30 meters. Spear aroused the interest of the Israeli armed forces. As usual, Israeli companies do not name their customers, but, apparently, the Thai army has become the starting customer, although the number of purchased systems remains unknown.

Singapore-based ST Kinetics developed, on its own initiative, an 120-mm automatic smooth-bore mortar SRAMS (Super Rapid Advanced Mortar System - an ultra-high-speed advanced mortar set), which recoil forces are reduced to less than 26 tons, and the maximum rate of fire is 10 per minute. The SRAMS mortar weighs less than 1200 kg, is equipped with a barrel length 1800 mm, the angles of vertical guidance are 45 ° -80 ° and horizontal guidance ± 40 °. The patented barrel diffuser of the original design reduces the overpressure of the shock wave when fired, thereby increasing the safety of the calculation. This mortar, acquired by the UAE, was installed on the chassis of the RG-31 Agrab; The first batch of the 72 installation was delivered at the end of the 2014 of the year, while the next batch is currently being shipped from the 26 systems ordered later. The Agrab mortar ammunition processing system is based on two 23 roundabouts in each. An auxiliary power unit is installed on the machine for power supply of the complex during the stopping and powering of the fire control system (SLA) and the air conditioning system. Most of the systems produced in the UAE, where they are in service with special forces, which use them intensively in Yemen. STK has recently launched a refinement program aimed at reducing the mass of the system and replacing all hydraulics with electric drives, and a kit is being developed for firing guided ammunition and projectiles equipped with programmable fuses.

120-mm automatic smooth-bore mortar SRAMS

The Spanish company NTGS (New Technologies Global Systems) (a recently created small engineering enterprise) developed the Alakran mortar. This system uses a different principle instead of the traditional mechanism for reducing the recoil forces; A large square base plate 120-mm mortar mounted on the rear platform of the machine transfers the recoil forces to the ground. Horizontal guidance angles are ± 60 °, vertical guidance is from 45 ° to 90 °, and the mortar is guided by electromechanical drives. Guidance is performed automatically using the MAD 1 (Mortar Aiming Device) computerized pointing device; Shooting tables, geographic information systems, and target data are stored in the battery commander’s computer, which is connected to the SLA by radio. The MAD 1 device is equipped with GPS, orientation and elevation sensors. The limited mass of the system allows it to be installed on a pickup truck with a tonnage of 1,5; during movement, the mortar barrel is placed horizontally on the load platform. At the end of 2016, NTGS and its partner Everis, which is responsible for integration, achieved their first export success - an unnamed country ordered 100 Alakran 120 mortar complexes to be installed on Toyota Land Cruiser 4X4 vehicles.

Alakran mortar, created by the Spanish company NTGS

The latest development of the Israeli company Elbit Systems - Spear mortar complex, which, thanks to an effective recoil mechanism can be installed on light vehicles

Mortar complex Vingpos with 81-mm barrel, developed by the Norwegian company Vinghog (Rheinmetall division), was created in accordance with the Norwegian requirements

After the acquisition of Norwegian Vinghog, German company Rheinmetall introduced 2014-mm automated system in 81 year, developed in accordance with the requirements of the Norwegian defense supply organization and finally configured for Hagglunds CV90 armored vehicle production MULTI version of BAE Systems. Mortar complex, known under the designation Vingpos Mortar Weapon System (MWS), is installed on the base, which allows you to quickly remove it from the MULTI armored vehicle in order to use this chassis for other purposes; By the way, 16 of such machines were ordered by Norway. One of the main design requirements was to minimize the recoil forces acting on the chassis. Vinghog turned to the German company Weforma Dampfungstechnik GmbH, specializing in braking technology, which developed two hydraulic shock absorbers of constant stiffness with pneumatic springs, which reduce the recoil force from 412 kN to about 100 kN during the rollback 90 mm. The weight of the sliding parts is approximately 340 kg, two shock absorbers of the recoil system absorb about 2700 joules. Mortar L16A2, which is in service with the Norwegian army, was made then by the company Royal Ordnance; It can be easily removed for maintenance or in the event of a misfire. A mounting system was also developed that made it easier to install mortars of other models. The total mass of the Vingpos MWS complex is less than 1000 kg; during movement, the mortar is transported inside the vehicle with closed hatches in the roof. An electric motorized base plate rotates ± 90 °, and the vertical angles are + 45 ° / + 86 °. The guidance is fully automatic, the mortar Vingpos is equipped with an INS / GPS navigation and positioning system, as well as a motion sensor, all of which are connected to the Konsberg Odin fire control computer via a data distribution unit; the only manual operation is loading. In the event of a power system malfunction, the manual backup branch allows firing from a mortar, but with limited functionality. One soldier, using a human-machine interface in the form of an 6,5-inch touch screen, can service a Vingpos mortar. In addition to the Norwegian order, Rheinmetall also hopes for potential foreign customers, while considering an option with an 120-mm barrel.

Thales South Africa developed the Scorpion mobile mortar system, armed with Denel 81-mm long-range mortar

The Thales South Africa Scorpion mortar mounted on the Polaris Ranger 6x6 chassis was shown at IDEX 2015

In 2012, Thales South Africa first introduced the 81-mm Scorpion, the development of which was completed later, at the end of 2014, 2014. The system is based on a platform with electric motors that provide guidance in azimuth and elevation. Data for the shooting provides a strengthened tablet computer, while the data from the advanced observer or command post of the upper echelon is transmitted to the complex via the built-in radio channel. The location provides a device that includes GPS, inertial navigation system and odometer. Palletized (based on the type of pallet) Scorpion complex is powered by rechargeable batteries; reloading is provided by a generator carrier platform, the power supply unit is equipped with a decoupling relay for recharging the main and backup batteries. Mortar calculation can shoot the first projectile 15 seconds after stopping the machine; the maximum rate of fire is 20 shots per minute, loading is done manually, the number of shots in the ammunition depends mainly on the carrier platform. The standard armament of the complex is a Denel 81-mm long-range mortar. However, for those armies that use ammunition of Soviet origin, a barrel with a diameter of 82 mm can be installed. The recoil system allows the Scorpion mortar system to be installed on any light platform, ranging from the Wasp / Hornet 2,5-ton amphibious assault vehicle to large SUVs, such as the Toyota Land Cruiser, Nissan Patrol, Land Rover Defender and HMMWV. The system — only a mortar or a combination of a mortar with missile launchers — can be mounted on a four-wheel trailer, which allows the towing vehicle to carry more ammunition and, as a result, increases combat capabilities. A special set for fire control groups was developed, which is equipped with the same navigation system as on a mortar platform, as well as an aiming set mounted on a mast with a typical optoelectronic kit including an angular measuring device, a thermal imager, a laser range finder, a day camera, a digital compass and GPS The imager, as a rule, comes in the form of binocular devices Sophie LR (Long Range) or Sophie MF (Multi-Function), the latter of which allows you to capture targets also when removed from the mast.

Light assault car Wasp

Binocular thermal imaging device Sophie LR

After the announcement of the first contract for their Eimos mortar complex (Expal Integrated Mortar System - Expal integrated mortar system), the Spanish company Expal, part of the Maxam group, began delivering to the customer in 2015, apparently from the Middle East. The Eimos complex combines the company's 81-mm long-range mortar and a platform that allows simplified installation on light vehicles, in this case the URO Vamtac 4xXNNUMX. According to the company, electric drives provide horizontal and vertical guidance of the mortar, whose SLA provides 4 accuracy in azimuth and elevation when using only GPS, while the built-in inertial navigation / GPS unit halves this value. The hydraulic system reduces the recoil forces by more than 90%, and the recoil length is 300 mm. This allows you to install a mortar on light machines without an additional stabilization system or supports, for some platforms only minimal modifications of the suspension are needed. The mortar can be quickly removed and installed on the ground, the reverse process of installation on the platform takes three minutes. Data for shooting provides the system Techfire, which allows you to control the process of firing at different levels, in the base case at the level of the firing unit. Complexes sold to a launch customer include Techfire for the platform, as well as for higher levels, including advanced observers. Shepherd-Mil drone also entered into this contract. This 2,8 kg drone with a camera for low illumination levels allows you to detect and capture targets thanks to installed geolocation software. In the standard version, Eimos includes two vertical stacks of 26 rounds of ammunition each, while six ready rounds are placed on the turntable. The system weighs about 500 kg, but depending on the configuration, the mass may vary. The Eimos complex is also capable of accepting a 60 mm mortar made by the same company. After stopping the machine, the first mine is shot off in 10 seconds, the transfer speed is 9 degrees / s. The mortar needs a calculation service of at least two people, the maximum rate of fire is 25 shots per minute. The Spanish company continues to refine its system and offers a recently revealed new version of its Eimos mortar with some key improvements. The design of the new platform reduces the time required for the calculation to prepare the mortar for firing; The system is installed on a new URO VAMTAC pickup with a four-seater cab. A new weather station was installed to improve the accuracy of ballistic calculations, and the updated Techfire software was integrated with new functionality. The latest Techfire version includes a Shepherd-Mil drone, which is now able to work as an advanced observer. The Techfire system, operated by several non-called customers, was recently purchased by two more European countries.

US military in search of a new mortar

The US Army is in search of a mortar system for expeditionary forces, which must be “modular, capable of being installed on a variety of platforms, automated, because it must perform work in wireless remote mode, have a high rate of fire and zero readiness for firing, be functionally flexible, capable protect advanced bases and combat posts, as well as capable of carrying out mobile operations, high-precision, with automated computerized guidance. "

To this end, the American Army’s Arms Research and Development Center is developing an automated direct-fire / indirect-fire Mortar complex for firing direct and indirect fire. It includes a state-loaded mortar mounted on a platform, which reduces the recoil force 8 times, which makes it possible to install a mortar on vehicles like HMMWV armored cars and even trailers. ADIM is equipped with an improved version of the M95 MFCS (Mortar Fire Control System) fire control system, designated AFCS-M (Automated Fire Control System-Mortar), which complies with all involved communication protocols. This allows the calculation to conduct firing remotely from the shelter in the mode "from sensor to arrow" and perform automated tactical tasks. The mortar needs very little preparation time for firing, and AFCS-M is easily integrated with the inertial navigation unit and the GPS receiver. The system of electromechanical actuators Actuator Control System (ACS), developed at the Arsenal Picatinny plant, allows you to fully automate the process of firing.

The ADIM complex has a magazine for 20 shots, a minimum range of 300 meters and a maximum 6300 meter, a mortar rotates 360 °, and vertical guidance angles are -3 / ° + 85 °. Armament can be controlled remotely in protection situations of advanced bases or out of the machine when installed in the cockpit console MFCS. In addition to the traditional tasks of firing from closed positions, the platform with the recoil system allows the use of a mortar for direct fire and at low elevation angles. This is necessary to combat targets in shelters and on higher ground, especially at close range. The total mass of the system is approximately 1000 kg.

The ADIM mortar was demonstrated in January 2015 of the year during the Army Expeditionary Warfighter Experiment exercise, and shot a total of 174 mines in remote control mode. Due to the limitations of the design of the as-yet-refurbished safety device, tasks with position change were carried out only with shooting simulation. They confirmed the ability of the system to receive fire calls, after stopping the vehicle to start a fire mission, perform automatic aiming and firing and resume movement, all this in less than 50 seconds. As for fire missions, they also included two special types: the task of suppressing several targets, when one projectile is fired at a given target and then the sequence is repeated at other targets, and automated search and firing when the projectiles are shot in the area surrounding a specific target. The American army, represented by ADIM, intends to have a mobile and maneuverable system capable of moving along dirt roads and working in mountainous areas, which, for example, is typical of Afghanistan, where heavier systems could not satisfactorily provide fire support for the advancing infantry.

Materials used:

www.ruag.com

www.tda-armements.com

www.elbitsystems.com

www.stengg.com

www.ntgs.es

www.rheinmetall-defence.com

www.thalesgroup.com

www.maxam.net

armytechnology.armylive.dodlive.mil

waronline.org

www.wikipedia.org

en.wikipedia.org

Information