Ground forces are preparing for action in the most severe conditions

The TALOS exoskeleton, which is being developed for US special operations forces, is being evaluated, including the possibility of providing the owner with protection from the adverse effects of the environment.

NATO and its allies have recently focused on operations in a narrow range of external conditions. However, there is also a need for deployment in a more unfavorable environment.

Special Operations Forces (MTR) are proud to retain the ability to act across a wide range of external conditions. However, the operational space of even the most advanced units over the past decade has been limited to counter-terrorism and counter-insurgency actions, conducted mainly in and around settlements.

No matter how hard these units try to incorporate combat training in extreme conditions into their regular training cycles, the current high rate of operations sometimes prevents them from mastering new special skills.

That is why organizations such as the US Special Operations Command (USSOCOM) are currently absorbed in exploring their current and future capabilities in all extreme environmental conditions, including hostilities in a cold climate, at sea, in the desert and jungle, etc.

This process has affected all structures of the Navy Special Operations Command (NSWC), the US Navy Special Forces units are again familiar with the possibilities of conducting military operations in the Arctic. Until recently, these opportunities were regularly maintained only in the special forces group number two (SEAL Team Two).

A source associated with USSOCOM said that an unnamed unit of the Joint Special Operations Command (JSOC) turned to another elite unit from the NATO MTR community about military operations in tropical conditions, because in the past decade due to the prevalence of military operations in the urban environment in this area has lost some of its competencies. This request, the source explained, did not concern the requirements for combat training; rather, it was connected with the conduct of a counterterrorist operation in the unnamed region of Africa.

However, there is a convincing explanation for why even the best MTRs of the world believe that it is difficult to maintain competitive superiority in all these extreme conditions. According to the Society for human capabilities in extreme conditions, such conditions include those that "people, as biological organisms, do not fit and require much more effort to adapt."

“Human activity in these conditions often adversely affects its performance and significantly reduces it. Conditions that are considered extreme in nature include special operations, underwater operations, actions in the northern and hard-to-reach areas, mountains, nuclear and chemical contamination, that is, the whole environment in which a person must do his work, despite the most difficult conditions and severe stress, ”explained the representative of the Society.

“The importance of maximizing the efficiency and health of a person in these conditions is easy to understand. Meanwhile, there are discussion sites where efforts are mainly aimed at physiological and technical adaptation to extreme conditions, but, unfortunately, there are no such forums in which emphasis would be placed on behavioral (psychological, cognitive, perceptual, psychophysiological and the social aspect of human performance and the interconnection between human and technology, ”he added.

This is a special area that confirms the considerable interest in the MTR community of different countries, especially when it comes to demonstrating the technologies of a future soldier, including tactical light combat equipment of the operator TALOS (Tactical Assault Light Operator Suit), which is designed to increase mobility, protection, mortality and simplified Establishment of communication with special forces serving in the urban environment.

Joint Acquisition Task Force, a TALOS tactical group, which is a group of specialists recruited from various USSOCOM advanced commands, considers the integration of wearable basic equipment with the technology that provides the “interface” between the TALOS exoskeleton and its operator.

One member of the JATF group explained that addressing these issues remains among the top priorities in the current fiscal year. “The solution will include several integrated biometric sensors, providing personalized situational awareness to the operator during the task, which will allow the nearest tactical operations center to monitor the most important biometric parameters of the owner and other relevant information.

In addition, JATF also considers other ergonomic issues related to carrying the exoskeleton under extreme conditions, such as the northern, tropical, coastal and desert areas of operations, as well as the expanded use of backing and ventilation systems to extend the wearer's performance during the execution of tasks. However, regarding the use of the TALOS exoskeleton in these conditions, the program is particularly classified and, therefore, the representative of the group refused to give additional details.

As the official representative of the program explained, at the end of the research these options are likely to be shown with the final TALOS demonstration system in 2018.

With regard to equipment for the marine environment, the USSOCOM also deals with issues in this area, exploring options for the Maritime Assault Suit System (MASS) marine assault equipment and Lightweight (L-MASS) marine equipment designed for the NSWC command.

According to the request for proposals, first released in February 2016, the L-MASS system is a suit worn on top of the rest of the clothes, which will allow special forces of the US Navy and other special forces fleet “Pass” from water to a dry (or other) environment and vice versa, without the need to change clothes.

As stated in the requirement, in which sea, land, air conditions and conditions on board ships are highlighted: “MASS and L-MASS will keep the operator dry in sea and land extreme conditions and under all weather conditions, without hampering movements typical for combat missions or reduce their amplitudes with such activities as swimming, running, assault actions and handling weapons.

“Both MASS and L-MASS should be light, sit comfortably on the body, should keep the wearer dry when immersed in water without a significant increase in weight, do not make excessive noise when performing typical movements, and should be easily and easily put on and removed.

Maritime Assault Suit System (MASS) Marine Assault Equipment and Lightweight Equipment (L-MASS) (below)

NSWC is expected to issue an initial order requirement of approximately 1000 MASS / L-MASS suits for the initial assessment process, where the issue of procurement opportunities for MTRs will be resolved.

In September 2016, the NSWC also released a requirement for special equipment - non-traditional equipment, allowing special forces to operate across a wide range of “extreme conditions during long-term continuous wear.”

The requirement provides for the supply of “durable casual clothing of everyday type and durable clothing of tactical type to ensure the deployment of personnel of the naval special forces in all unique situations, not only combat. Special operations in such diverse and dissimilar conditions determine the need for a large range of durable items of tactical and everyday clothing, the delivery of which can be carried out as soon as possible. ”

Sources at USSOCOM confirmed that the selected equipment would be used by naval special forces, as well as other units of the fleet that are under the command of this Command; all sets of selected suppliers will be delivered to Little Creek Expeditionary Base and Coronado Air Force Base.

Russia is carrying on a similar activity, the special forces brigade of which has experienced special equipment for a hot climate at exercises in Egypt.

According to the Russian Ministry of Defense, the amphibious units conducted exercises in October 2016, together with the Egyptian units, practicing the tactical training scenarios of small units and conducting live firing.

The ministry declined to comment on specific technologies, but explained that the uniform, which underwent a number of operational tests and evaluation in Egypt, was specifically designed for a “hot climate” with the integration of heat and high humidity control technologies.

Also, in accordance with the needs of modern operational space, there was a need for improved equipment for chemical / biological warfare, one of which was shown at the conference of the Association of the American Army AUSA in October 2016.

The company WL Gore, the creator and manufacturer of clothing for military structures, developed the Gore-Tex technology, which according to its statements protects owners from chemical and biological weapons similar to those used by the Islamic state (prohibited in the Russian Federation) in Syria and northern Iraq.

Suits by WL Gore, manufactured using Chempak, could replace existing kits worn by regular and special units that are not entirely suitable for long-running operations, especially in hot climates.

A chemical / biological protective equipment system is a breathable solution using permeable fabric that minimizes heat exposure to the wearer. The representative of the company WL Gore explained that elastic knitted underwear allows maximum free movement, and "this gives excellent mobility and combat effectiveness in normal and extreme conditions."

“Her versatile design makes it easy to integrate wearable clothing into various suits designed for RCB intelligence and special operations tasks,” he said.

The representative of the NATO MTR explained that such a decision is easy to integrate into existing equipment, for example, in the popular line of combat equipment and field uniform Sguy Precision, which includes a shirt and pants G3; and external items of clothing, such as the FieldShell 2 jacket, LWF, and the Halfjak Insulated jacket and the Compact Assault Ghillie camouflage kit.

Difficult problems of extreme conditions need to be addressed not only for dismounted soldiers, but also for combat vehicles, within which it is also necessary to maintain temperatures acceptable to the crew and on-board optical and electronic equipment.

Technical solutions and technical specifications that determine the design and implementation of heating and ventilation systems for HVAC (heating, ventilation, and air conditioning) military vehicles are basically similar to solutions and specifications for civilian platforms. These systems are very effective in hot, dusty and humid conditions and are easy to maintain and able to fit into a limited cabin space.

In addition, the inherent dangers of military operations often force crew members and personnel to take cover in armored corps to protect against enemy fire. At the same time, there are not too many options for cooling the internal volume in the event of a rise in temperature and, therefore, adequate climate control becomes not only an element of comfort, but also personal safety.

The American company Red Dot Corporation entered the HVAC military systems market in 2004 after receiving a HVAC solution for armored vehicles with enhanced armor High-Mobility Multipurpose Wheeled Vehicle (HMMWV) as part of the urgent operational requirements of the contract from the Office of Armored Vehicle Equipment (TASOM). The company states that they have created a prototype cooling system that can lower the temperature in the cabin of the car by 17 ° C. Three months later, the new system went into mass production; almost 30000 HVAC kits were supplied for the HMMWV armored vehicles of the US Army and Marine Corps. Other troop platforms that have received new HVAC systems from Red Dot Corporation include the MATV category MRAP vehicles, as well as the FMTV family vehicle (Family of Medium Tactical Vehicles).

“A typical requirement is to reduce the temperature in the cab to 60 ° C at an outdoor temperature of about 27 ° C in approximately 54 minutes,” said Randy Grover of Red Dot Corporation. - Based on the volume given to us, we are trying to adjust the components that can provide the highest BTU values per hour (BTU is a British thermal unit, the amount of heat required to heat 1 pounds of water per 1 degree F).

“We must try to install the largest heat exchangers in the machine — an evaporator and a condenser,” he added. “Many times the equipment supplied by state organizations attempted to have the available volume, for example, it is often radio stations, so this is the greatest difficulty for us to squeeze these above-mentioned performance characteristics into these limitations ... This is a constant battle for a place in the sun.”

The latest success of the Red Dot Corporation was the Ministry of Defense program for the JLTV (Joint Light Tactical Vehicle) tactical vehicle, which should replace a number of obsolete HMMWV platforms and provide increased protection for their strength, survivability and increased payload. Unlike the HVAC systems developed for the already existing vehicles of the US military, the cooling system will be integrated into brand new JLTV cars.

“For example, under the FMTV program, a large steel box served as a container for HVAC components, which proudly spoke between the driver and the commander,” Grover said. “However, on JLTV it is located under the dashboard like on most commercial platforms, while Oshkosh chose a plastic case solution ... that is, the difference between the system on the JLTV car and the civilian car is minimal - it’s just the size and shape.”

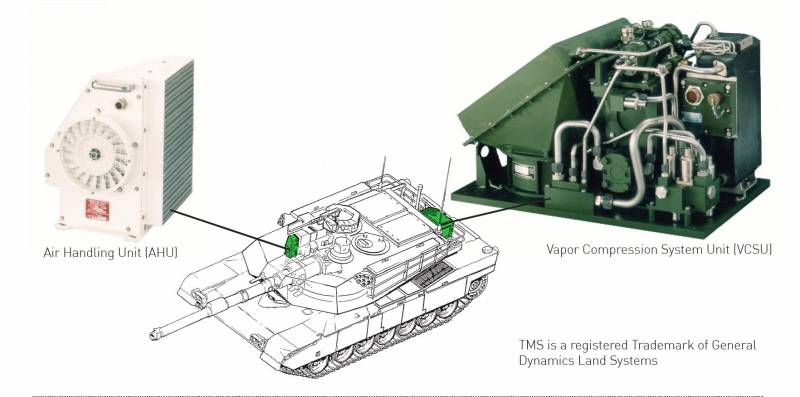

For heavy military equipment, temperature control for the crew and on-board electronics is also very important, and in some cases just vital. Under a contract issued by General Dynamics Land Systems (GDLS), Meggitt Defense System developed the Model 3212 Thermal Management System (TMS) for the M1A2-SEP (System Enhancement Package) of the main combat tank Abrams. This system is specifically designed to remove excess heat generated by on-board electronic systems and to maintain optimum performance accordingly.

Thermal Management System Model 3212 Thermal Management System for Abrams Tank

According to the company, TMS is characterized by a modular design, which includes a vapor compression unit VCSU (Vapor Compression System Unit) with a length of 76 cm, width 42 cm and height 47 cm, which contains refrigeration equipment with hydraulic drive. VCSU itself is placed in a protected container, installed in the aft niche of the tower; It delivers cooled propylene glycol and water, which through protected pipes come to the AHU (Air Handling Unit) ventilation unit. For the internal volume of the tank AHU provides cooling capacity up to 7,5 kW (25600 BTU / h). It produces volumetric air intakes into the habitable compartment, not only cooling the air inside to a temperature of 18 ° C, but also fighting the heat generated by the onboard electronic systems through direct contact with the cooling plate.

Meggitt has also developed an auxiliary cooling system and an ACPS (Auxiliary Cooling and Power System) power unit that regulates heat transfer and generates spare power; the compact independent unit of the system does not require electricity from the on-board network of the machine. The ACPS consists of three main components: the ACPU (Auxiliary Cooling and Power Unit) cooling and power generation unit, the AHU and the control module. According to the manufacturer, the system can provide cooling power up to 7 kW and electrical power up to 7 kW DC with voltage 28 volts for 8 hours without refueling. ACPS is powered by a multi-fuel generator powered by diesel fuel and various types of aviation kerosene JP 4, JP 8 and Jet-A.

The AHU ventilation unit consisting of a DC-powered fan on 28 volts and an air-liquid heat exchanger is based on the system used in the TMS thermal management system for MBT M1-X2 SEP. The installation provides air conditioning for crew members, as well as on-board electronics.

The risks associated with insufficient cooling are well known and documented. As a well-known example, MBT T-90С are available to the Indian army, whose characteristics were significantly worsened due to the lack of air conditioners. In a parliamentary report published in 2014, the General Financial Controller and Auditor criticized the army for spending 1,35 a billion dollars on 657 Russian T-90С tanks that were not equipped with cooling systems, which led to a deterioration of the fire control systems, thermal sights and launch mechanisms rockets that have been exposed to heat and dust for a long time; The report also noted a low level of comfort for the crew.

Auxiliary Cooling and Power System manufactured by Meggitt is capable of providing armored vehicles with cooling capacity up to 7 kW. The photo system is installed in the back of the tower of the American tank M1 Abrams

It is clear that a significant part of the Indian T-90С tanks was deployed in the Rajasthan desert region, where daytime temperatures exceed 55 ° С, and in vehicles it reaches 70 ° С. To solve this problem, the Combat Machines Research Center (CVRDE), which is also responsible for the development and research of the Arjun OBT and armored combat vehicles (BBM) of the Indian armed forces, has begun developing solutions for working in such conditions.

“To dissipate the heat generated by coolant, engine oil, charge air and gear oil in modern BBMs, a compact cooling system is installed,” CVRDE said in a statement. “BBMs in India often work at ambient temperatures above 50 ° C.”

“However, there have always been problems with the internal volume of BBM, and any increase in the volume of subsystems leads to an increase in mass. Therefore, proper configuration, design and development of cooling systems for BBM are very important. ”

In practice, the BBM cooling system by means of active heat exchange copes with the waste heat generated by the electronics and the engine in all modes of operation. According to CVRDE, the pressure drop through the cooling system must be kept to a minimum in order to reduce its bleeding and a corresponding decrease in the available power of the machine. However, this process is complicated by the conditions in which the machines must operate, often the efficiency of the cooling system decreases as a result of high dustiness and high ambient temperatures.

The problem is even more acute when it comes to the shortage of usable volume. In order to maximize the efficiency of cooling systems, which must somehow be installed in limited volumes of BBM, CVRDE engineers developed a compact aluminum radiator with fins having a large surface area per unit volume and, consequently, a larger heat exchange area compared to traditional designs, and implemented This technology is in some of its new locally produced heat exchangers.

According to CVRDE, an aluminum radiator with a set of fins used in cooling systems of local power units has a greater heat exchange surface per unit volume - up to 1800 м2 / м3 - compared to the systems available on the market, which, as a rule, ensure efficiency cooling within 1100 m2 / m3. New systems include multi-mesh radiators with offset ribs with heat exchange in the 1100-1700 m2 / m3 range. The complete system is made up of heat dissipation 720 kW.

The cooling system is also supported by several high-speed fans capable of moving a larger volume of air through the cooling system, while specially designed ventilation ducts make it possible to maintain acceptable temperatures for the crew during low-speed maneuvers, such as overcoming water hazards. These fans must provide cooling for the air flow and overcome resistance in the air ducts caused by contamination or other external factors.

“Since these fans must rotate at a speed of 5500 rpm, their workmanship must be very high and they must be dynamically balanced. Due to volume limitation, it is not possible to provide cooling capacity up to 55 ° C. Therefore, in order to control the heat load on the cooling system, we have developed automatic power control protocols that actively regulate the temperature of the coolant at higher ambient temperatures, ”the center said in a statement.

Since the armies of many countries increasingly rely on electronic systems for various military operations, both on foot and on combat vehicles, the value of thermal control will increase. Most likely, this will occur in the form of the integration of modern technologies of cooling and thermal insulation in the initial stages of designing equipment systems and vehicles, and not in the form of modernization kits for existing systems.

Materials used:

www.shephardmedia.com

www.dtic.mil

www.gore.com

www.reddotcorp.com

www.meggittdefense.com

mil.ru

www.drdo.gov.in

www.gdls.com

www.wikipedia.org

en.wikipedia.org

Information