Military transport aircraft Fairchild XC-120 Pack Plane (USA)

Classical transport aircraft transport the payload inside the fuselage in a corresponding large-sized cabin. If necessary, the cabin can be equipped with special equipment, seats for passengers, etc. At the end of the forties, an original proposal appeared that made it possible to greatly simplify the re-equipment of the aircraft for new goals and objectives, as well as to reduce the time required to load it. Designers from Fairchild Aircraft offered to transport the cargo not inside the aircraft, but in a special container. The latter was to be attached to the aircraft and be able to undock.

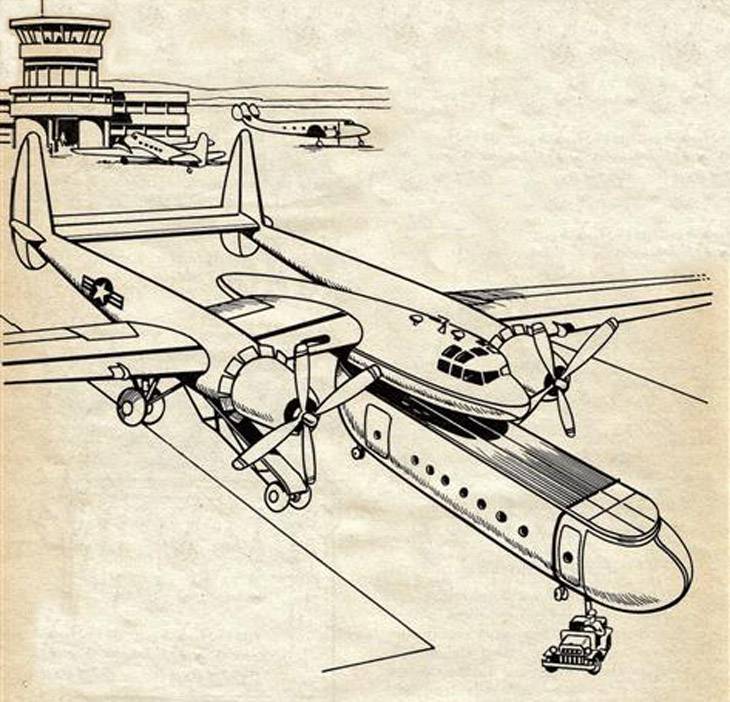

General view of the aircraft XC-120 with a suspended container. Photo Diseno-art.com

As planned by the authors of the original proposal, the use of a detachable container made it possible to drastically reduce the time for preparing for departure. The plane could arrive at its destination, dump the cargo hold with certain supplies or special equipment, then take a new one and go to another airfield. With this operation, after the first landing, it was only necessary to refuel the car and hang the new container. In addition, the unusual architecture of technology could be used to expand the range of tasks. It was possible to build specialized cargo or passenger containers, as well as make mobile command posts, hospitals, etc.

Fairchild offered the original idea to the US military and was able to interest it. The existing situation in the world demanded the further development of both the armed forces as a whole and their logistic system. A military transport aircraft capable of carrying containers with different loads was of great interest to the customer. The new project received the support of the army.

Working with a hanging container in the artist's view. Figure Diseno-art.com

The project received the official designation XC-120. Also used is the name of the Pack Plane ("Airplane with a box"), which is sometimes written together. In the future, after the completion of tests and adoption, the name of the project was to lose the letter “X”, denoting new developments that had not yet been brought to use in practice. It is also known that the serial XC-120 could get the name C-128.

In the framework of the new project, it was proposed to use finished products and units borrowed from serial equipment. This approach made it possible to drastically reduce the project development timeframes, as well as simplify the future mass production of military transport aircraft. From the point of view of design, the new “Airplane with a box” was supposed to be a deep modernization of the Fairchild C-119 Flying Boxcar, adopted earlier a little. The existing aircraft was supposed to “share” some new large airframe units, a power plant, etc. Also used the existing two-beam scheme. At the same time, a part of the existing products needed major modifications needed to solve the main tasks of the project.

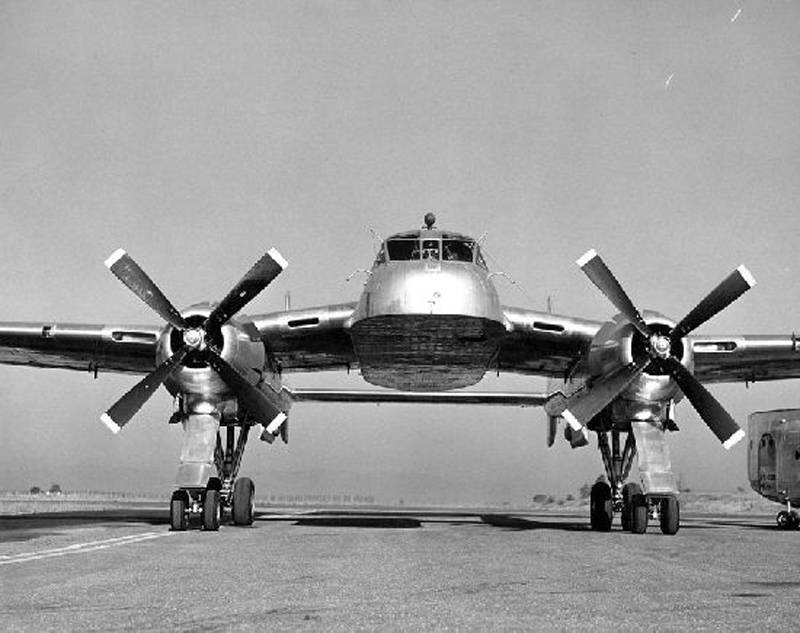

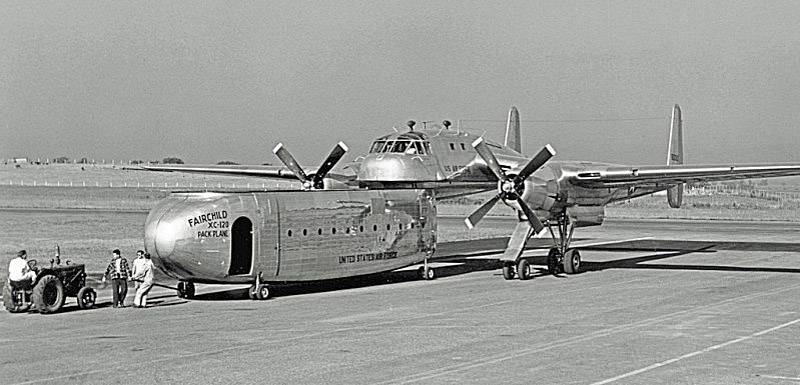

Experienced aircraft without container. USAF photo

The proposal to abandon their own cargo cabin led to the need to develop a new fuselage and a special container for the transport of goods. They were based on the units of the C-119 aircraft fuselage, but it required a noticeable change in their shape. As a result, for example, the bow of the container only indirectly resembled the nose of the base machine.

A new fuselage was designed drop-shaped. He received a flat horizontal bottom, and the sides and roof were made in the form of a single curved surface. The nose of the fuselage contained a cabin for five crew members. Other volumes were used to install this or that equipment. So, at the rear of the cabin and in the tail of the fuselage were placed electric lifts of the cargo container, and next to them there were locks to secure the payload in the desired position.

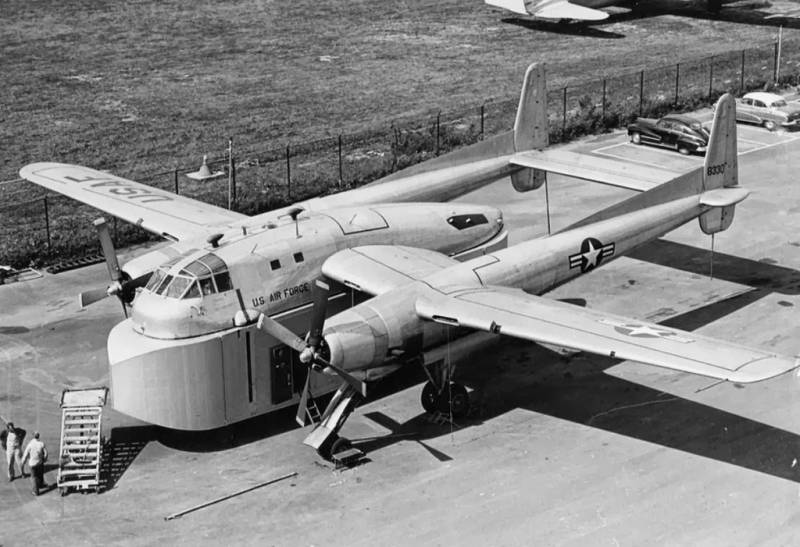

Without a container, the car had a distinctive appearance. USAF / Diseno-art.com Photos

In the central part of the fuselage mounted wing center section units. To increase the height of the aircraft, necessary for lifting the container to a safe height, the center section received a negative transverse angle V. The angled root parts of the wing were connected to two beams that contained the engine and were the basis of the tail unit. Consoles were attached to the beams outside. The aircraft of the new type retained the developed wing mechanization in the composition of the flaps and ailerons. On the leading edge of the wing there were several intake devices for supplying air to the systems of the power plant.

Like the basic “Flying freight car”, the new “Airplane with a box” was to be built according to a two-beam scheme. Instead of the elongated tail of the fuselage, it was proposed to use two separate beams placed on the sides of the fuselage. In the bow of the beam, coupled with the center section, was the engine. Next to the power plant were chassis niches. On the tail end of the beam, a keel with a gargrotte and ventral ridge were installed. Between the beams there was a stabilizer with a rudder. Small additional planes were placed on the outside of the beams. The plumage received a standard set of steering wheels with trimmers.

XC-120 without container in flight. USAF / Diseno-art.com Photos

The front section of the beams housed two Pratt & Whitney R-4360 Wasp Major piston engines. Motors of this type were built in a radial pattern and had 28 cylinders arranged in four rows. The power of each engine in takeoff mode reached 3250 hp. Cooling of the cylinder block was carried out by supplying air through a round front window. The engines were equipped with four-blade propellers.

The proposed fuselage design with overhead cargo container did not allow the use of traditional chassis systems. Because of this, in the project XC-120 Pack Plane appeared the original composition of the racks. In both beams of the base model aircraft there were niches for cleaning the main landing gear. In the new project, the dimensions of these compartments were increased due to changes in the design of landing gears. Two main racks with twin wheels of larger diameter were saved. In addition, a pair of front struts appeared on the beams. To increase the chassis base, the front struts had a specific design that brought the twin wheels of small diameter to the level of the propeller plane. The design of each rack and its drives made it possible to change the ground clearance of the aircraft to simplify the installation of the container. Both racks of each beam were removed in flight by turning back.

For transportation of goods it was proposed to use a special removable container, which is a multipurpose cabin. The container was made in the form of a device of large length of rectangular cross-section, equipped with a nose and tail fairings. The nose cone had an ogival shape and was made of two parts. To carry out loading half of the fairing diverged to the sides, providing access to internal volumes. In the left half of the fairing there was a door of small width. The tail fairing had a similar design, but differed in shape: its upper part was made straight, and the bottom was set at a slight angle. In the left half of the tail fairing there was another door.

The basis of the design of the container was the power set of rectangular frames and a large number of longitudinal stringers. Over the frame was installed metal trim. In a flat roof and a curved bottom of the container there were reinforced areas necessary for the transport of aircraft and transportation by land.

Military transport aircraft XC-120 Pack Plane had to take the container "on board" using a set of connectors. On the roof of the container there were several spherical protrusions-supports, which were to engage with the clips on the bottom of the fuselage and be fixed with locks. To lift the container to the fuselage and lower it to the ground, it was proposed to use several electric winches with remote control. The interaction of the winches with the container was provided by a set of fasteners on the sides of the latter. Along the perimeter of the roof of the container was a rubber seal that protects the joint from external influences.

To move on the ground, the container had to be equipped with its own wheels. Before "unloading" the aircraft on the attachments in the nose and tail parts of the container, it was proposed to install two-wheeled self-guided trolleys. After that, it was necessary to open the locks and lower the container onto its own wheels. In this form, the cargo compartment could be towed by any suitable tractor.

The container stands with open hatches and is ready for loading. Photo Diseno-art.com

To manage a promising aircraft was a crew of five, located in the forward cabin of the fuselage. The crew included the commander and co-pilot, navigator, radio operator and flight engineer. During loading and unloading operations, two crew members became the operators of the respective systems and were responsible for working with the container. All crew jobs were located in a common cabin, which was proposed to get into in an unusual way. In the flat bottom of the fuselage there was a hatch equipped with a ladder. In the absence of a container, the crew had to climb the stairs into the cabin. After installing the container to the stairs, it was proposed to get through the side doors and the corresponding hatch in its roof.

The total length of the new aircraft with a suspended cargo container was 25,25 m, wingspan - 32,46 m, height - 7,65 m. Wing area - 134,3 sq.m. An empty plane with a container weighed 18,14 T, the maximum take-off weight reached 33,75 T. The division of the fuselage into the main part and the removable container resulted in a slight decrease in load parameters compared to the base C-119 aircraft. The new XC-120 could take on board only 9 tons of cargo versus 12,5 tons from a production car. To accommodate the cargo proposed to use a large compartment volume 76,45 cubic meters.

The container is loaded and rolled up under the plane. Photo Diseno-art.com

The proposed architecture of a promising military transport aircraft made it possible to effectively solve a wide range of transportation and other tasks. In a removable container it was possible to transport a variety of loads of appropriate sizes and weights. It was also possible to install landing sites for 65 paratroopers with parachutes and weapons. In the case of the container it was possible to place a stretcher for the wounded or even a compact medical center. The possibility of creating mobile headquarters and other systems of one purpose or another was not ruled out. The size and carrying capacity of the container, as well as the possibility of its discharge, gave the army the widest possibilities.

The XC-120 Pack Plane was supposed to reach a maximum speed of up to 476 km / h while cruising around 340 km / h. The practical ceiling was set at the level of 6700 m, the range - 3700 km. It should be noted that the exact characteristics of the aircraft depended on a number of factors, primarily on the configuration. Thus, the presence of the container increased the air resistance and, as a result, reduced the actual performance. The absence of the container, respectively, allowed the aircraft to fly faster and farther.

The machine is preparing for takeoff. USAF photo

The development of the Fairchild XC-120 Pack Plane project was completed at the beginning of 1950. Soon began the construction of the first prototype of such a machine. An unfinished C-119B Flying Boxcar serial aircraft with a 10312 serial number was taken as the basis for the prototype. The glider of this car lost most of the fuselage, as well as undergone other changes, stipulated by the new project. From the dismantled part of the fuselage was assembled one of the experienced containers. According to various sources, during the construction period, several such products were assembled in a cargo configuration.

The widest use of components and assemblies of serial equipment allowed us to accelerate the construction of an experimental aircraft. The prototype was completed in the early summer of the 1950 year, after which it was tested. The first flight of an experienced "Plane with a box" took place on 11 in August of the same year. The plane passed all the necessary tests, during which both the flight and operational characteristics, as well as the work with the cargo container were checked. During these tests, the car, in general, showed itself well.

In flight with a payload. Photo Diseno-art.com

During 1950, the experienced XC-120 passed ground and flight tests. In addition, the car several times attracted to participate in various demonstration events. In 1951, the prototype was transferred to Eglin Air Force Base (Florida), where air force specialists were to test it. In addition, at this stage of testing it was planned to determine the actual operational characteristics of the machine and, as a consequence, to draw conclusions about the possibility of using such equipment in the troops. According to the results of these checks, the issue of adopting a promising aircraft for arming was to be resolved.

The military carefully studied the proposed transport aircraft and made conclusions. It was found that the car of the original architecture in its flight data is almost no different from the serial aircraft C-119 Flying Boxcar. Operational characteristics and possibilities for the transportation of goods were also similar, although the new XC-120 and lost in the maximum capacity. The ability to quickly drop the container, significantly speeding up the process of preparing the aircraft for a new flight, was called an absolute advantage. Also, a potential customer was somewhat interested in the proposal to create specialized containers for one purpose or another.

However, it was not without claims. So, in terms of performance and flight data, the new XC-120 looked almost like a complete C-119, but with a smaller payload. In addition, the design of the aircraft was attended by a significant number of completely new devices that have not yet had time to prove their performance in difficult conditions. Finally, there were doubts about the feasibility of serial construction of promising and interesting, but overly complex aircraft.

In 1952, the Pentagon announced its final decision. With all its advantages, the Fairchild XC-120 Pack Plane military transport aircraft had a number of characteristic drawbacks and ambiguous features. After weighing all the pros and cons, the potential customer decided to abandon the purchase of such equipment. Plans for mass production were canceled. The army decided to continue the operation of the “Flying cars” without the addition or replacement of “Airplanes with a box”.

Test flight USAF photo

After the official rejection of the purchase of serial equipment, the only built XC-120 remained out of work. This machine was not needed by the customer and was not required by the manufacturer. Because of this, after some downtime, the prototype went for disassembly. According to some information, it was rebuilt according to the original project C-119B and included in one of the serial batches supplied under the army order. On this in stories The original project was put a full stop.

The aim of the Fairchild XC-120 Pack Plane project was to create a promising military transport aircraft of modular architecture, capable of performing basic cargo operations as quickly as possible and transporting a variety of payload options. The assigned design tasks were successfully solved with the help of several original ideas, but the plane still did not go into series. Transport vehicles of traditional design were more convenient and more profitable in terms of mass operation. Further aviation industry in different countries has repeatedly made attempts to create similar projects, but not one of them has reached the full operation of serial equipment.

Based on:

http://airwar.ru/

http://globalsecurity.org/

http://popmech.ru/

http://diseno-art.com/

http://avia-museum.narod.ru/

http://aviastar.org/

XC-120 Goes to Eglin for Tests. Aviation Week, 11 June 1951

Information